Motor, axial fan using said motor, and axial fan used for indoor machine of air conditioner

An axial flow and fan technology, applied in the direction of electromechanical devices, control mechanical energy, electrical components, etc., can solve the problems of increased length of motor 1, decreased capacity of indoor units, and complicated configuration, so as to reduce the length of the axial direction and reduce the The effect of the number of parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

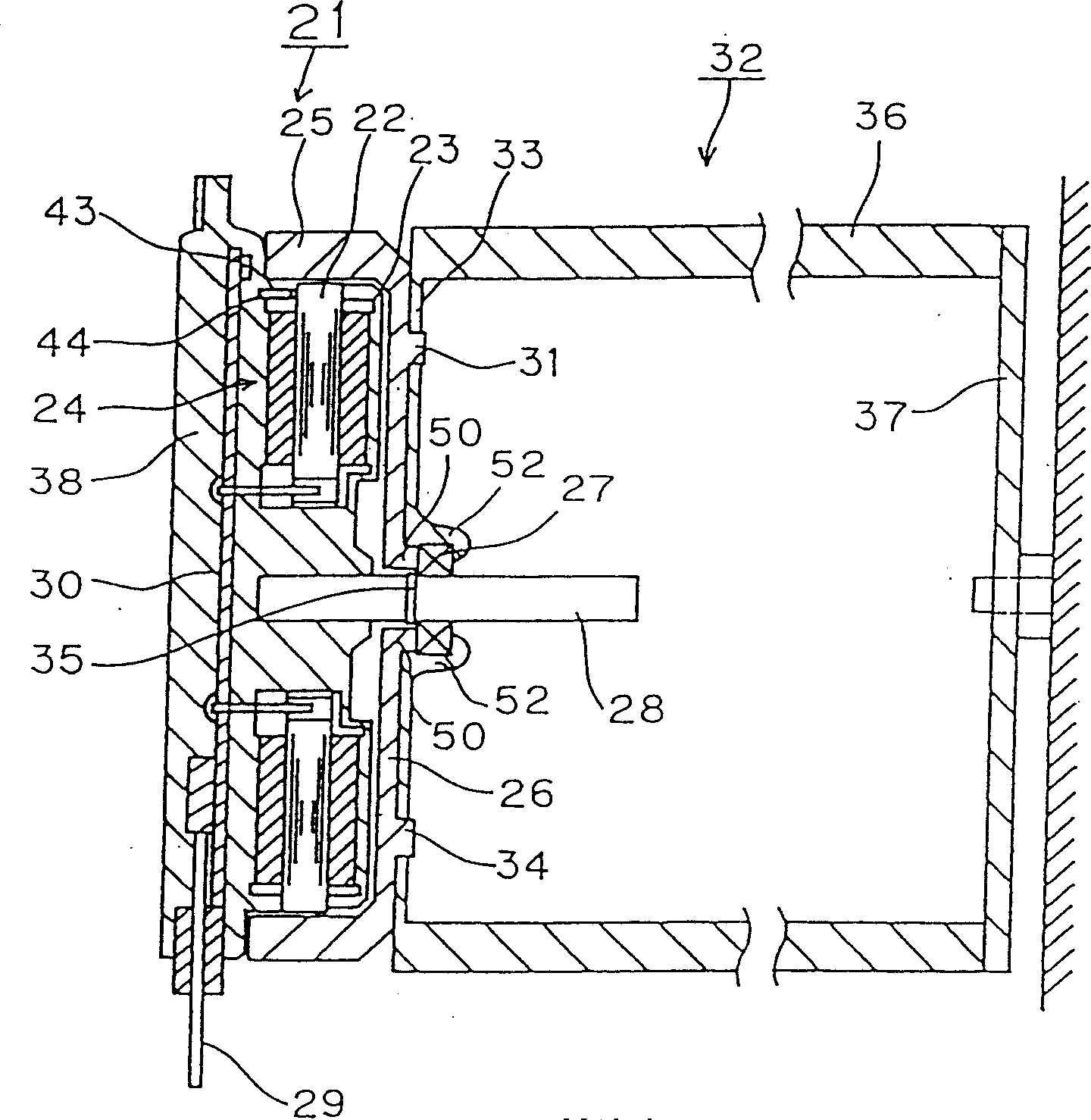

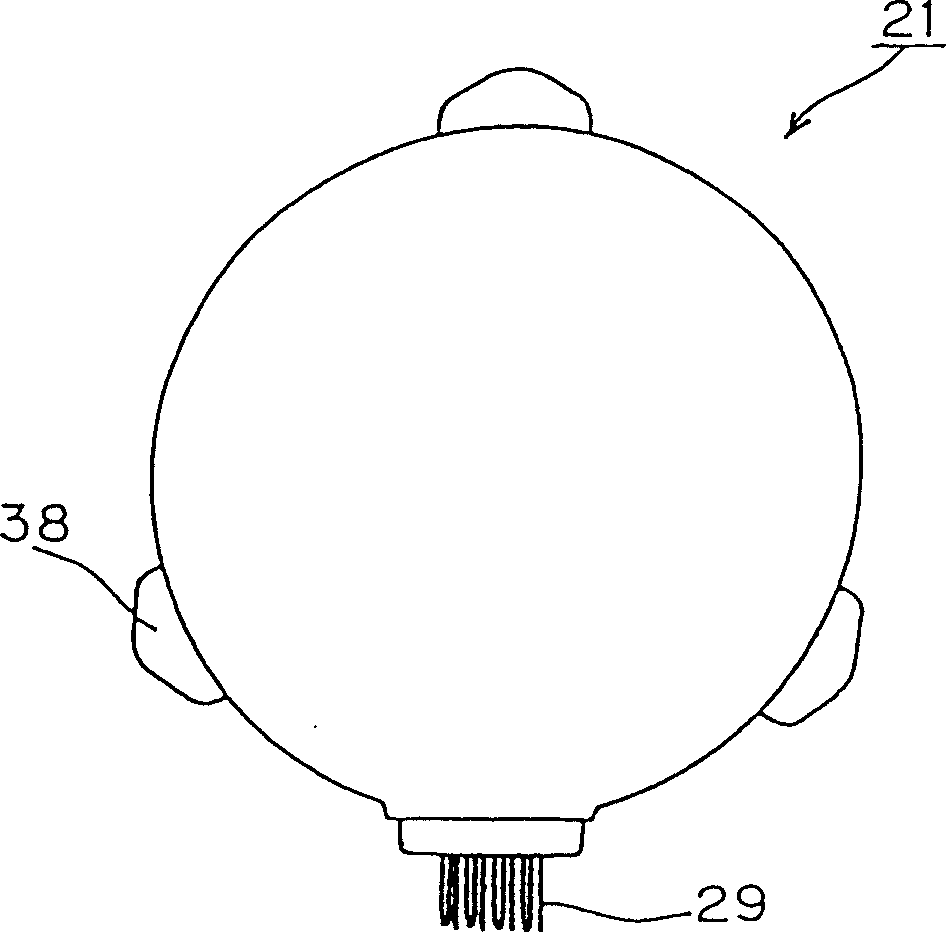

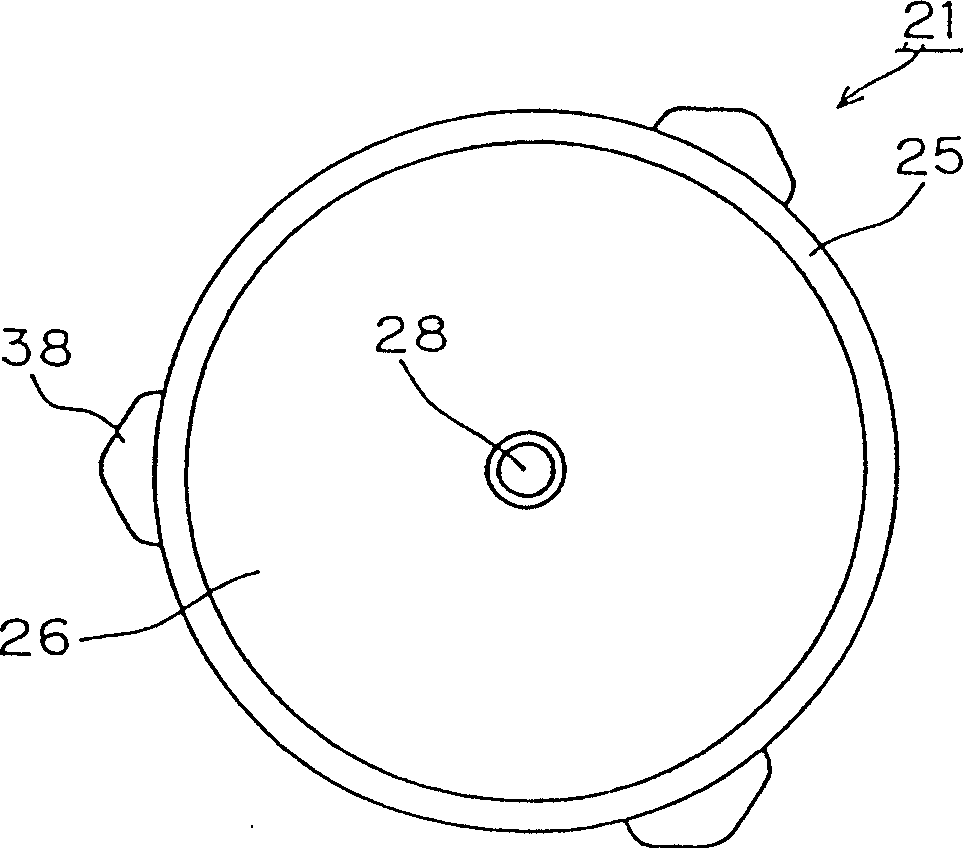

[0056] Figure 1-Figure 3 In order to show the figure of the first embodiment of the present invention, figure 1 It is a cross-sectional view of the thin outer rotor type brushless DC motor (hereinafter referred to as the motor) 21 of the present embodiment, figure 2 is the left side view of the motor 21, image 3 It is the right side view of the motor 21. Below, refer to Figure 1-Figure 3 The configuration of the motor 21 will be described.

[0057] In the motor 21 , a coil 23 is wound around an iron core 22 to form a substantially cylindrical stator 24 .

[0058] On the outside of the stator 24 in the radial direction, a substantially cylindrical rotor 25 composed of permanent magnet pieces and the like is arranged at a distance from the stator 24 . One end in the axial direction of the rotor 25 constitutes a connecting portion 26 extending radially inward, and an annular protrusion 50 is formed at the radially inward end of the connecting portion 26 , that is, near ...

no. 2 Embodiment

[0069] Figure 4 It is a sectional view of the motor 21a of the second embodiment.

[0070] This embodiment is similar to the above-mentioned first embodiment, and the same reference symbols are used for corresponding parts.

[0071] The present embodiment is characterized in that the radial rolling bearing 27 of the first embodiment is replaced by a radial sliding bearing (hereinafter referred to as a sliding bearing) 39 . For this purpose, the base 41 of the substantially hollow truncated cone-shaped holding member 40 made of elastic body (such as hard rubber) is fixed to the rotor radially inwardly of the annular connecting member 33 of the axial flow fan 32. 25 ring-shaped protrusions 50 .

[0072] A concave holding groove 42 is formed along the entire circumference of the holding member 40 in the vicinity of the end on the side opposite to the base 41 . The sliding bearing 39 whose outer peripheral surface has a shape corresponding to the shape of the holding groove 42...

no. 3 Embodiment

[0075] Figure 5 It is a sectional view showing the motor 21b of the third embodiment.

[0076] In the above-mentioned first and second embodiments, the wiring board 30 is arranged on the opposite side of the axial flow fan 32 with respect to the stator 24, but in the present invention, it may be arranged as Figure 5 As shown, the wiring board 30 is arranged on the same side as the axial fan 32 with respect to the stator 24 . Obviously, also in such a modified example, the same operational effects as those described in the above-mentioned first embodiment can be realized.

[0077] That is, also in this embodiment, the same operational effects as those described in the above-mentioned first embodiment can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com