Gamma correcting device and method for LCD

A gamma correction, liquid crystal technology, applied to static indicators, instruments, etc., can solve problems such as color drift of liquid crystal screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

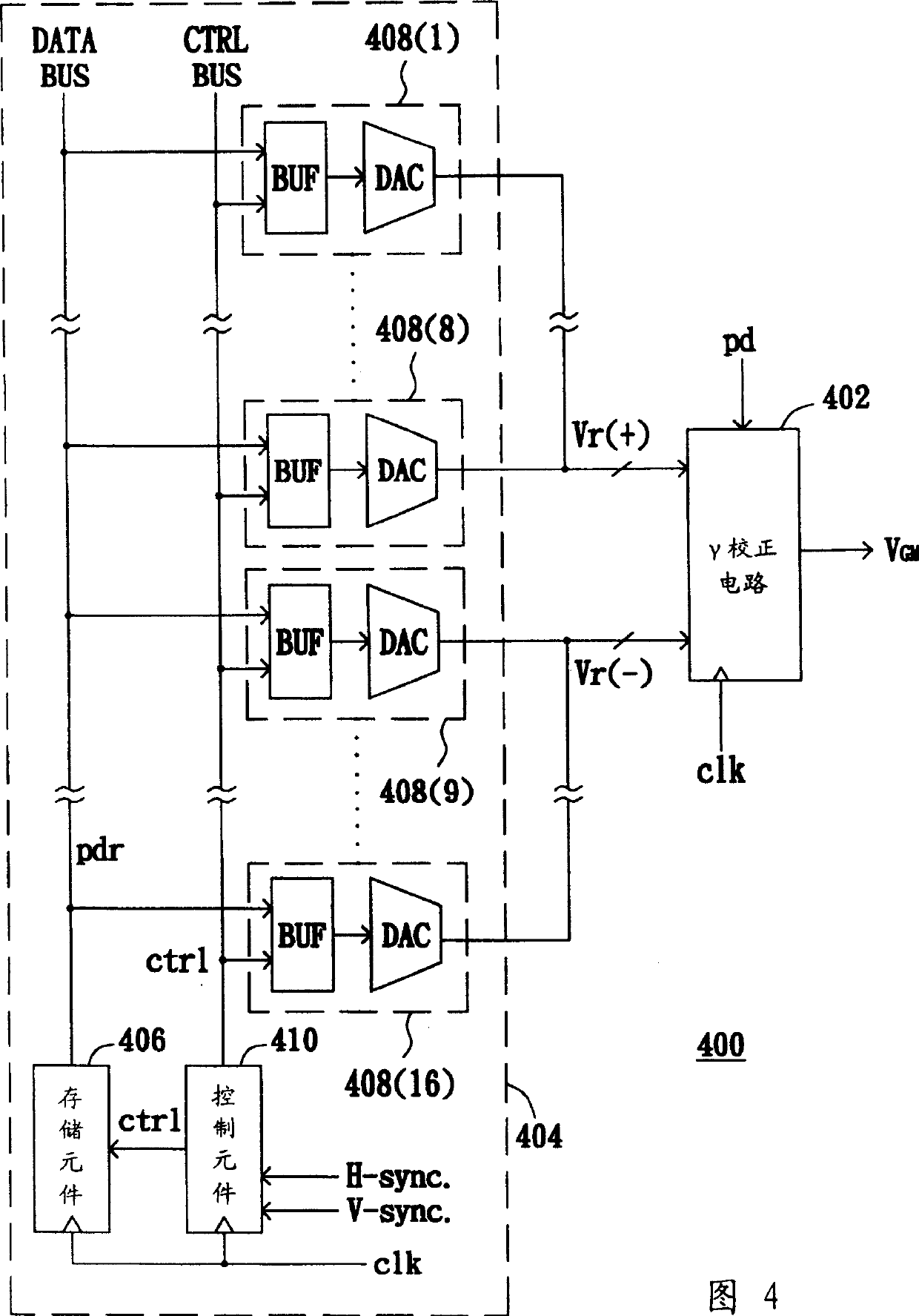

[0040] The present invention is characterized in that the entire liquid crystal screen is divided into multiple screen blocks. When gamma correction is performed, gamma correction is performed according to the color displayed by the pixel corresponding to each pixel data and the screen block to which the pixel belongs.

[0041]The idea of the present invention is to divide the entire liquid crystal screen into multiple screen blocks and perform gamma correction respectively. In this embodiment, the resolution is 1024×768 (that is, there are 768 pixel rows on the liquid crystal screen, and each pixel row has 1024 display units, and each display unit has three pixels, which display red, blue and green respectively. ) color LCD screen as an example, the entire LCD screen is divided into a total of 192 screen blocks of 16×12. Compared with the whole LCD screen, in each screen block, the distance between the upper panel and the lower panel of pixels is not much different, so the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com