Two rail five car side drag circular suspension delivery machine

A technology for hanging conveyors and car sides, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., and can solve the problems of inability to turn, bulky, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

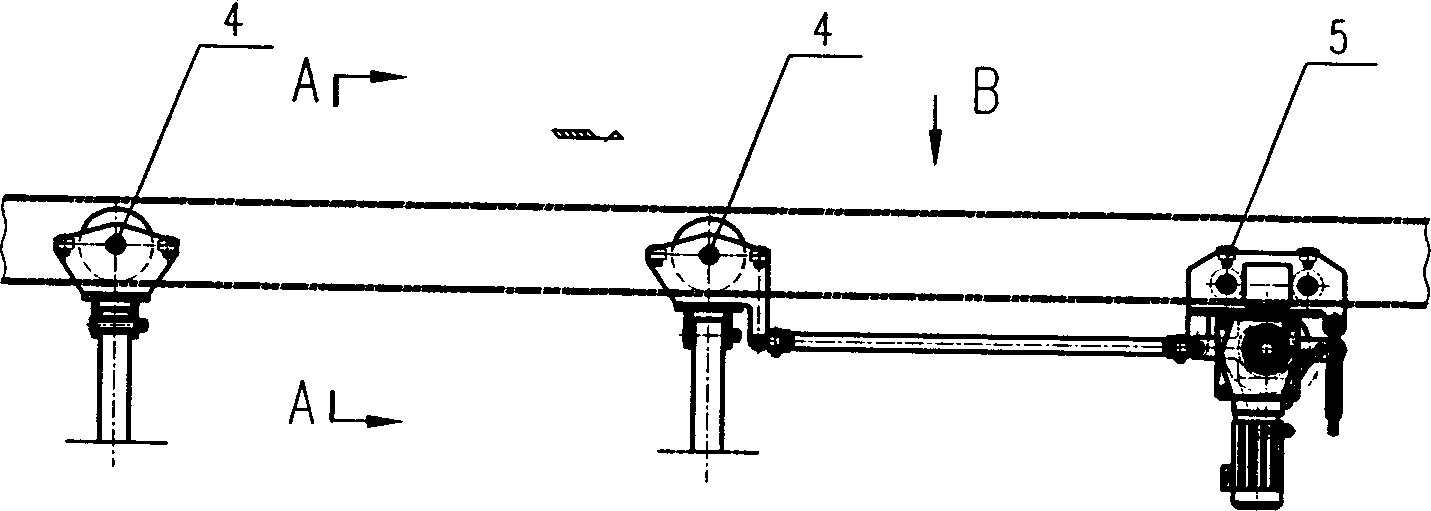

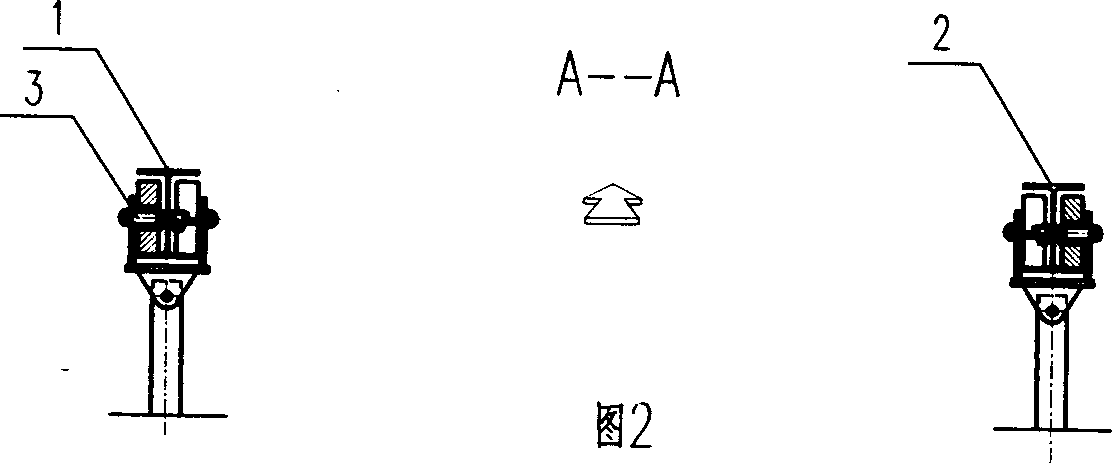

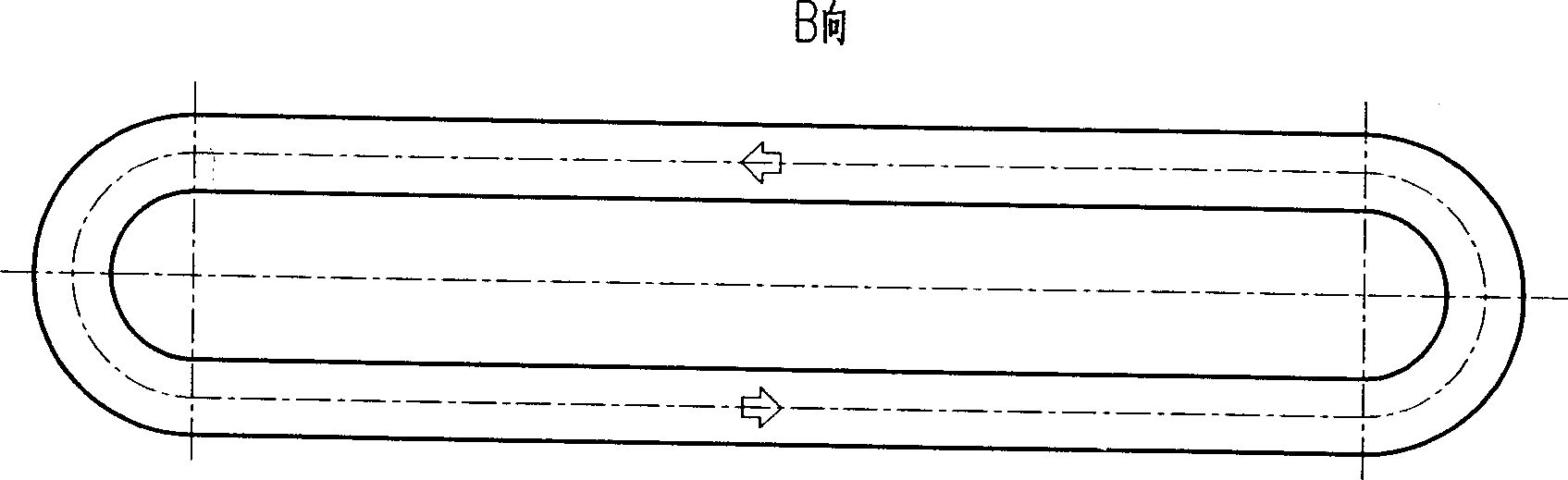

[0012] Compare the accompanying drawings. Two ring-shaped H-shaped steels 1 and 2 (double rails) are equipped with two sets of load-bearing trolleys 3 and 4 (four load-bearing trolleys), that is, there are two load-carrying trolleys 3 and 4 in H-shaped steel 1 and 2, and two load-carrying trolleys in H-shaped steel 2. The carrying trolley 4 is towed by the traction trolley 5 in the H-shaped steel 2, and what is arranged on the periphery of the H-shaped steel 2 is a power supply system. The traction trolley 5 adopts a spring adjustable friction wheel drive device, which is composed of a motor reducer 6, a drive friction wheel 7, Spring adjustable device 8, frame 9 form, and wherein motor speed reducer 6, driving friction wheel 7, spring adjustable device 8 are connected to each other by frame 9 and form traction trolley 5. During work, the motor in the traction trolley 5 drives the driving friction wheel 7 to run in the annular H-shaped steel 2, thereby driving the two carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com