Transfer pump for block and stem material

A technology for conveying pumps and materials, which is applied in the field of conveying equipment for tuber materials. It can solve problems such as material damage, low production efficiency, and waste of raw materials, so as to reduce radial and tangential impact forces, avoid cutting and crushing impacts, The effect of active fraction growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

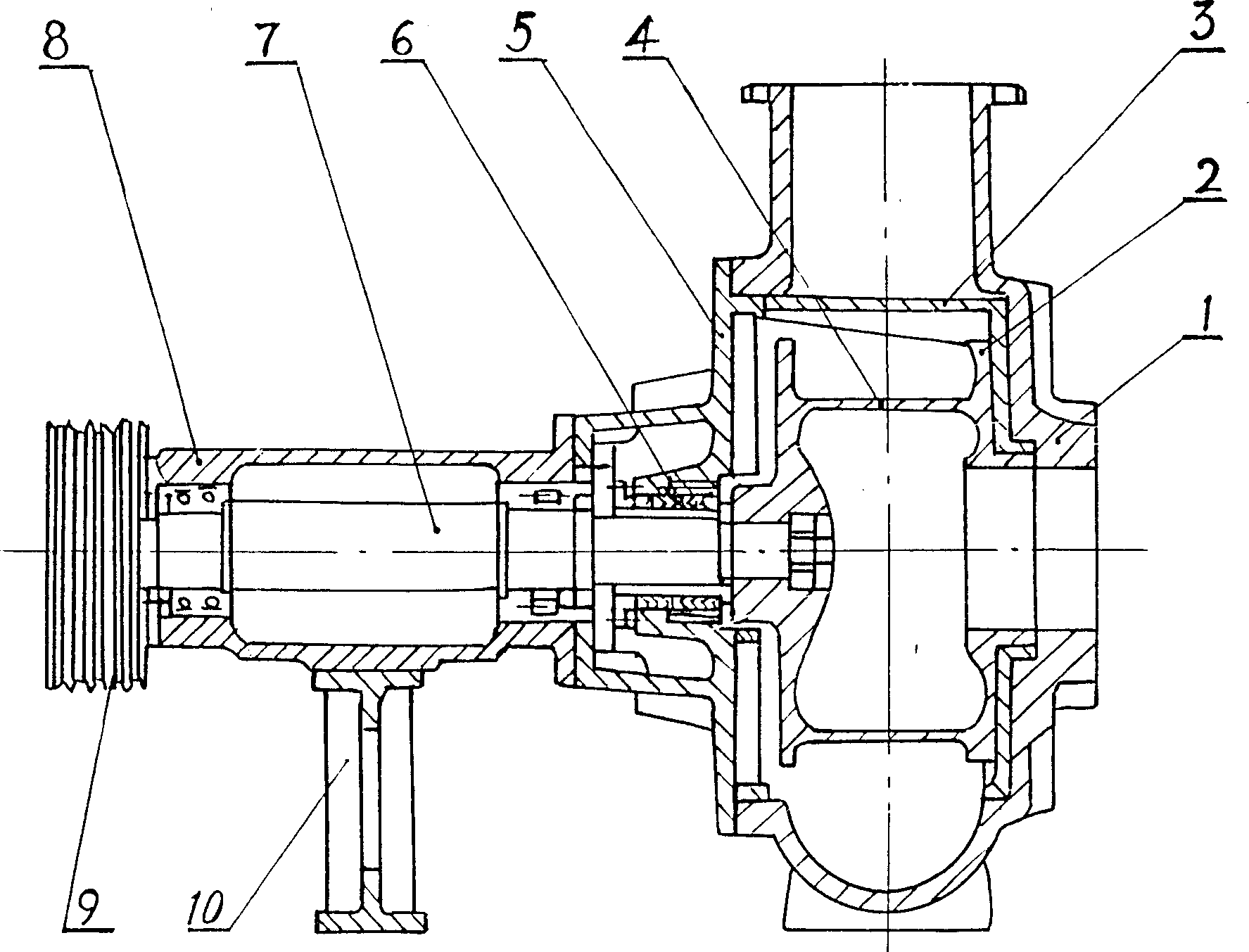

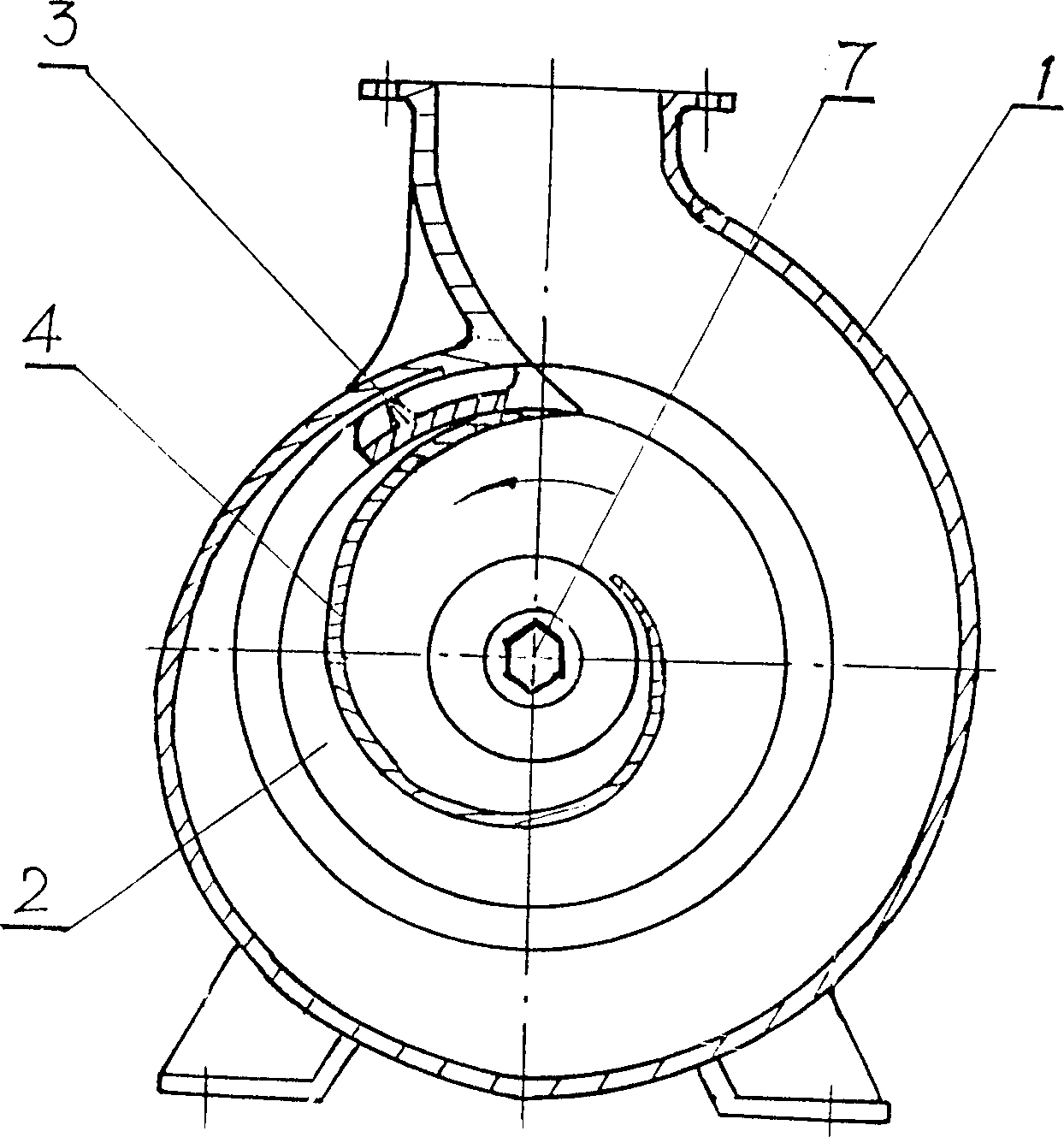

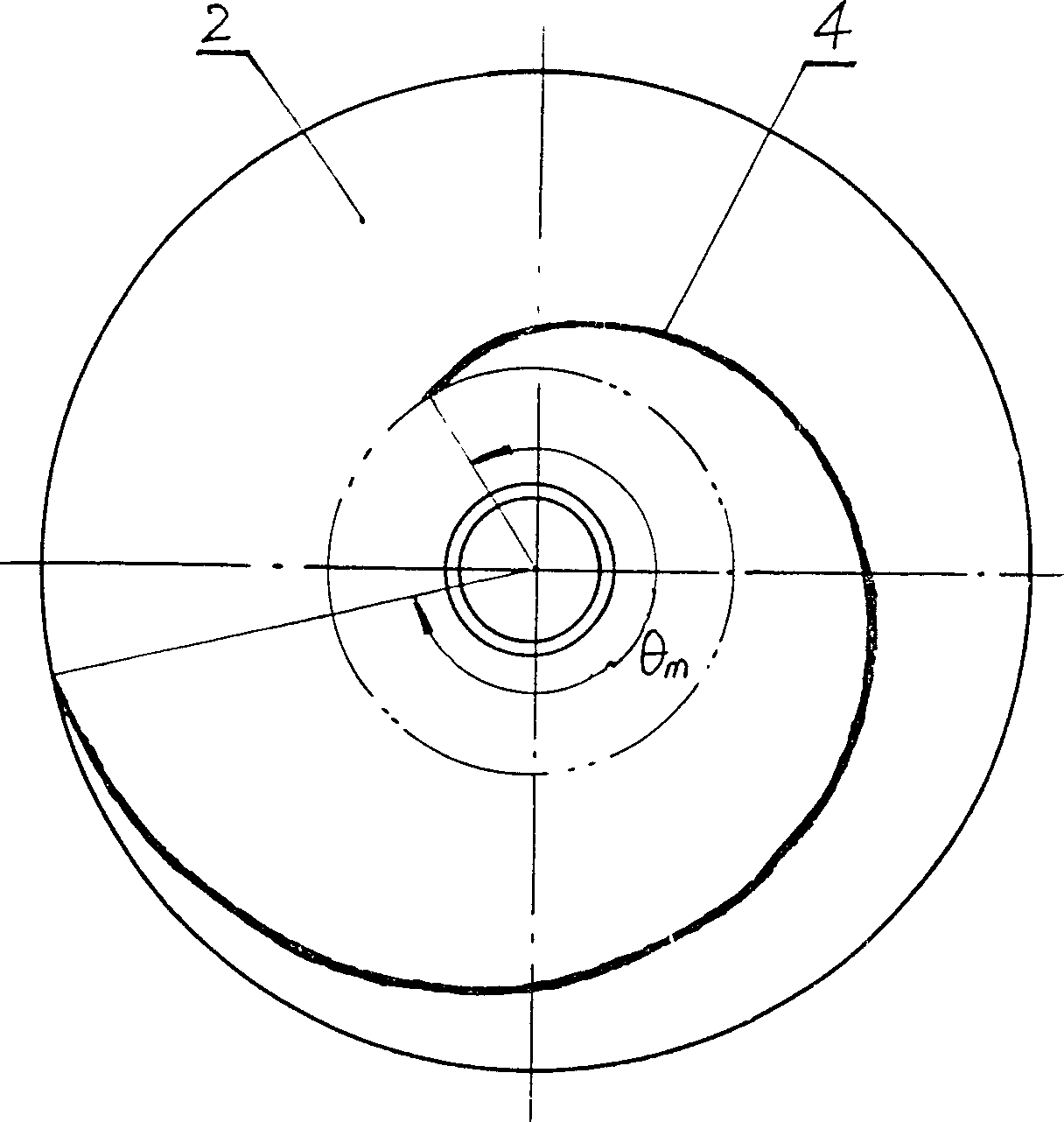

[0013] figure 1 , figure 2 Shown is a tuber material delivery pump of the present invention, the feed hole on the pump body 1 corresponds to the position of the impeller feed inlet of the impeller 2, and the flow channel of the pump body 1 is an involute variable-section flow channel; it is fixedly installed on The partition tongue 3 on the pump body 1 is located above the impeller 2, and a detachable structure is adopted between the partition tongue 3 and the pump body 1, which not only helps to improve the processing accuracy and manufacturability of the partition tongue, but also prevents the return of materials and reduces Water leaks back, which is beneficial to improve the working efficiency of the pump. The impeller drive shaft 7 is supported on the bearing bracket 8 through bearings, and extends into the pump body 1 through the pump cover 5, and the impeller 2 is installed at the front end of the impeller drive shaft 7; the above-mentioned bearings adopt roller beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com