Cleaning of oil-contaminated solids

a technology of oil-contaminated solids and solids, which is applied in the direction of gas emission reduction, process efficiency improvement, etc., can solve the problems of incineration often proceeding without properly using caloric energy, forming toxic compounds such as polyaromatic compounds, and reducing the life of heterogeneous catalysts. , to achieve the effect of recovering caloric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

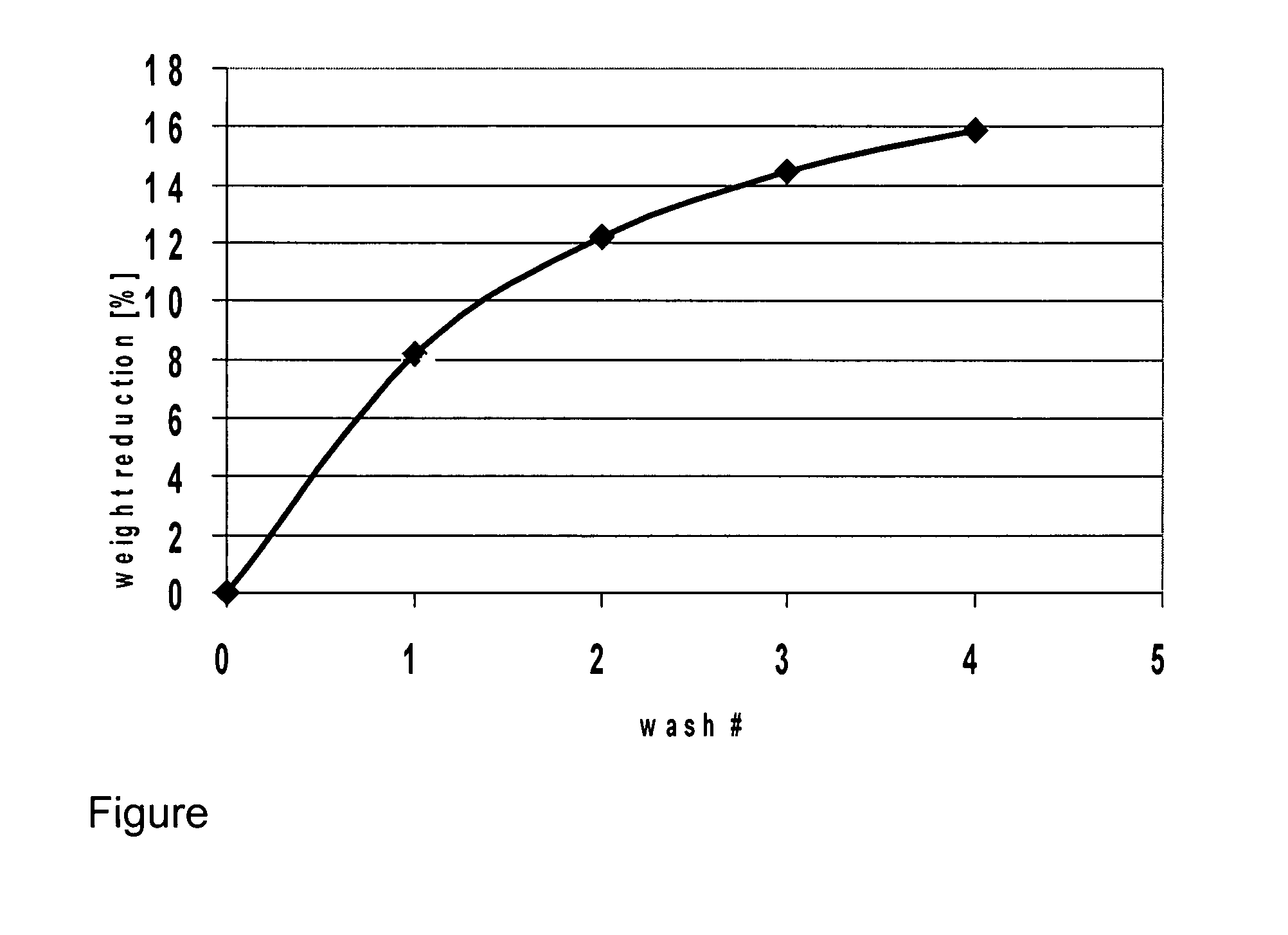

Image

Examples

Embodiment Construction

[0040]The inventive method is preferably used to treat oil contaminated catalyst granulates, for example catalyst particles having an average diameter of about 5 mm. Spent catalyst is contaminated with oil, hydrocarbons and other substances which are often pyrophoric. Further, several toxic products are stuck to the surface of the catalyst which require a proper handling.

[0041]The catalyst granulate is filled into a metal basket which is then enveloped by a plastic foil. Since the catalyst material is contaminated with oil and other highly inflammable substances that filling process includes a certain risk of ignition. However, the loading of the catalyst granulate into the metal baskets is carried out at the refinery or petrochemical plant which is equipped with appropriate fire extinguishing means.

[0042]Then the enveloped catalyst granulate is transferred to a carbon dioxide cleaning installation. During the transport the plastic foil excludes any air from the inflammable catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com