Azeotropic distillation method

An azeotropic distillation and azeotropic technology, applied in the field of azeotropic distillation, can solve problems such as difficult stable operation, irregular fluctuations in temperature distribution, and excessive flow changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

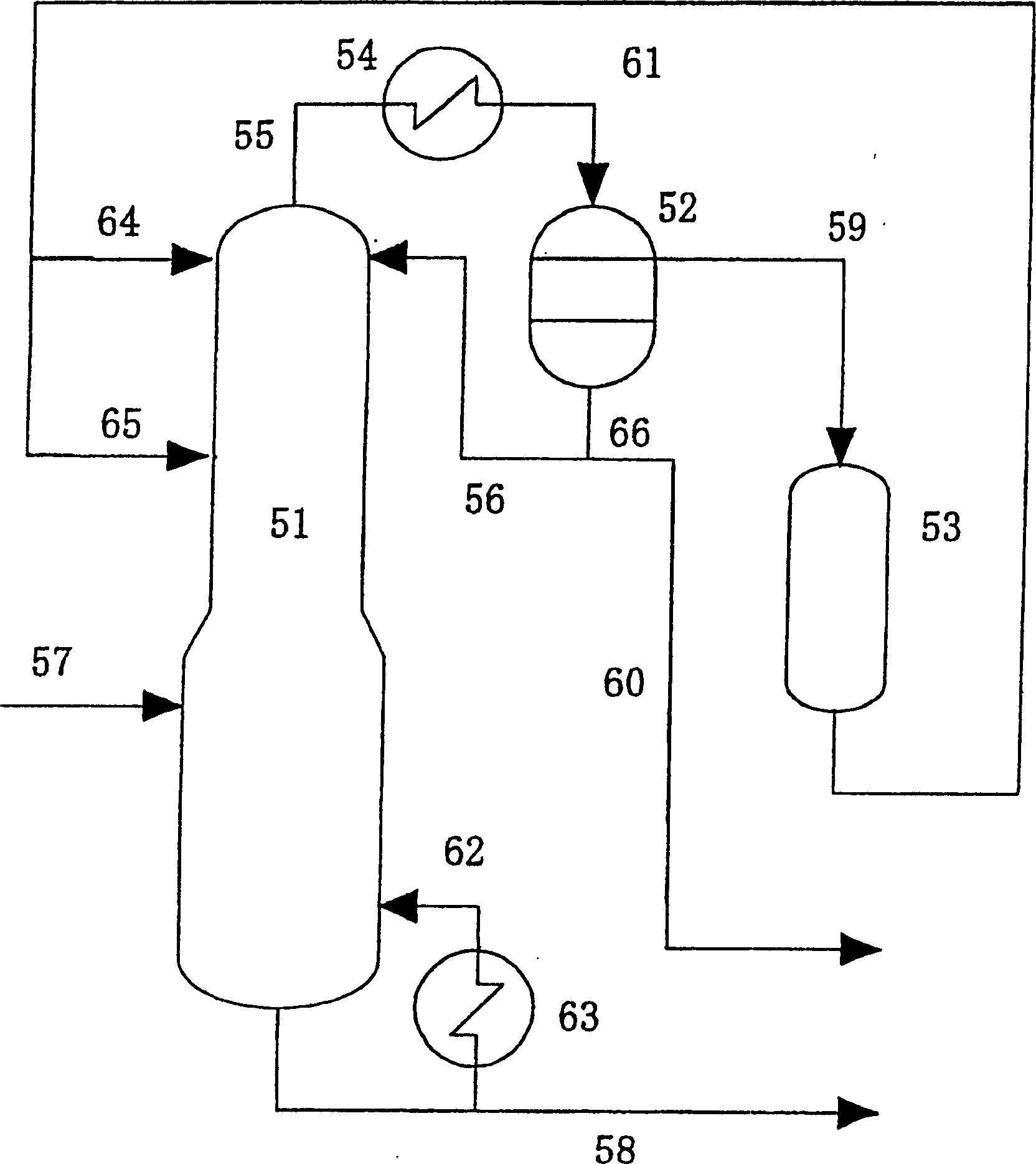

[0076] use figure 2 The equipment shown in implements the inventive method, adopts the aqueous solution that contains acetic acid as the solution to be distilled by the method for continuous distillation, and butyl acetate is as entrainer. As the azeotropic distillation column in which the azeotropic distillation is performed, a plate column having a total number of plates of 60 was employed.

[0077]The continuous azeotropic distillation was initiated in the following manner. A liquid mixture consisting of 75.0% by weight of acetic acid, 24.9% by weight of water and 0.1% by weight of butyl acetate was fed to the azeotropic distillation column 51, and the reboiler 63 of the azeotropic distillation column was used for heating. Total reflux is thus performed. Thereafter, butyl acetate from the entrainer tank 53 was gradually fed as an entrainer to thereby form a three-component azeotropic distillation consisting of acetic acid / water / butyl acetate. After the azeotropic zone i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com