Funnel slag removing device for roller-way slag treatment process

A slag cleaning and funnel technology, which is applied in lighting and heating equipment, etc., can solve the problems of easy adhesion of residual steel slag, large labor, and threats to the personal safety of operators, and achieves the effect of compact structure, economical investment and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

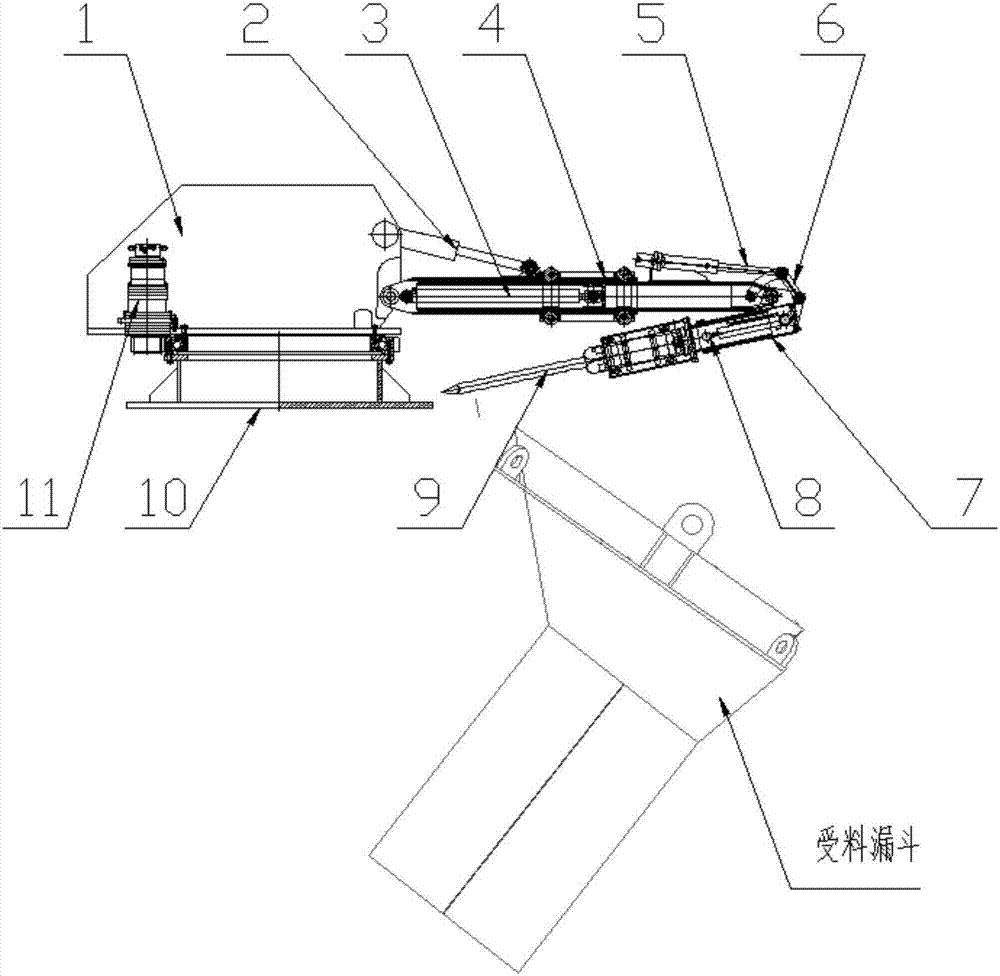

[0031] See figure 1 , the funnel slag removal device of this embodiment is used for the drum slag treatment process, and the funnel is marked as "receiving funnel" in the figure, and the funnel slag removal device includes:

[0032] support frame one (1);

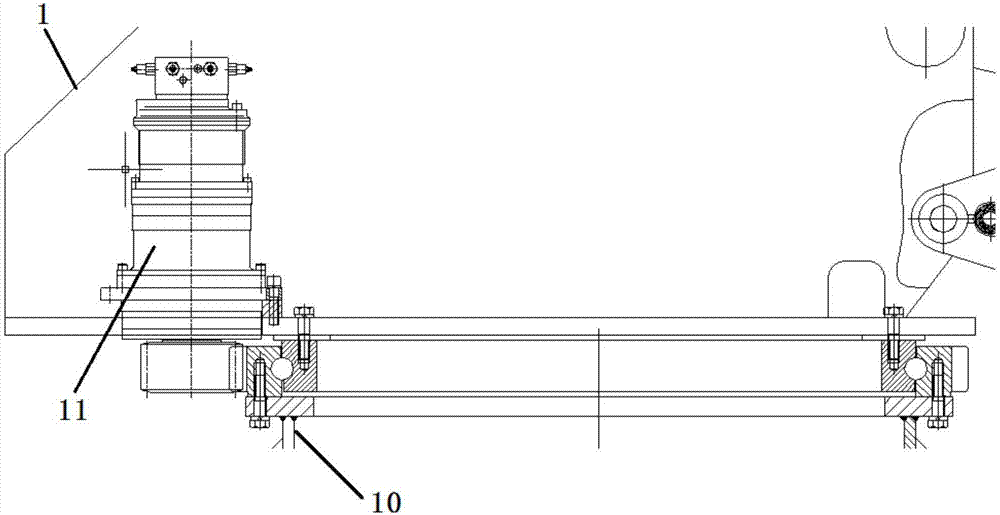

[0033] Support frame two (10);

[0034] hydraulic motor (11);

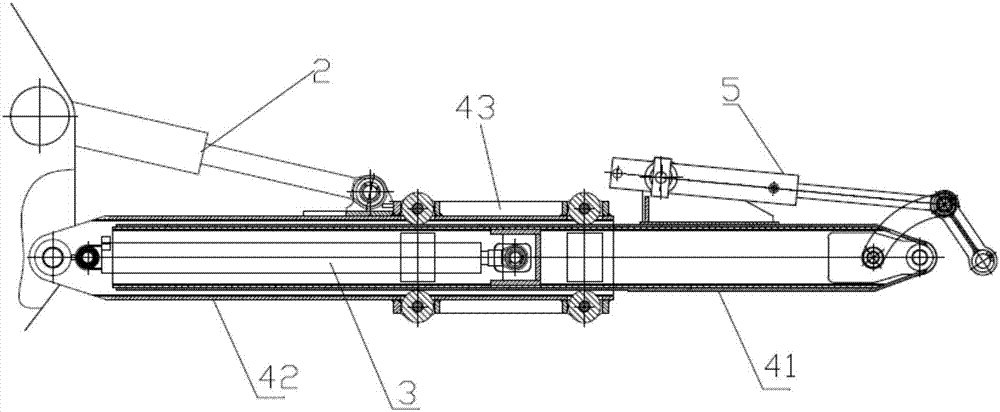

[0035] One hydraulic cylinder or one pneumatic cylinder (2);

[0036] Two hydraulic cylinders or two pneumatic cylinders (3);

[0037] Sliding sleeve one (4);

[0038] Hydraulic cylinder three or pneumatic cylinder three (5);

[0039] Connecting rod structure (6);

[0040] Sliding sleeve two (7);

[0041] Four hydraulic cylinders or four pneumatic cylinders (8);

[0042] Bit (9);

[0043] in,

[0044] The support frame two (10) is arranged on a suitable operating platform according to the process layout requirements, and the support frame one (1) realizes its relative to the support frame through the hydraulic motor (11) and the rotary support structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com