Paper structure having at least three regions including decorative indicia comprising low basis weight region

A low-quantity, marking technology, applied in papermaking, patterned paper, paper machines, etc., can solve the problems of reducing paper strength and achieve the effect of enhancing the aesthetic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

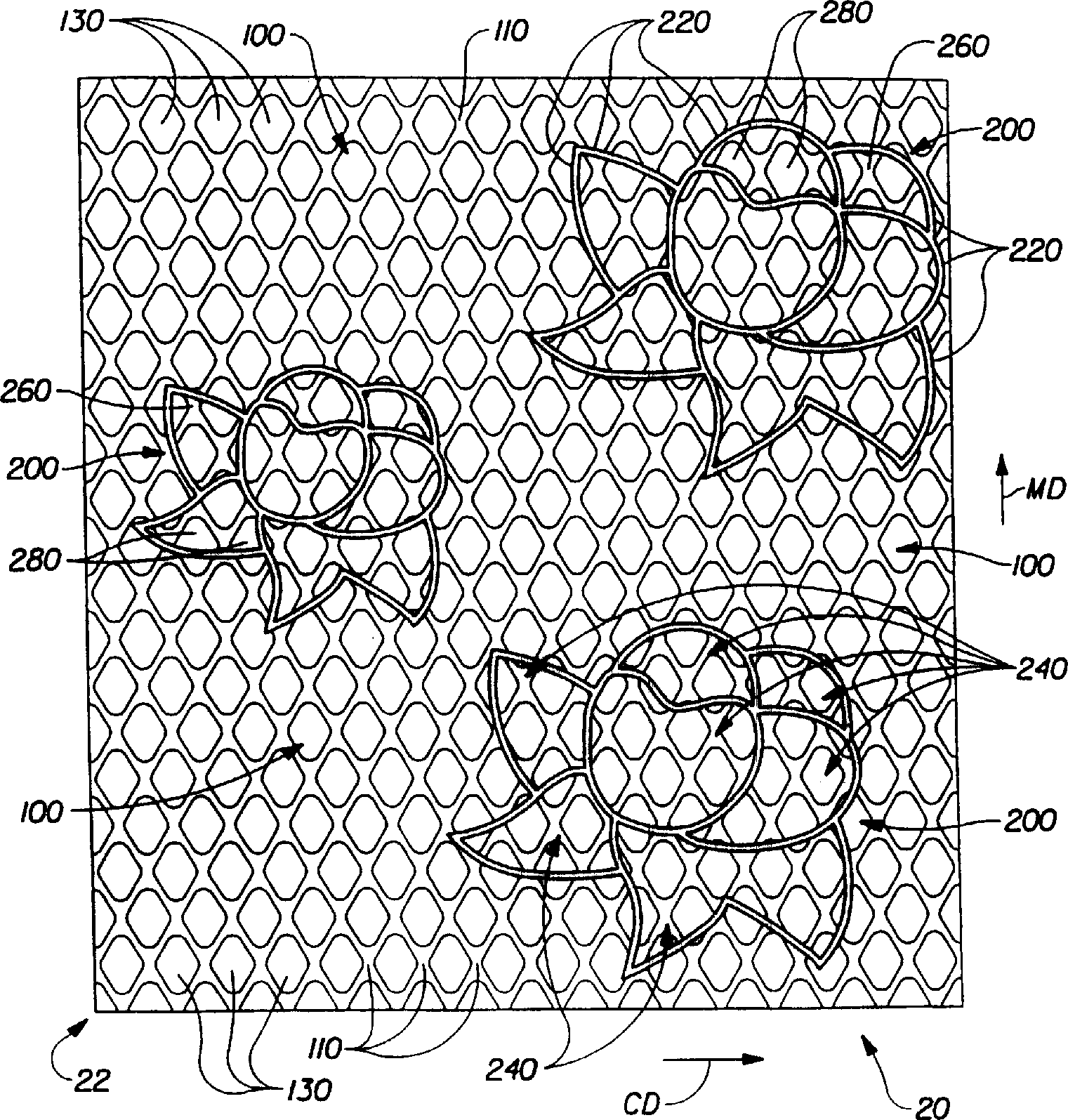

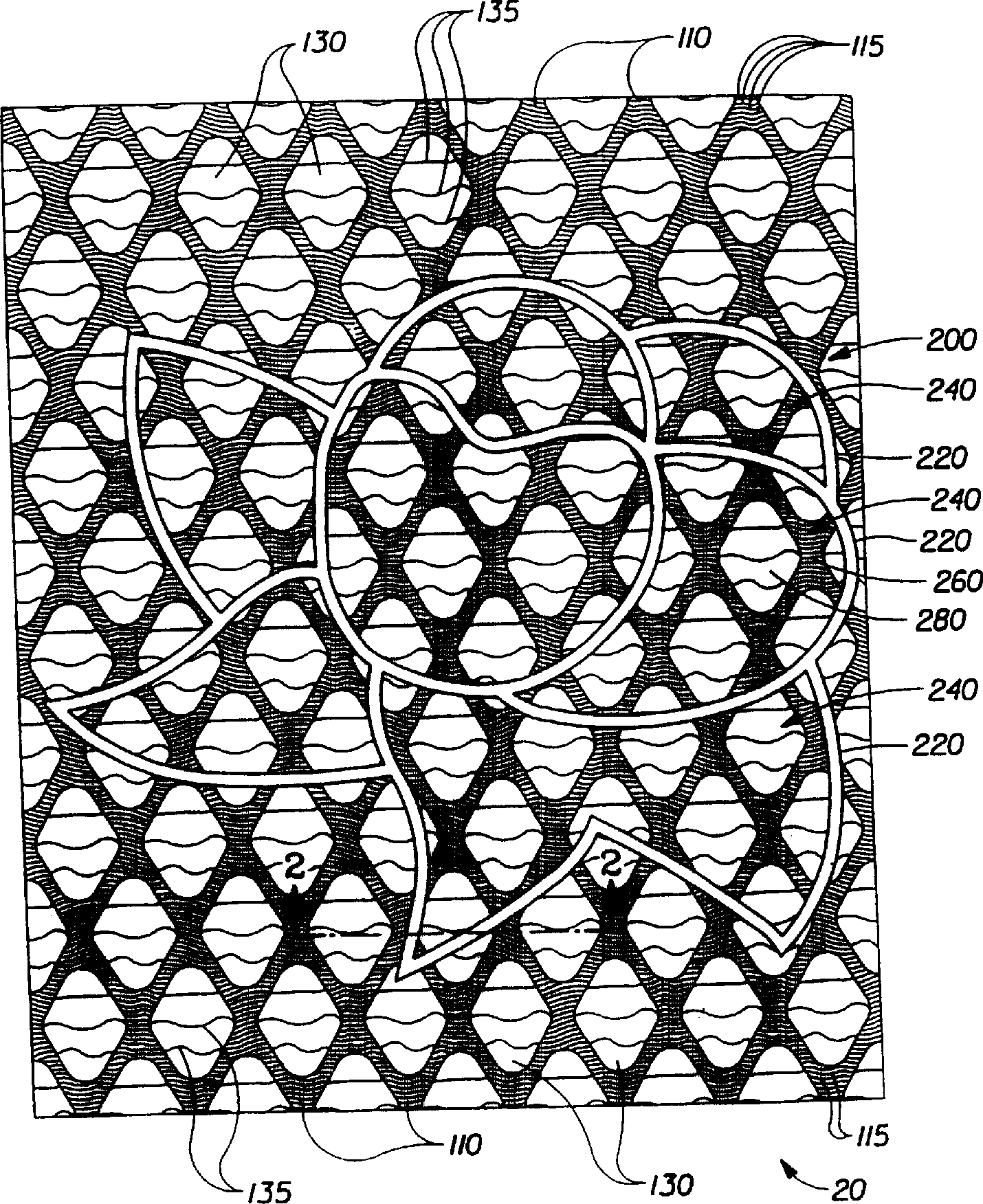

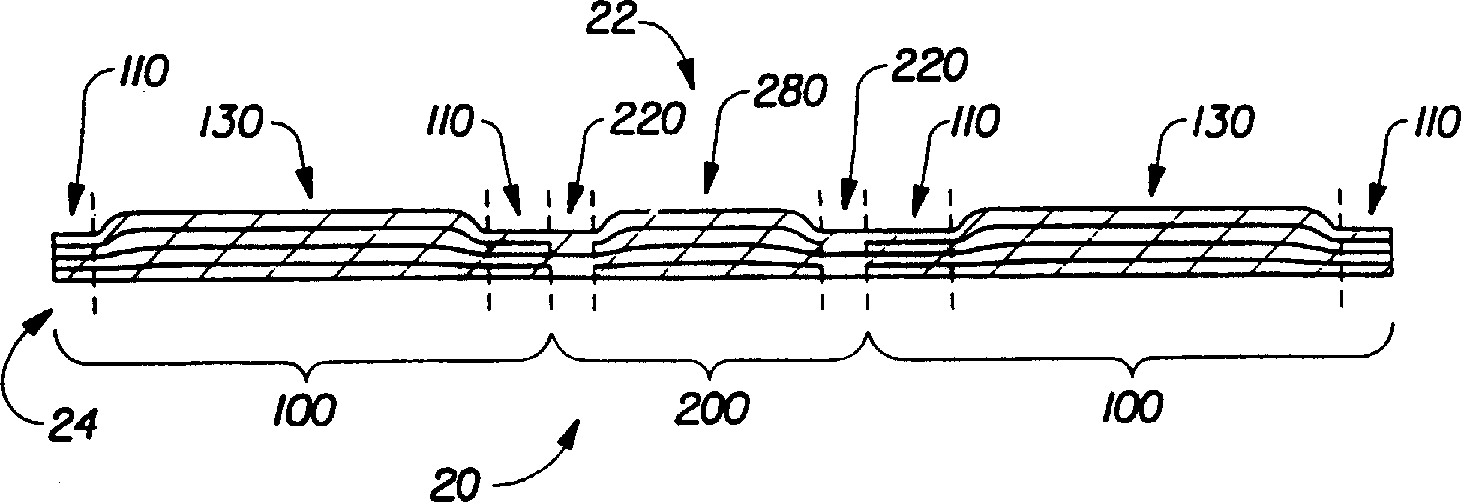

[0067] The paper structure 20 according to the present invention can utilize Figure 4 The papermaking equipment shown is prepared. The paper of the invention is initiated by providing a plurality of fibers to be suspended in a liquid carrier, such as an aqueous dispersion of papermaking fibers in the form of a suspension; and depositing the papermaking fiber suspension from the headbox 1500 onto the fiber retention forming element 1600 Preparation method of structure 20. exist Figure 4 Here, the forming element 1600 is in the form of a continuous strip. A suspension of papermaking fibers is deposited onto the forming element 1600 and dewatered from the suspension by the forming element 1600 to form a web of papermaking fibers supported on the forming element 1600 . The papermaking fiber suspension may include relatively long fibers having an average fiber length greater than or equal to 2.0 mm, and relatively short fibers having an average fiber length less than 2.0 mm. ...

example 1

[0141] First, a 3% by weight aqueous suspension of northern softwood kraft (NSK) fibers was prepared using a conventional pulper. A 2% solution of a temporary wet strength resin (ie, PAREZ 750 sold by American Cyanamid Company, Stanford, CT) at a rate of 0.2% dry fiber weight was added to the NSK stock tube. The NSK slurry was diluted to a concentration of about 0.2% at the mixing pump. Next, a 3% by weight aqueous suspension of the eucalyptus fibers was obtained using a conventional pulper. A 2% solution of debonding agent (ie, Adogen SDMC sold by Witco Corporation, Dublin, OH) was added to a eucalyptus pulp tube at a rate of 0.1% by weight of the fiber. The eucalyptus slurry was diluted to a consistency of about 0.2% at the mix pump.

[0142] The treated furnish streams are mixed in the headbox and deposited to Figure 16 Forming element 1600 is shown so as to form a uniform web. Forming element 1600 includes a Fourdrinier forming wire having flow restricting features 16...

example 2

[0147] First, a 3% by weight aqueous suspension of northern softwood kraft (NSK) fibers was prepared using a conventional pulper. Temporary wet strength resin (i.e., PAREZ sold by American Cyanamid Company (Stanford, CT)) was added at a ratio of 0.2% by dry fiber weight. 750) 2% solution was added to the NSK slurry tube. The NSK slurry was diluted to a concentration of about 0.2% at the mixing pump. Next, a 3% by weight aqueous suspension of eucalyptus fibers was prepared using a conventional pulper. A 2% solution of a debonding agent (i.e., Adogen® sold by Witco Corporation (Dublin, OH) SDMC) was added to a tube of eucalyptus pulp. The eucalyptus slurry was diluted to a consistency of about 0.2% at the mix pump. Furthermore, a 3% by weight aqueous suspension of eucalyptus fibers was obtained using a conventional pulper. A 2% solution of a dissociating agent (i.e., Adogen® sold by Witco Corporation (Dublin, OH) SDMC) and a 2% solution of dry strength binder (i.e., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com