Shaft sealing structure of centrifugal compressor

A centrifugal compressor and shaft sealing technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of cost increase, number of parts and installation man-hours, etc., and achieve the effect of shortening the length of the shaft direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

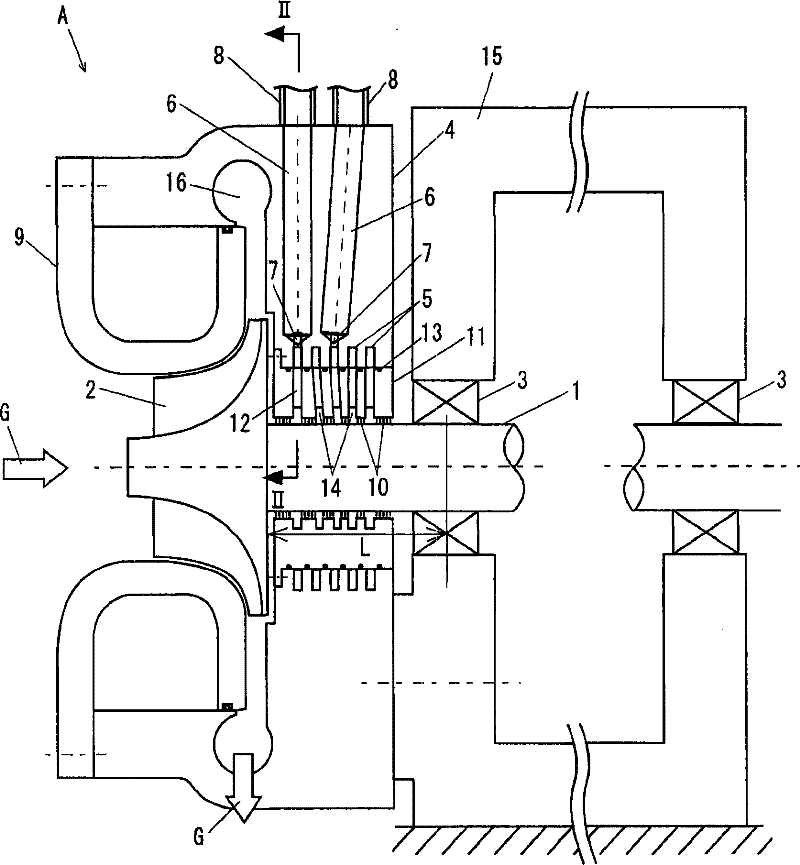

[0040] Figure 2 to Figure 7 It is a figure which shows the structure of the shaft seal structure A of the centrifugal compressor concerning 1st Embodiment of this invention.

[0041]figure 2 , Figure 4 and Image 6 It is a cross-sectional view of the seal structure A in the axial direction, and shows cross-sections in phases different from each other in the circumferential direction. image 3 yes figure 2 The II-II line profile, Figure 5 yes Figure 4 Sectional view of line IV-IV, Figure 7 yes Image 6 Sectional view of line VI-VI. Among them, in image 3 , Figure 5 and Figure 7 In , only the housing 4 is shown.

[0042] exist figure 2 , Figure 4 and Image 6 Among them, the rotary shaft 1 is rotatably supported by a support bearing 3 fixed to a gear box 15 . The centrifugal impeller 2 is integrally connected to the tip of the rotary shaft 1, and the centrifugal impeller 2 is rotated by rotationally driving the rotary shaft 1 by a driving device not shown...

no. 2 Embodiment approach

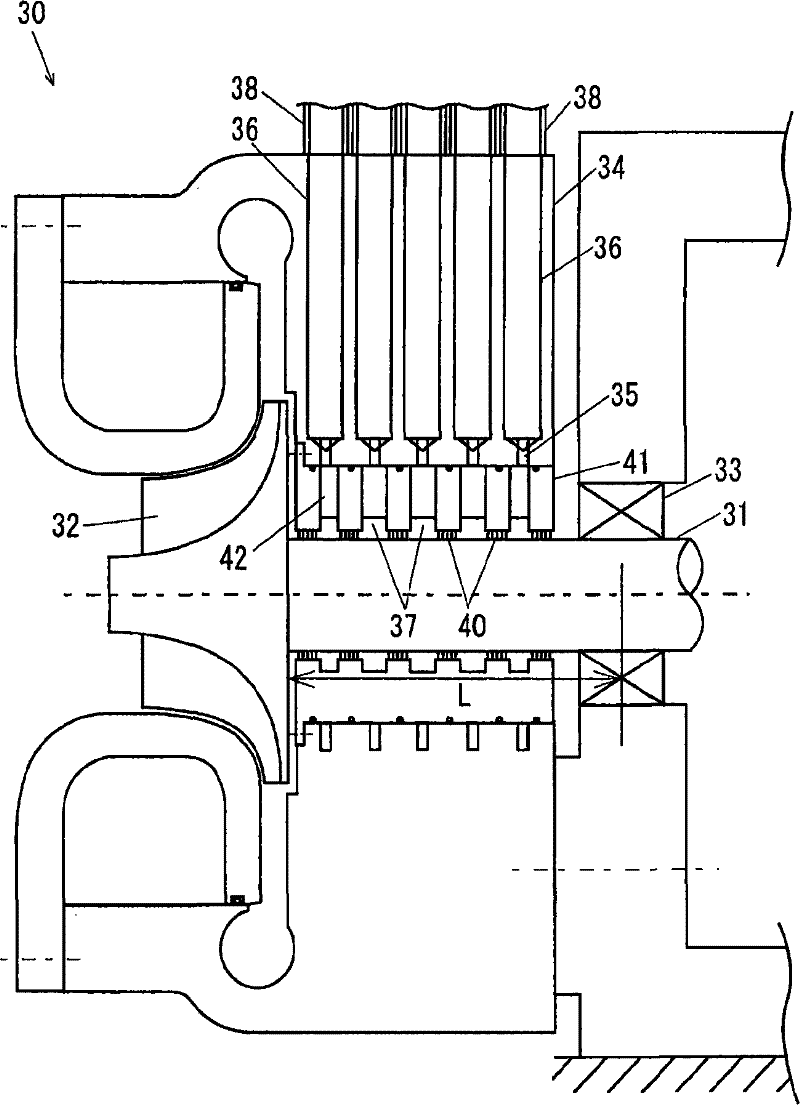

[0055] Figure 8 It is a sectional view in the axial direction showing the structure of the shaft seal structure B of the centrifugal compressor according to the second embodiment of the present invention. exist Figure 8 In , a cross-section of one phase in the circumferential direction is shown.

[0056] In the present embodiment, a plurality of ring-shaped equalizing pressure chambers corresponding to the spaces (seal chambers 14 ) between the plurality of labyrinth groups 10 are formed at intervals in the axial direction on the outer peripheral portion of the labyrinth ring 11 . Room 5. In the inner peripheral portion of the casing 4, a plurality of dug-in portions 7 that expand radially outward in a part of the outer peripheral portion of each pressure equalization chamber 5 in the circumferential direction are formed. Thus, the location where the pressure equalization chamber 5 is provided differs between this embodiment and the first embodiment.

[0057] exist Fig...

no. 3 Embodiment approach

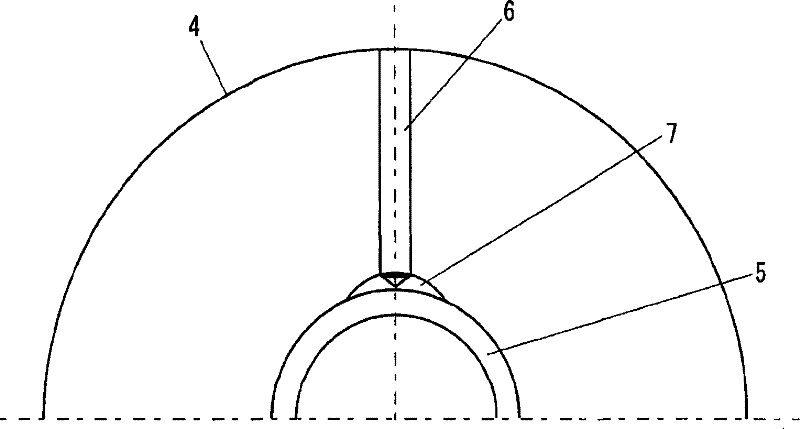

[0060] Figure 9 It is a sectional view in the axial direction showing the structure of the shaft seal structure C of the centrifugal compressor according to the third embodiment of the present invention. exist Figure 9 In , a cross-section of one phase in the circumferential direction is shown.

[0061] In this embodiment, at the boundary portion between the housing 4 and the labyrinth ring 11, a plurality of annular grooves formed on the inner peripheral portion of the housing 4 and the labyrinth rings are formed at intervals in the axial direction. The ring-shaped pressure equalizing chamber 5 formed by the annular groove on the outer peripheral portion of 11. Each pressure equalization chamber 5 corresponds to a space (sealed chamber 14 ) between the plurality of labyrinth groups 10 . A plurality of dug-in portions 7 that expand radially outward in a part of the outer peripheral portion of each pressure equalization chamber 5 in the circumferential direction are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com