Process arrangement in the short circulation of a paper machine

a technology of paper machine and short circulation, applied in the wet end of the machine, papermaking, textiles and papermaking, etc., can solve the problems of short circulation and air saturated, and achieve the effect of reducing the energy needed for pumping and increasing the back pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

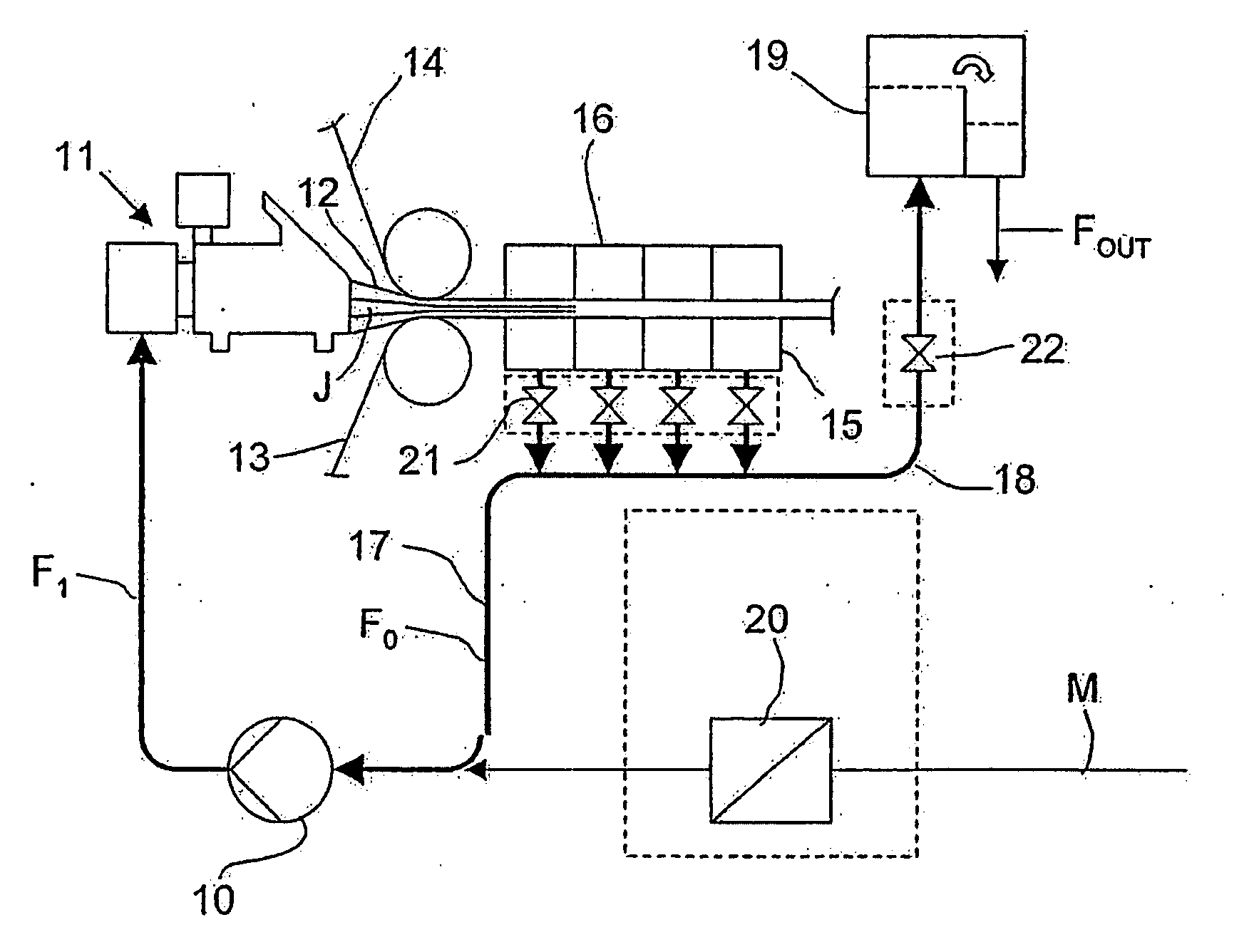

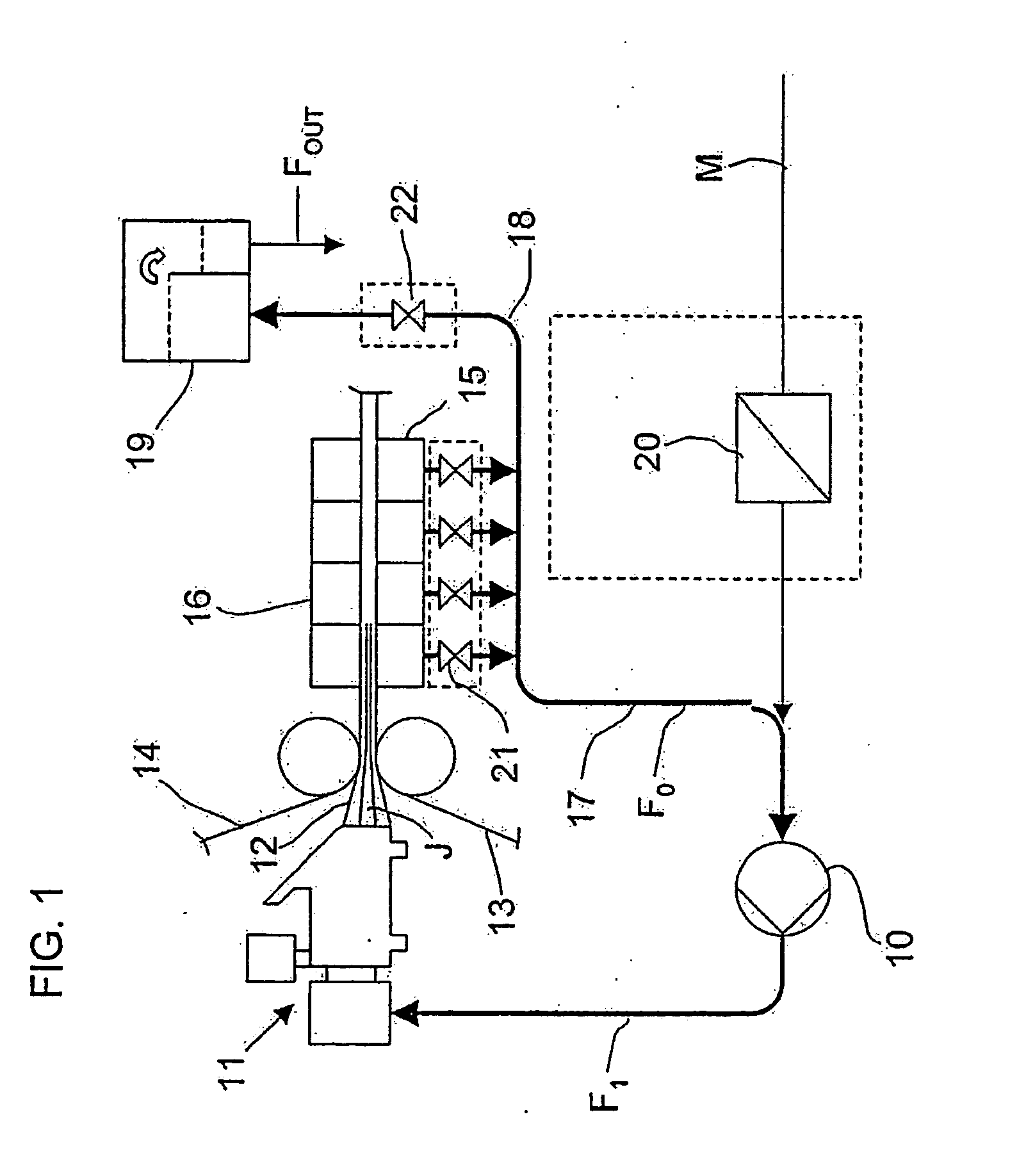

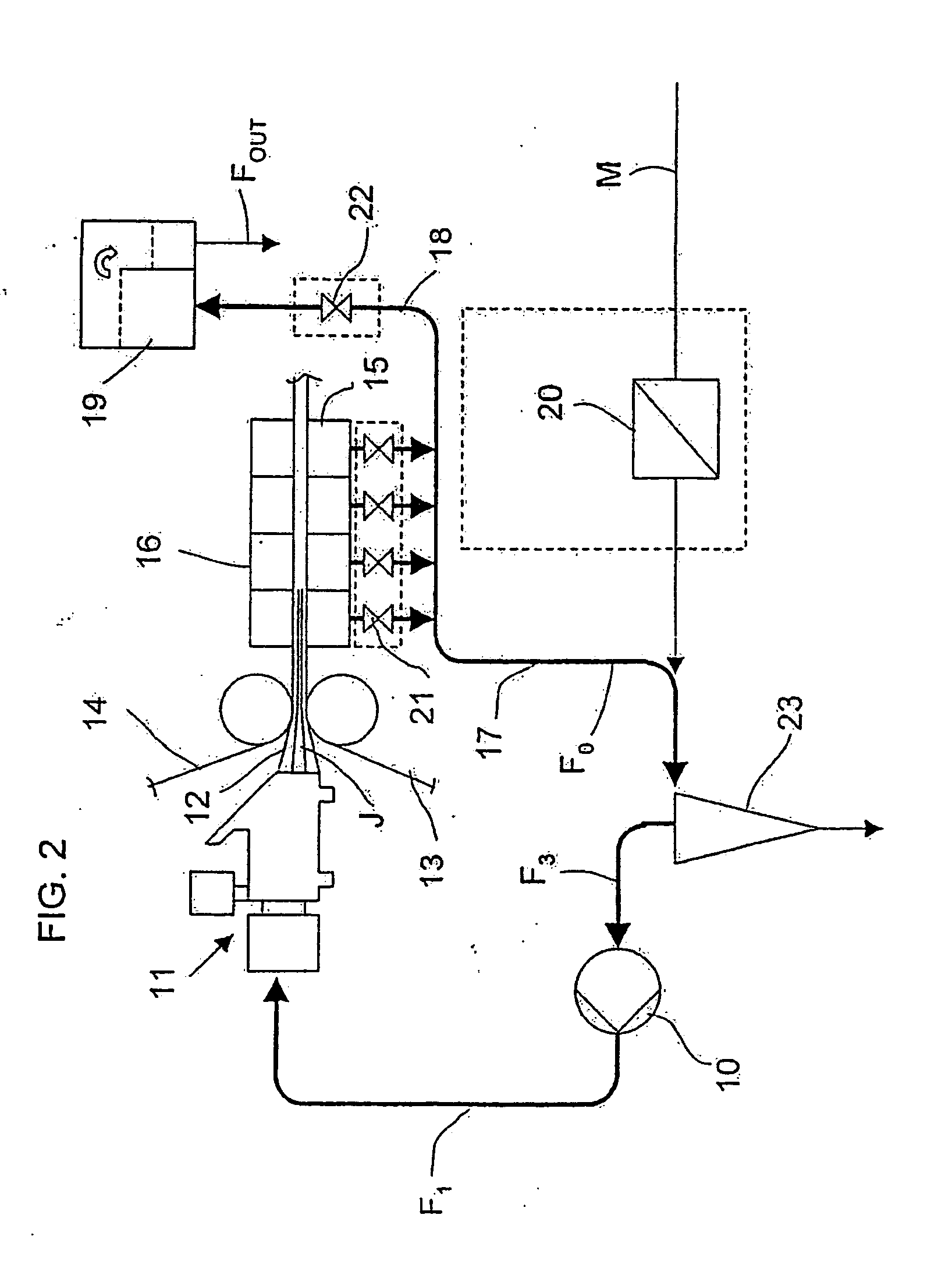

[0017]FIG. 1 shows a short circulation process arrangement for a closed former in which pulp suspension or wire water is not in contact with the ambient air at any stage. The parts of the process outlined with broken lines are not necessary in the process arrangement in accordance with the invention.

[0018] Thick stock M to be passed to a paper machine is conducted, possibly through a screening stage 20, so as to be mixed with wire water F0 flowing in a dilution duct 17 on the suction side of a feed pump 10. The dilution of the stock is accomplished as pipe dilution without a separate wire pit. The feed pump 10 pumps a diluted pulp suspension F1 into a headbox 11. A pulp suspension jet J is passed from the headbox 11 between walls 12 provided as continuations of a slice opening into a forming gap defined by two wires 13 and 14 such that between the headbox 11 and first dewatering boxes 15, 16 of a forming section the pulp suspension jet does not come into any contact with the ambien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com