Dewatering process for using filtration aid in band filter

A belt filter, belt filter press technology, applied in the direction of mobile filter element filter, filtration separation, separation method, etc., can solve the problems of huge improvement investment and limited efficiency improvement, and achieve less dosage, filter aid and other problems. The effect of less agent loss and improvement of pressing dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The dehydration method using a filter aid in a belt filter includes a filter aid application process, and a filter aid is applied to the surface of the filter belt through a filter aid application device arranged at the entrance of the press filter part of the belt filter. of filter aids. Examples The filter aid is selected from liquid surfactants of hydrocarbons and AEO; the device for applying the filter aid is a spray device with a spray head.

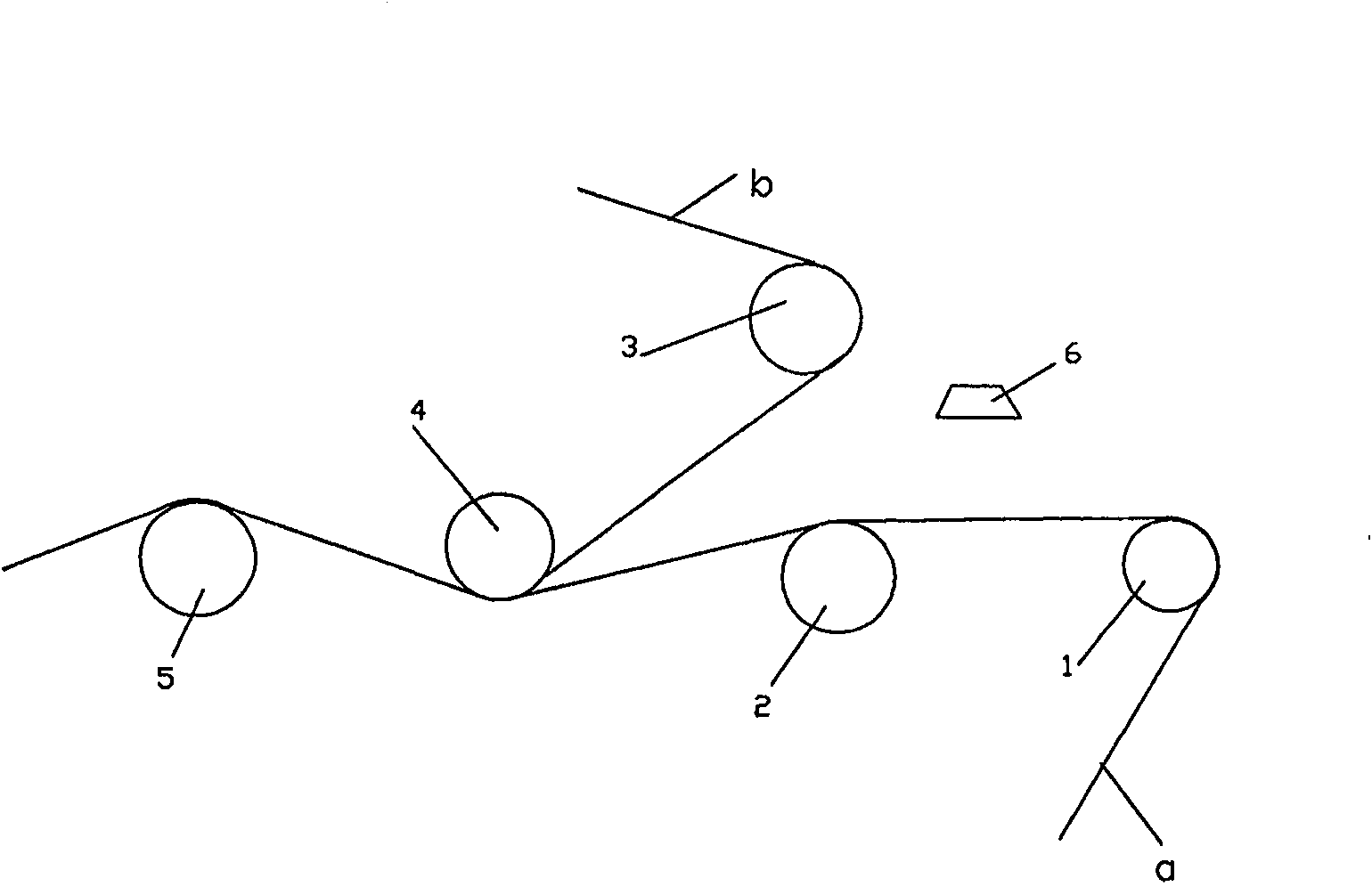

[0018] For the specific setting of the filter aid application device in this embodiment, see figure 1 , the spray device is installed in the press filter part of the belt filter, which is composed of the lower filter belt a wrapped around the press rolls 1, 2 and 5 and the upper filter belt b wrapped around the press rolls 3 and 4 at the entrance of the press filter part By adjusting the spray direction of the spray head 6 of the spray device, the filter aid can be applied to the lower filter belt a or the upper filter belt ...

Embodiment 2

[0021] In this embodiment, the filter aid is directly applied to the material to be dehydrated.

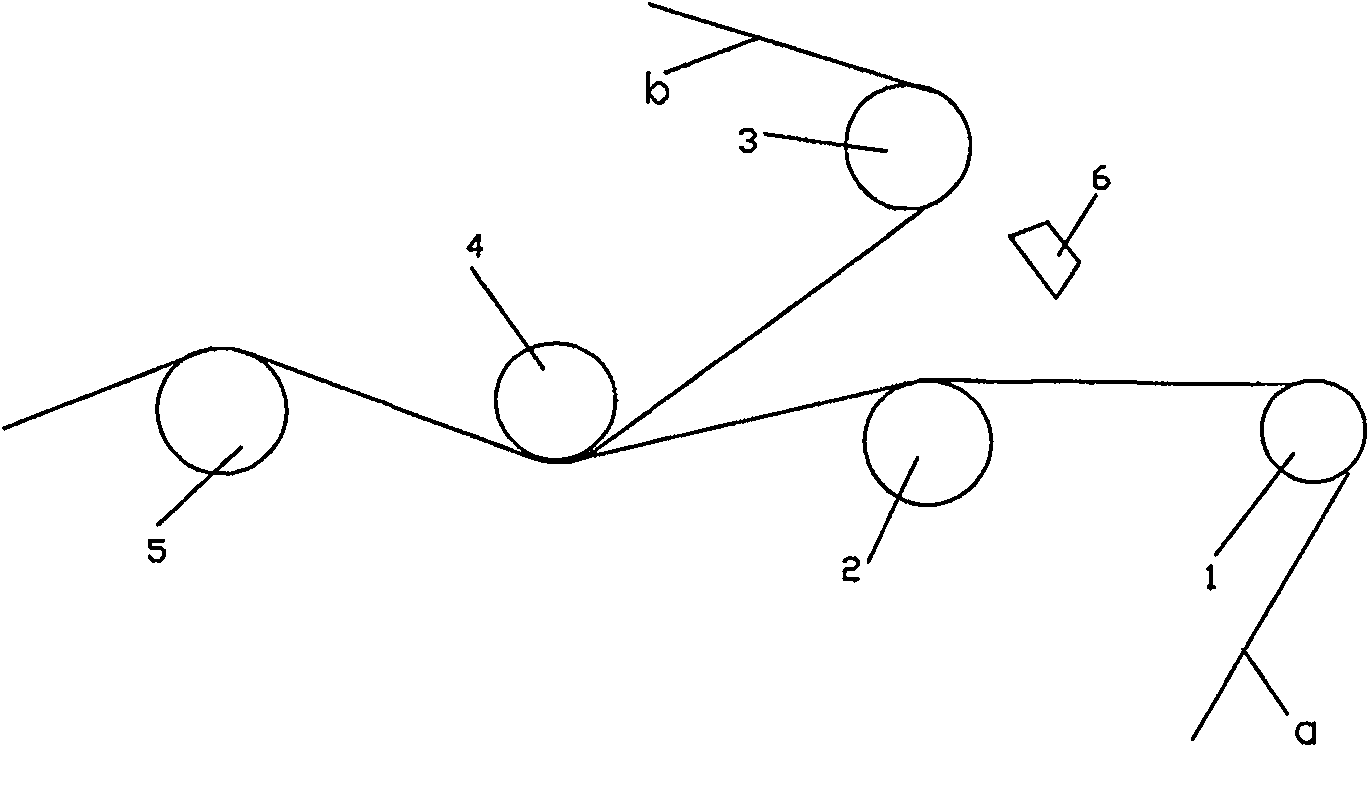

[0022] see figure 2 , the sprinkler sprinkler head 6 installed at the entrance of the press filter part sprays filter aid on the dehydrated material added on the lower filter belt a by the belt filter feeding device to increase the dehydration of the dehydrated material. Other methods of this embodiment are the same as embodiment 1.

[0023] The filter aid can also be applied in advance before the dehydrated material is loaded into the feeding device, and directly mixed in the dehydrated material.

Embodiment 3

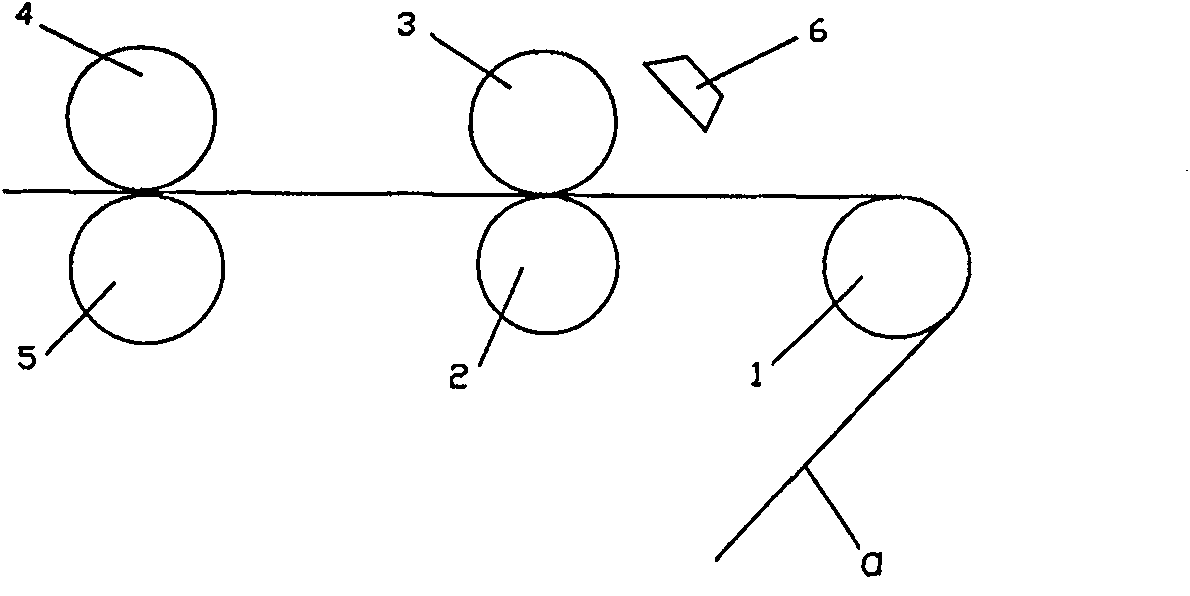

[0025] see image 3 , the filter aid applying device applies the filter aid to the surface of the press roll. The belt filter of the present embodiment has no upper filter belt, the lower filter belt a is wrapped around the press rolls 1, 2, 5, the press rolls 3, 4 are pressed on the lower filter belt a, and the spray head 6 of the spray device is inclined The ground spraying filter aid is at the entrance of the dehydrated material composed of the press roll 3 and the lower filter belt a. Since there is no upper filter belt, most of the filter aid is sprayed on the surface of the press roll 3, so that the filter aid and The dehydrated material is fully contacted to enhance the effect of applying filter aid. Other methods of this embodiment are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com