Patents

Literature

38results about How to "Investment economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

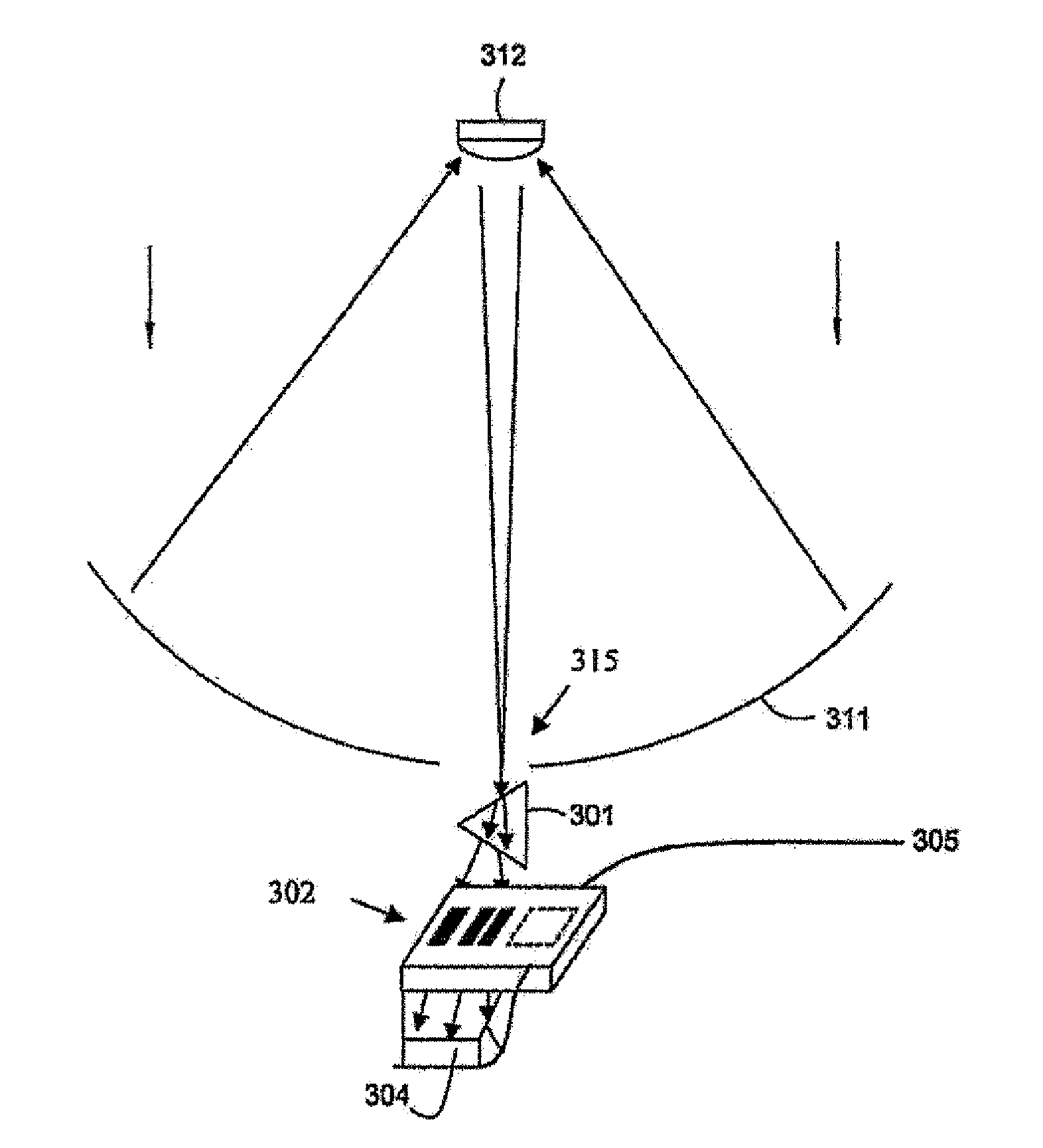

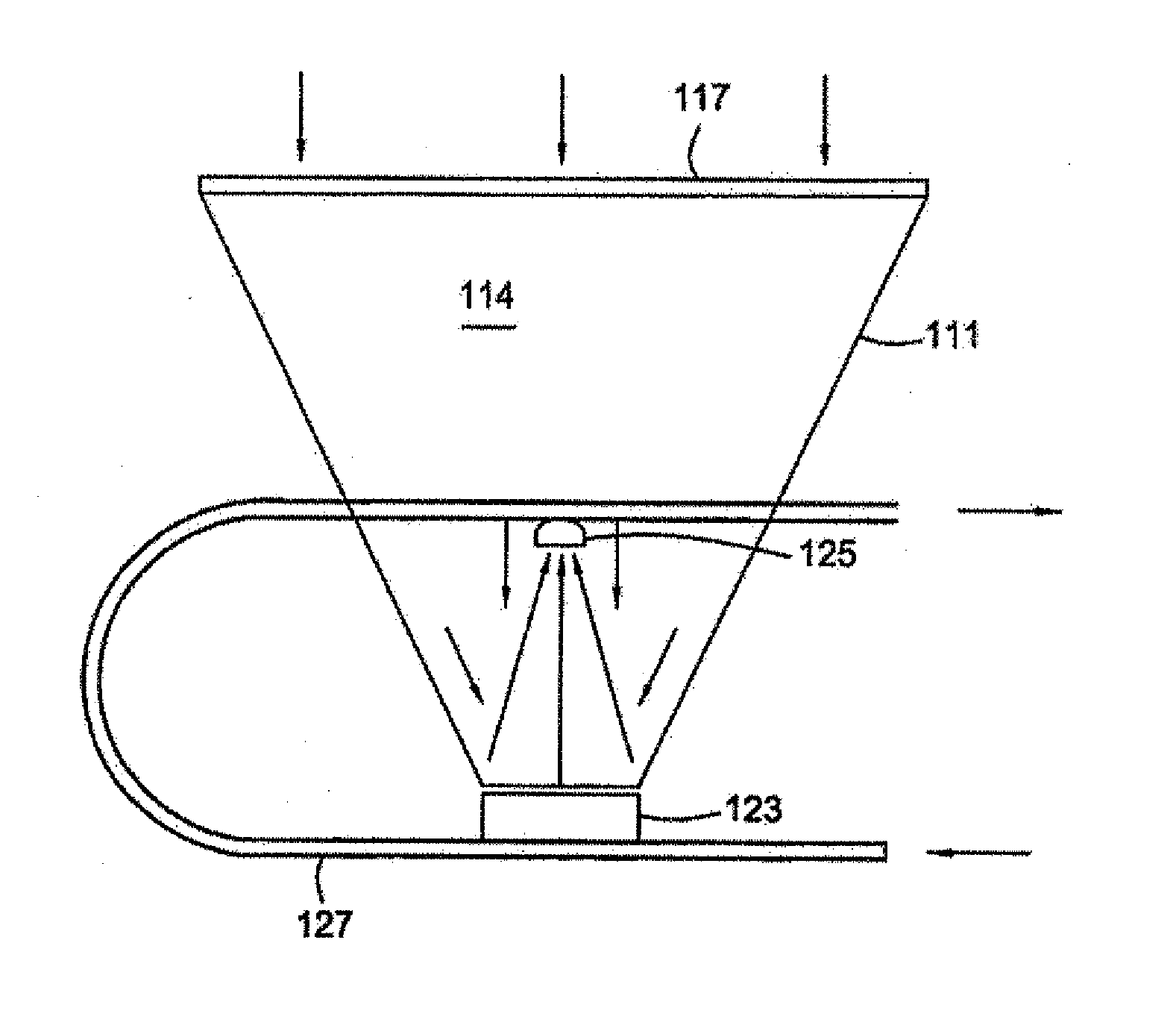

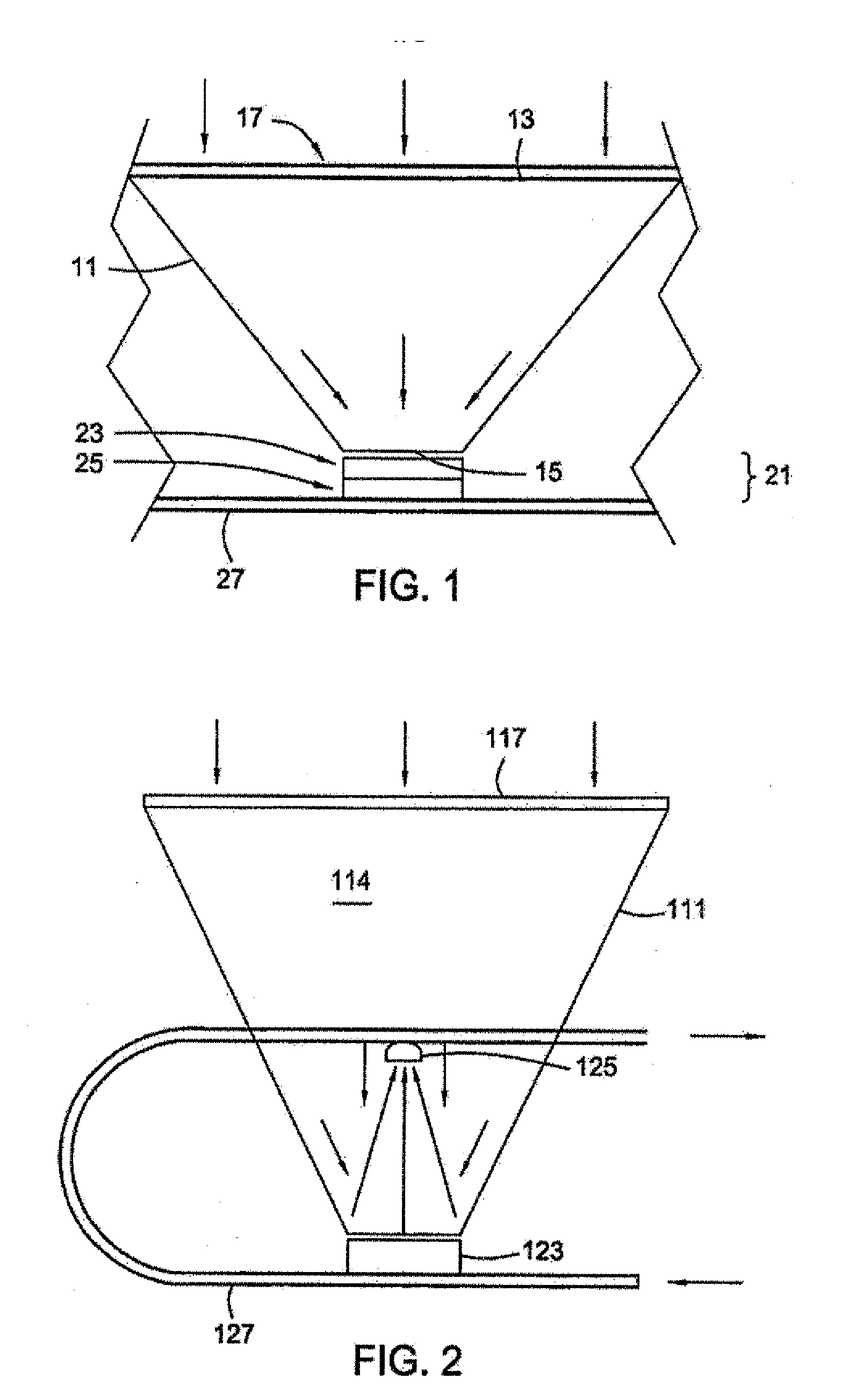

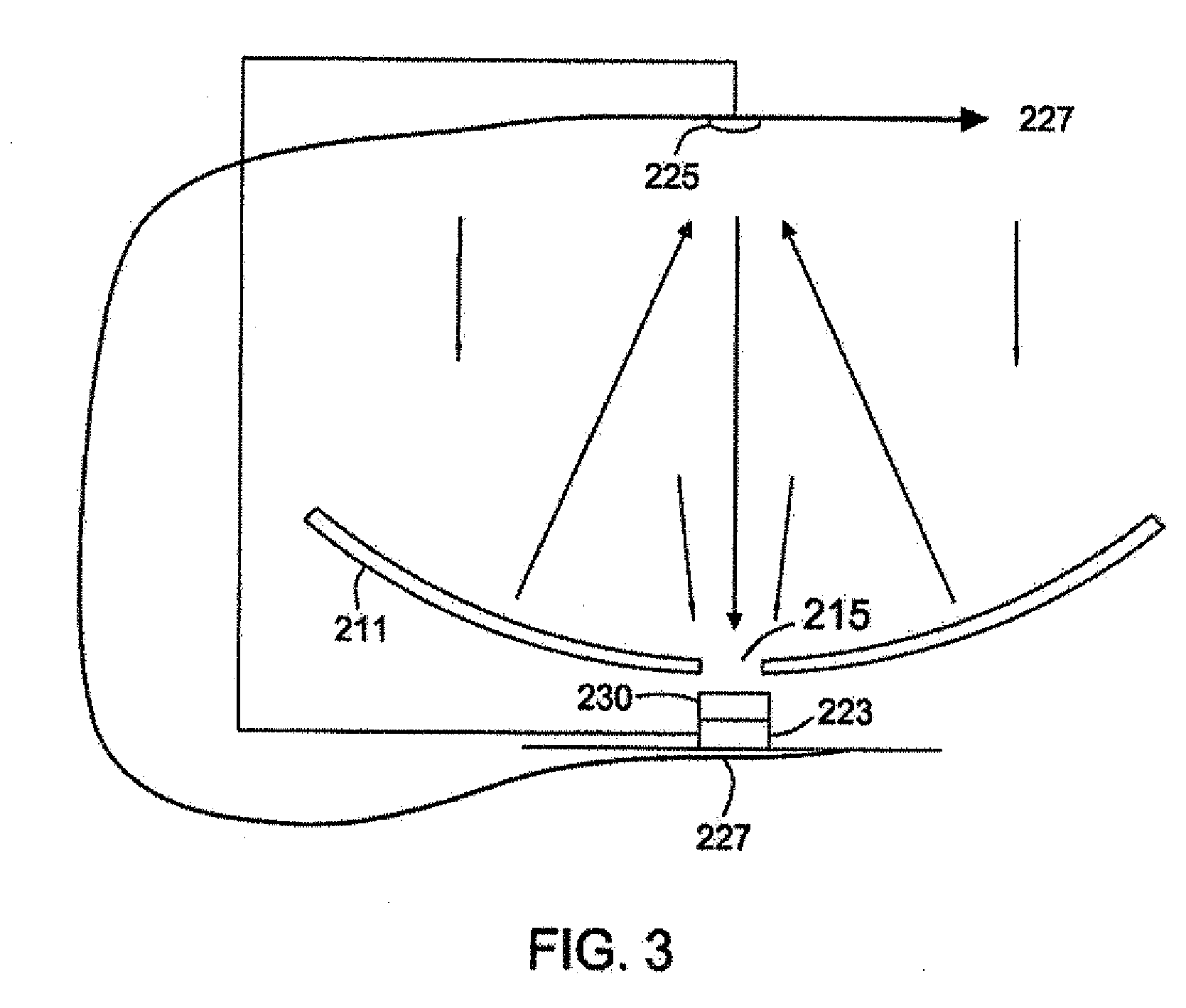

Integrated solar energy conversion system, method, and apparatus

InactiveUS20070289622A1Improve efficiencyEconomic return investmentSolar heating energySolar heat collector controllersWorking temperatureEngineering

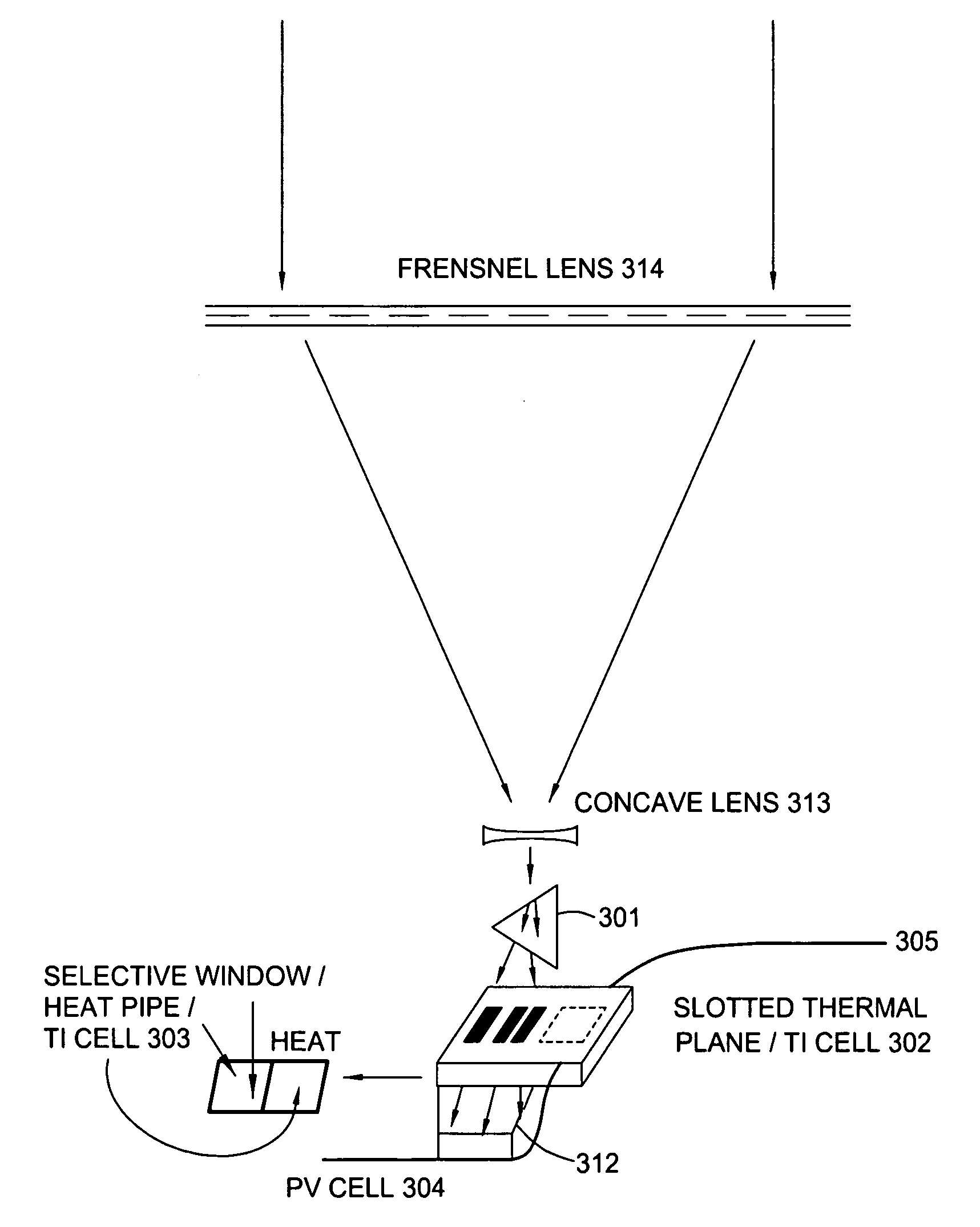

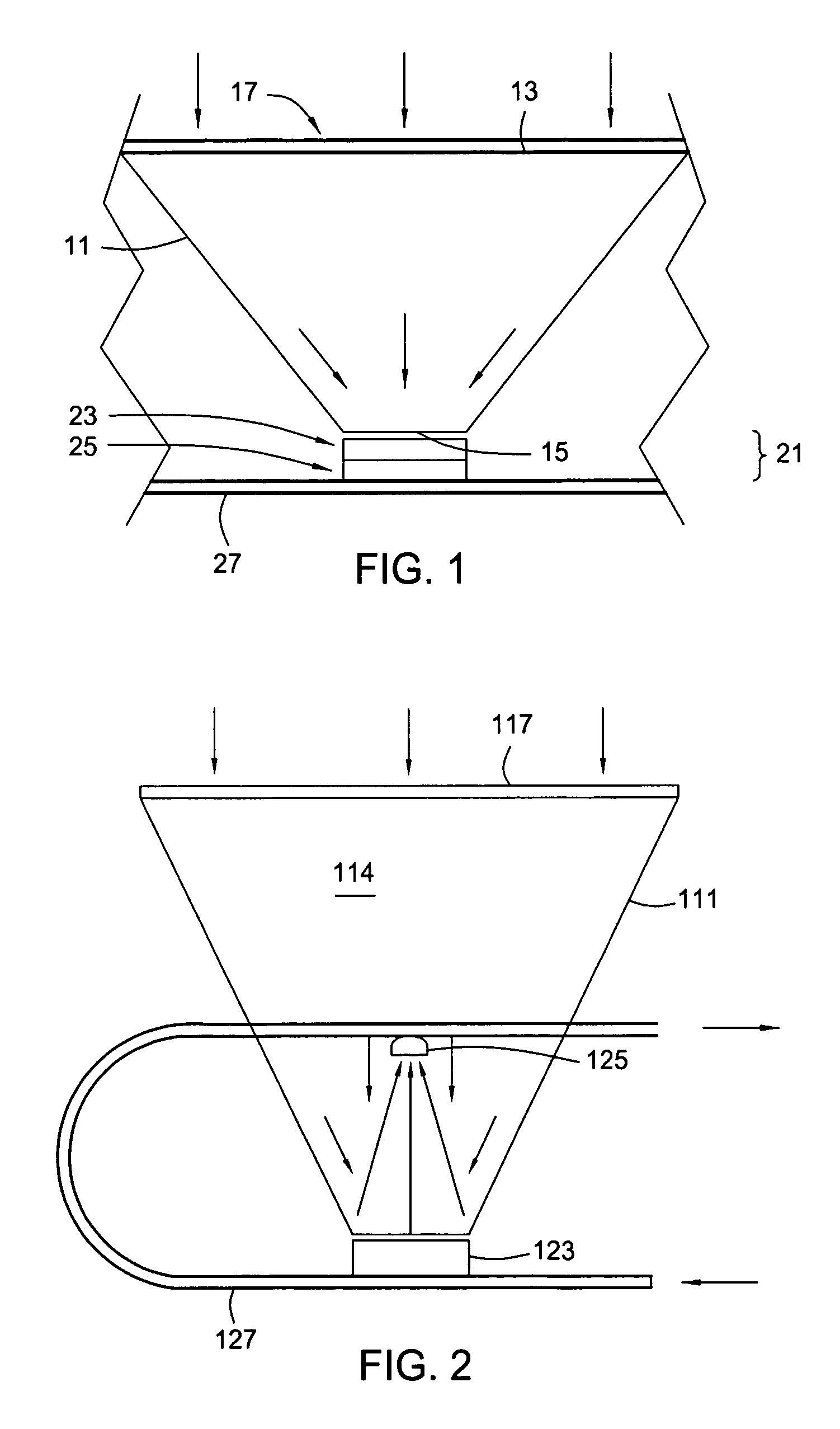

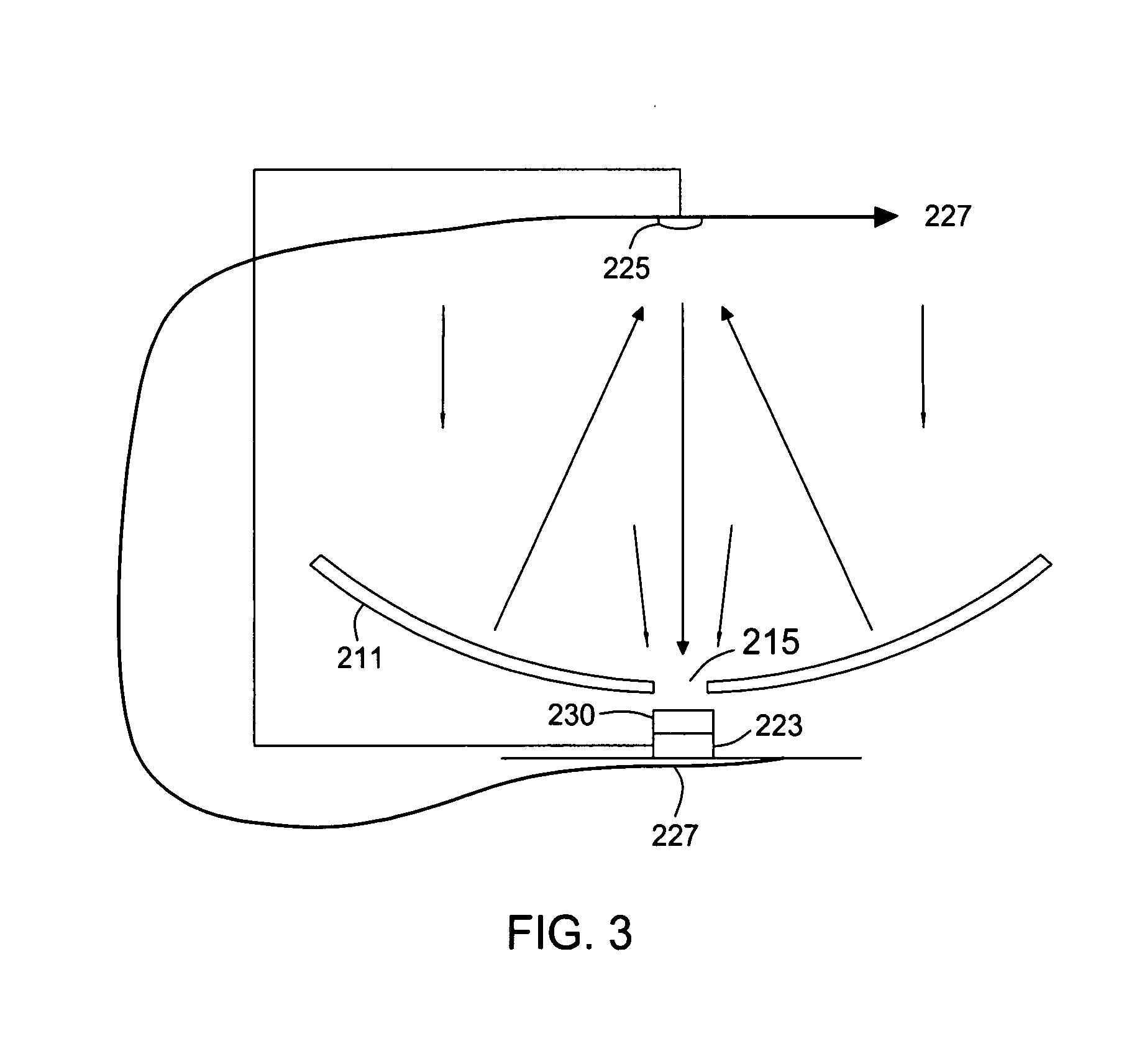

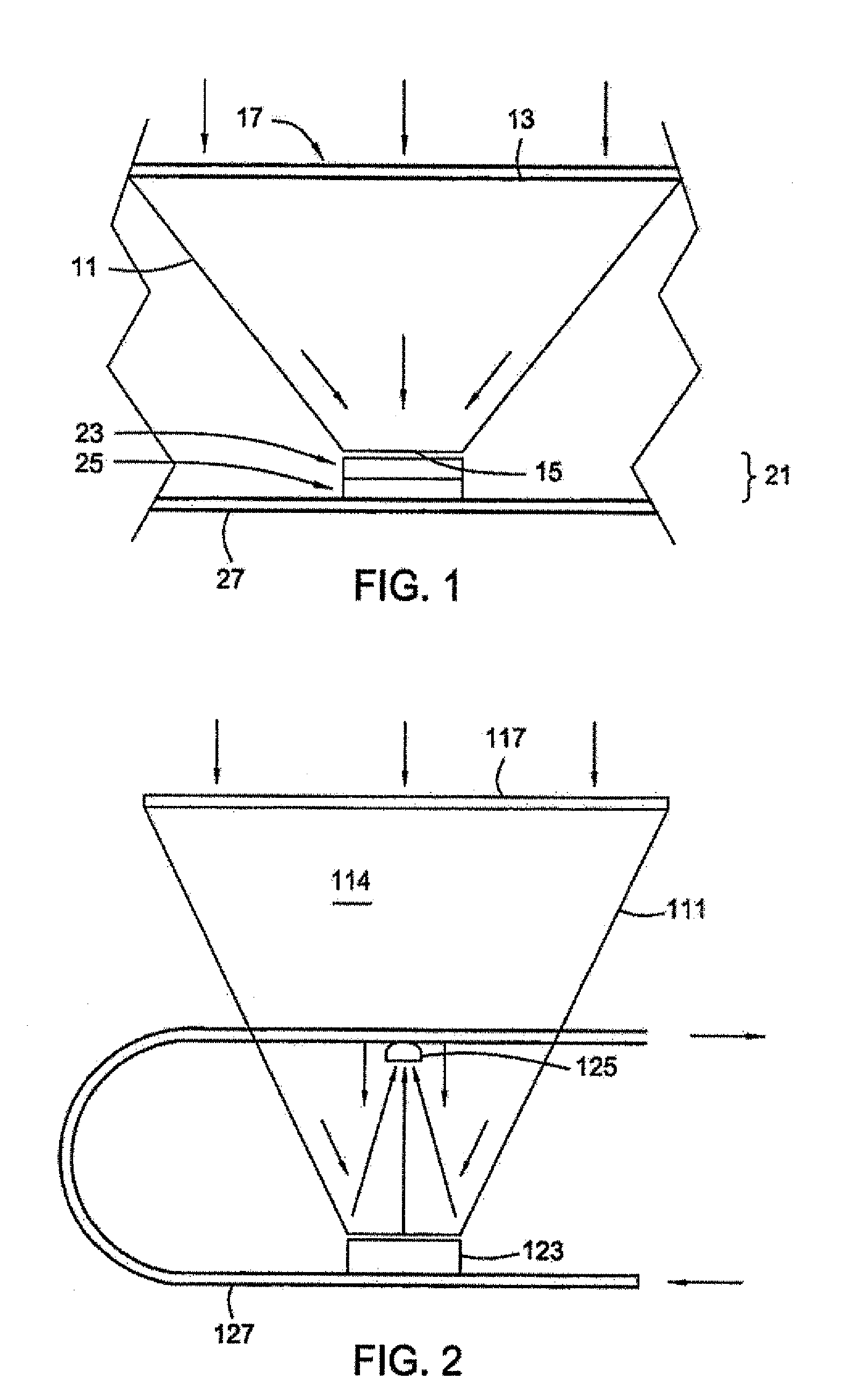

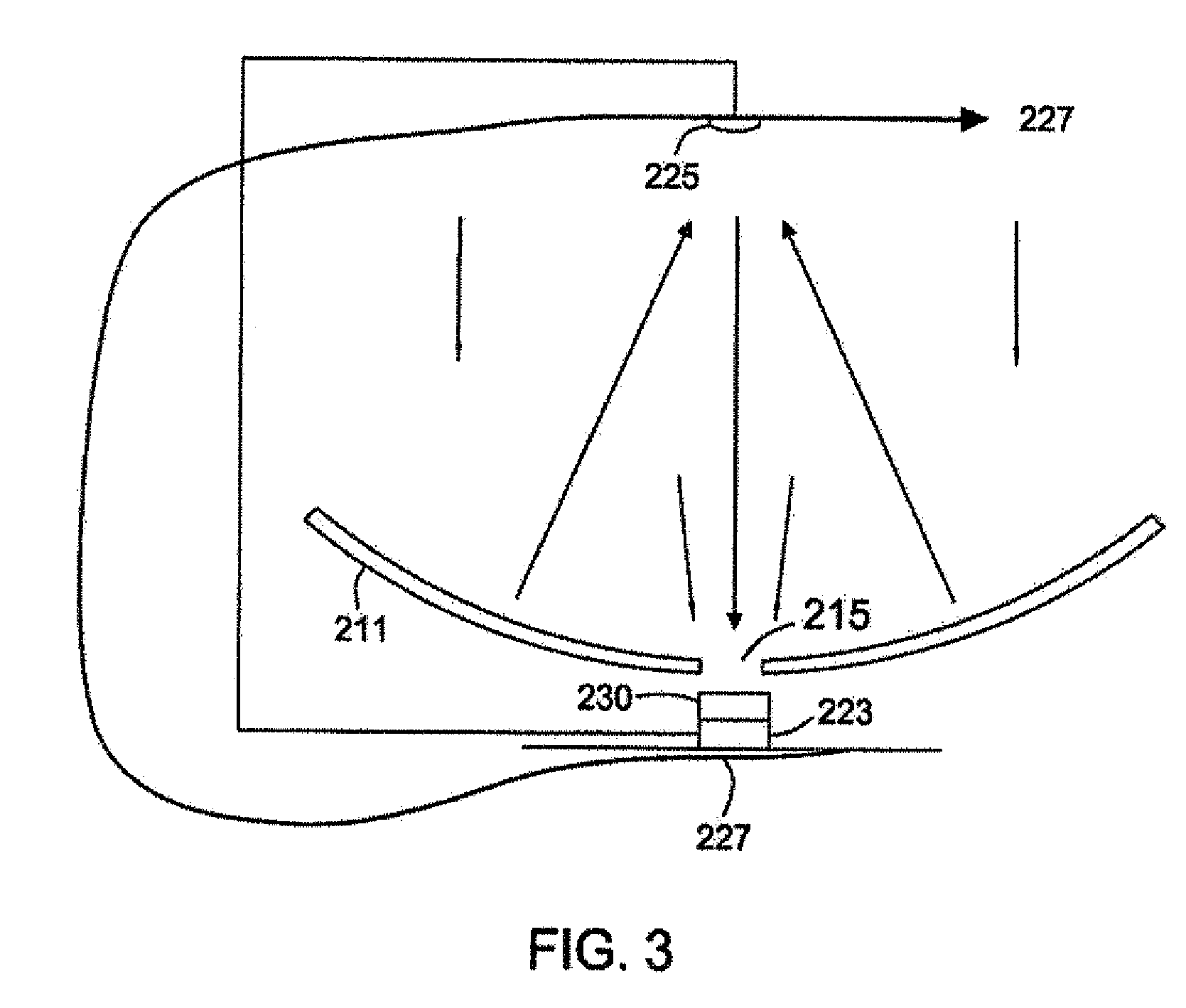

A solar energy conversion package includes a photovoltaic (PV) cell, a thermionic or thermoelectric conversion unit and a thermal heating system. Solar radiation is concentrated by a lens or reflector and directed to the PV cell for electrical power conversion. A water circulation system maintains the PV cell at working temperatures. The thermionic or thermoelectric conversion cell is coupled between these cells in the thermal path to generate additional power. Additional efficiencies may be gained by partitioning the solar radiation with prisms or wavelength specific filters or reflective coatings into discrete spectrum segments optimized for each conversion unit for maximizing efficiency of electrical energy conversion and equipment design. Integrating all three of these conversion techniques produces a synergistic system that exceeds the performance conventional solar conversion systems.

Owner:LOCKHEED MARTIN CORP

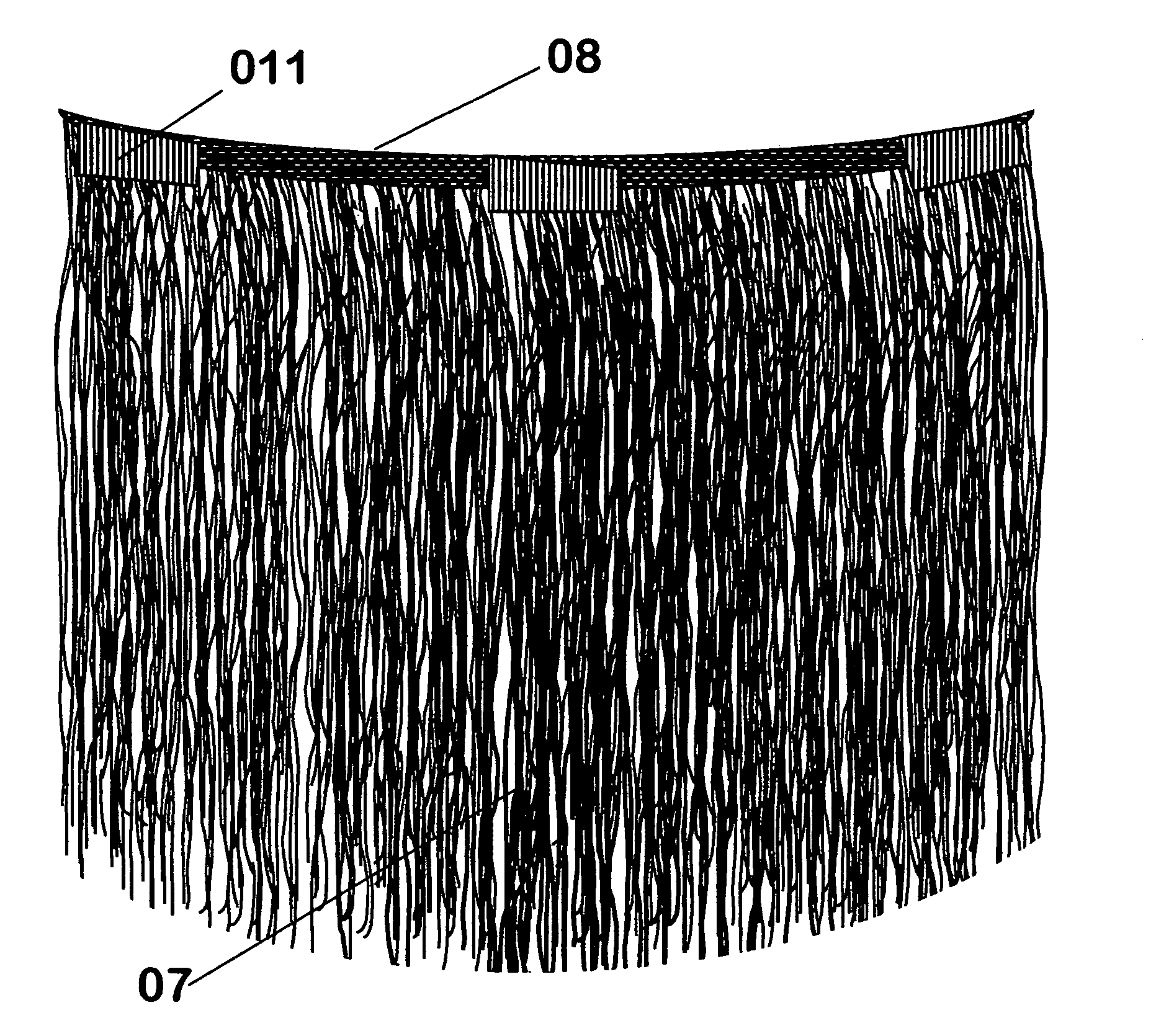

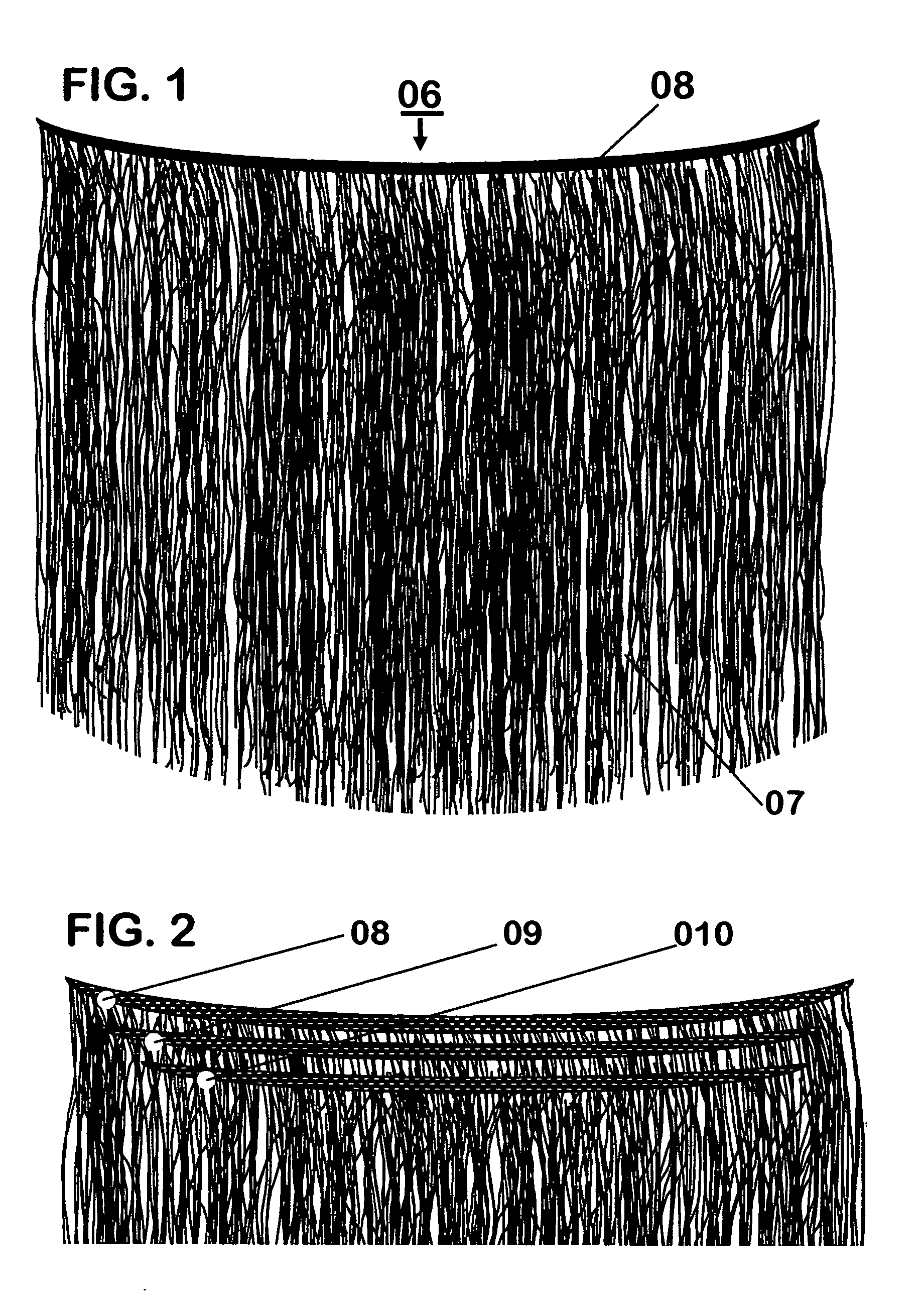

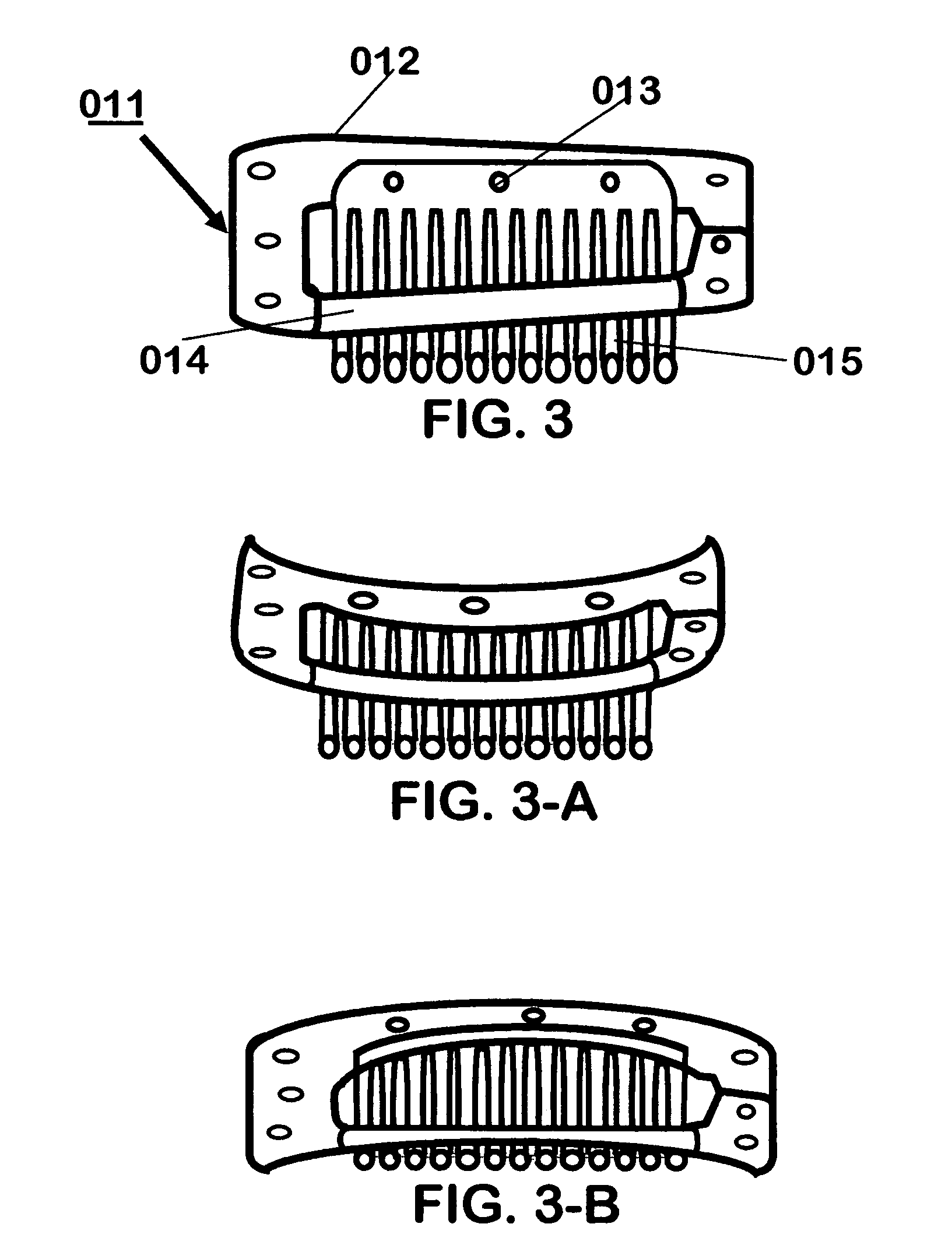

Instant hair extention and method for attachment

InactiveUS20050194015A1Facilitate freer flowing hairEliminating appearanceHair accessoriesToupeesEngineeringHair characteristics

An improved hair extension having snap-lock attaching clips useful for instantly attaching or detaching the hair extension or track to the wearer's natural hair. The hair extension comprises 2 to 3 layers of human or synthetic hair tracks sewn together to create one thicker layer and 3 snap-lock clips, all sewn onto the base of the lead extension along the top inside edge. The wearer can quickly and easily apply the extension to their natural hair with the confidence of a firm and secure grip and enjoy the appearance of fuller, longer, more natural looking hair, while maintaining a completely unnoticeable appearance to the on-looker.

Owner:WATTS TERESA YVETTE

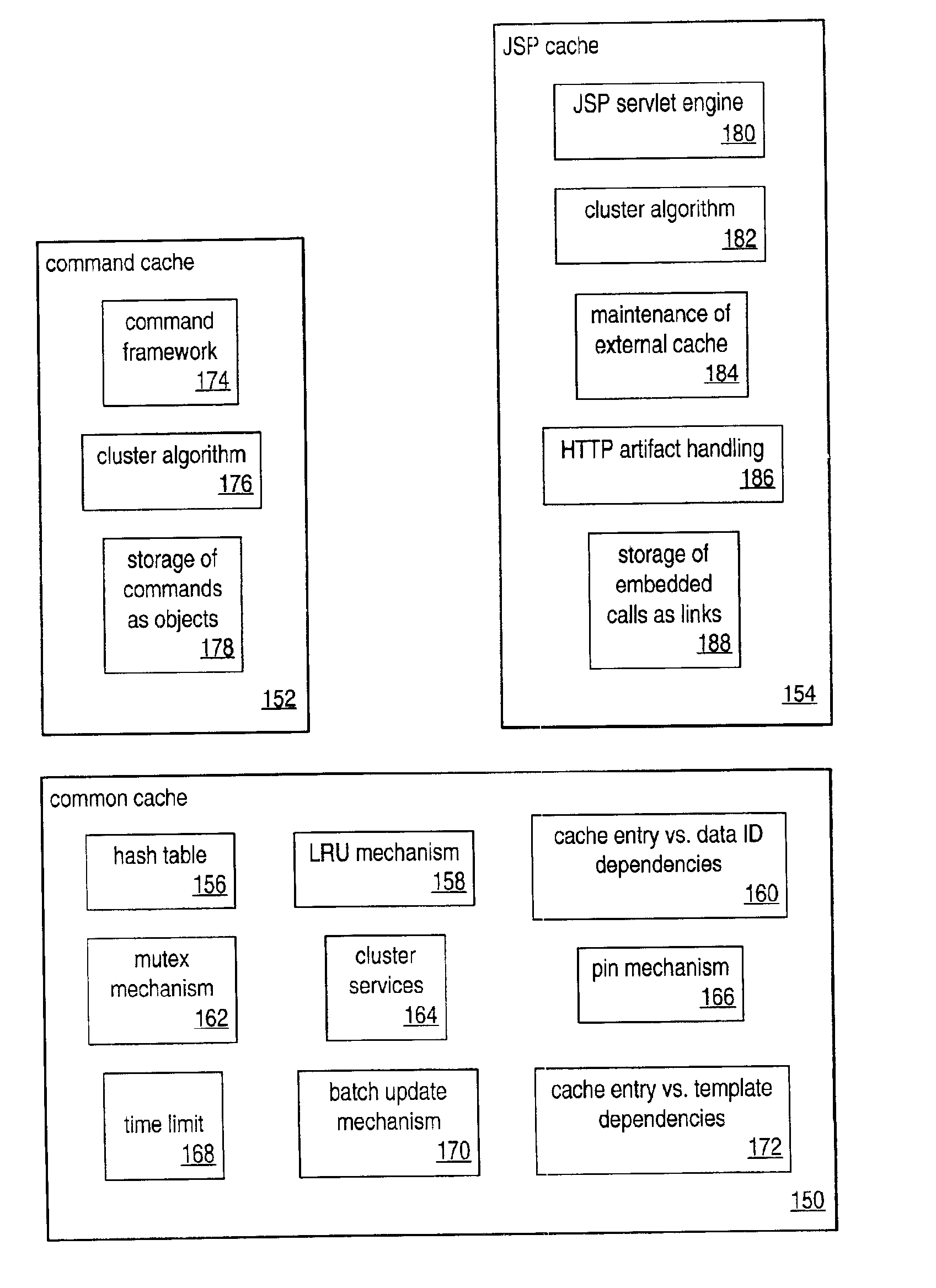

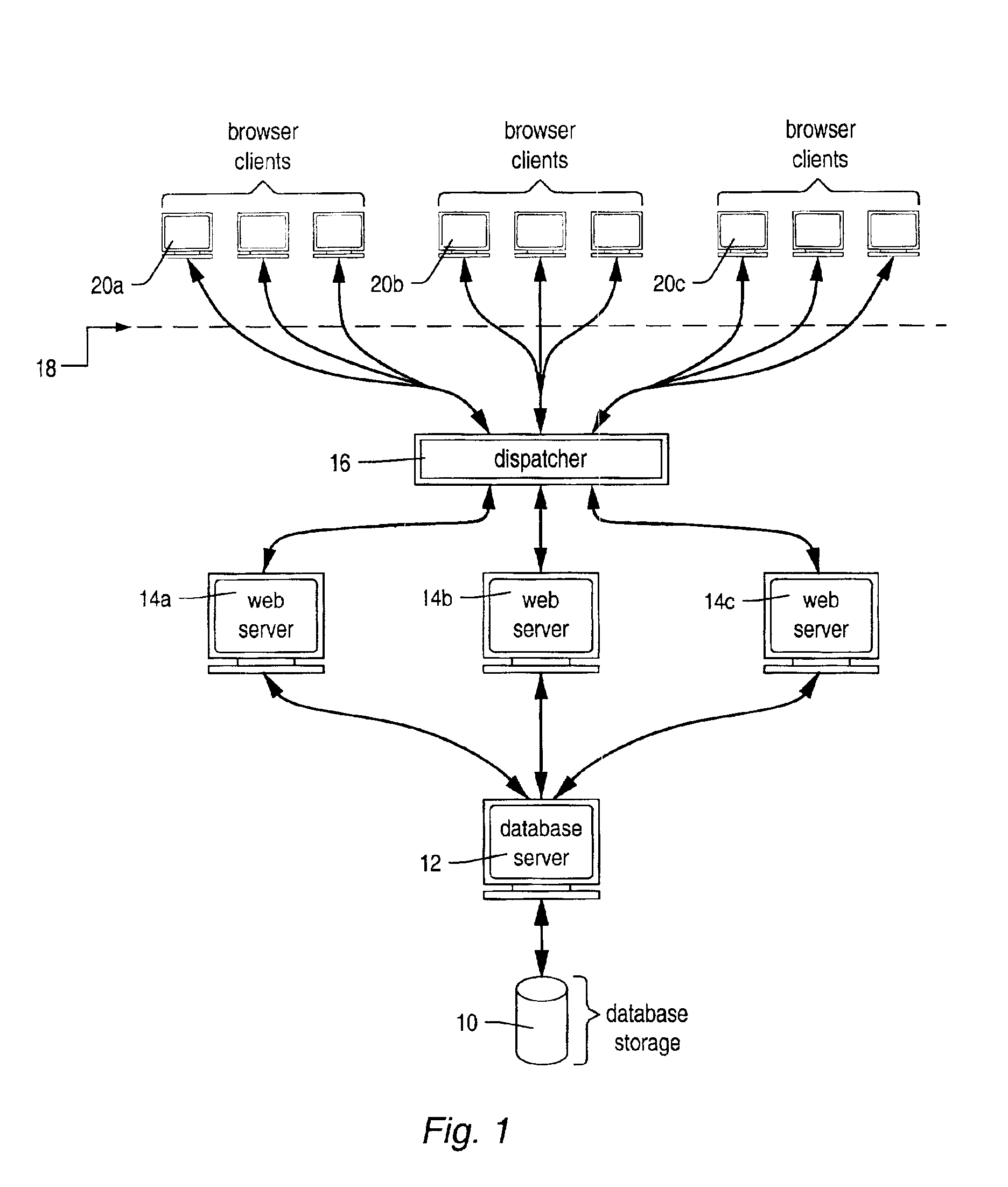

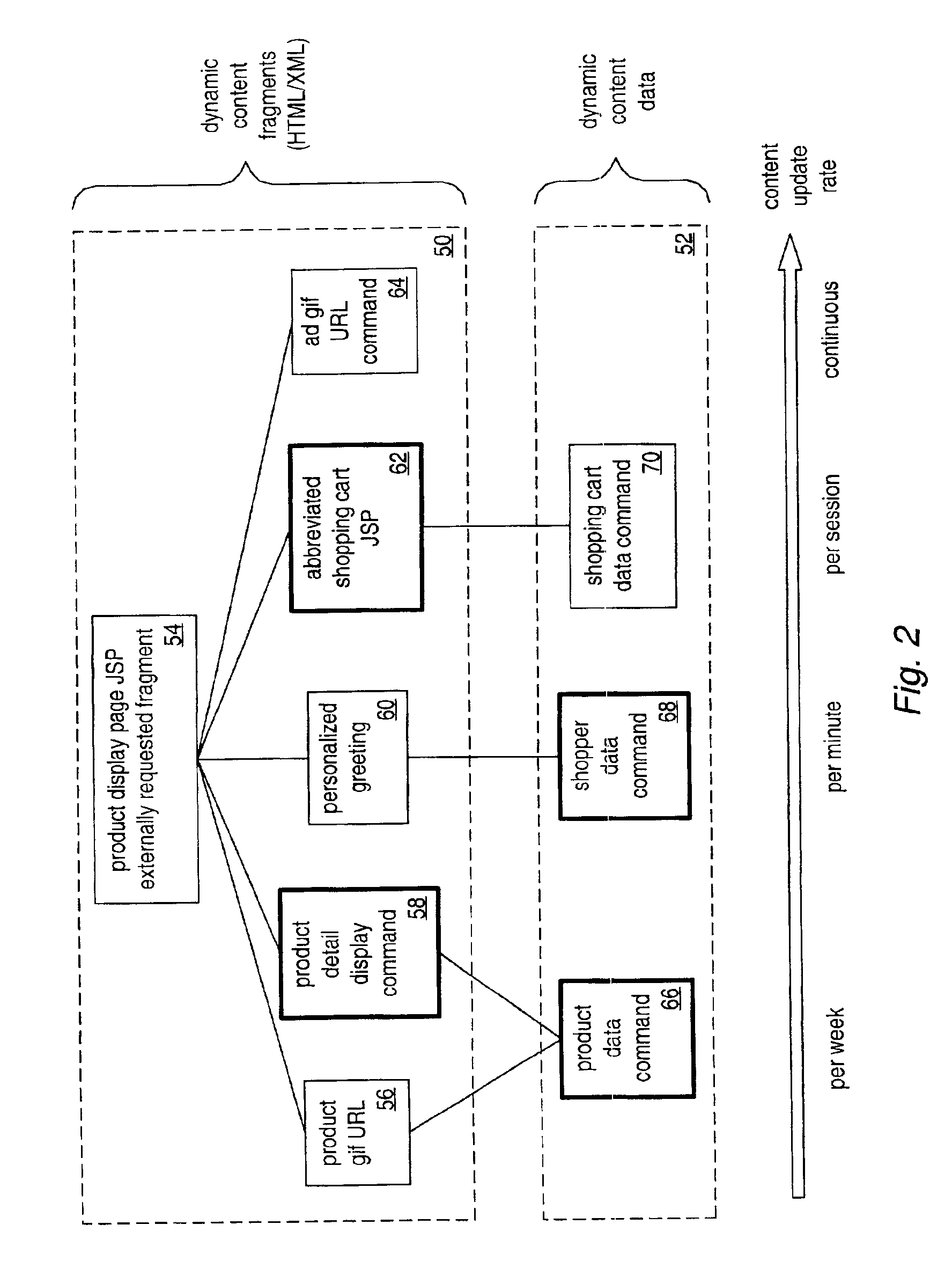

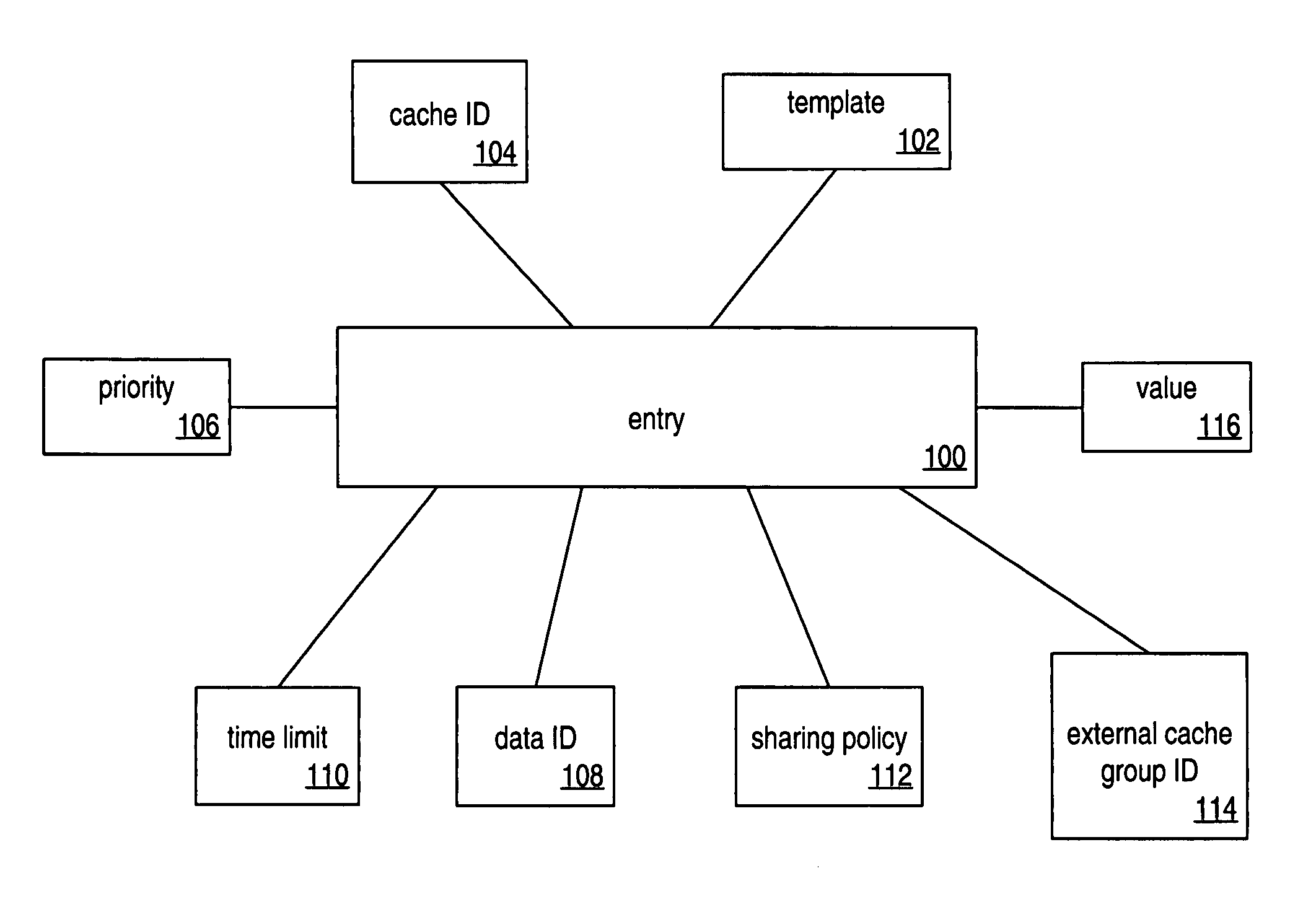

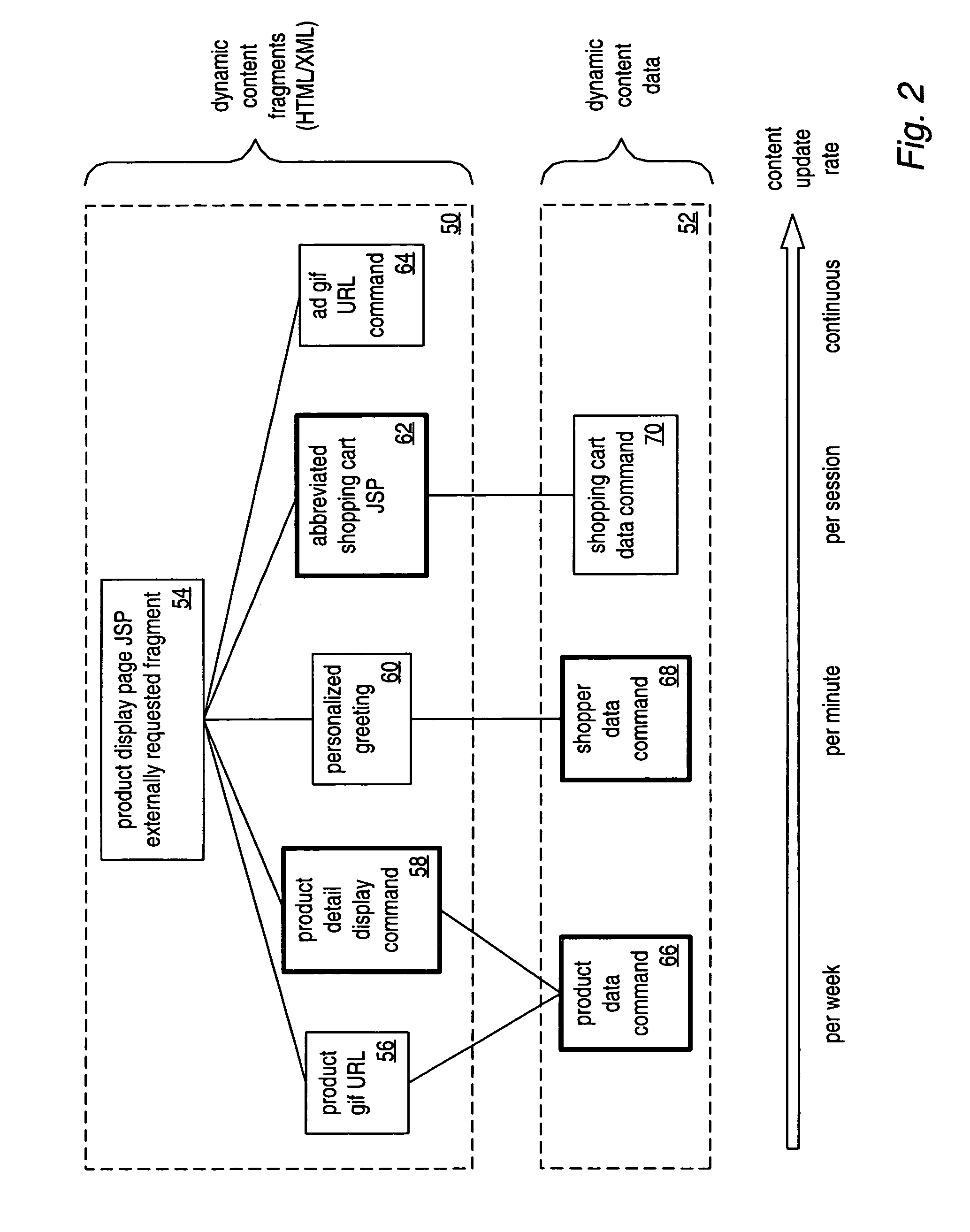

Integrated JSP and command cache for web applications with dynamic content

InactiveUS6877025B2Improve responsivenessShort response timeMultiple digital computer combinationsTransmissionWeb applicationParallel computing

A system and method are disclosed, according to which, the responsiveness of client / server-based distributed web applications operating in an object-oriented environment may be improved by storing both JSPs and commands in the same cache. Some of the code and data structures required for caching JSPs are the same as for commands, and are saved in a common area of the cache. A second area of the cache is reserved for code and data specific to JSPs, and a third area is reserved for code and data specific to commands. This arrangement avoids the difficulty of judiciously apportioning the available cache between JSPs and commands.

Owner:IBM CORP

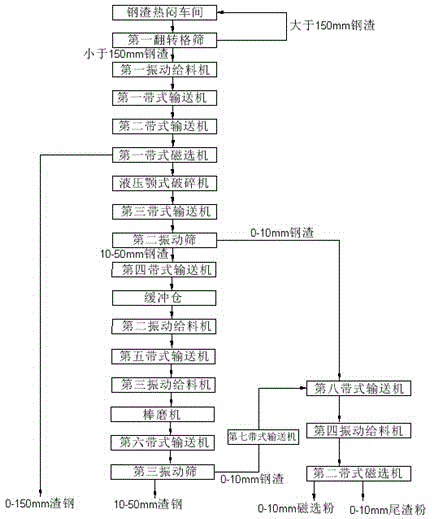

High-efficiency economic secondary treatment process for steel slag

ActiveCN104004867AHigh recovery rate of slag steelHigh utilization rate of tailingsSievingScreeningSlagMagnet

The invention relates to a high-efficiency economic secondary treatment process for steel slag. The process comprises the following steps: step 1, allowing steel slag processed in an enclosed steel slag heating workshop to enter a first overturning grate for screening and carrying out magnetic separation on materials on the grate by using an electromagnetic chuck; step 2, allowing materials below the grate to enter a first belt magnet separator for magnetic separation and allowing non-magnetic steel slag to enter a hydraulic jaw crusher for crushing; step 3, allowing the material processed by the hydraulic jaw crusher to enter a second vibrating screen for screening and allowing materials below the second vibrating screen to enter a second belt magnet separator for magnetic separation so as to obtain magnetic separation powder and tailing powder; and step 4, allowing materials on the second vibrating screen to enter a rod mill for rod milling, allowing materials having undergone rod milling to enter a third vibrating screen for screening and allowing materials below the third vibrating screen to enter the second belt magnet separator for magnetic separation so as to obtain magnetic separation powder and tailing powder. The process provided by the invention can maximumly recover steel slag, has a high slag steel recovery rate and a high tailing utilization rate and is simple and easily practicable.

Owner:WISDRI ENG & RES INC LTD

Static test method of horizontal shaft wind turbine vane scale model based on equal strength principle

ActiveCN103196666AAccurate Structural Performance DataThe test result is accurateMachine part testingScale modelTurbine

The invention discloses a static test method of a horizontal shaft wind turbine vane scale model. The method aims at replacing a full-size vane static test experience through a low-cost and high-efficiency scale model experience detection and computational analysis mode. The method is characterized in that a static test experience of the vane model is adopted to replace the traditional full-size vane static test experience, vanes of the vane model are narrowed in size with an equal proportion, and an experience load of the scale model can be confirmed according to the requirement that the scale model and prototype vanes meet equal strength of the structure. According to the test method, not only are currently-used vane static test devices adopted, but also low-cost small-type test devices and equipment can be adopted to conduct the static experience. Through accurate design and numerical calculation, the scale model and the full-size vanes can have a relatively accurate structural size corresponding relation and a load corresponding relation, and accuracy of test results can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Process of producing gypsum block directly with chemical gypsum

InactiveCN1810697AReduce process linksSave energySolid waste managementCeramic shaping apparatusSlagSlurry

The process of producing gypsum block directly with chemical gypsum includes the reaction between chemical gypsum and water in steaming condition to eliminate one hemicrystalline water molecule, mixing hemicrystalline water gypsum slurry, industrial slag and water absorbent to obtain the mixture material, and molding the mixture material to form the gypsum block. Compared with available technology, the process uses no drying, dedusting and dewatering apparatus, and has low power consumption, environment friendship, less covered area and low cost.

Owner:张继忠 +1

Pseudo goethite method for removing iron in zinc leaching solution

InactiveCN103468951AFast precipitation reactionRapid Settling RemovalProcess efficiency improvementPregnant leach solutionRoom temperature

The invention provides a pseudo goethite method for removing iron in a zinc leaching solution. The method comprises the following steps: adjusting the PH of leachate to be 4.5-5 by using calcium carbonate at room temperature; adding oxydol into the leachate to enable ferrous iron ions to be removed in a manner of goethit, and keeping the pH to be 4.5-5 by adding calcium carbonate; lastly, filtering to remove goethit precipitation. According to the method, a heating process is eliminated, the setting velocity of iron is improved, energy consumption is effectively reduced, and moreover, the production efficiency is improved.

Owner:HUBEI DABEIJIANG ENVIRONMENTAL TECH CO LTD

Pyrometallurgical separation method for zirconia/hafnium dioxide mixture

ActiveCN103725901AEasy to separateInvestment economyRecycling and recovery technologiesProcess efficiency improvementHafnium tetrabromideZirconium(IV) bromide

The invention relates to a pyrometallurgical separation method for a zirconia / hafnium dioxide mixture. The zirconia / hafnium dioxide mixture, carbon and pure bromine react at 650 DEG C for 1 hour to obtain bromides of zirconium and hafnium, the bromides of the zirconium and the hafnium are added into a fused salt mixture to perform rectification separation, the temperature of the tower bottom of a rectifying tower is kept below 357 DEG C for 2 hours, and a non-target is obtained; the non-target is kept at 357 DEG C for 5 hours, and a target, namely high-purity zirconia tetrabromide is collected; residue in a kettle is stored; rectification separation is performed in the same equipment, the temperature is increased to 400 DEG C and kept for over 5 hours, hafnium tetrabromide is obtained, and the zirconia tetrabromide and the hafnium tetrabromide are respectively subjected to metathesis to obtain pure zirconium and pure hafnium. The separation effect is good, and the equipment investment is economical, so that industrialization is facilitated. The pyrometallurgical separation method can fill a blank in China, and greatly contributes the localization of zirconia / hafnium nuclear materials.

Owner:ЧЖУ, СИНФЭН

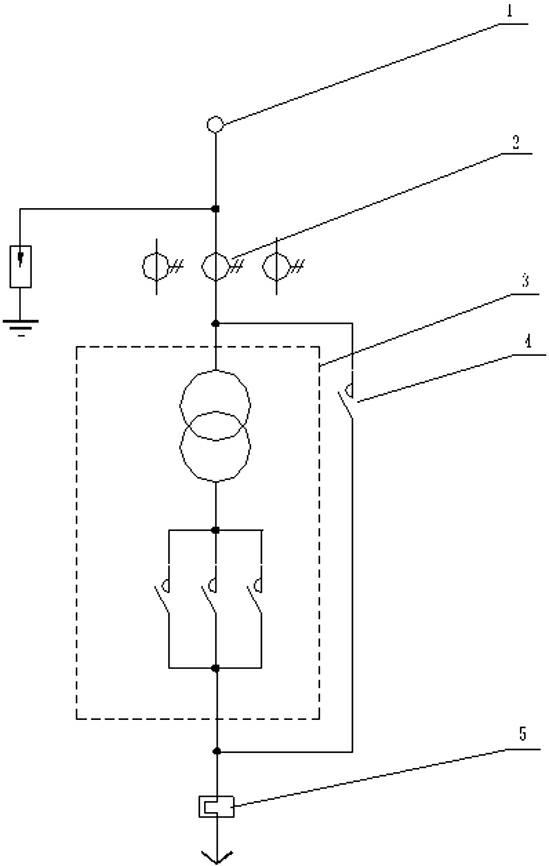

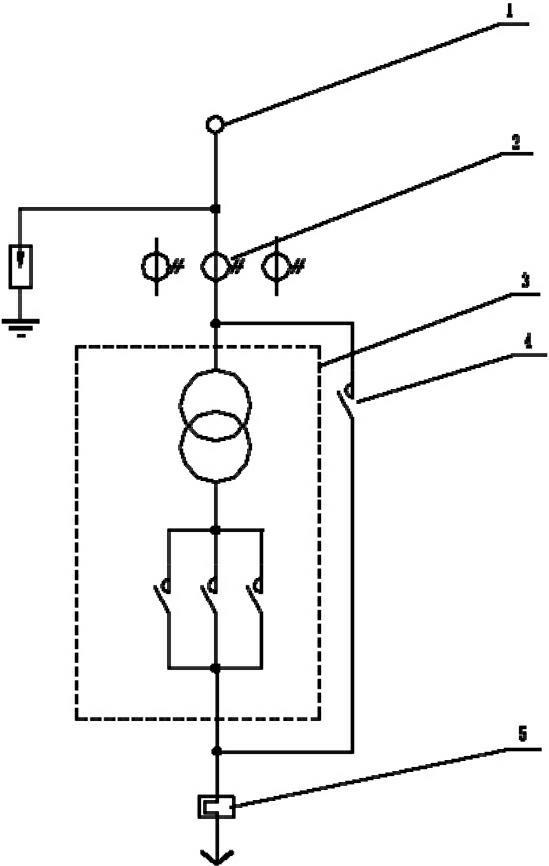

Street light power-saving device

InactiveCN102186299AEasy to installReduce human and material resources inputElectrical apparatusElectric lighting sourcesAutotransformerElectricity

A street light power-saving device relates to the technical field of street light control and is provided with an air switch connected with a power supply; the other end of the air switch is connected with the input end of an auto-transformer and the input end of a by-pass contactor respectively; and the switch output end of the auto-transformer and the output end of the by-pass contactor are connected with a thermal relay respectively. The street light power-saving device can save electricity by 20 percent to 40 percent by controlling the switching time of a street light through the combination of a time control switch or a celestial clock and a main switch, has independent by-pass, a manual or automatic switching function and protective functions for short circuit, overload and the like.

Owner:江苏恒格节能科技有限公司

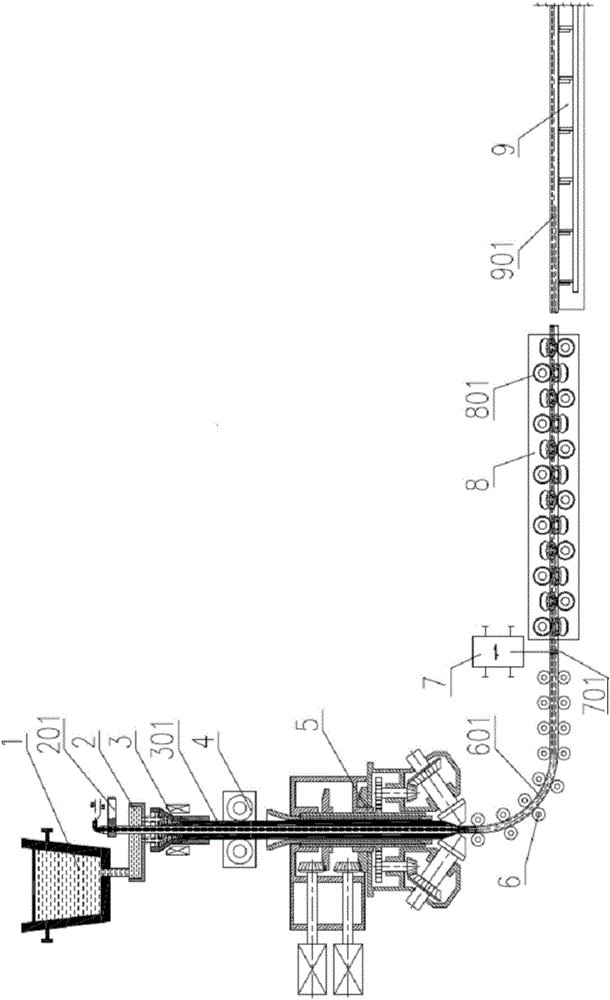

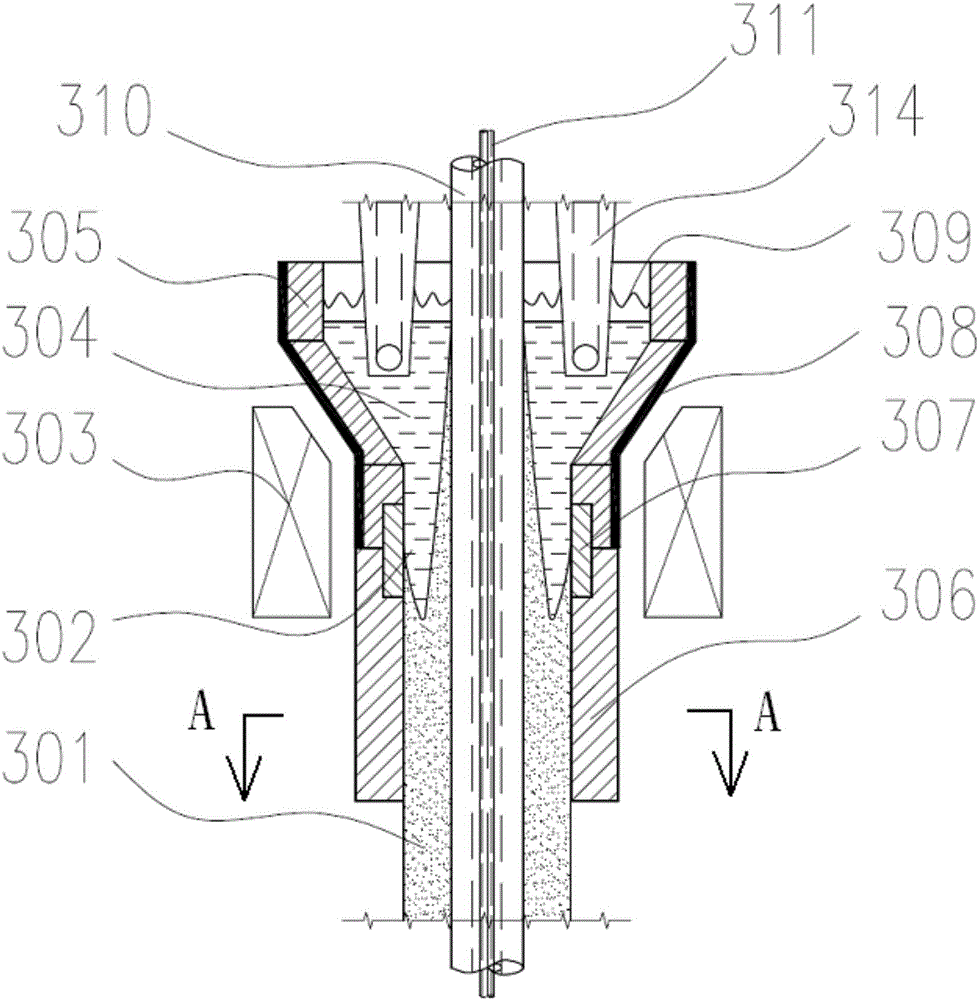

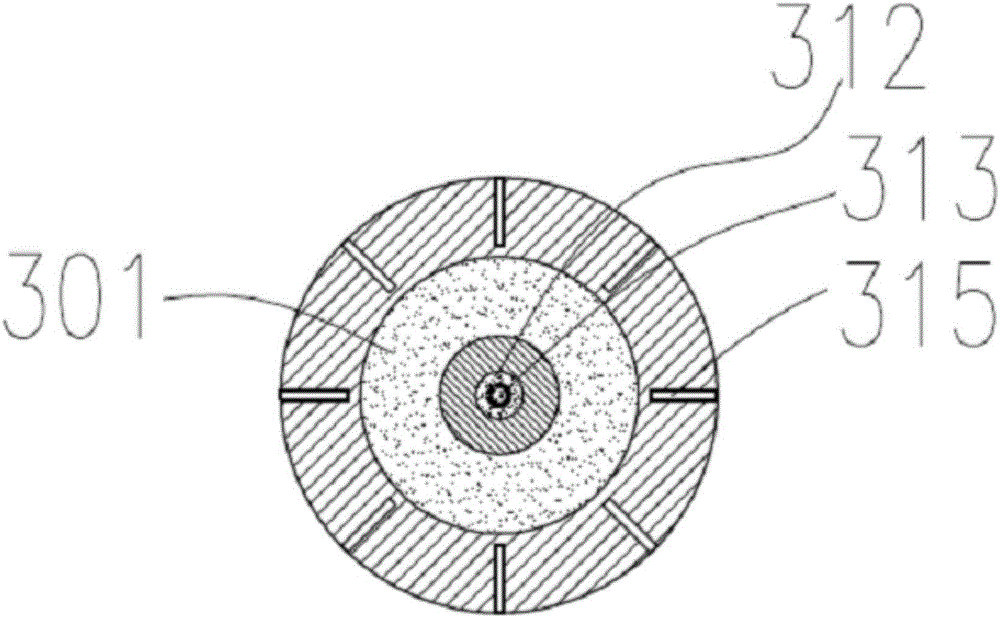

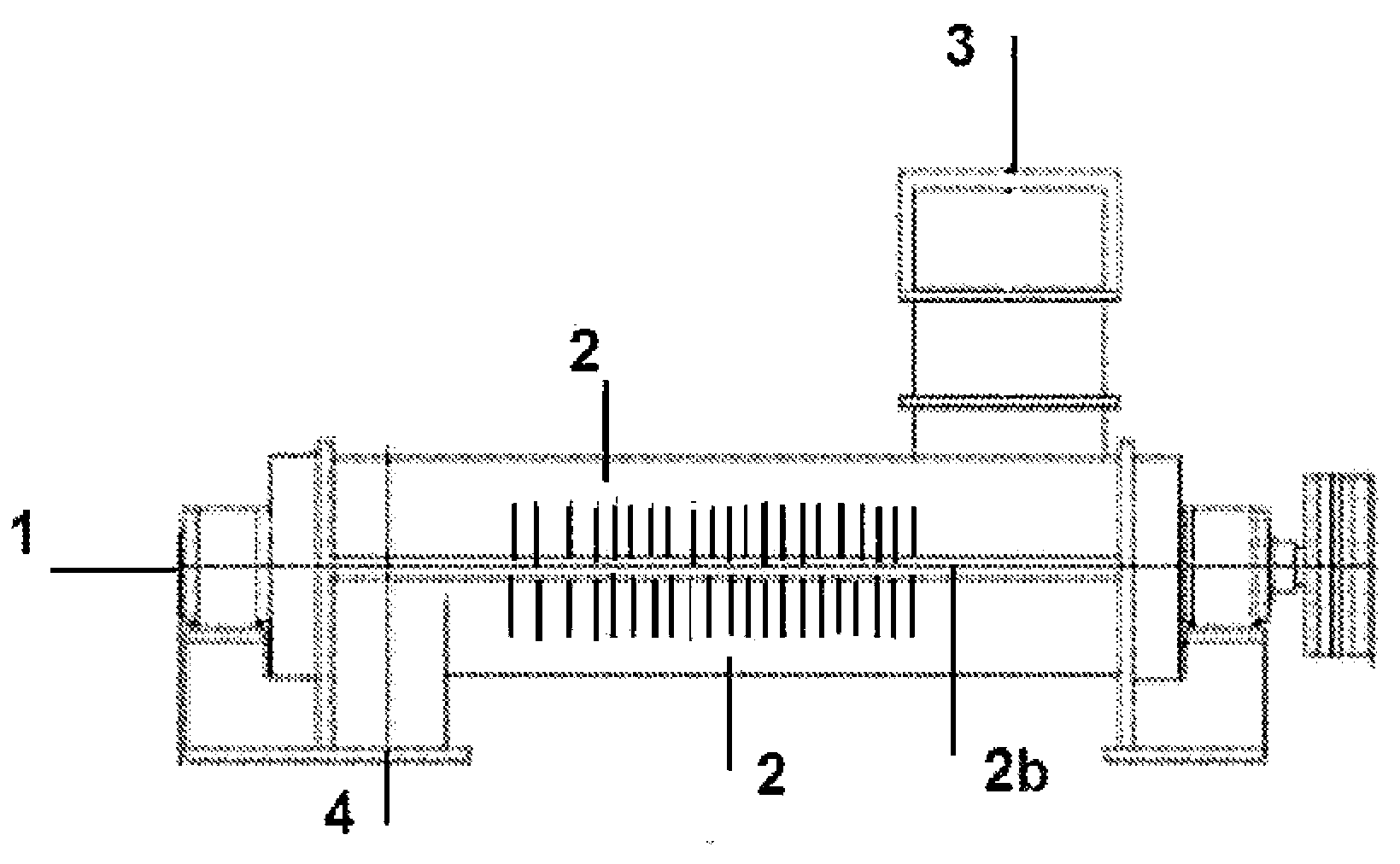

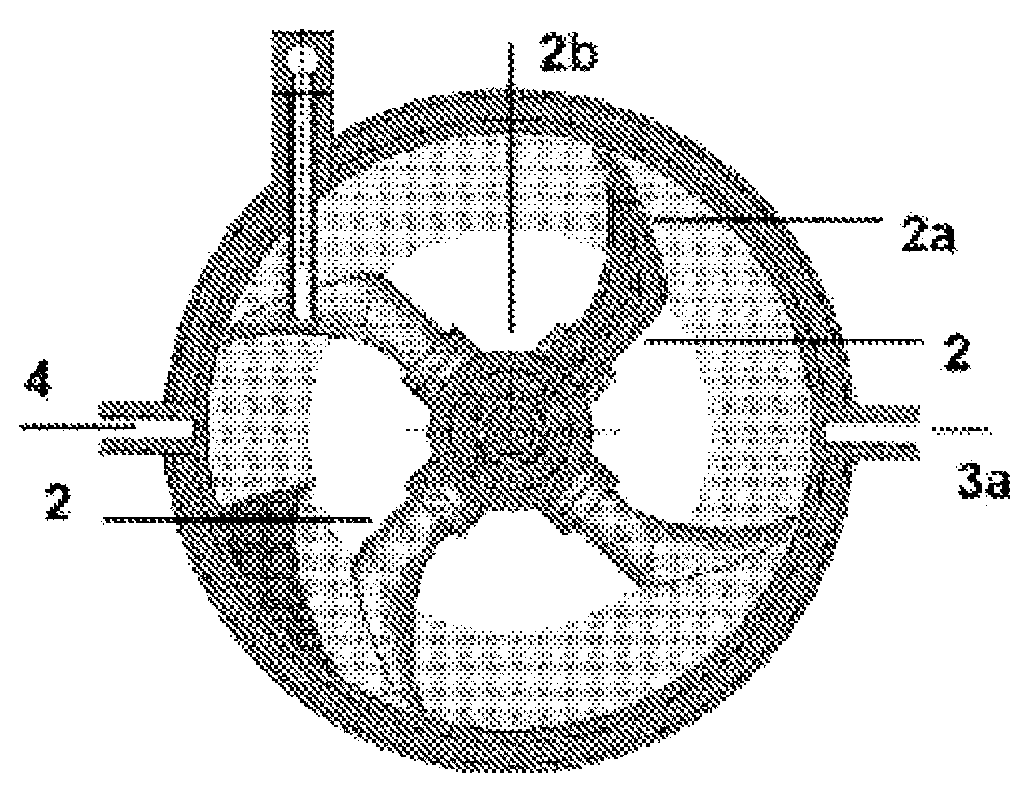

Pipe crystallizer and continuous-casting and continuous-rolling pipe production line

ActiveCN106424612AReduce manufacturing costReduce reheatMetal rolling stand detailsMetal rolling arrangementsProduction lineGraphite

The invention provides a pipe crystallizer and a continuous-casting and continuous-rolling pipe production line. The pipe crystallizer comprises an outer component (306) and an inner component (310); the outer component (306) comprises an open hot top (305) and a lower barrel which are vertically correspondingly connected; the open hot top (305) is funnel-shaped; a graphite ring (307) is arranged in the position where the open hot top (305) and the lower barrel are connected and is located on the inner surface of the outer component (306); a metal shielding cover (308) is arranged outside the open hot top (305); and an induction coil (303) is arranged outside the outer component (306). With the pipe crystallizer and the continuous-casting and continuous-rolling pipe production line, the intermediate link for pipe blank cooling and reheating with energy consumed for no reason is abandoned, continuous casting and pipe rolling are directly and closely joined, the short-process technology for continuous casting, pipe rolling and sizing is put forward, and the economical, efficient, energy-saving and environment-friendly effects are realized.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH +1

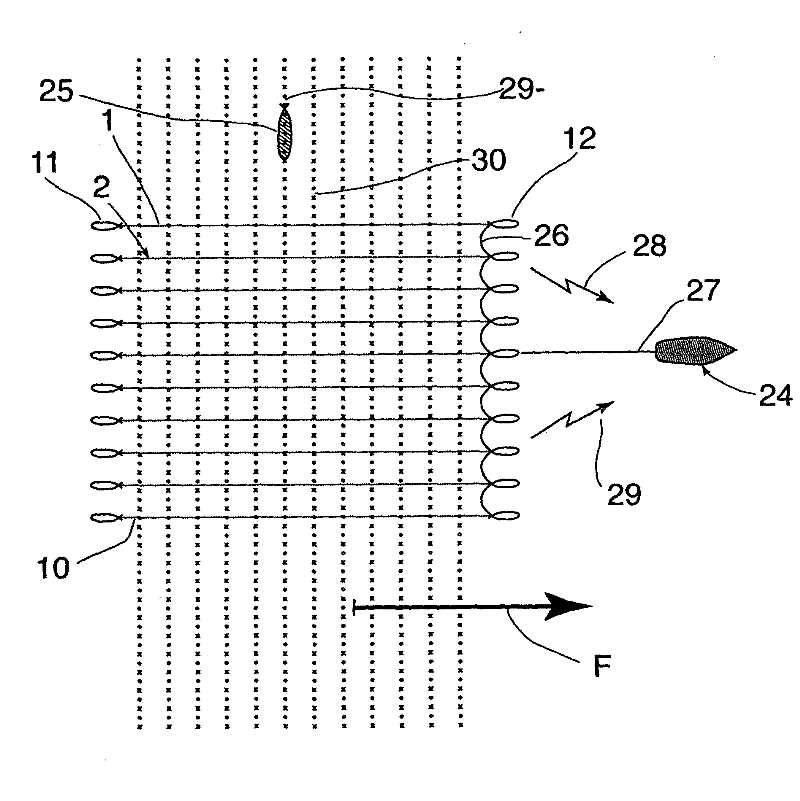

Augmentation method and apparatus for conducting underwater seismic surveys

InactiveCN102272632ADetection widthInvestment economySeismology for water-covered areasReflected wavesProspecting

Enhanced method and device for aquatic seismic prospecting are provided. In the method and the device of the type: - a submerged mobile seismic source is positioned, able to create one or more disturbances transmitted through the aquatic medium in the form of waves able to be reflected on the bottom of the water and the different deep underlying geological layers; - at least one cable, and preferably several, provided with a plurality of sensors is positioned, able to collect said reflected waves; - said seismic source is triggered with one or more repeats thus creating one or more disturbances; - said reflected waves are picked up using said sensors.

Owner:KIETTA

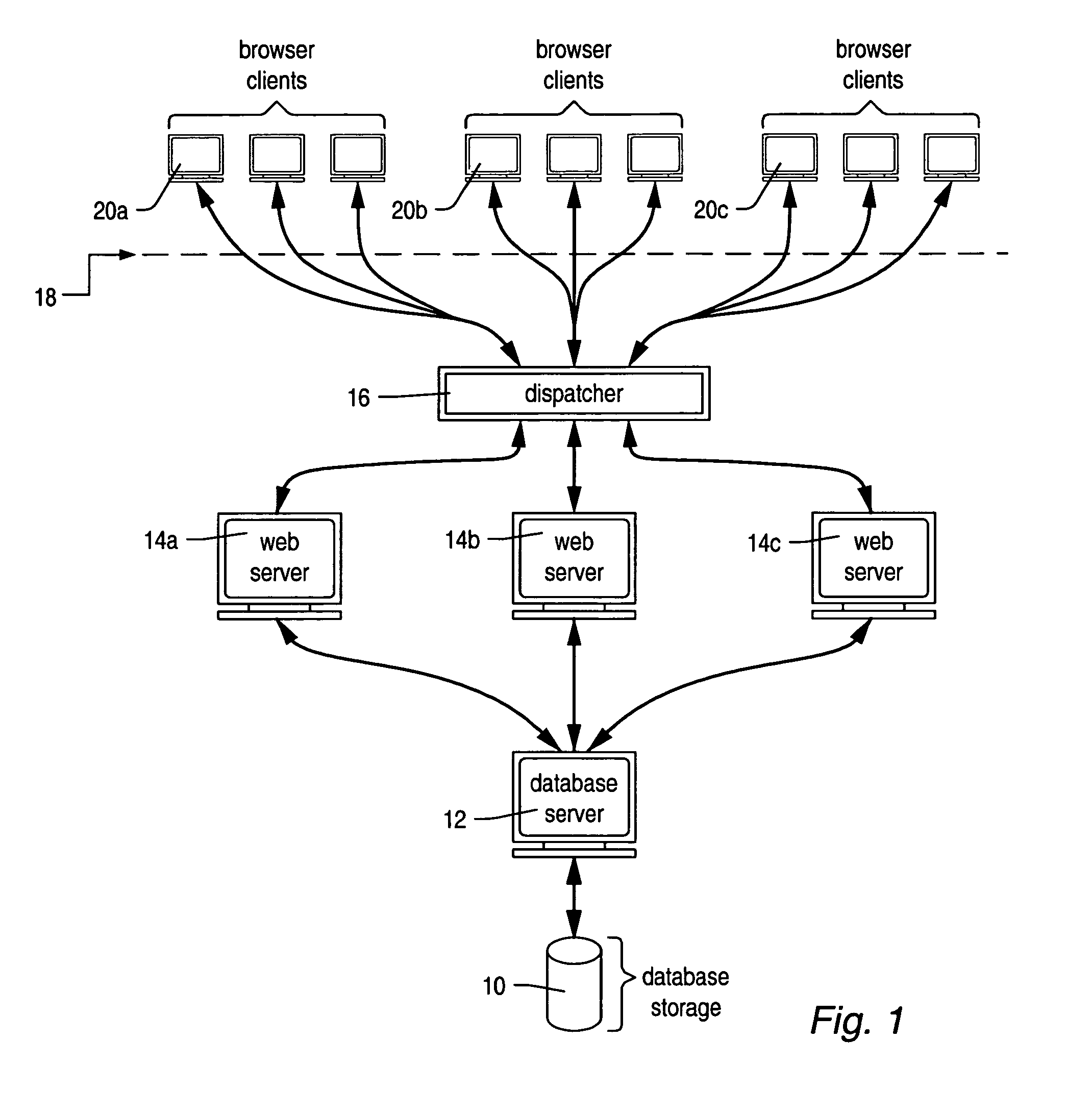

Detecting and handling affinity breaks in web applications

InactiveUS7702800B2Shorten response timeImprove responsivenessMultiple digital computer combinationsElectric digital data processingClient-sideUser identifier

A system and method are disclosed, according to which, the responsiveness of client / server-based distributed web applications operating in an object-oriented environment may be improved by detecting and handling affinity breaks between a client and server. Affinity exists when a client's requests are all routed to the same server. This is often the case, for example, during secure online transactions. A problem occurs when the preferred server becomes temporarily unavailable, and the client's requests are directed to a different server. When the original server is restored, it must detect the fact that its affinity with the client was disrupted, and any client-specific data in its cache may be invalid. In an exemplary embodiment of the system and method disclosed herein, an “affinity command” is exchanged between the client and the server during each client request. The affinity command contains a user ID associated with the client and a “generation ID”, which is unique for each request. When a request is received from a client, the server examines the generation ID in the accompanying affinity command and compares it to its internally recorded value. If they match, the server knows it has not missed any requests. In this case, the server updates the generation ID and sends the new value back to the client, along with the requested cache entry. If the generation ID received from the client fails to match the recorded value, an affinity break is detected, and the server updates its cache from the database.

Owner:IBM CORP

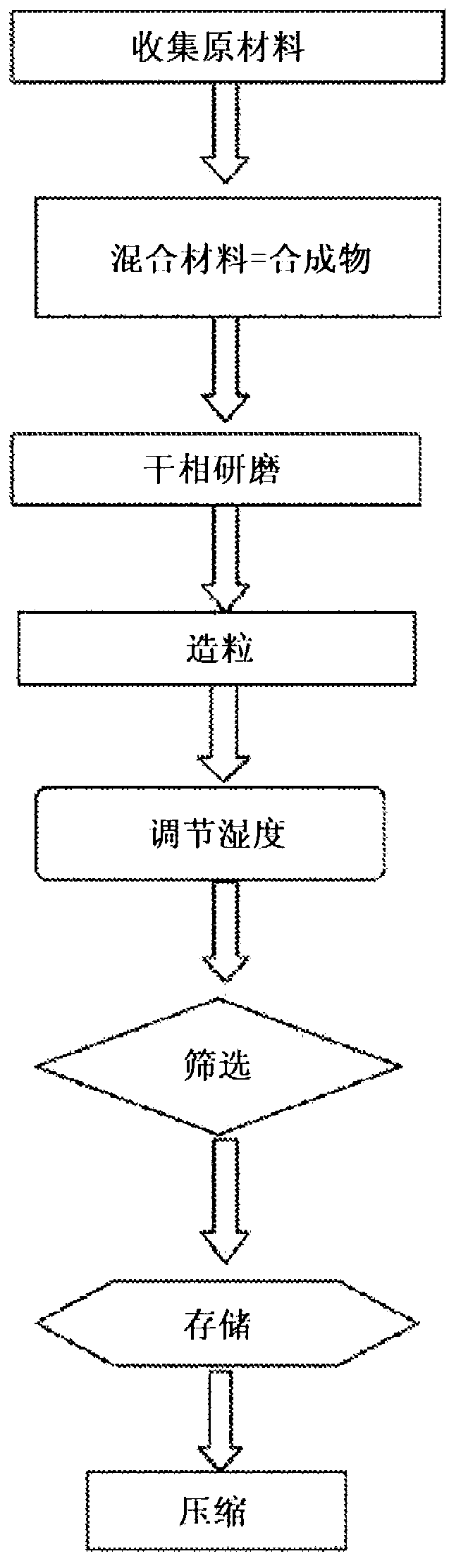

Granulation by agglomeration of ceramic compositions ground in dry phase

ActiveCN103269784AEliminate high energy consumptionGuaranteed plasticityGranulation in stationary drums/troughsGrain treatmentsWater tableWater level

The invention relates to the granulation by agglomeration of ceramic compositions ground in dry phase. The invention offers an alternative to the method of wet-phase grinding and drying by atomisation. The method consists of dry-phase grinding and preparation of argillaceous ceramic compositions with no binders, additives or deflocculants using argillaceous materials (approx. 60%) in a mixture with inorganic materials, grain sizes of less than 120 micrometres, in a horizontal rotary cylindrical appliance with deflecting paddles; the intake of said minerals, powdery materials and water taking place at one end of said appliance; and the rotation of said appliance causing the formation of granules that are moved by said deflecting paddles. The output of the granulated material is located at the opposite end of said appliance. The invention offers the following advantages: energy savings of 80%; savings in water consumption during granulation of 75% to 80% plus an extra 10% to 20% of savings in the pressure for pressing the granules. The time required to change from one ceramic composition to another is one hour, compared with several days using the current atomisation method. The granulation method constitutes novel environmental technology with zero pollution of the atmosphere and the water table, and with much lower water consumption.

Owner:安东尼奥·阿尔诺·维拉诺瓦

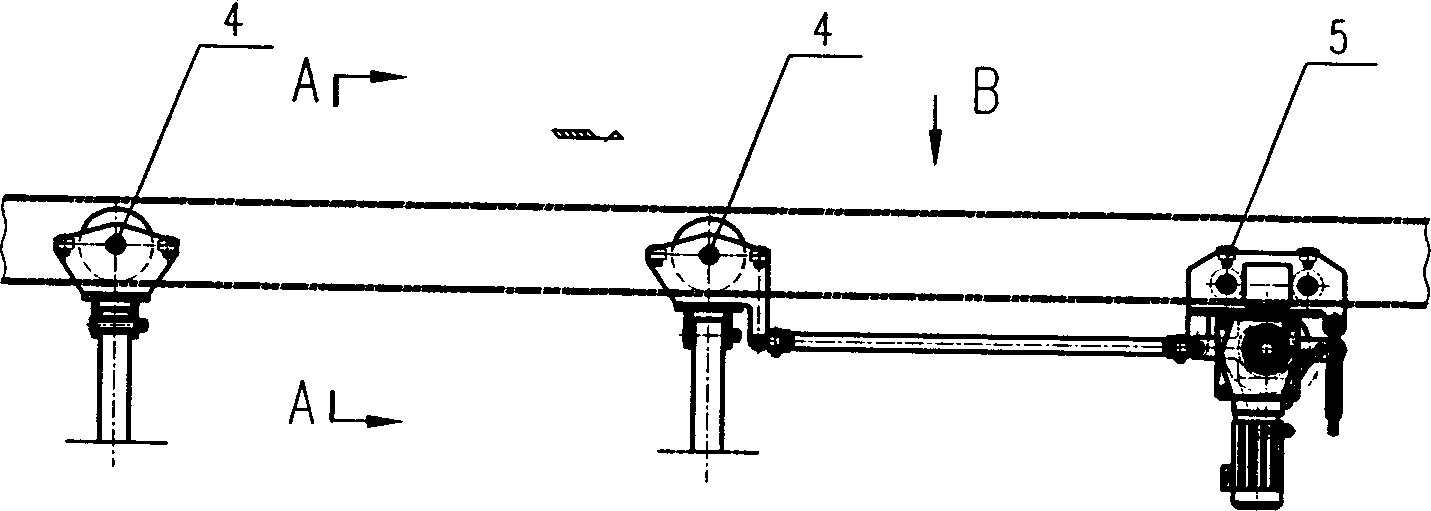

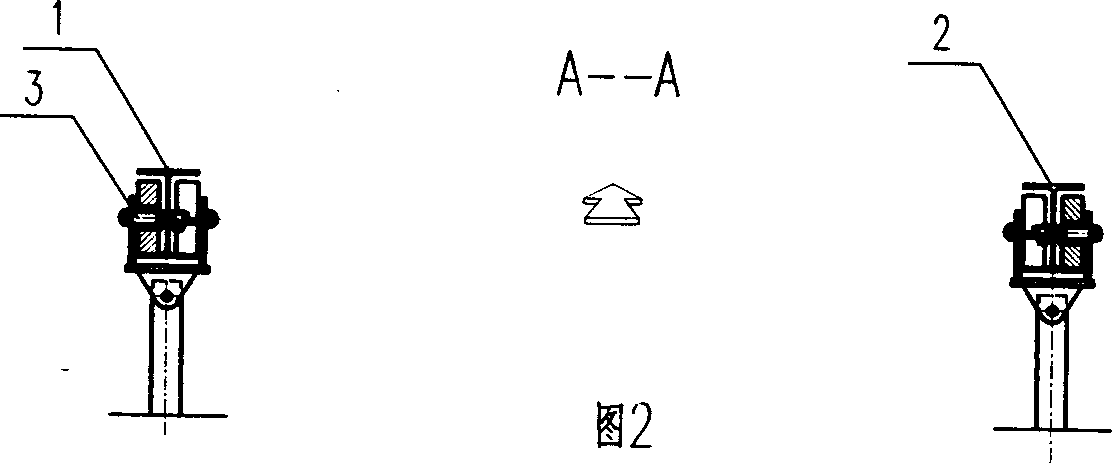

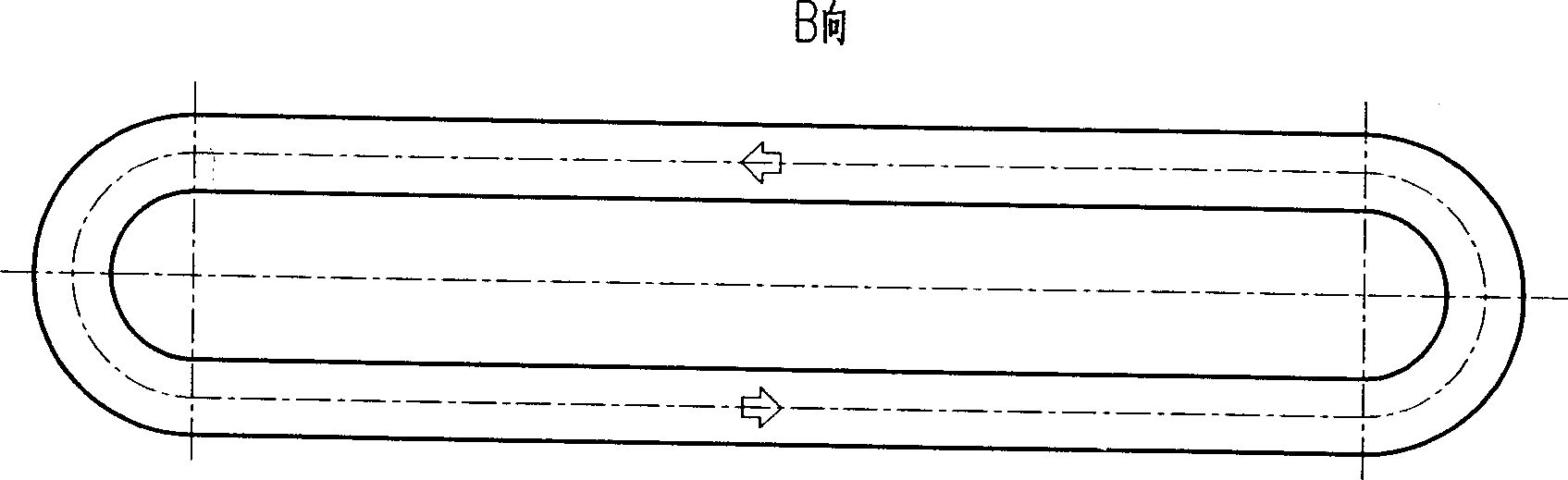

Two rail five car side drag circular suspension delivery machine

InactiveCN1410343AIncrease flexibilityImprove carrying capacityConveyor partsMechanical conveyorsLow noiseStructural engineering

A dual-track laterally-driven circulating overhead converyer for conveying big objects is composed of two H-shaped steel section loops, two bearing carriages on the internal H-shaped steel section track, one traction trolley and two bearing carriages on the external H-shaped steel section track, and a power supply system. For the said traction trolley, a spring regulatable friction roller driver is used. Its advantages are making turn easily, simple structure, low noise, low cost, and high reliability.

Owner:MIRACLE AUTOMATION ENG CO LTD

Integrated solar energy conversion system, method, and apparatus

ActiveUS8188366B2Low costImprove efficiencySolar heating energySolar heat collector controllersWorking temperatureEngineering

A solar energy conversion package includes a photovoltaic (PV) cell, a thermionic or thermoelectric conversion unit and a thermal heating system. Solar radiation is concentrated by a lens or reflector and directed to the PV cell for electrical power conversion. A water circulation system maintains the PV cell at working temperatures. The thermionic or thermoelectric conversion cell is coupled between these cells in the thermal path to generate additional power. Additional efficiencies may be gained by partitioning the solar radiation with prisms or wavelength specific filters or reflective coatings into discrete spectrum segments optimized for each conversion unit for maximizing efficiency of electrical energy conversion and equipment design. Integrating all three of these conversion techniques produces a synergistic system that exceeds the performance conventional solar conversion systems.

Owner:LOCKHEED MARTIN CORP

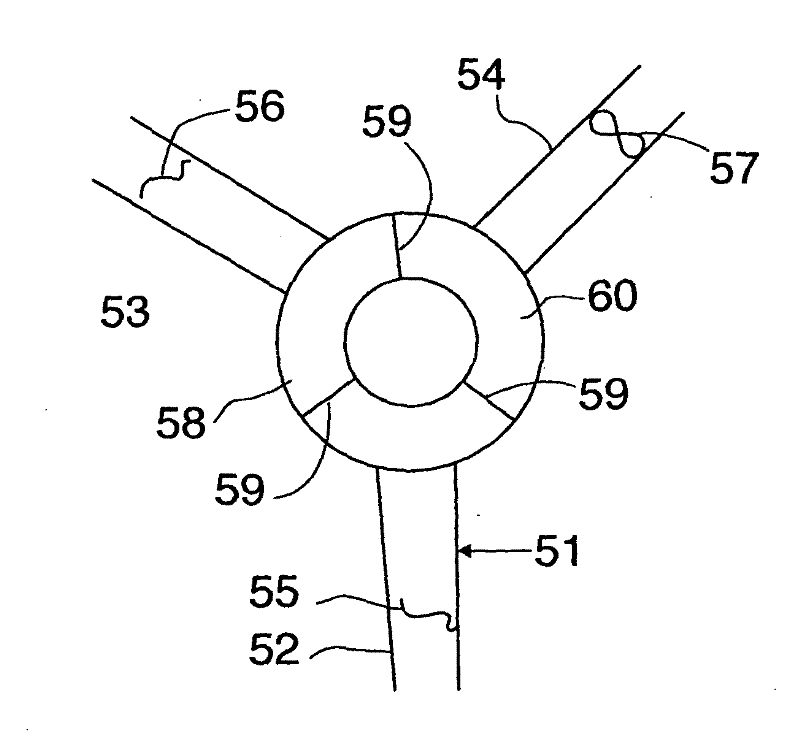

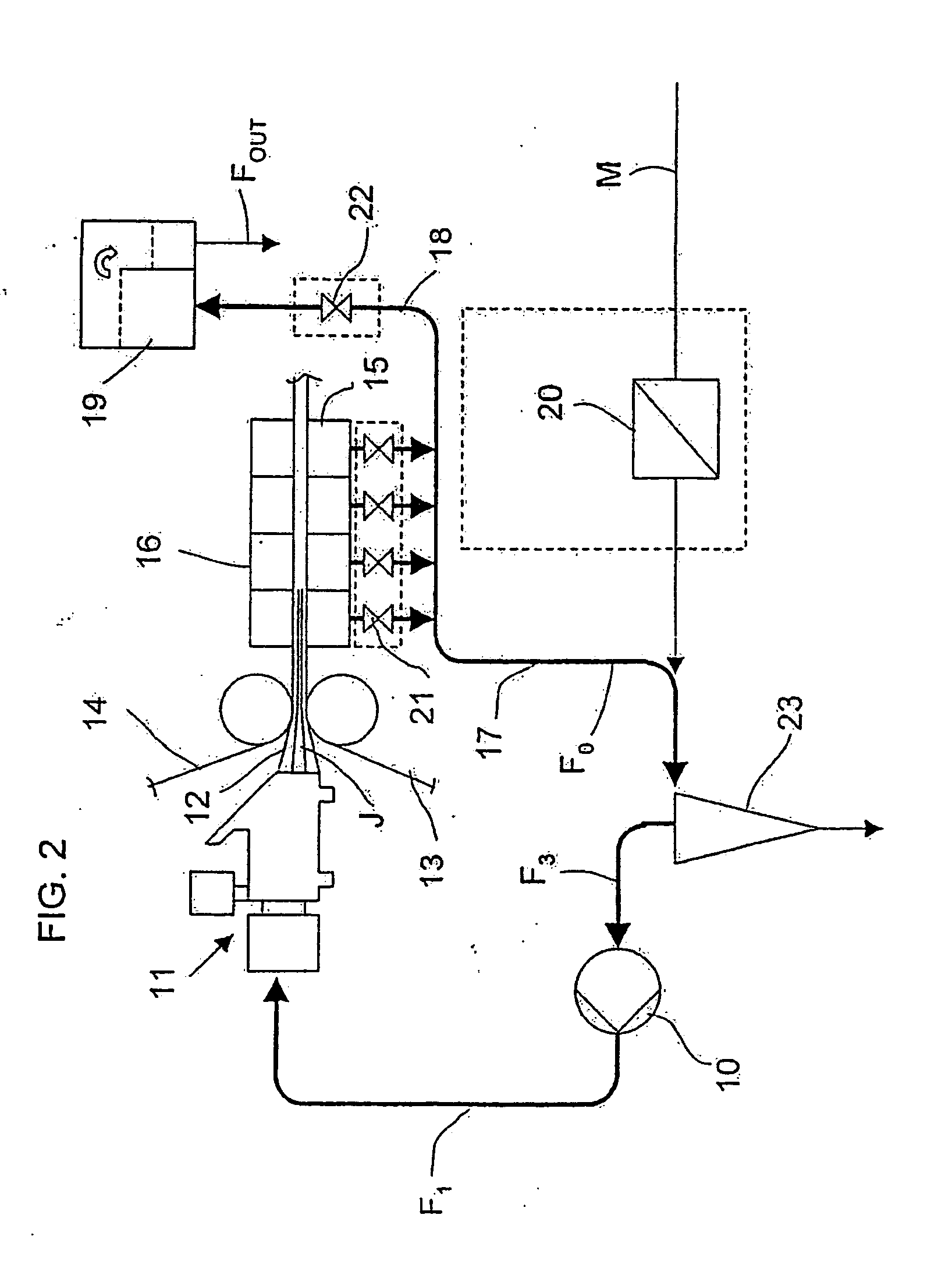

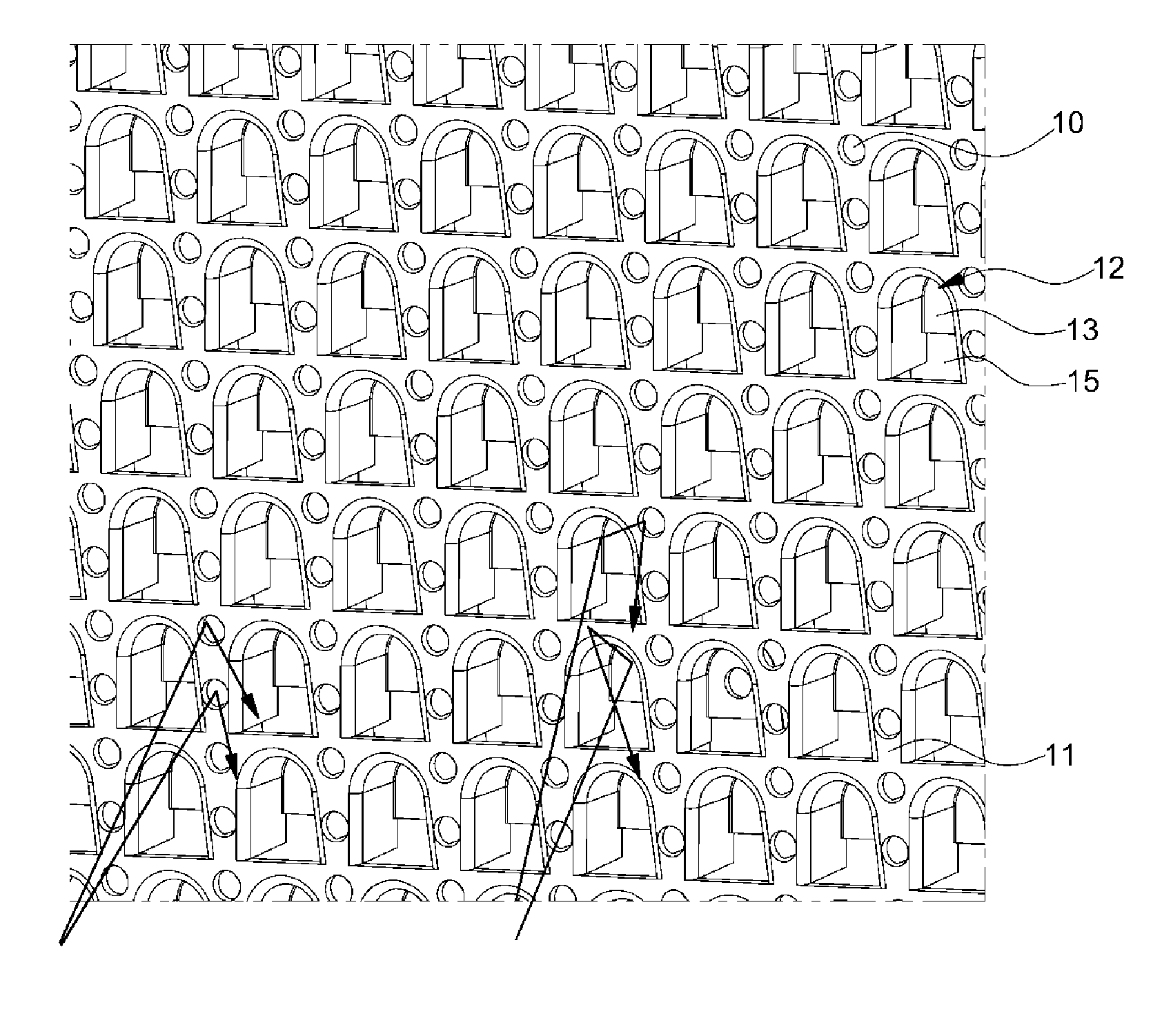

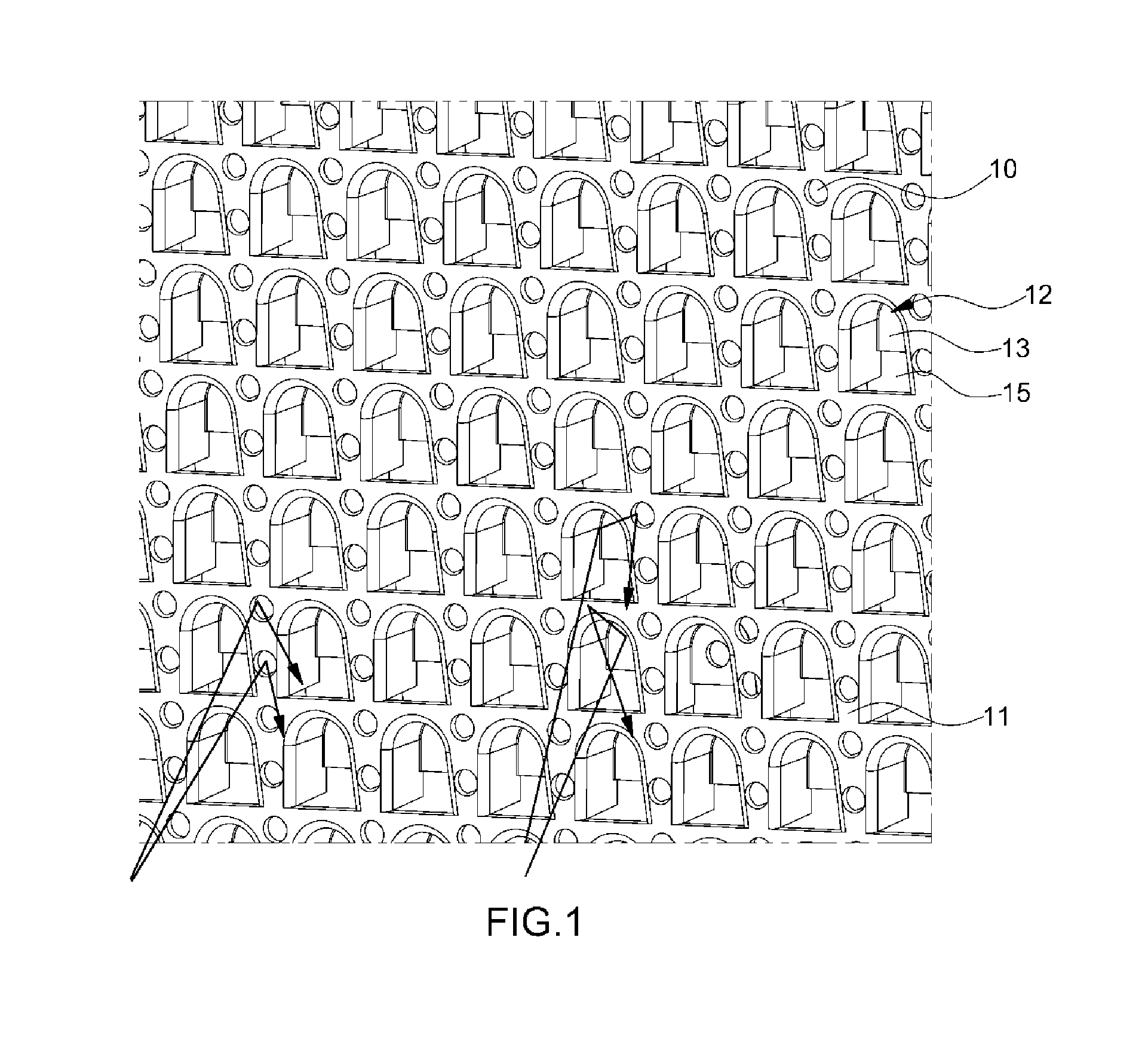

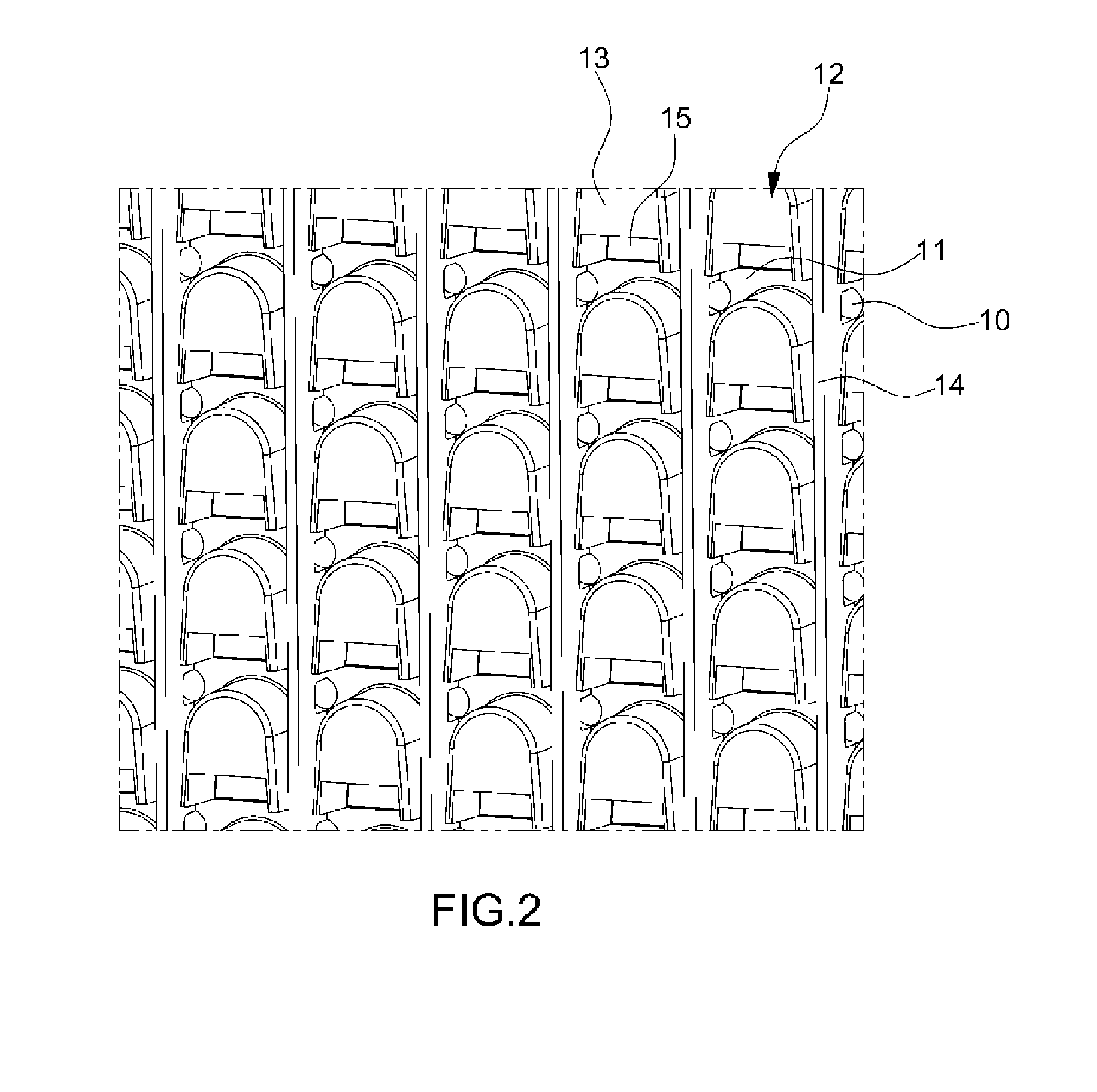

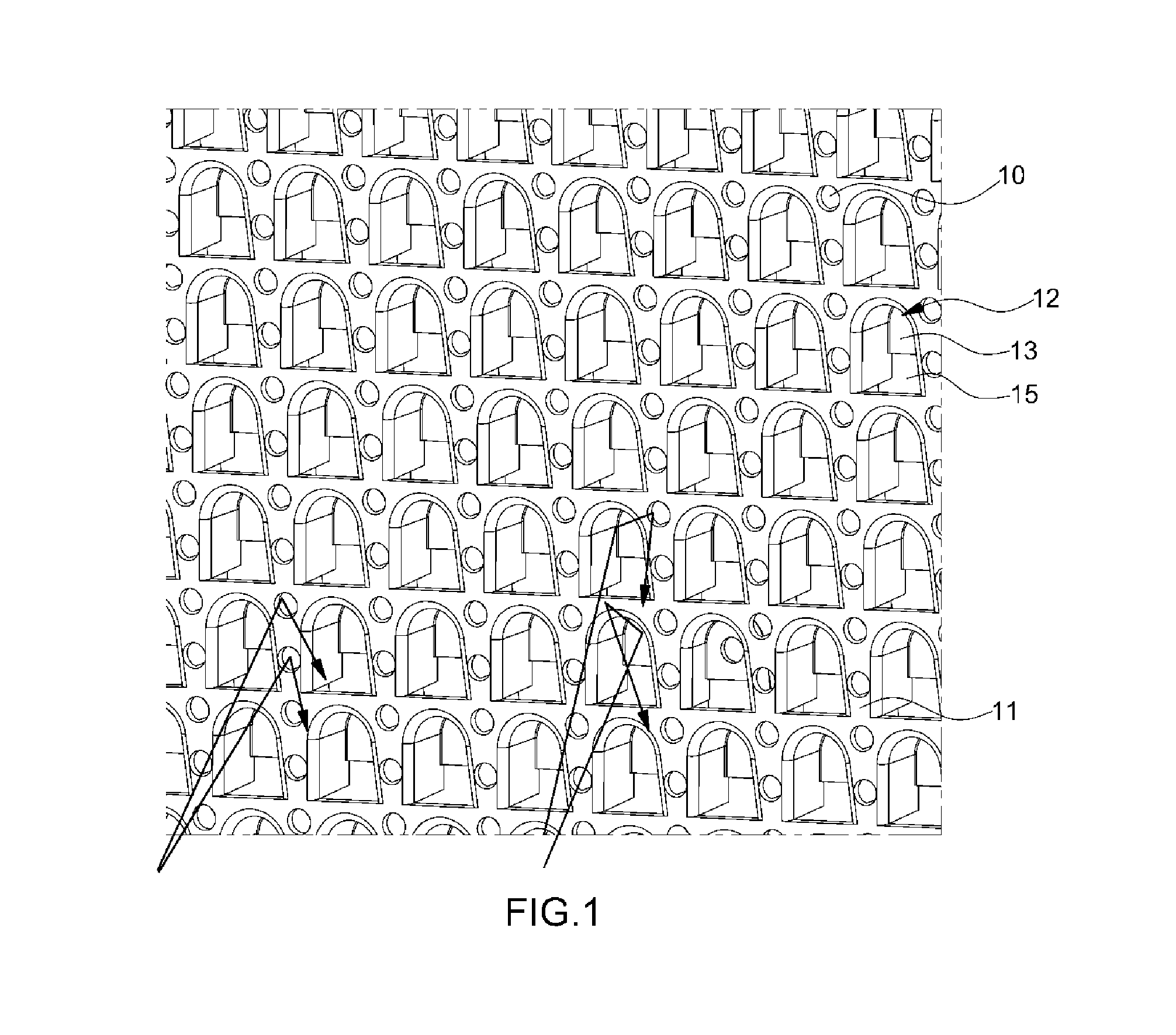

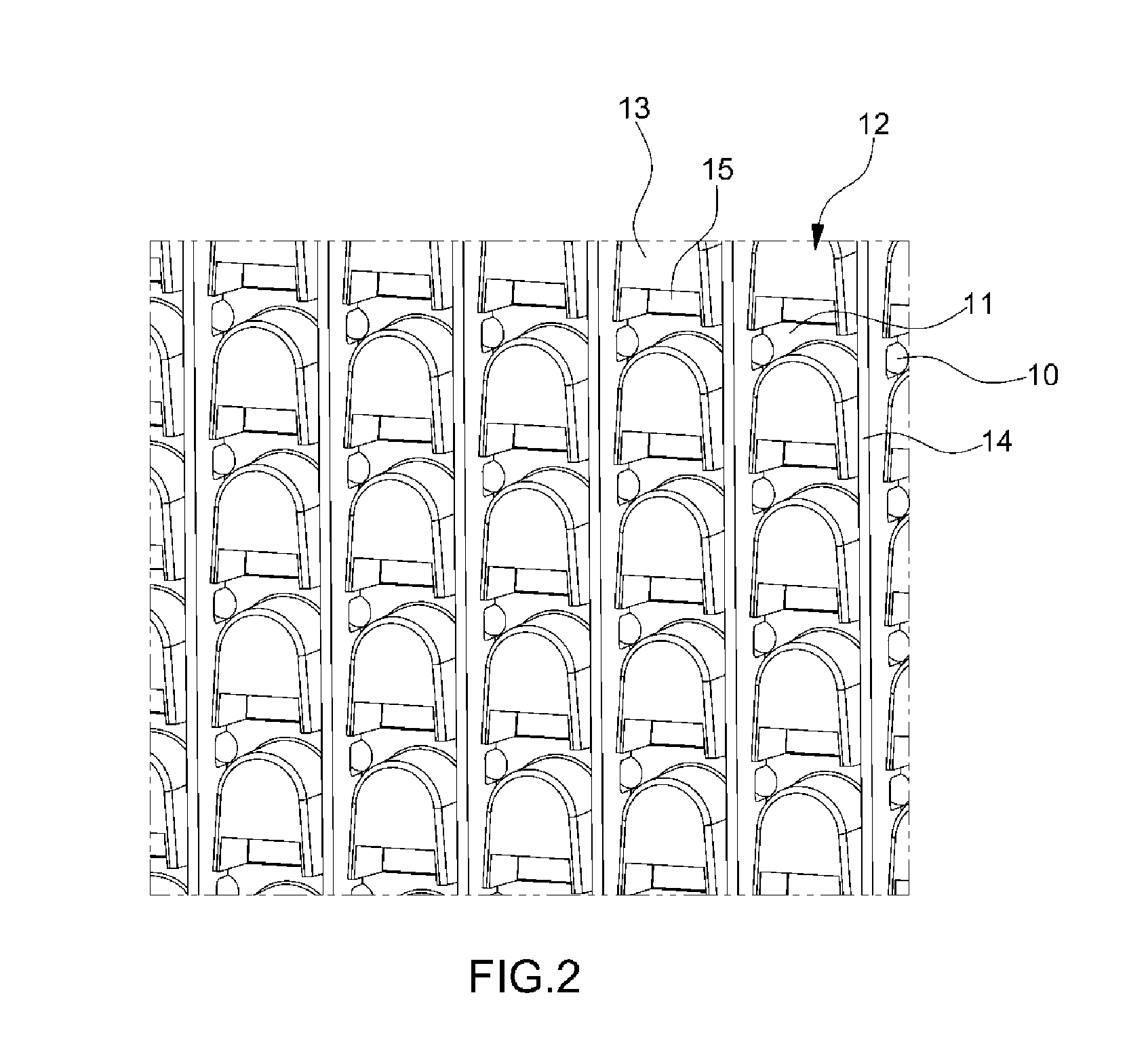

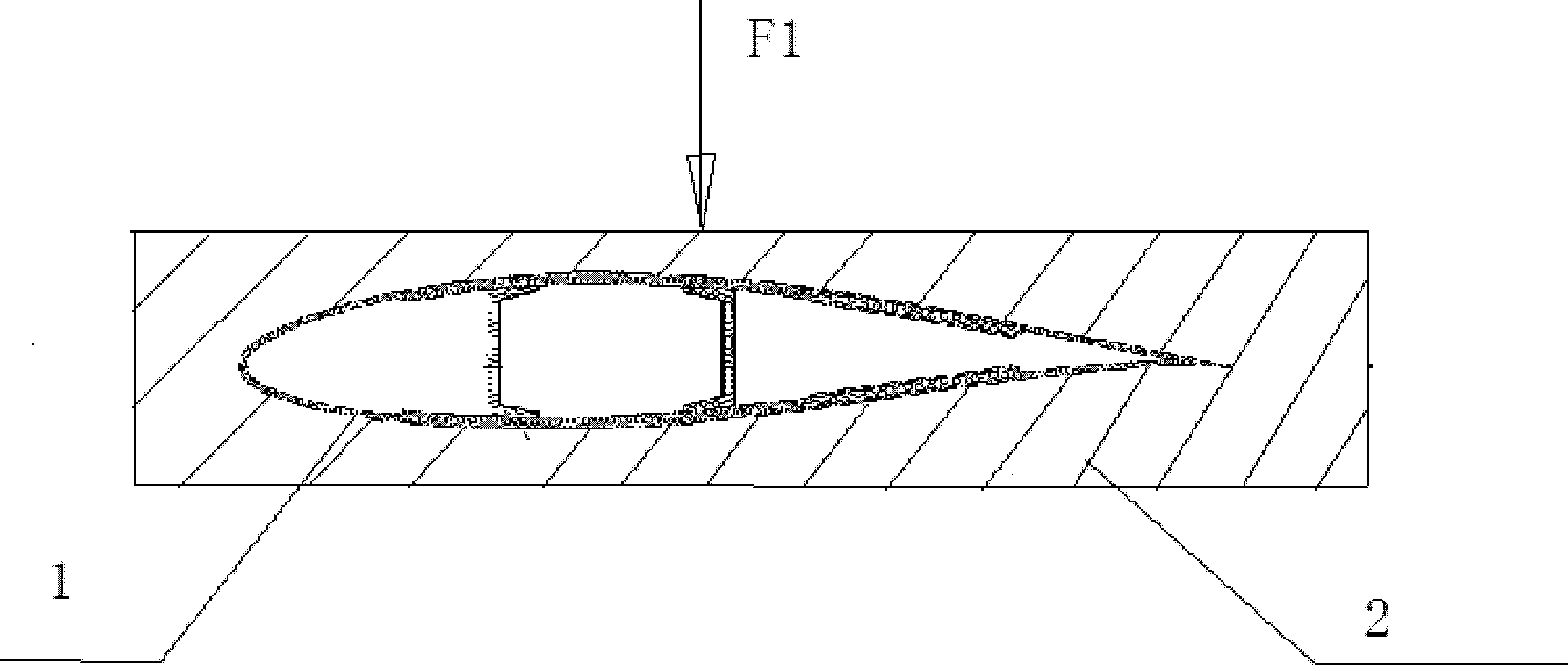

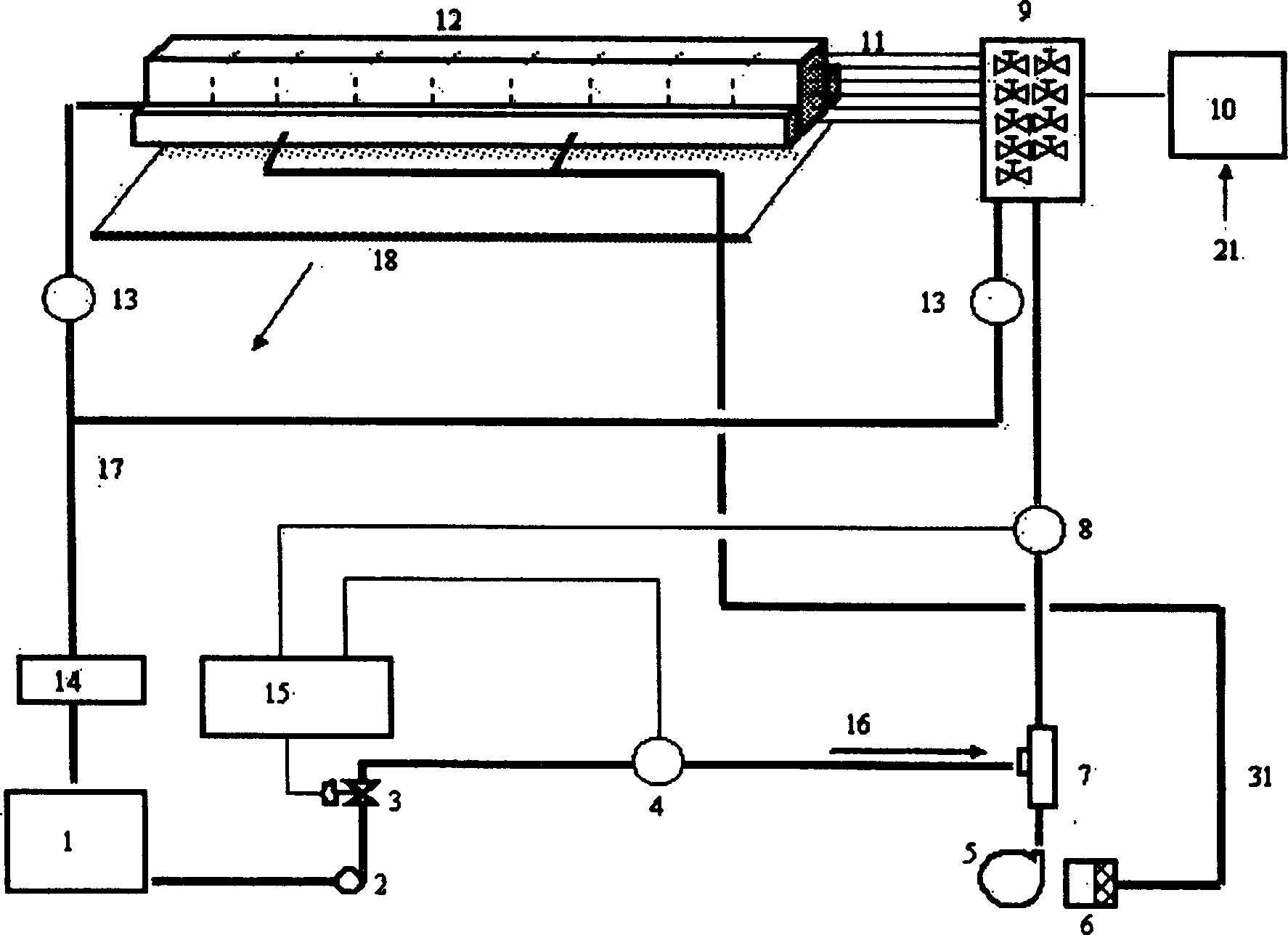

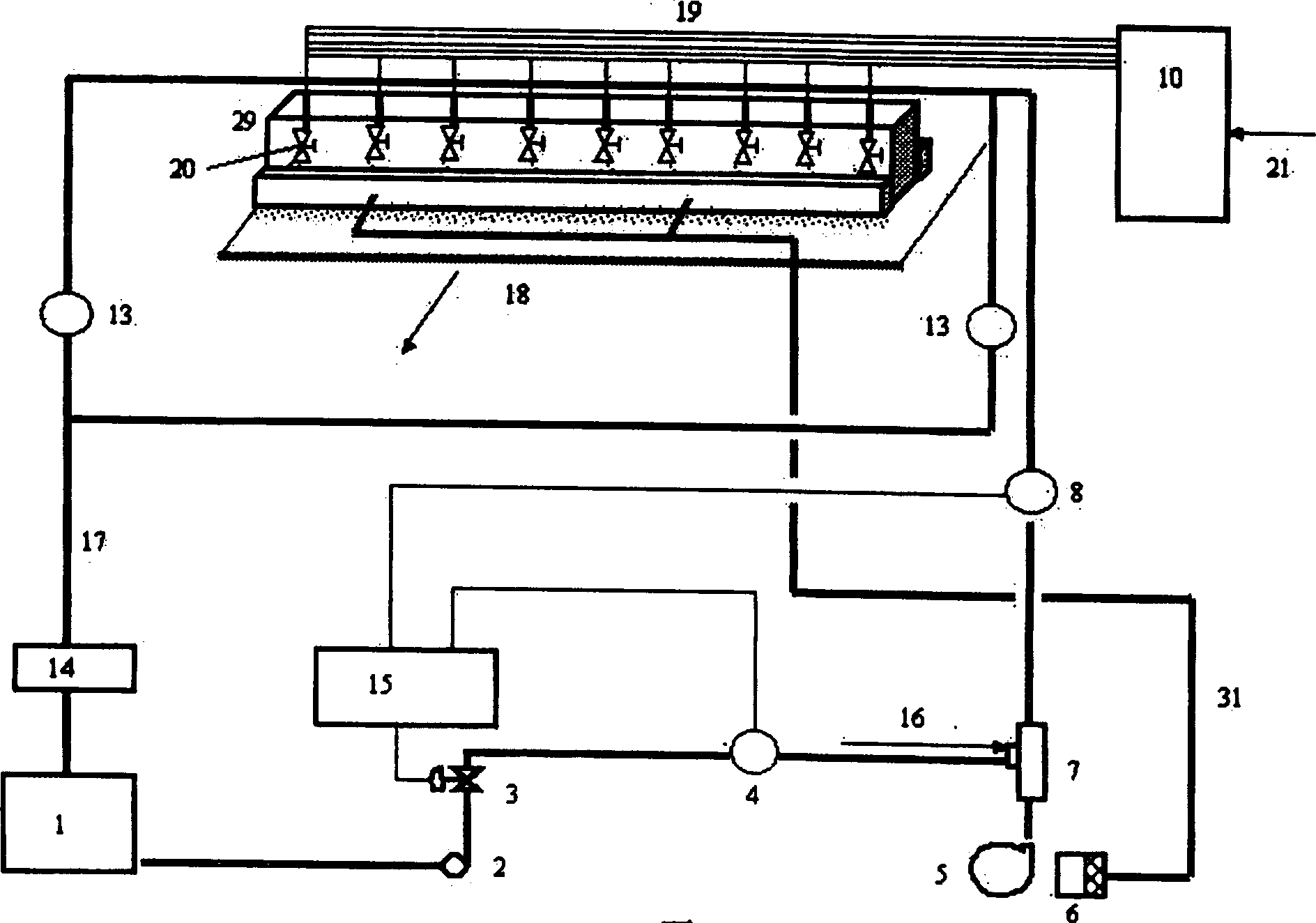

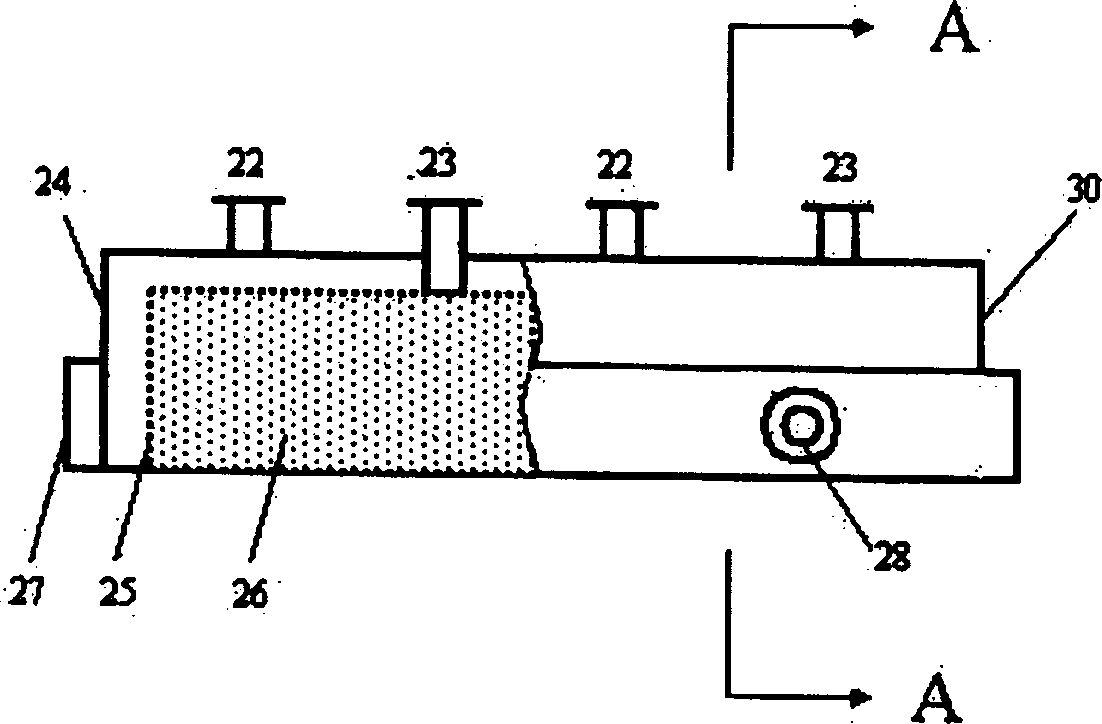

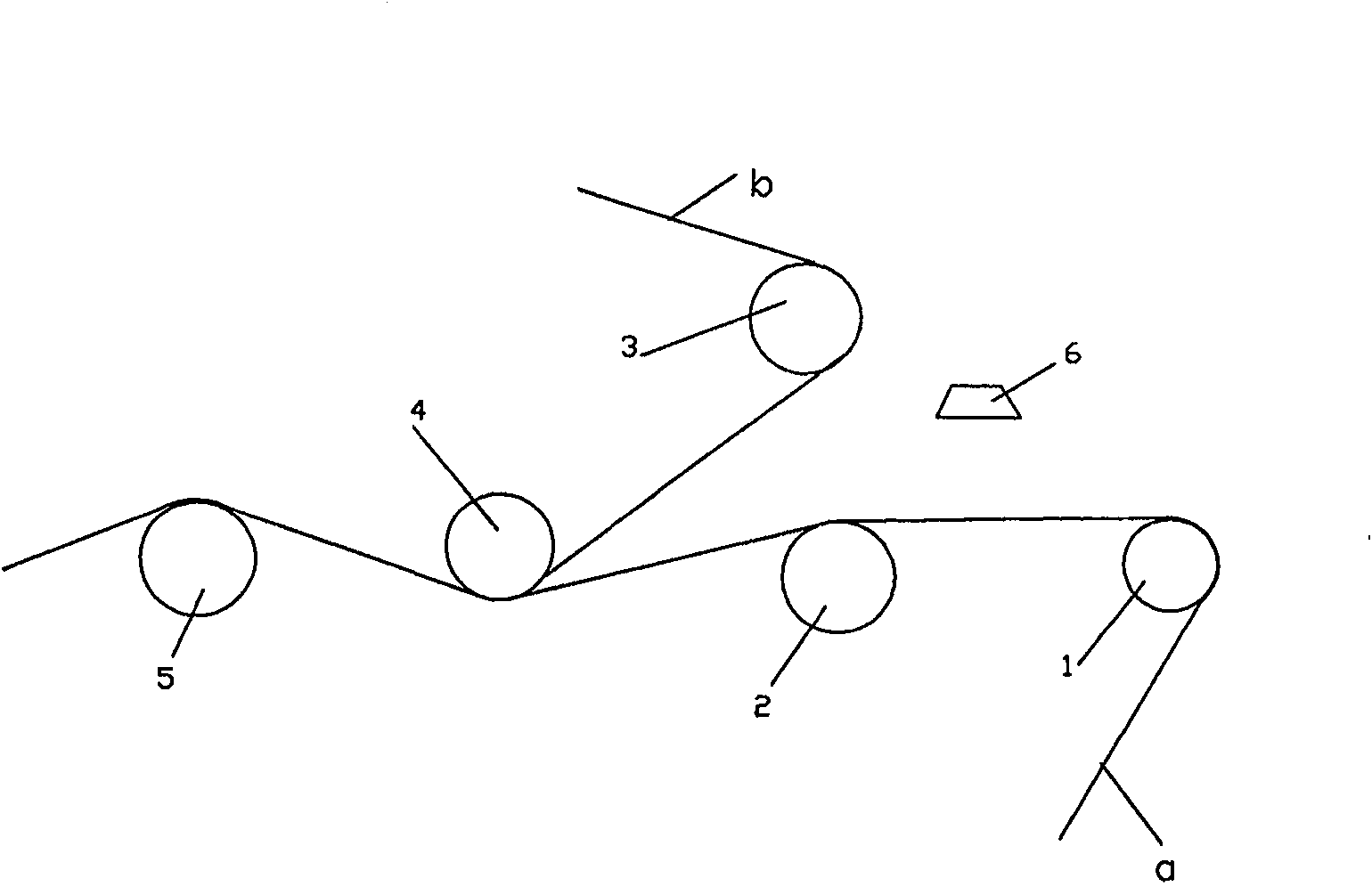

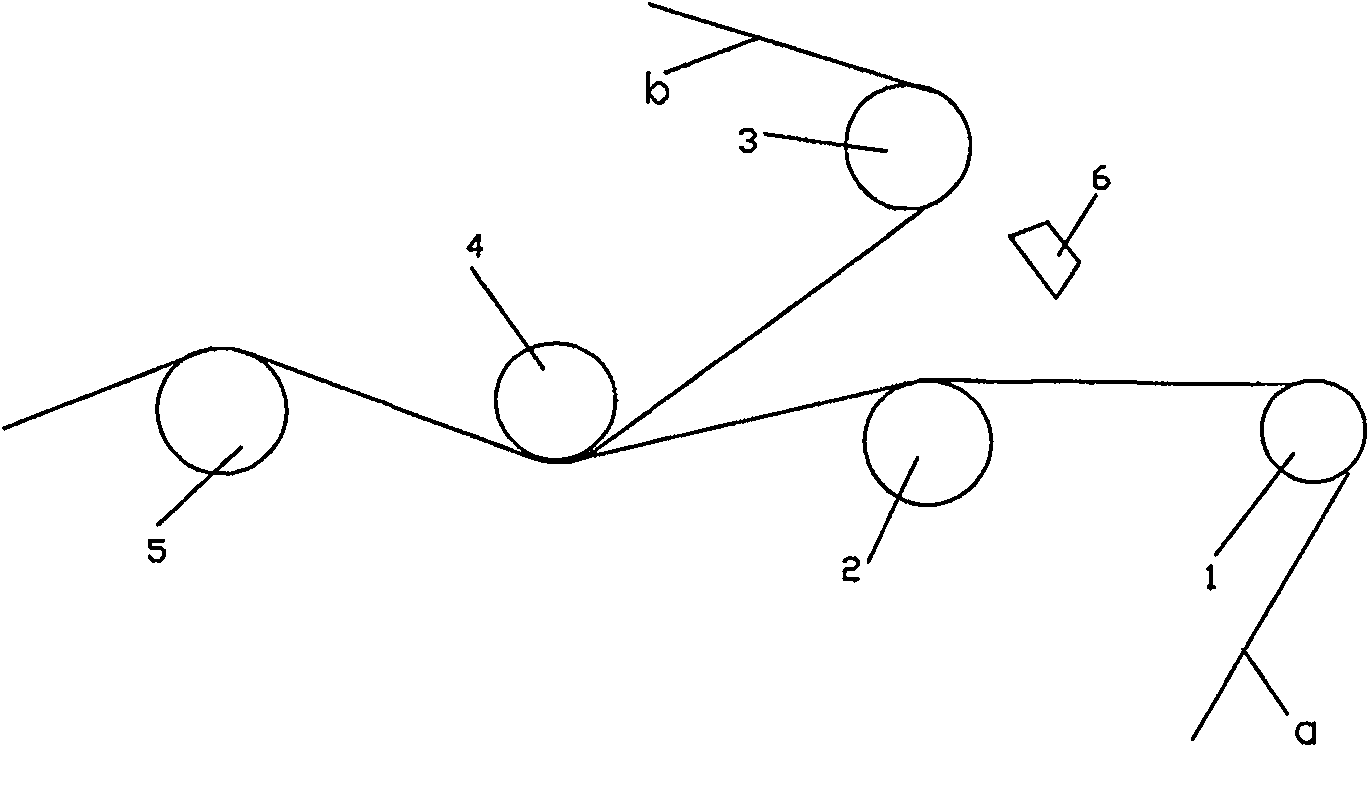

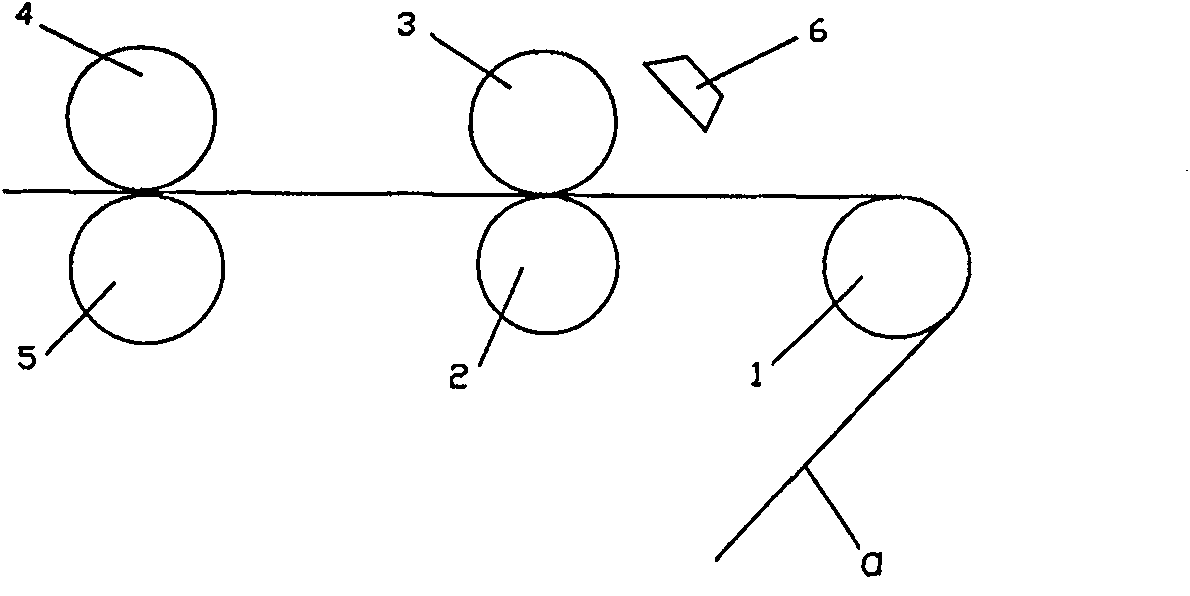

Process arrangement in the short circulation of a paper machine

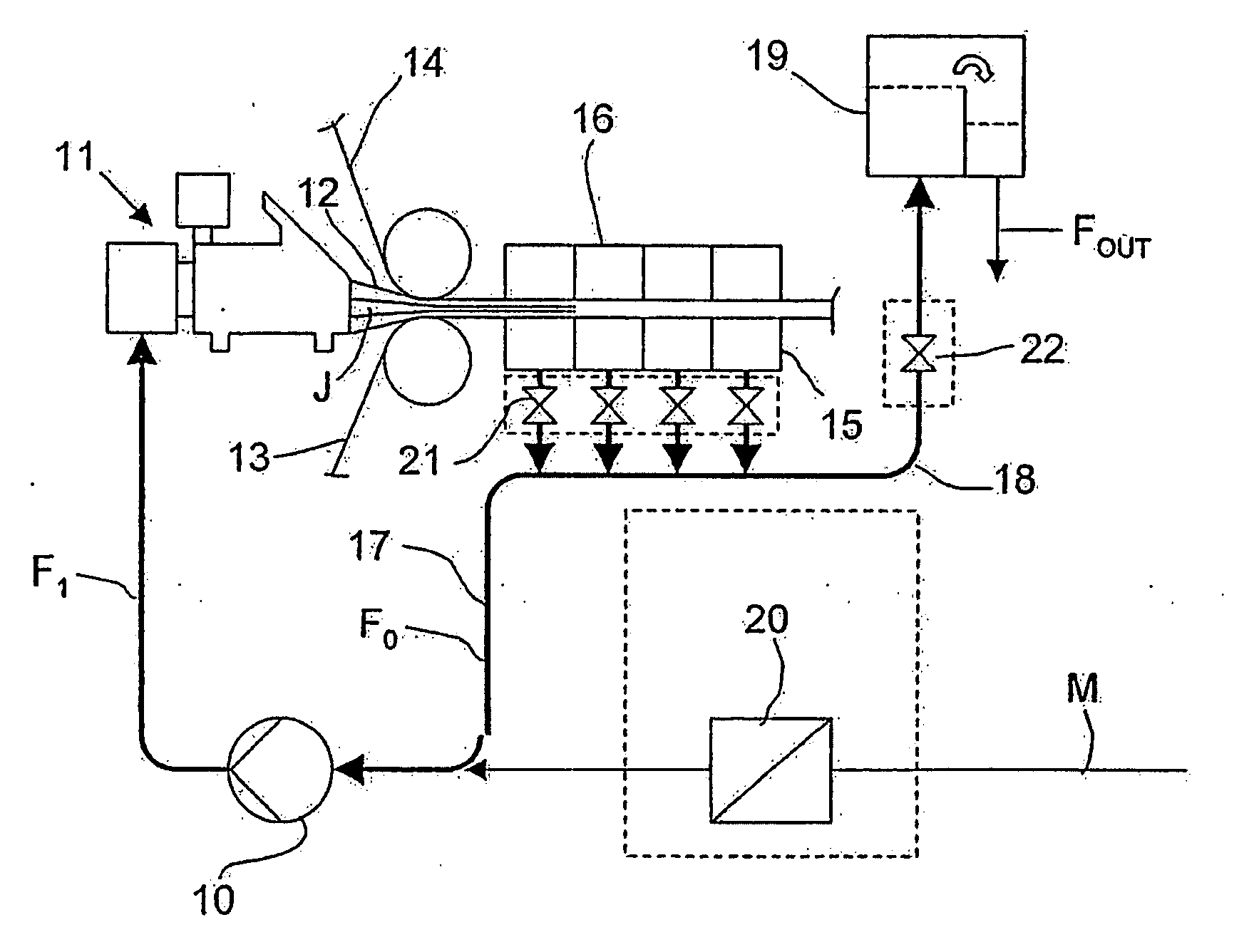

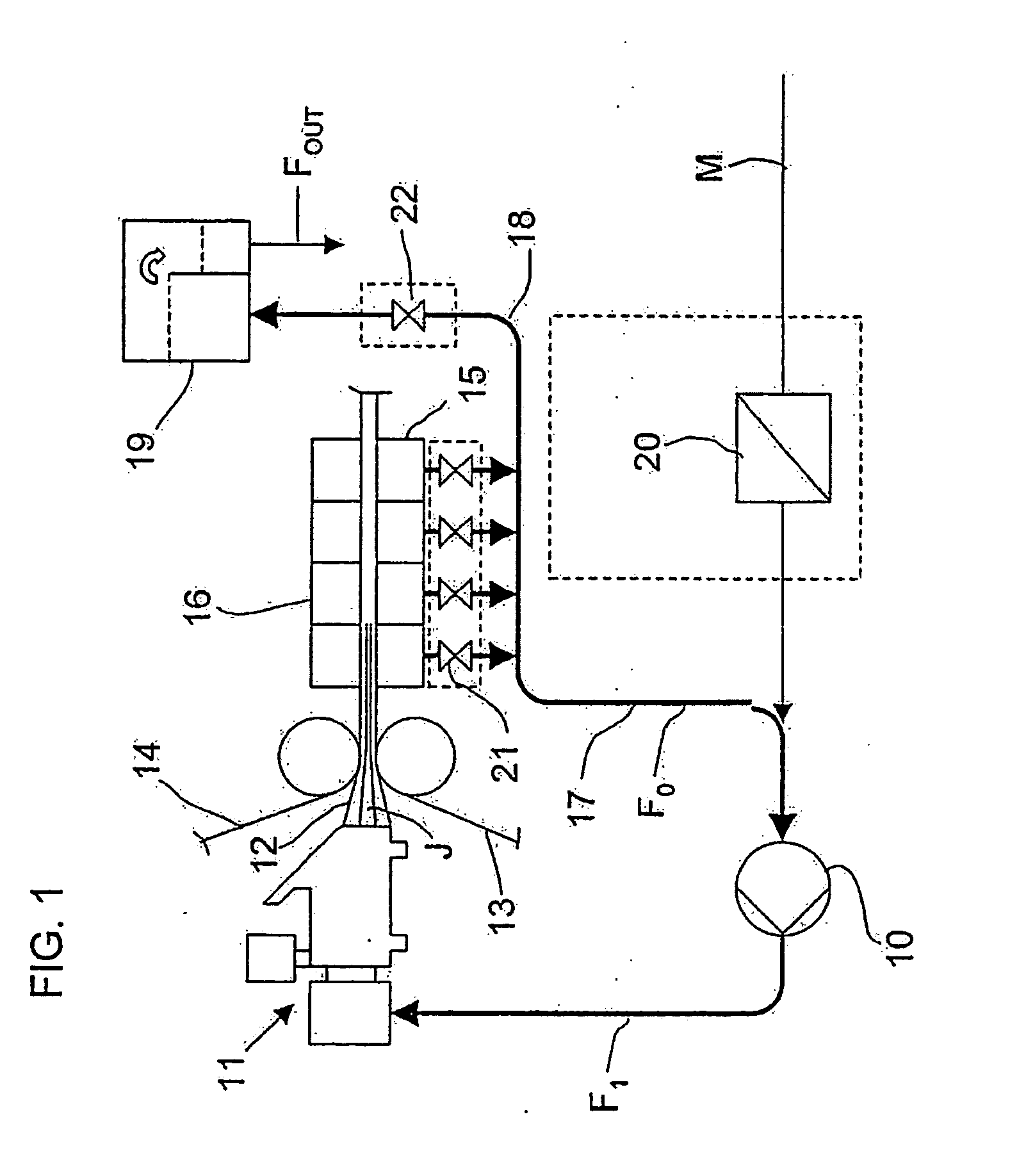

InactiveUS20050173087A1Increase back pressureLower energy requirementsMachine wet endFeeding pumpsElectric wire

A process arrangement in the short circulation of a paper machine comprises a feed pump (10), a headbox (11), means (12) for passing a pulp suspension jet (J) in a closed space from the headbox (11) into a forming gap defined by two wires (13, 14), dewatering elements (15, 16) placed against the wires (13, 14) a dilution duct (17) for passing wire water from the dewatering elements (15, 16) to stock dilution, and an outlet duct (18) for passing excess wire water out of the short circulation. The dilution duct (17) and the outlet duct (18) are in flow communication, and the outlet duct (18) has means (19, 22) for keeping the pressure in the dilution duct (17) even. For controlling the pressure in the short circulation of a closed former, excess wire water is passed out through a tank (19) provided with an overflow or other control.

Owner:VALMET TECH INC

Water splash preventing apparatus for vehicle

Owner:HYUNDAI MOTOR CO LTD

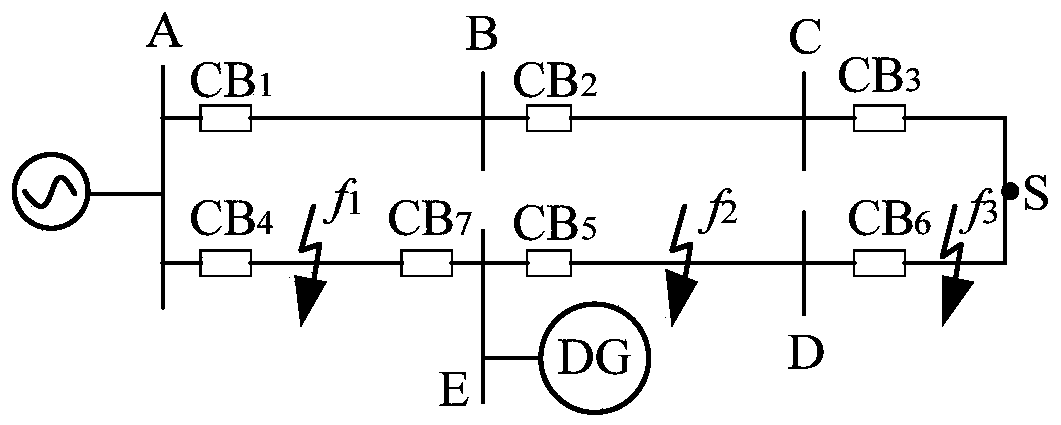

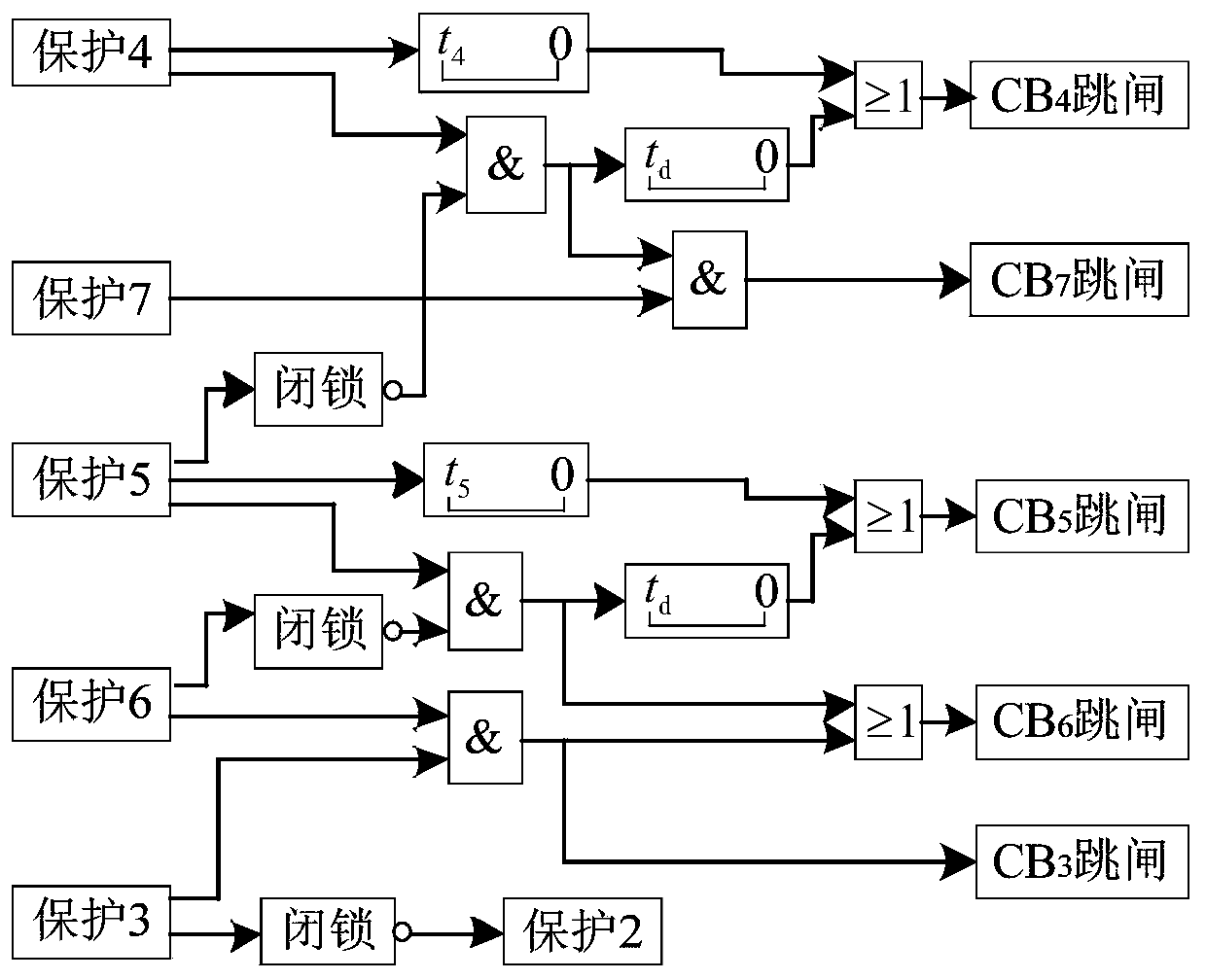

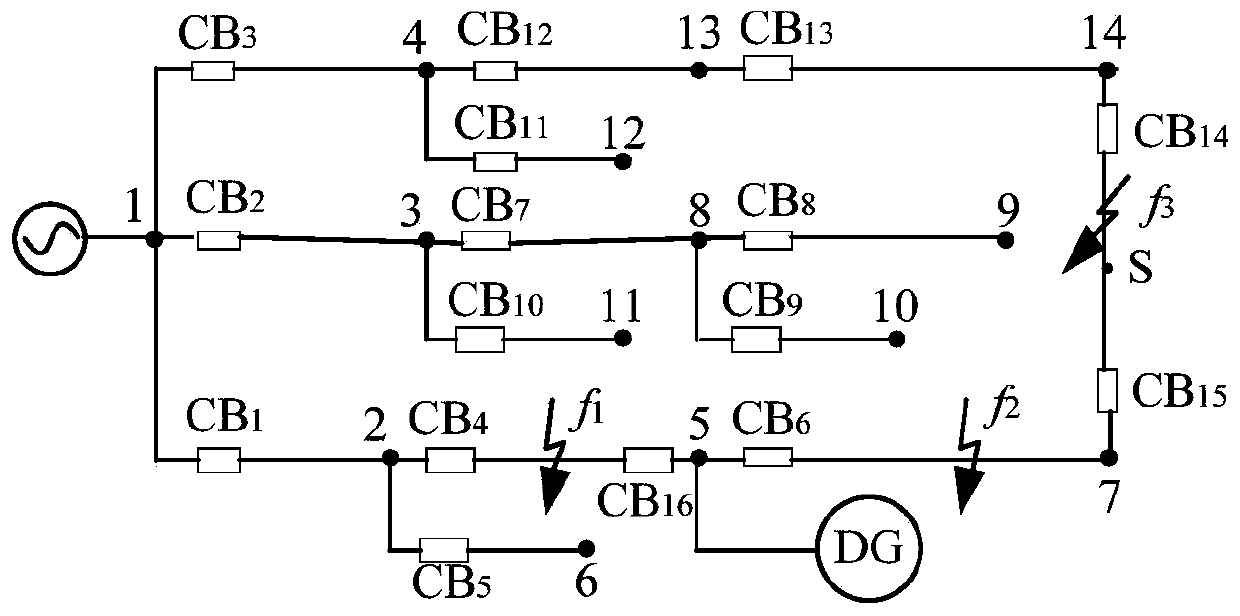

Protection method for closed-loop power distribution network containing distributed power supply

InactiveCN110649581AImprove power supply reliability and DG utilizationInvestment economySingle network parallel feeding arrangementsArrangements responsive to excess currentDistribution gridCut-off

The invention discloses a protection method for a closed-loop power distribution network containing a distributed power supply. The method comprises the following steps: accessing a DG to a power supply branch of the power distribution network, and arranging a DG circuit breaker on the access bus of the DG, wherein the DG circuit breaker is used for short-circuit current detection and direction judgment; connecting the tail end of the power supply branch with the DG and the tail end of another power supply branch through an interconnection switch to form the closed-loop power distribution network; adopting a longitudinal overcurrent protection technology for the closed-loop power distribution network, and carrying out opposite protection action by an upstream line if the upstream of the DGaccess bus is faulted in order to achieve isolation and maintain the DG in a power supply state; and carrying out protection action by a downstream line if the downstream of the DC access bus is faulted in order to achieve isolation and keep the DG in the power supply state. The method can isolate any fault of the closed-loop power distribution network in a very short time, at most one bus loadis lost, and the DG is not cut off, so the power supply reliability and the DG utilization rate of the closed-loop power distribution network can be effectively improved.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

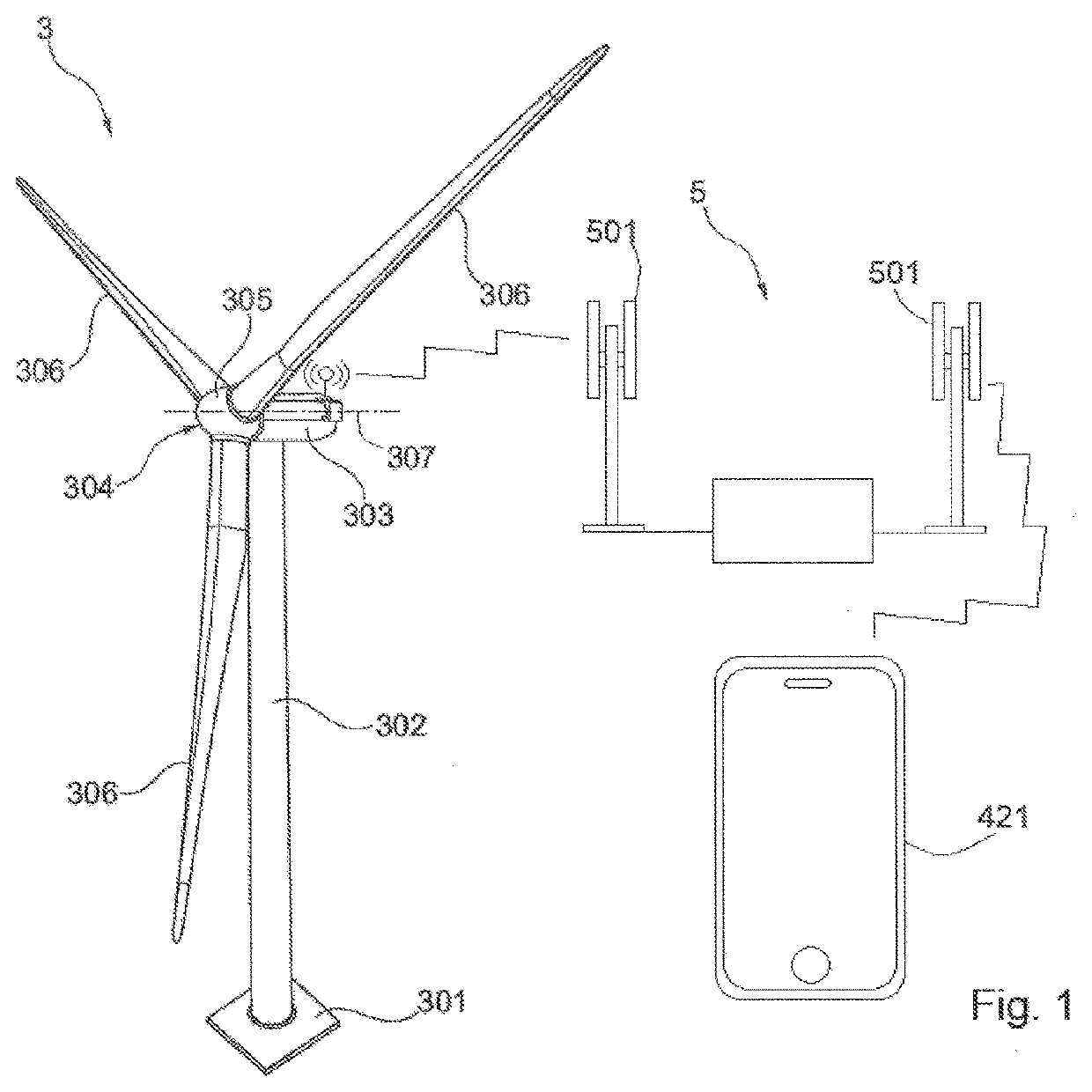

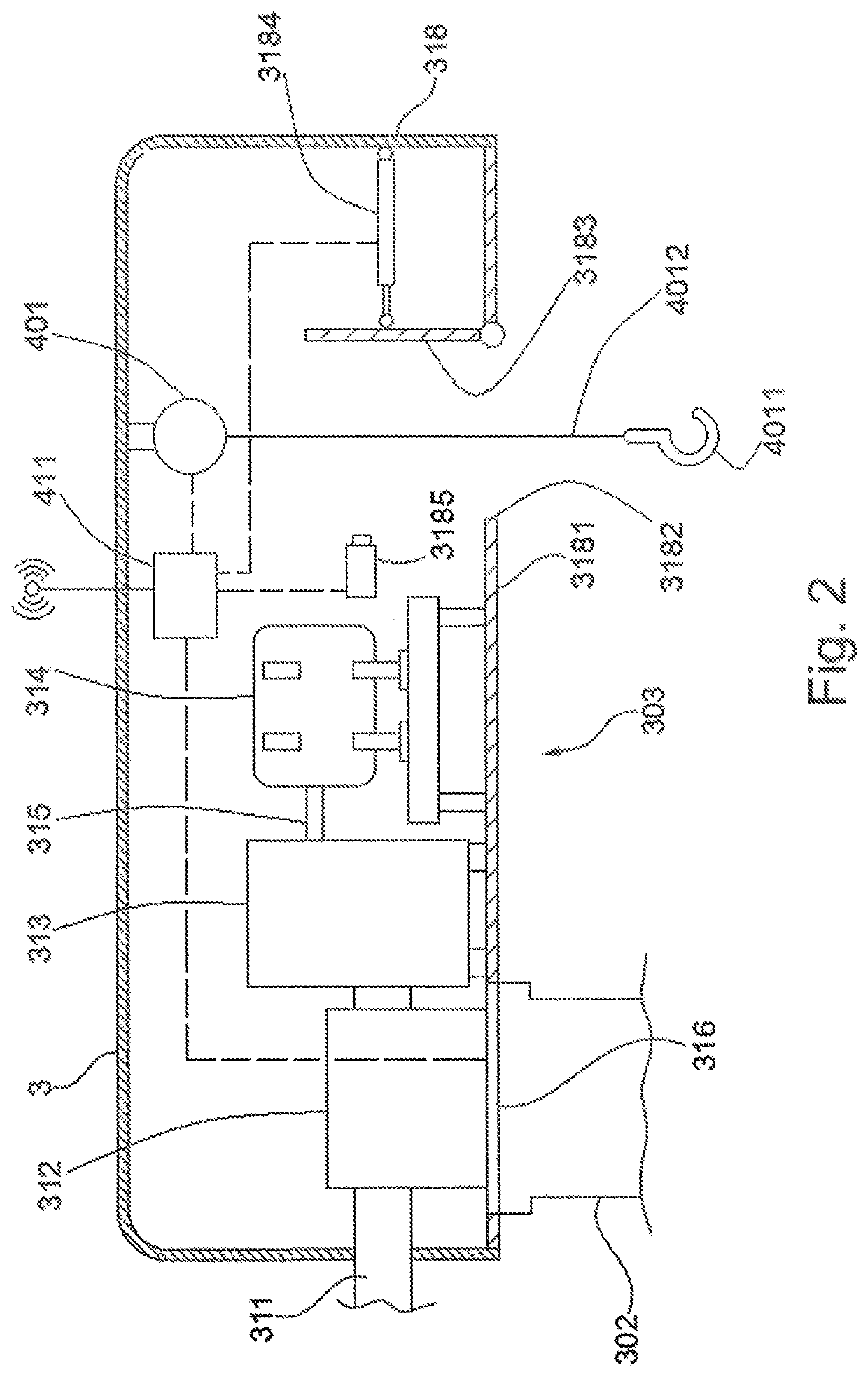

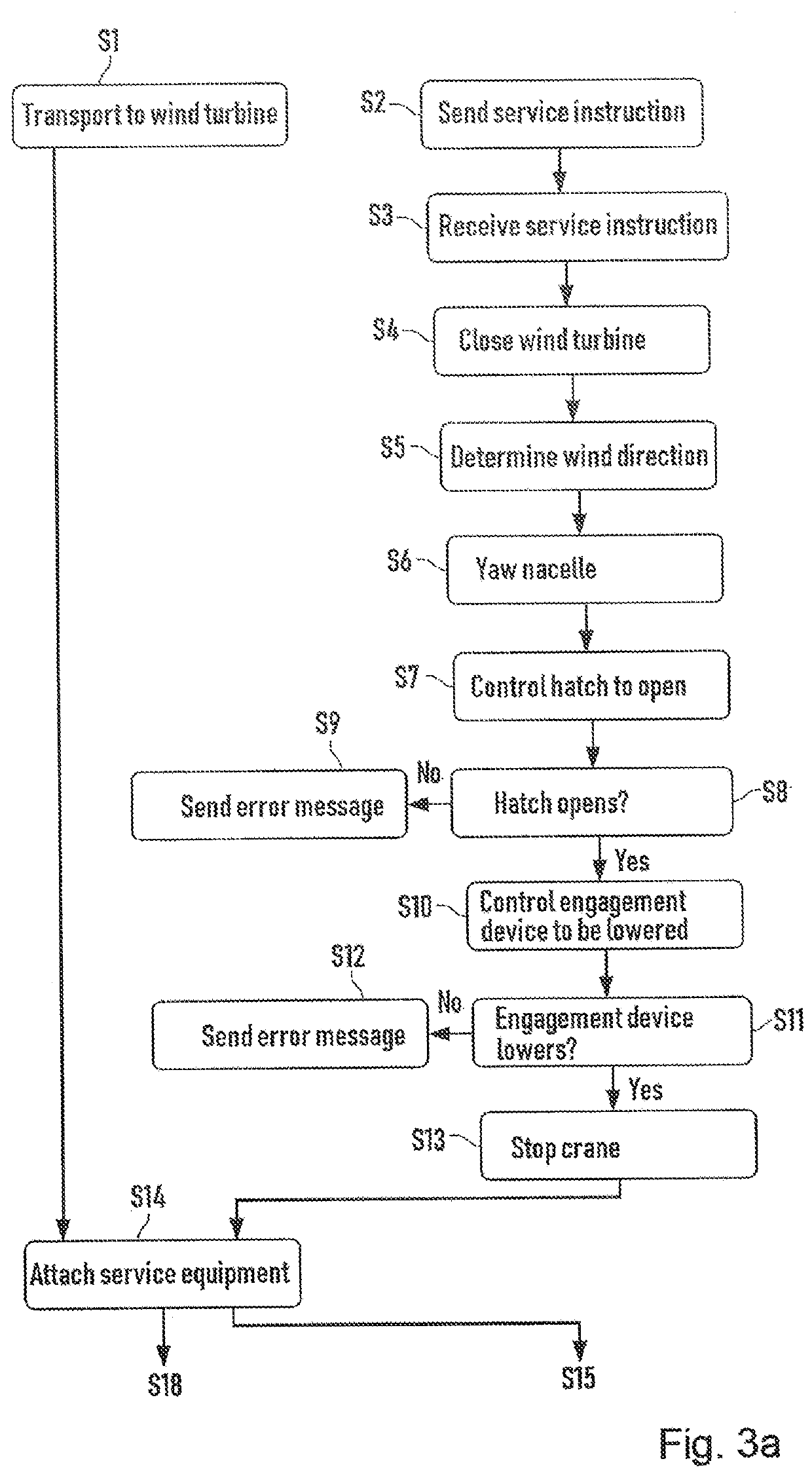

Improvements for servicing a wind turbine

PendingUS20220235743A1Lower a free endTime-savings for service operationsEngine manufactureWind motor supports/mountsMarine engineeringClassical mechanics

The invention provides a method and a wind turbine (3) comprising a crane (401), wherein the wind turbine (3) further comprises an on-site control module (411), which is connectable to a remote control unit (421) located outside of the wind turbine (3), for receiving control data from the remote control unit (421), the control module (411) further being arranged to control the crane (401) in dependence on the control data.

Owner:VESTAS WIND SYST AS

Pyro-separation method of zirconia/hafnium oxide mixture

ActiveCN103725901BEasy to separateInvestment economyMetal recyclingRecovering materialsZirconium(IV) bromideHafnium tetrabromide

A separation method of a zirconia / hafnium oxide mixture. Putting the zirconia / hafnium oxide mixture, charcoal and pure bromine into a reaction for one hour under 650℃ to obtain bromide of zirconium and hafnium, adding the bromide of zirconium and hafnium into a molten salt mixture for distillation separation, and keeping a bottom of a distillation tower under 357℃ for two hours to obtain non-target substance; keeping for five hours at 357℃, and collecting high zirconium tetrabromide; saving residues in a kettle; performing distillation separation in a same device, hearting to 400 degrees, keeping for more than five hours to obtain hafnium tetrabromide, and using magnesium to displace the zirconium tetrabromide and the hafnium tetrabromide respectively to obtain pure zirconium and pure hafnium.

Owner:ЧЖУ, СИНФЭН

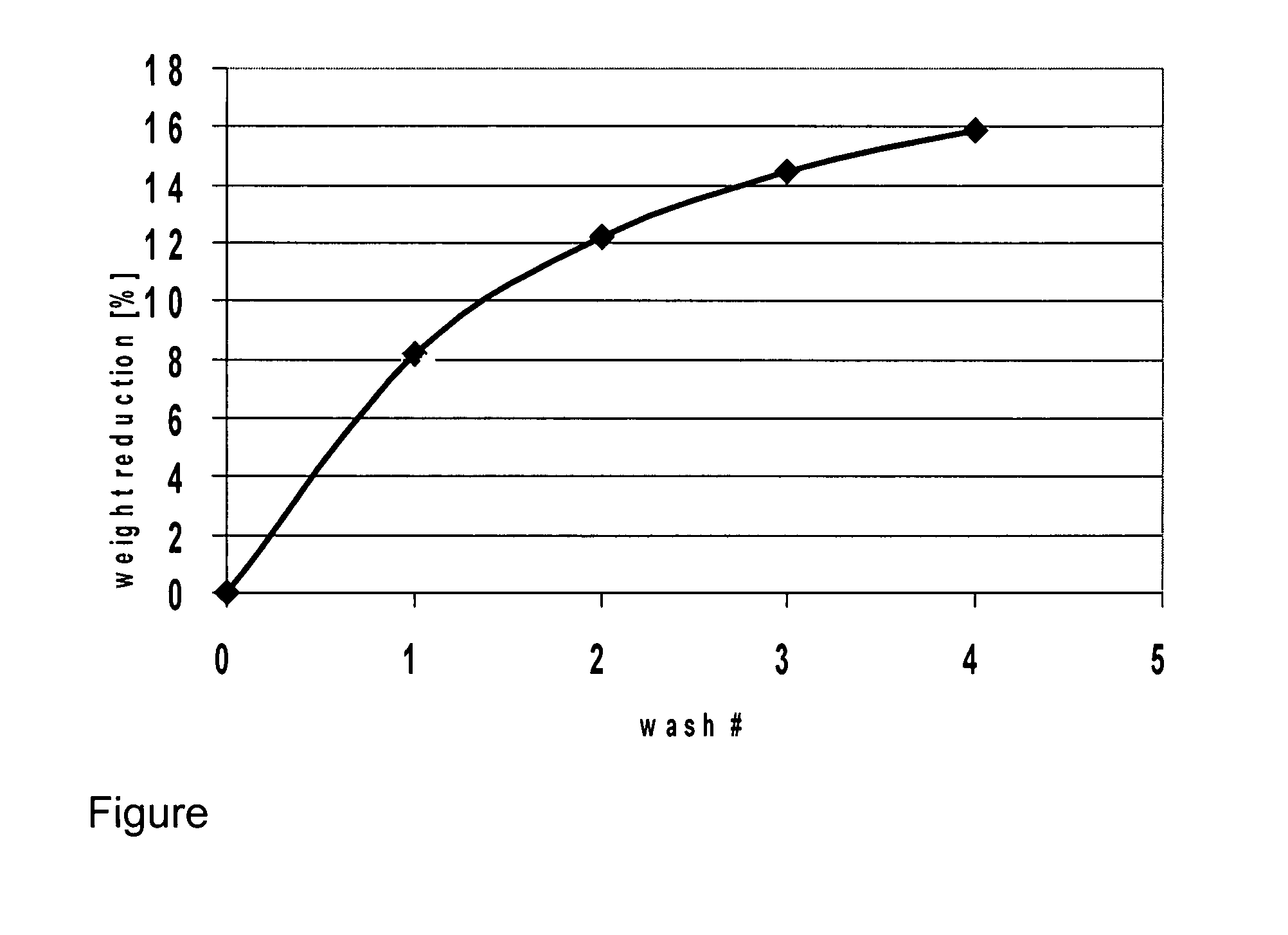

Cleaning of oil-contaminated solids

InactiveUS20090314135A1Recovers caloric energyConvenient treatmentProcess efficiency improvementGas emission reductionMetalChemistry

Owner:LINDE AG

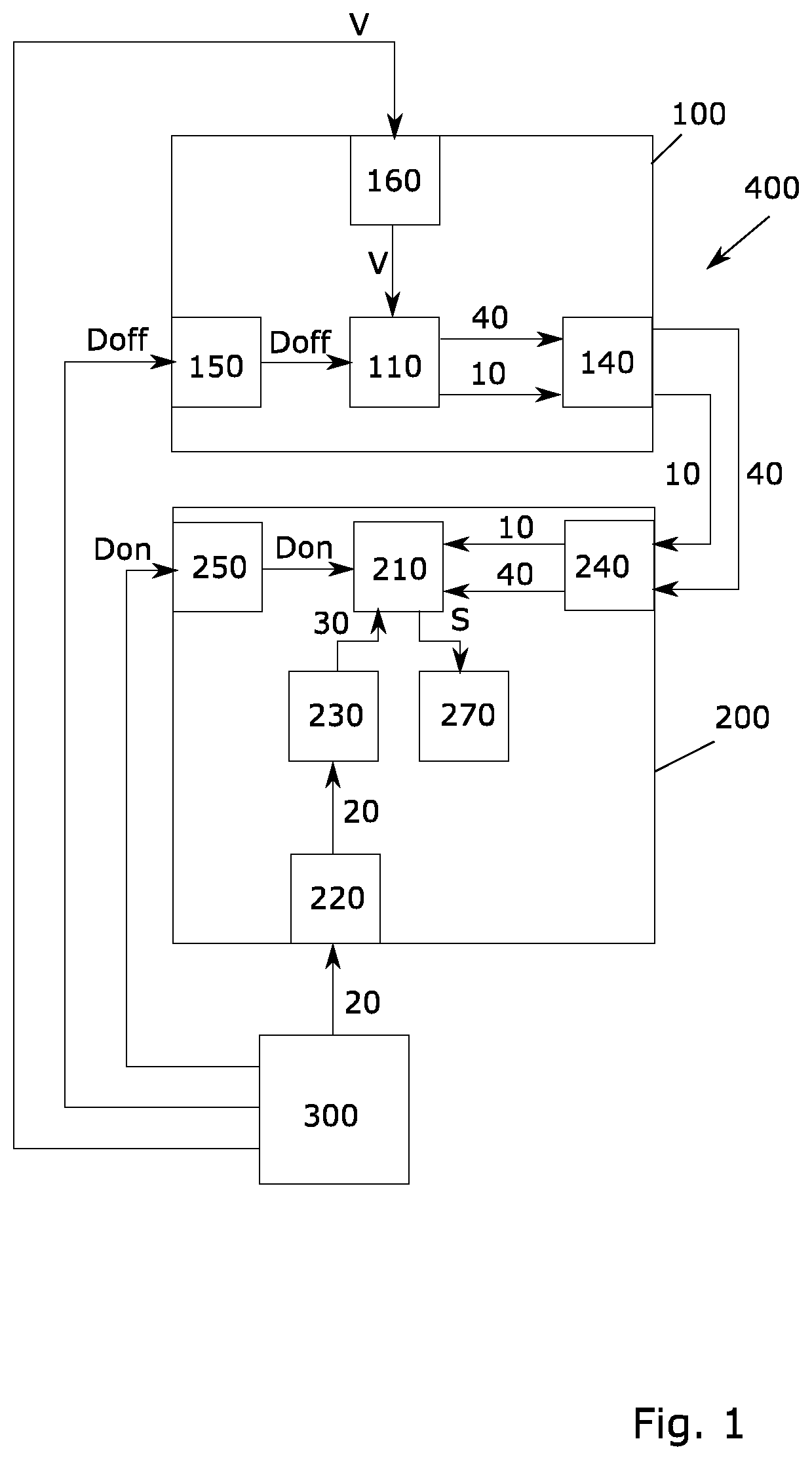

Method for plantation treatment of a plantation field

PendingUS20220167606A1Minimizes valueInvestment economyRemote controlled aircraftInsect catchers and killersComputer visionAgricultural engineering

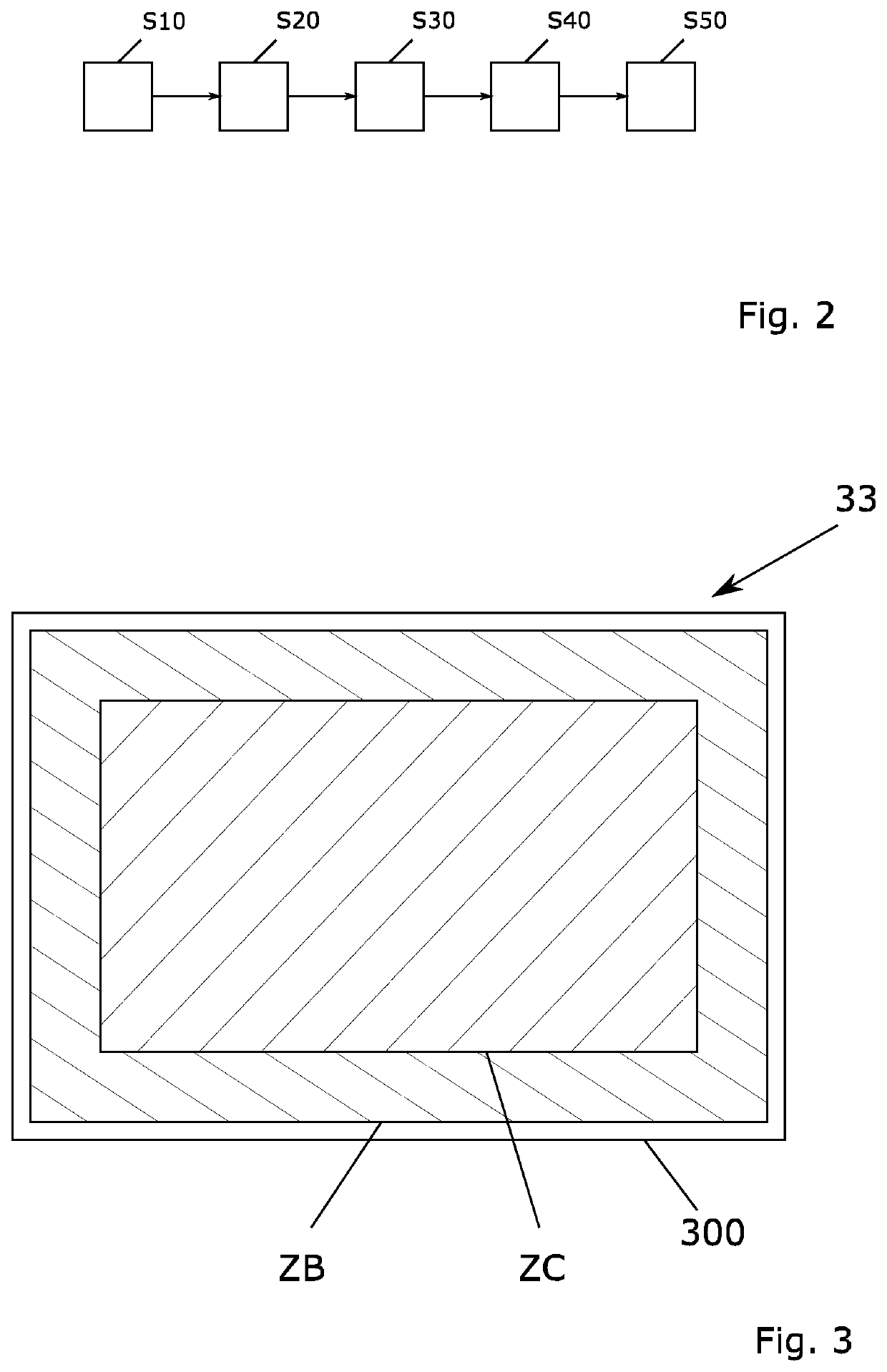

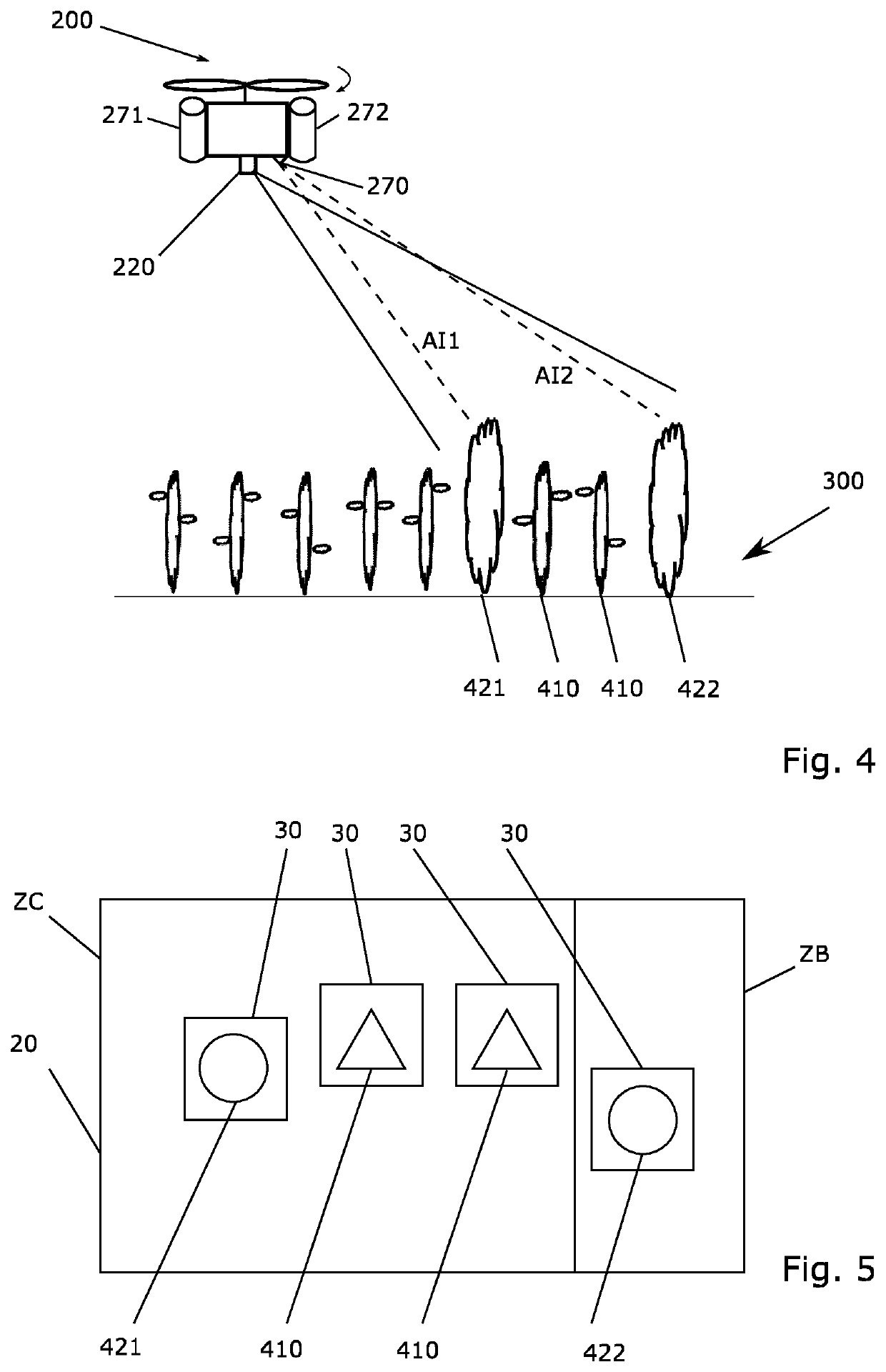

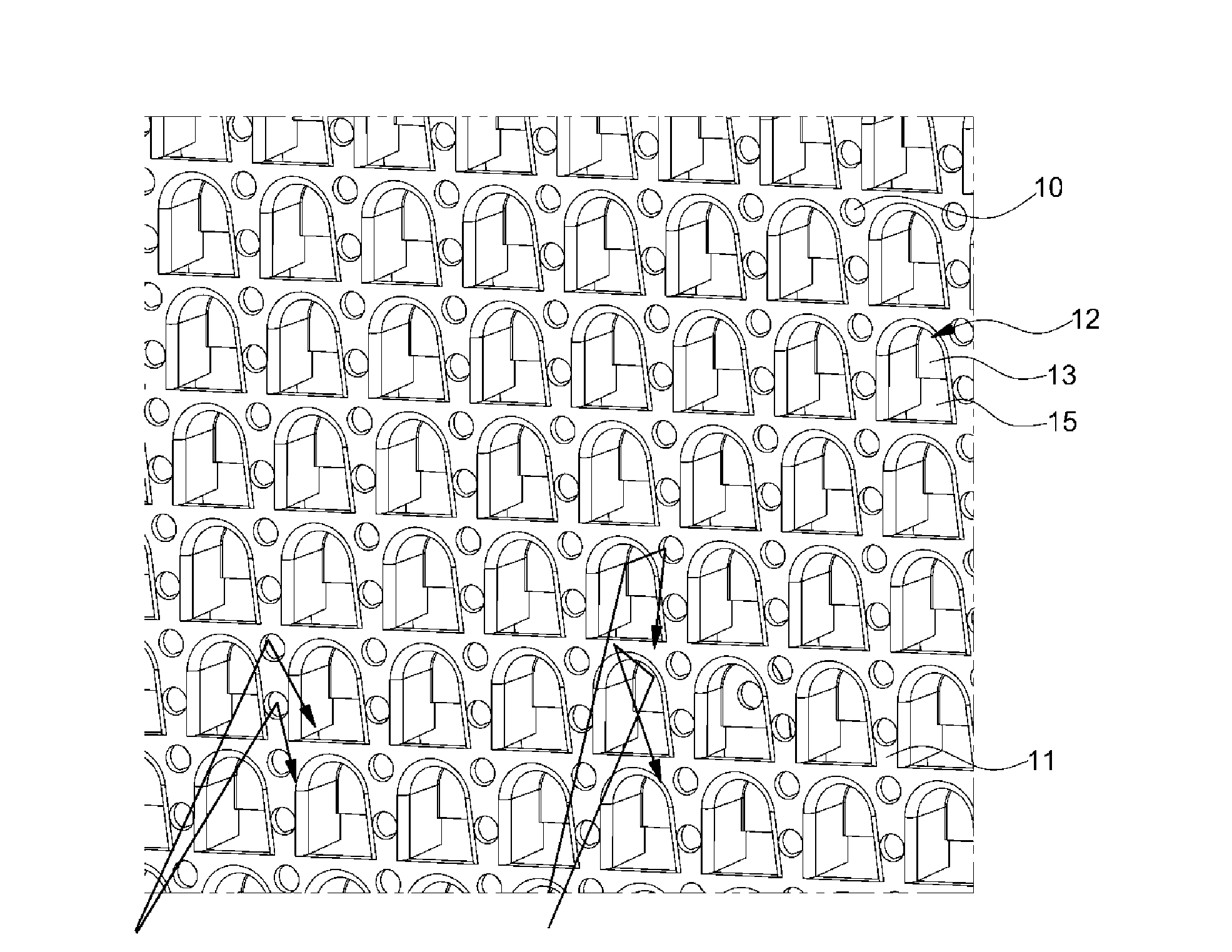

A method for plantation treatment of a plantation field, the method, comprising: receiving (S10) a parametrization (10) for controlling a treatment device (200) by the treatment device (200) from a field manager system (100), wherein the parametrization (10) is dependent on offline field data (Doff) relating to expected conditions on the plantation field (300); taking (S20) an image (20) of a plantation of a plantation field (300); recognizing (S30) objects (30) on the taken image (20); determining (S40) at least one treatment product composition (40) optionally dependent or based on the determined parametrization (10), online field data and / or the recognized objects (30); determining (S50) a control signal (S) for controlling a treatment arrangement (270) of the treatment device (200) based on the determined parametrization (10), the recognized objects (30) and the chosen treatment product composition (40).

Owner:BASF AGRO TRADEMARKS GMBH

Water splash preventing apparatus for vehicle

Owner:HYUNDAI MOTOR CO LTD

Evaluation method for fatigue damage and service life of horizontal axis wind turbine blade

ActiveCN102607831BGet actual lifespanShort cycleMachine part testingStrength propertiesFatigue damageFatigue loading

The invention discloses a test method for the fatigue damage and the service life of a horizontal axis wind turbine blade, aiming to obtain a more exact blade fatigue performance parameter by adopting a test detection and computational analysis means having low cost and high efficiency so as to meet the requirements of blade design, research and development and detection. The method is characterized in that on the basis of the characteristic that the impeller speed of a horizontal axis wind turbine is lower, and the period change frequency of various fatigue loads is also lower, a series of steps of carrying out static loading testing on the wind turbine blade to obtain a stress / strain amplitude distribution condition under the effect of various fatigue loads and analyzing by combining a material property curve and a cumulative damage theory are adopted to realize the evaluation to the blade fatigue performance. Compared with the traditional horizontal axis wind turbine blade fatigue testing technology, the method has the advantages of short period, low cost, capability of obtaining a final service life parameter of the blade, and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

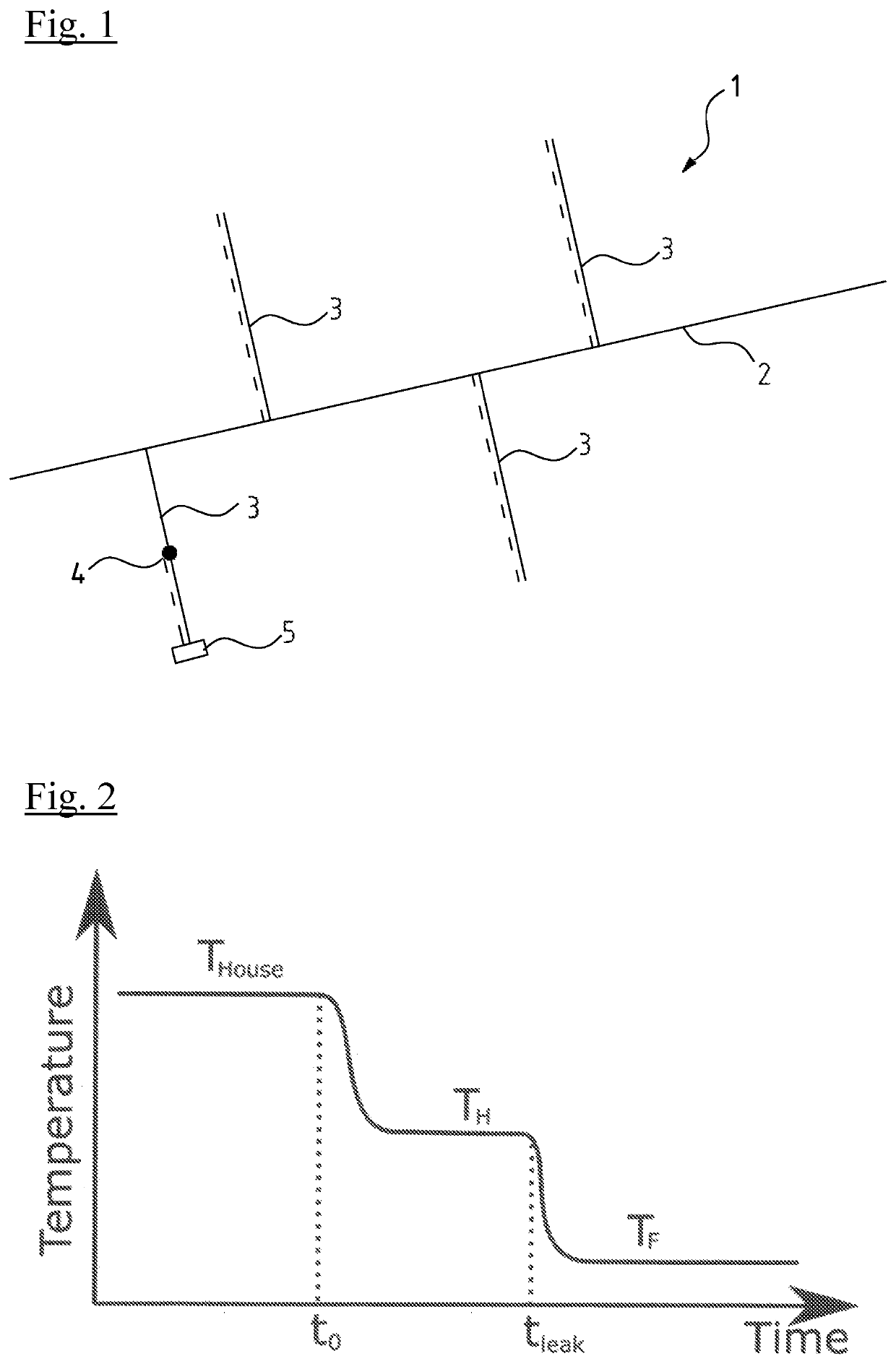

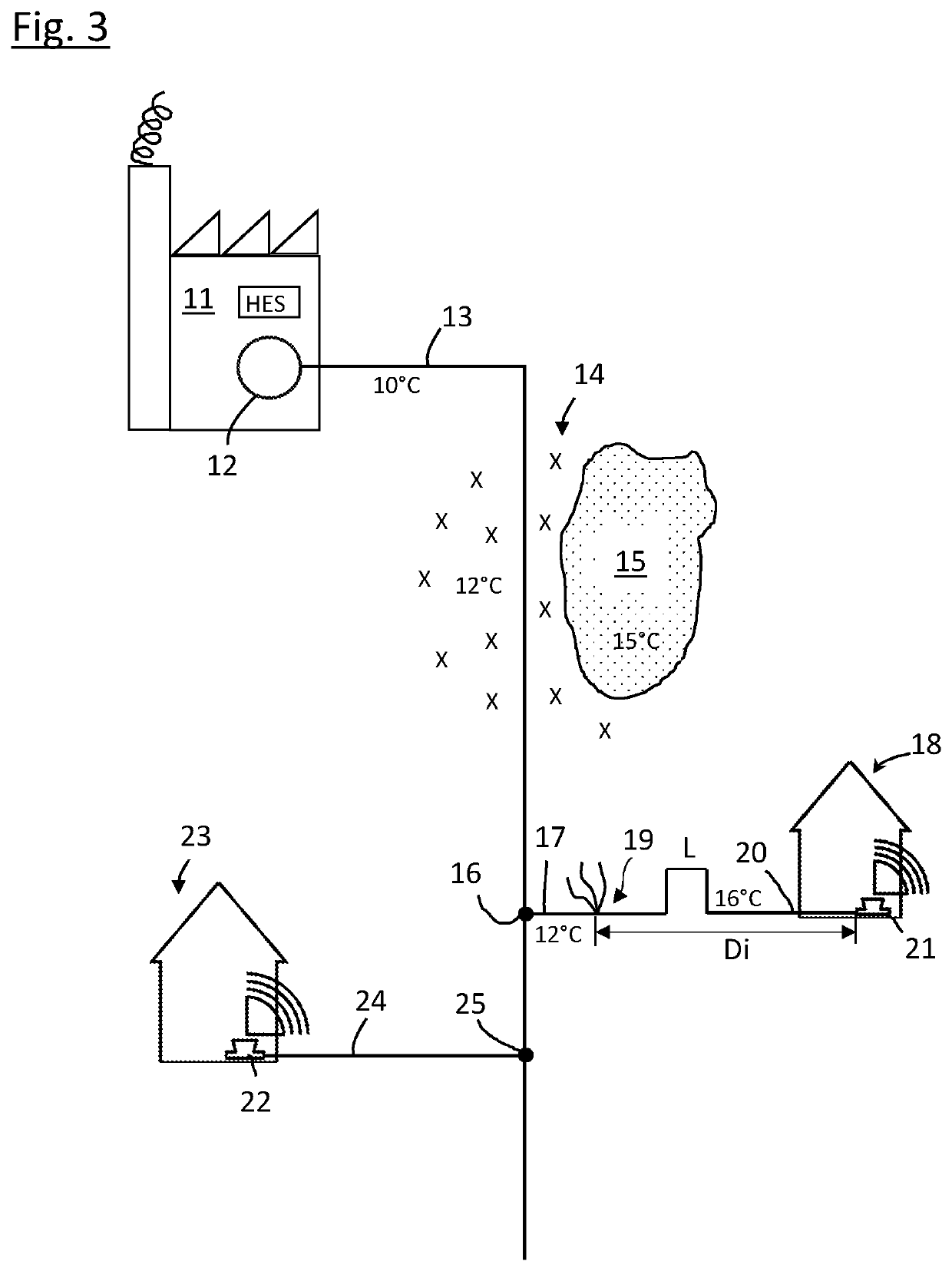

Method for locating a leak in a water supply network

PendingUS20220326107A1Investment economyOptimizationFluid-tightness measurementPipeline systemsWater sourceTemperature curve

A method for locating a leak (19) in a water supply network with a water source (11) and one or more water consumption meters (21, 22) on the consumer side. The method includes calculating a length of the pipe (17) between the consumption meter (21) and the leak (19) location based on a temporal temperature curve and a quantity of water flowing through the at least one consumption meter (21).

Owner:KAMSTRUP

Spraying method with controllable spraying amount

InactiveCN1260012CUniform horizontal distributionConvenient spray volumeSpraying apparatusAgricultural engineeringControl valves

Owner:ZHEJIANG HUAZHANG TECH

Dewatering process for using filtration aid in band filter

InactiveCN100569332CImprove dehydration efficiencySignificant lossMoving filtering element filtersBiochemical engineeringBand-pass filter

Owner:ZHEJIANG HUAZHANG TECH

Integrated Solar Energy Conversion System, Method, and Apparatus

ActiveUS20100269880A1Low costImprove efficiencySolar heating energySolar heat collector controllersWorking temperatureEngineering

A solar energy conversion package includes a photovoltaic (PV) cell, a thermionic or thermoelectric conversion unit and a thermal heating system. Solar radiation is concentrated by a lens or reflector and directed to the PV cell for electrical power conversion. A water circulation system maintains the PV cell at working temperatures. The thermionic or thermoelectric conversion cell is coupled between these cells in the thermal path to generate additional power. Additional efficiencies may be gained by partitioning the solar radiation with prisms or wavelength specific filters or reflective coatings into discrete spectrum segments optimized for each conversion unit for maximizing efficiency of electrical energy conversion and equipment design. Integrating all three of these conversion techniques produces a synergistic system that exceeds the performance conventional solar conversion systems.

Owner:LOCKHEED MARTIN CORP

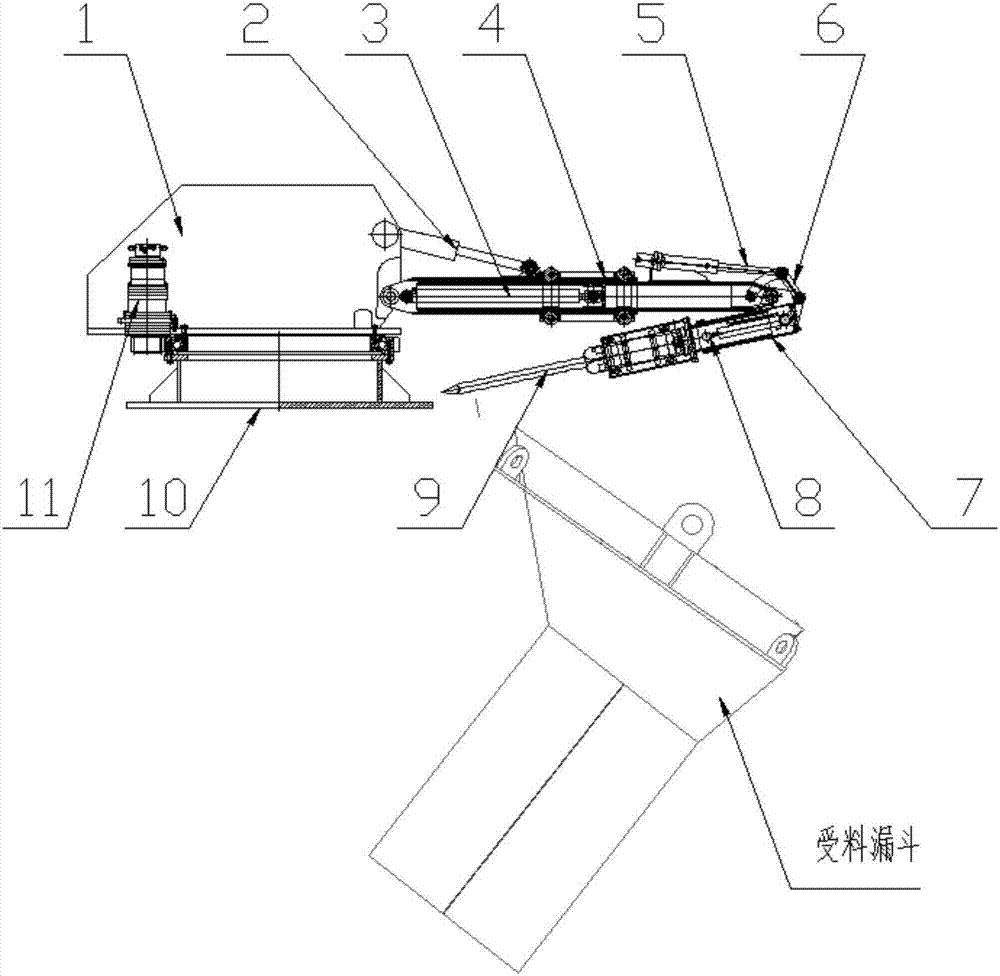

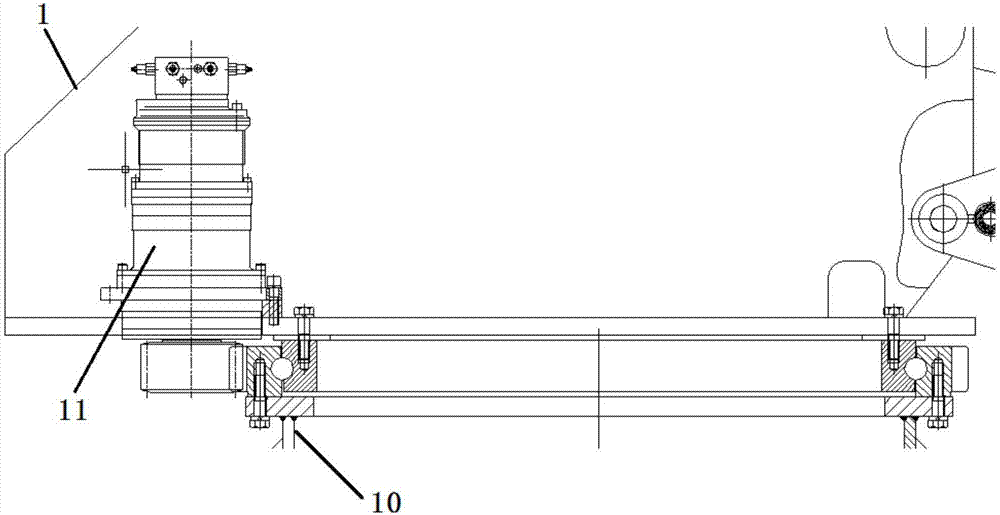

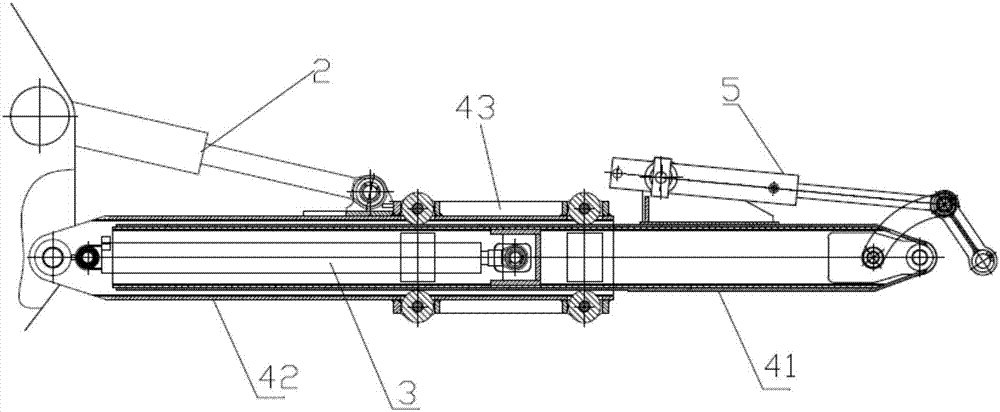

Funnel slag removing device for roller-way slag treatment process

InactiveCN107883389ACompact structureInvestment economyLighting and heating apparatusHydraulic motorHydraulic cylinder

The invention discloses a funnel slag removing device for a roller-way slag treatment process. The funnel slag removing device comprises a first supporting frame, a second supporting frame, a hydraulic motor, a first hydraulic cylinder or a first pneumatic cylinder, a second hydraulic cylinder or a second pneumatic cylinder, a first sliding sleeve, a third hydraulic cylinder or a third pneumatic cylinder, a connecting rod structure, a second sliding sleeve, a fourth hydraulic cylinder or a fourth pneumatic cylinder, and a drill bit; the first supporting frame enables other components of the funnel slag removing device to move by 360 degrees in the circumferential direction through the hydraulic motor and a revolving support assembled on the second supporting frame; the first hydraulic (pneumatic) cylinder and the first sliding sleeve are pivotally connected with the first supporting frame so that the first hydraulic (pneumatic) cylinder controls the first sliding sleeve to perform up-and-down arm swinging actions; the second hydraulic (pneumatic) cylinder is mounted on the first sliding sleeve to enable the first sliding sleeve to perform telescopic movement in the axial direction;and the third hydraulic (pneumatic) cylinder is assembled on the first sliding sleeve, the action of the drill bit is directly controlled through the first sliding sleeve, the connecting rod structure and the second sliding sleeve, and therefore the slag removing requirements of each position in the axial direction of a receiving funnel are met.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

Static test method of horizontal shaft wind turbine vane scale model based on equal strength principle

ActiveCN103196666BAccurately Obtain Static Structural PropertiesShort cycleMachine part testingScale modelTurbine

The invention discloses a static test method of a horizontal shaft wind turbine vane scale model. The method aims at replacing a full-size vane static test experience through a low-cost and high-efficiency scale model experience detection and computational analysis mode. The method is characterized in that a static test experience of the vane model is adopted to replace the traditional full-size vane static test experience, vanes of the vane model are narrowed in size with an equal proportion, and an experience load of the scale model can be confirmed according to the requirement that the scale model and prototype vanes meet equal strength of the structure. According to the test method, not only are currently-used vane static test devices adopted, but also low-cost small-type test devices and equipment can be adopted to conduct the static experience. Through accurate design and numerical calculation, the scale model and the full-size vanes can have a relatively accurate structural size corresponding relation and a load corresponding relation, and accuracy of test results can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com