Evaluation method for fatigue damage and service life of horizontal axis wind turbine blade

A wind turbine blade and fatigue life technology, applied in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc., can solve the problems of high cost, high testing cost, deviation of experimental results, etc., and achieve economical equipment investment, The effect of ensuring detection accuracy and avoiding analysis errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0030] In this embodiment, taking the current mainstream MW wind turbine blades as an example, the following steps are used for detection and result correction:

[0031] 1) According to the blade fatigue load spectrum provided by the design department, determine the load amplitude and average value of the fatigue loads that should be included in the evaluation analysis. In this example, select 7 load items that play a major role in the fatigue load spectrum to carry out follow-up assessment;

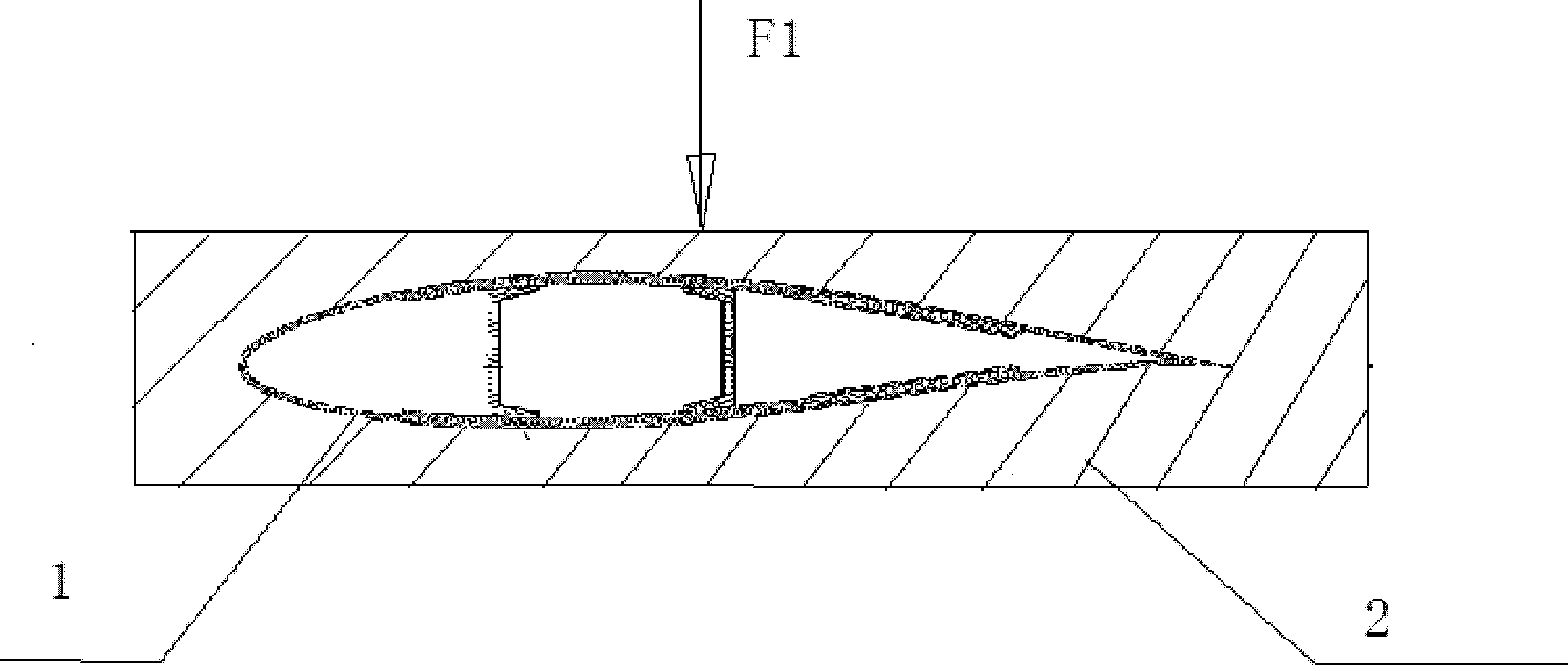

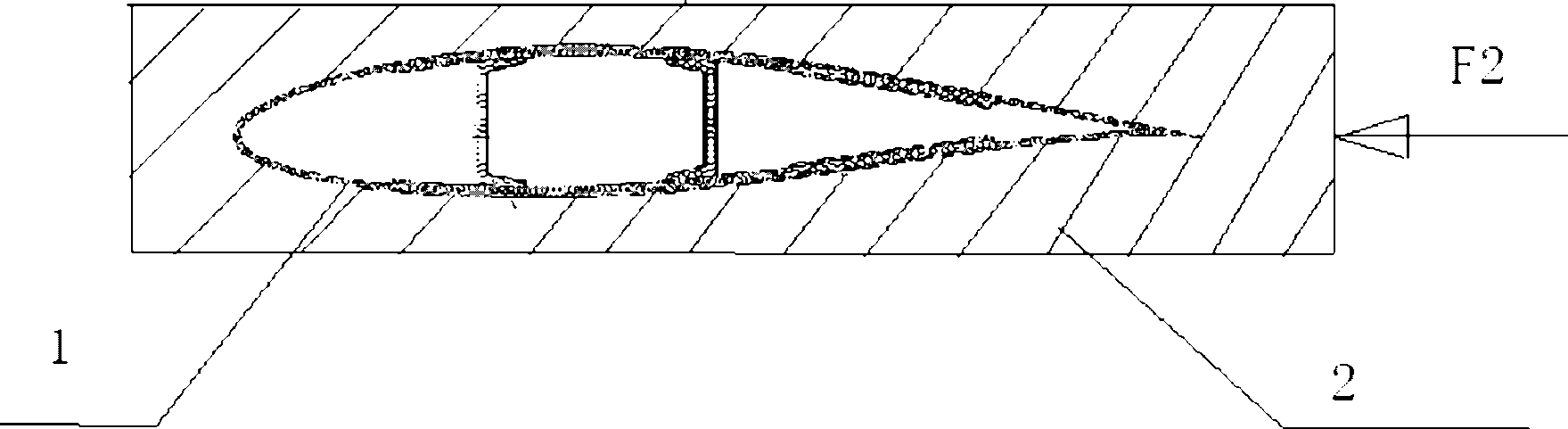

[0032] 2) Fix the blade on the blade test bench, and set strain gauges on the surface and inside of the blade. In this example, the number of sensors is 50, and the layout position covers the fatigue risk occurrence position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com