Air cylinder

A cylinder and cylinder hole technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

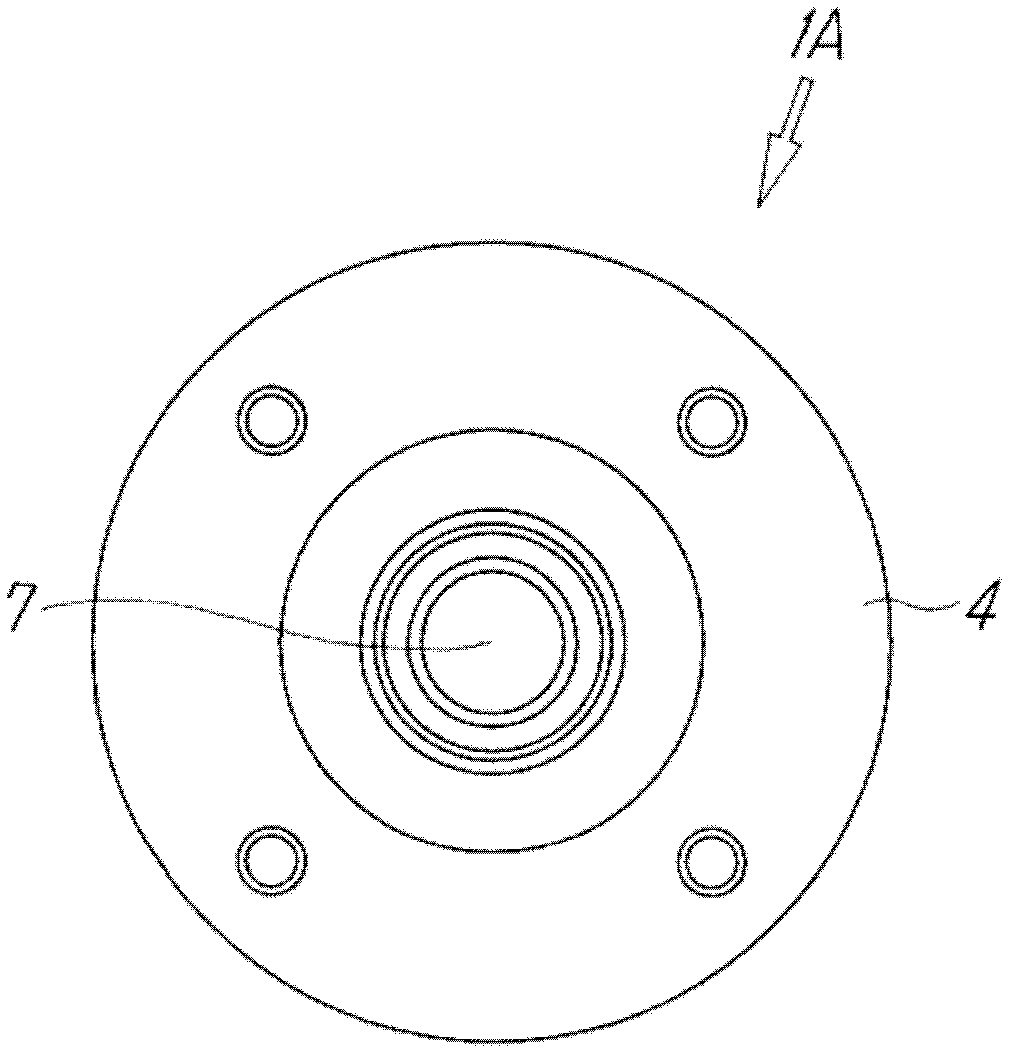

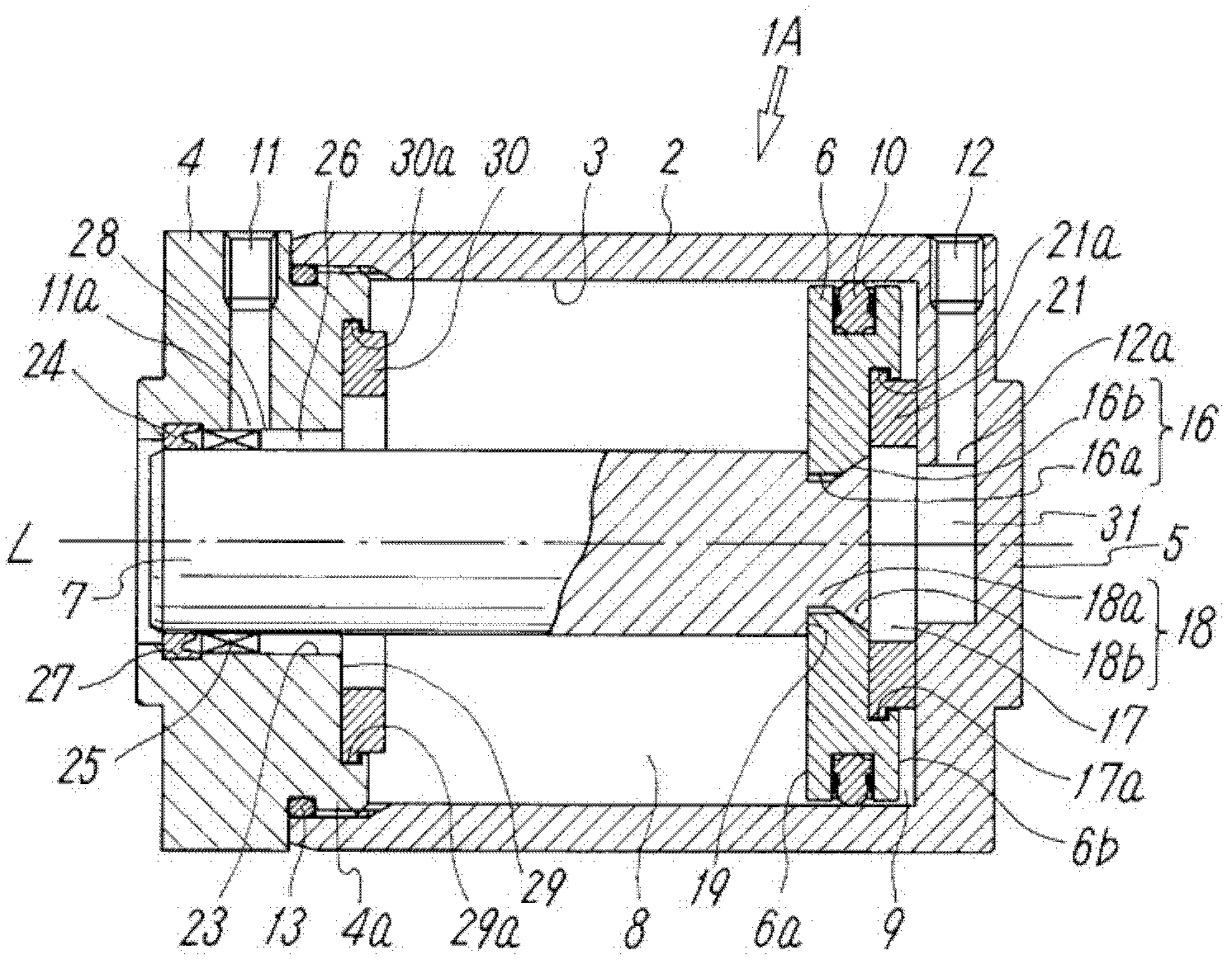

[0024] Figure 1 to Figure 3 The first embodiment of the air cylinder of the present invention is disclosed. This cylinder 1A comprises: cylindrical cylinder block 2, and it has circular cylinder bore 3 inside; Sliding in the cylinder hole 3 in the direction of the axis L; a piston rod 7 , the base end of which is connected to the piston 6 , and the piston rod 7 penetrates the end cover 4 slidably. In addition, this cylinder 1A includes: a first pressure chamber 8 formed between the above-mentioned piston 6 and the end cover 4; a second pressure chamber 9 formed between the above-mentioned piston 6 and the cylinder head cover 5; a first port 11 and a second port 12, the first port 11 is formed on the end cover 4 to supply compressed air into the first pressure chamber 8 or discharge compressed air from the first pressure chamber 8, the second port A portion 12 is formed on the cylinder head cover 5 for supplying compressed air into the second pressure chamber 9 or dischargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com