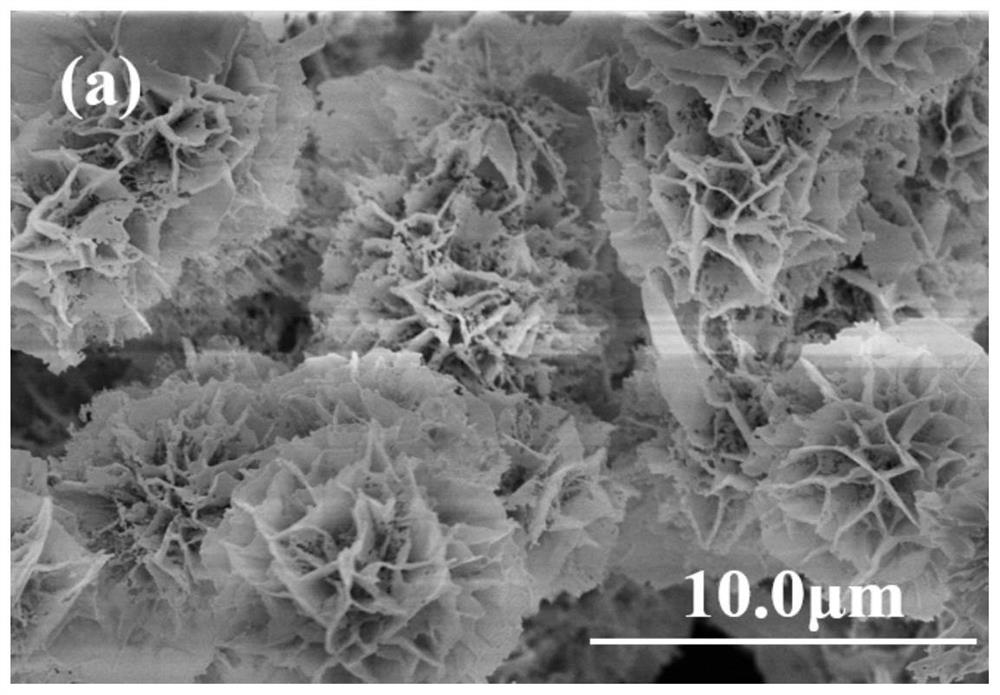

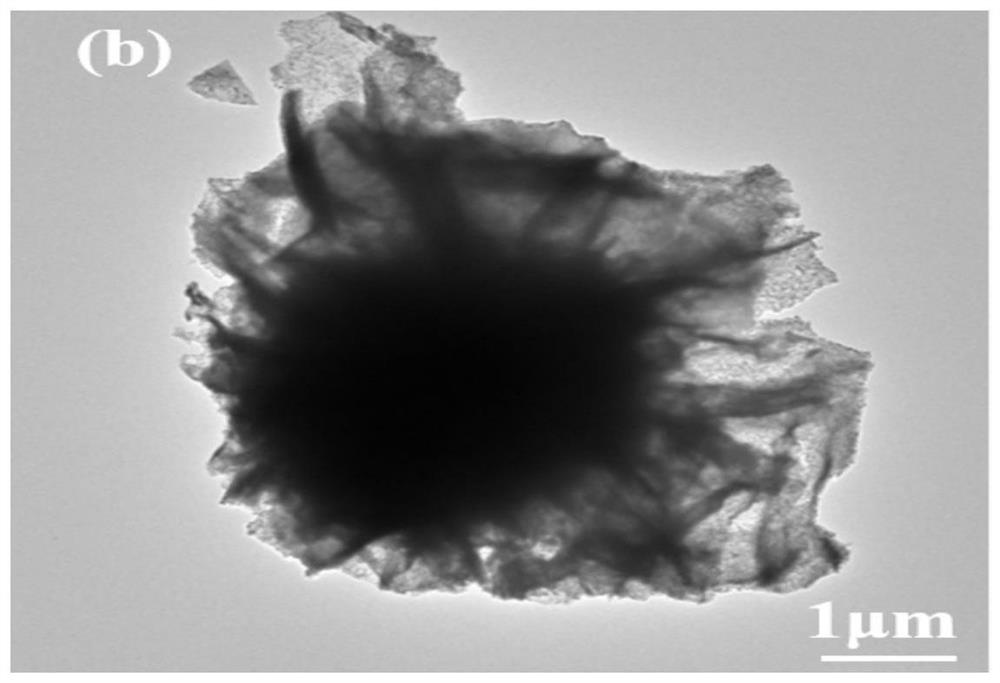

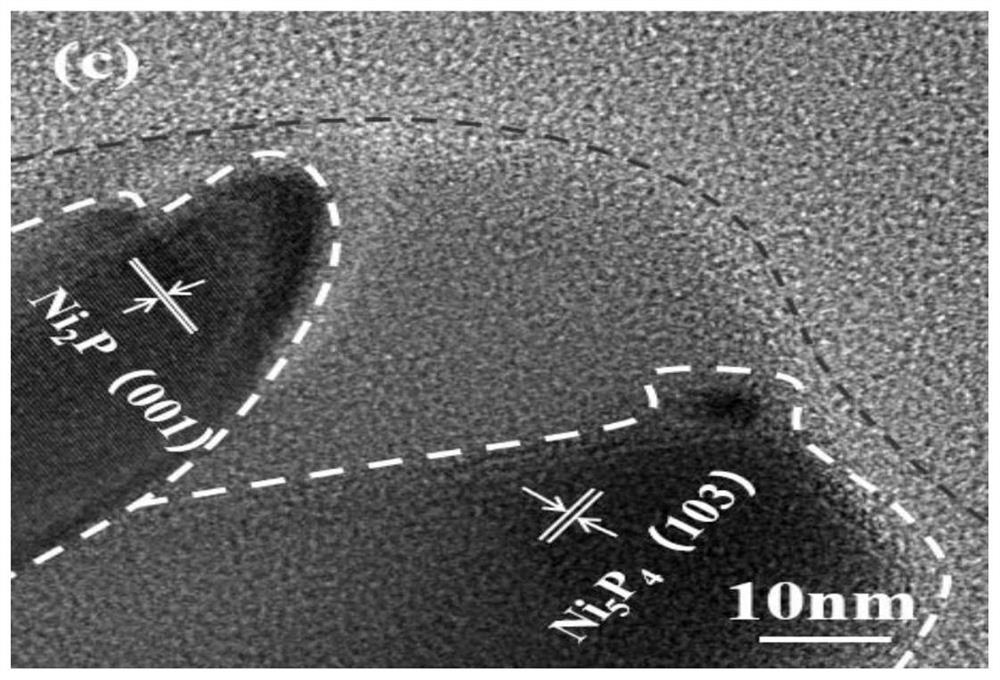

Preparation method and application of foamed nickel loaded nitrogen phosphorus oxygen/nickel phosphide flower-like material

A technology of foamed nickel and nickel phosphide, applied in chemical instruments and methods, phosphides, nitrogen compounds, etc., can solve problems such as reducing active sites, and achieve the effects of inhibiting agglomeration, good catalytic activity, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a foam nickel-supported nitrogen-phosphorus-oxygen / nickel-phosphide flower-like material (NPO / Ni x P y @NF) preparation method, including the following steps:

[0034] Step 1): place the nickel foam of 2*2cm successively in dilute hydrochloric acid, ethanol and deionized water for ultrasonic 30min;

[0035] Step 2): Dissolve 1.45g of nickel nitrate hexahydrate and 1.40g of hexamethylenetetramine in 50mL of deionized water, stir until the crystals disappear, and then continue to ultrasonically vibrate to ensure complete dissolution;

[0036] Step 3): place the pretreated nickel foam in step 1) and the solution obtained in step 2) together in a hydrothermal reaction kettle, and react at 120 ° C (the reaction temperature should be controlled to fluctuate not more than 5 ° C) for 14h ;

[0037] Step 4): take out the nickel foam in step 3), rinse it, transfer it to a vacuum drying oven, set it for 8 hours, and dry it at 70 °C;

[0038] Step 5): C...

Embodiment 2

[0040] A kind of foam nickel supported nitrogen phosphorus oxygen / nickel phosphide flower-like material (NPO / Ni xP y The preparation method of @NF) includes the following steps:

[0041] Step 1) place 2*2cm of nickel foam successively in dilute hydrochloric acid, ethanol and deionized water for ultrasonic 30min;

[0042] Step 2): Dissolve 1.45g of nickel nitrate hexahydrate and 1.40g of hexamethylenetetramine in 50mL of deionized water, stir until the crystals disappear, and then continue to ultrasonically vibrate to ensure complete dissolution;

[0043] Step 3): place the pretreated nickel foam in step 1) and the solution obtained in step 2) together in a hydrothermal reactor, and react at 100°C for 14h;

[0044] Step 4): take out the nickel foam in step 3), rinse it, transfer it to a vacuum drying oven, set it for 8 hours, and dry it at 70 °C;

[0045] Step 5): Collect the dried nickel foam, transfer it to a tube furnace, and place 0.5g NaH in a quartz boat near the gas i...

Embodiment 3

[0047] A kind of foam nickel supported nitrogen phosphorus oxygen / nickel phosphide flower-like material (NPO / Ni x P y The preparation method of @NF) includes the following steps:

[0048] Step 1): place the nickel foam of 2*2cm in dilute hydrochloric acid, ethanol and deionized water for ultrasonic 30min in turn;

[0049] Step 2): Dissolve 1.45g of nickel nitrate hexahydrate and 1.40g of hexamethylenetetramine in 50mL of deionized water, stir until the crystals disappear, and then continue to ultrasonically vibrate to ensure complete dissolution;

[0050] Step 3): place the pretreated nickel foam in step 1) and the solution obtained in step 2) together in a hydrothermal reactor, and react at 140°C for 14h;

[0051] Step 4): take out the nickel foam in step 3), rinse it, transfer it to a vacuum drying oven, set it for 8 hours, and dry it at 70 °C;

[0052] Step 5): Collect the dried nickel foam, transfer it to a tube furnace, and place 0.5g NaH in a quartz boat near the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com