Spraying method with controllable spraying amount

A technology of spray control and spray volume, applied in the direction of injection devices, etc., can solve the problems of wasting energy, affecting production, and large investment in equipment, and achieves the effects of uniform horizontal distribution, increased production, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

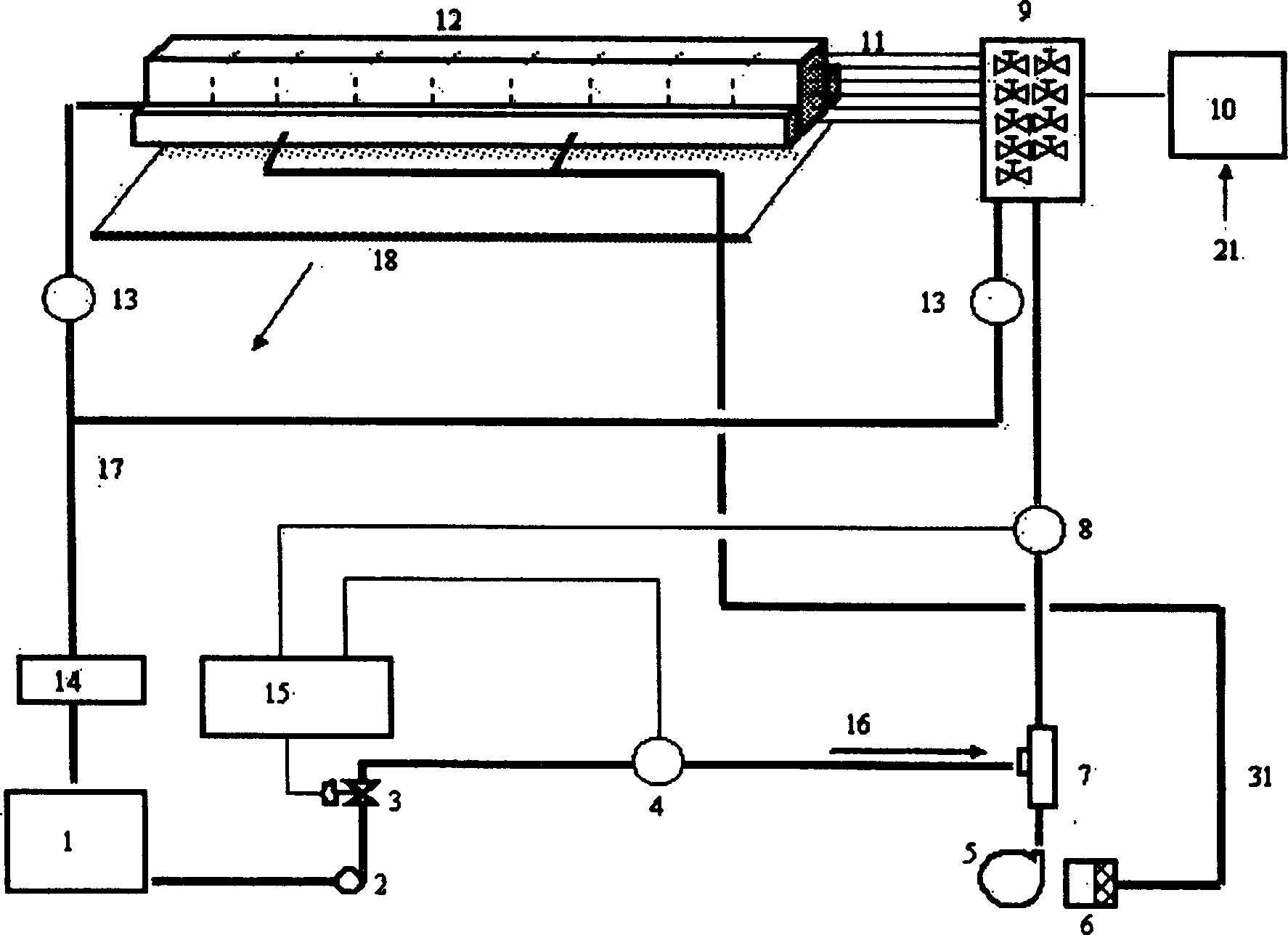

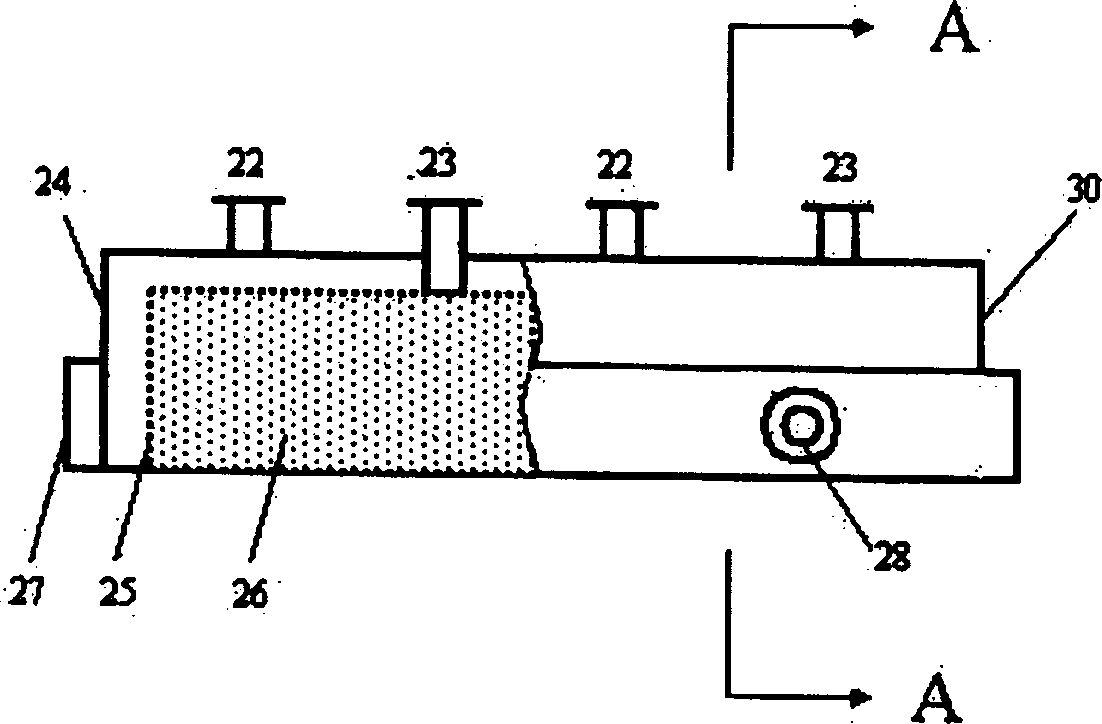

[0016] In the spraying method with controllable spray volume, the spraying system adopted is composed of atomizing device, dilution and delivery device, spraying and control device. see figure 1 , the atomization device contains a liquid storage tank 1, a pump 2, a control valve 3, flow meters 4, 8, a controller 15, compressed air 16 and an atomizer 7, and the liquid in the liquid storage tank 1 is controlled by the pump through the control valve 3 2 pumped out together with the compressed air 16 into the atomizer 7, the flowmeters 4 and 8 are respectively connected to the atomization inlet and outlet of the atomizer 7, and the controller 15 is connected to the flowmeters 4, 8 and the control valve 3. The diluting and transporting device contains a blower 5 and an air filter 6, and the wind generated by the blower 5 is filtered by the air filter 6 and sent to the atomizer 7. The spraying and control device includes a control valve cabinet 9, a control cabinet 10, a partition ...

Embodiment 2

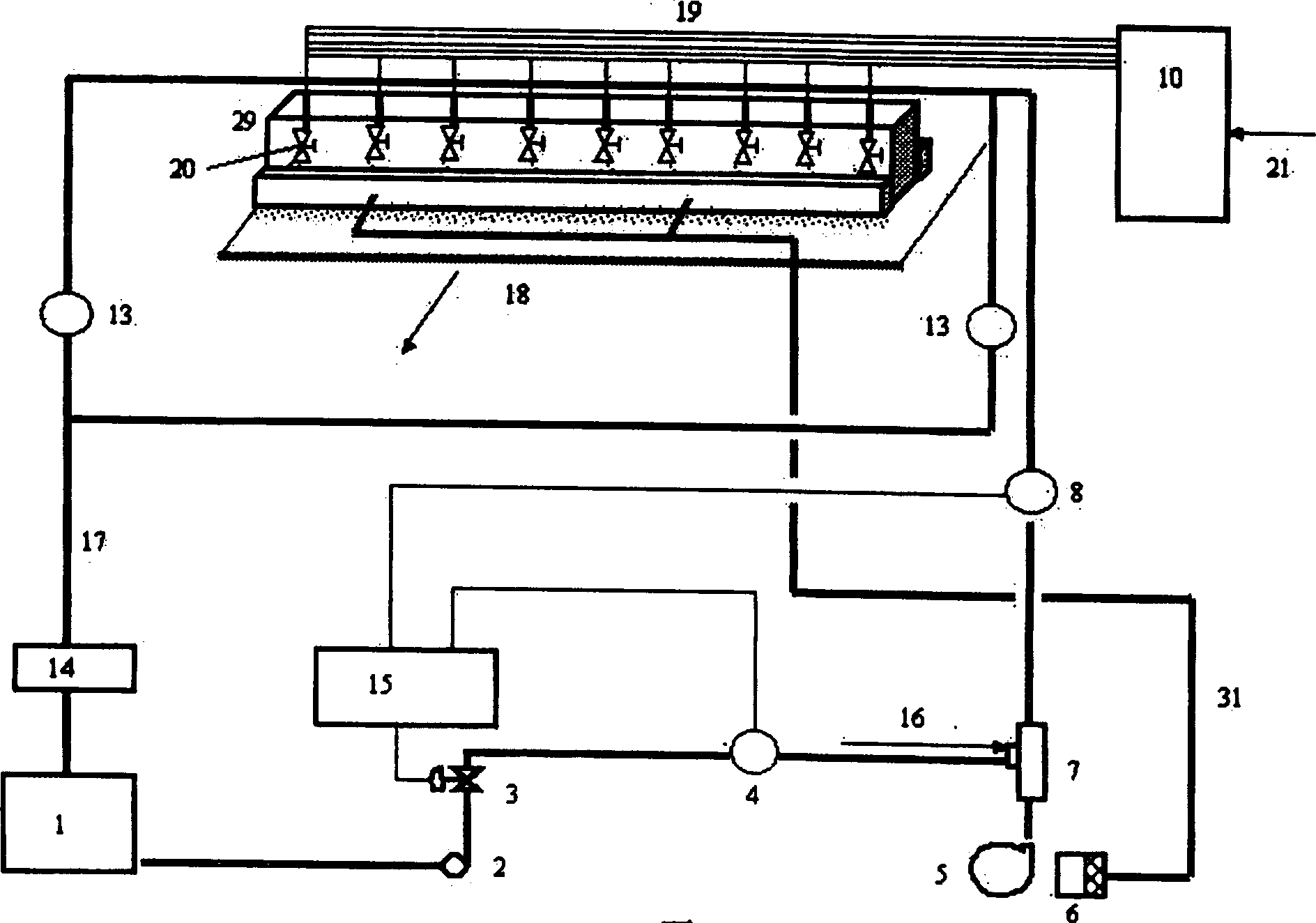

[0025] The spraying and control steps of the present embodiment adopt the mode of decentralized control, and the spraying control valve is a partition spraying valve 20, and the spraying valve 20 of its control partition spraying is directly installed in the spray box 29 of the spraying site, according to the automatic or automatic control of the control cabinet 10 Manually set the value 21, respectively control the spray valves 20 of each zone through the pneumatic signal tube bundle / electric control cable bundle 19, so as to control and adjust the spray volume of each zone. The difference between this embodiment and Embodiment 1 is that the control mode is different, and other operation steps are all the same.

[0026]The spraying and control device in the spraying system that this embodiment adopts is different from embodiment 1, others are the same, see specifically figure 2 . The control signal of the control cabinet 10 directly controls the partition spray valve 20 ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com