Granulation by agglomeration of ceramic compositions ground in dry phase

A composite, granulation technology, used in grain processing, granulation in stationary tanks/troughs, other household appliances, etc., can solve problems such as different performance, and achieve the effect of eliminating high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

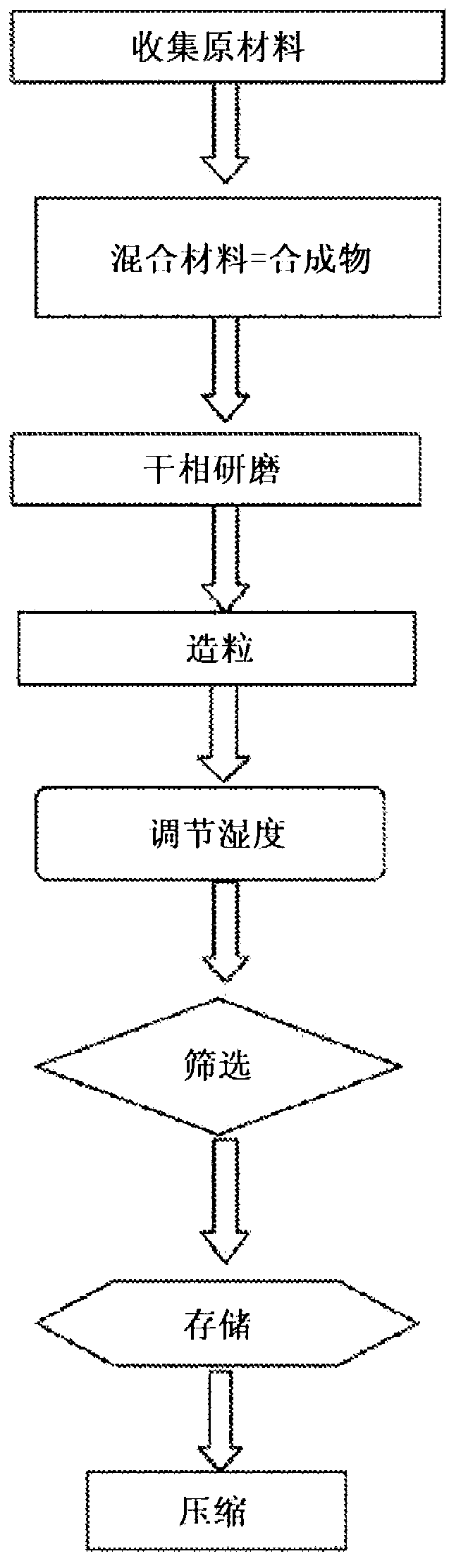

[0099] The preferred embodiment is based on successive steps according to figure 1 The illustrated execution, wherein the step of direct compression of the particulate ceramic composition additionally includes:

[0100] Gather raw materials

[0101] mixed material => composite

[0102] dry phase grinding

[0103] Granulation

[0104] filter

[0105] storage

[0106] compression

[0107] Observation: For the preferred embodiment, the components are mixed prior to granulation. A mineral with 62% illite clay was mixed with another mineral with a silica sand content of 30% and another mineral with potash content. The components are mixed prior to milling. The composition of the ceramic mixture before the end of grinding has a particle size of less than 120 microns. Table 1 below shows the chemical analysis of the resulting compositions.

[0108] Elements / Pelletizing Components

[0109] SiO 2 / 50.29

[0110] Al 2 O 3 / 25.37

[0111] Fe 2 O 3 / 2.51

[0112] Na 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com