Pipe crystallizer and continuous-casting and continuous-rolling pipe production line

A technology of continuous casting, continuous rolling and crystallizing, applied in metal rolling, metal rolling, metal rolling stands, etc., can solve problems such as energy waste, achieve investment economy, improve metal yield, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

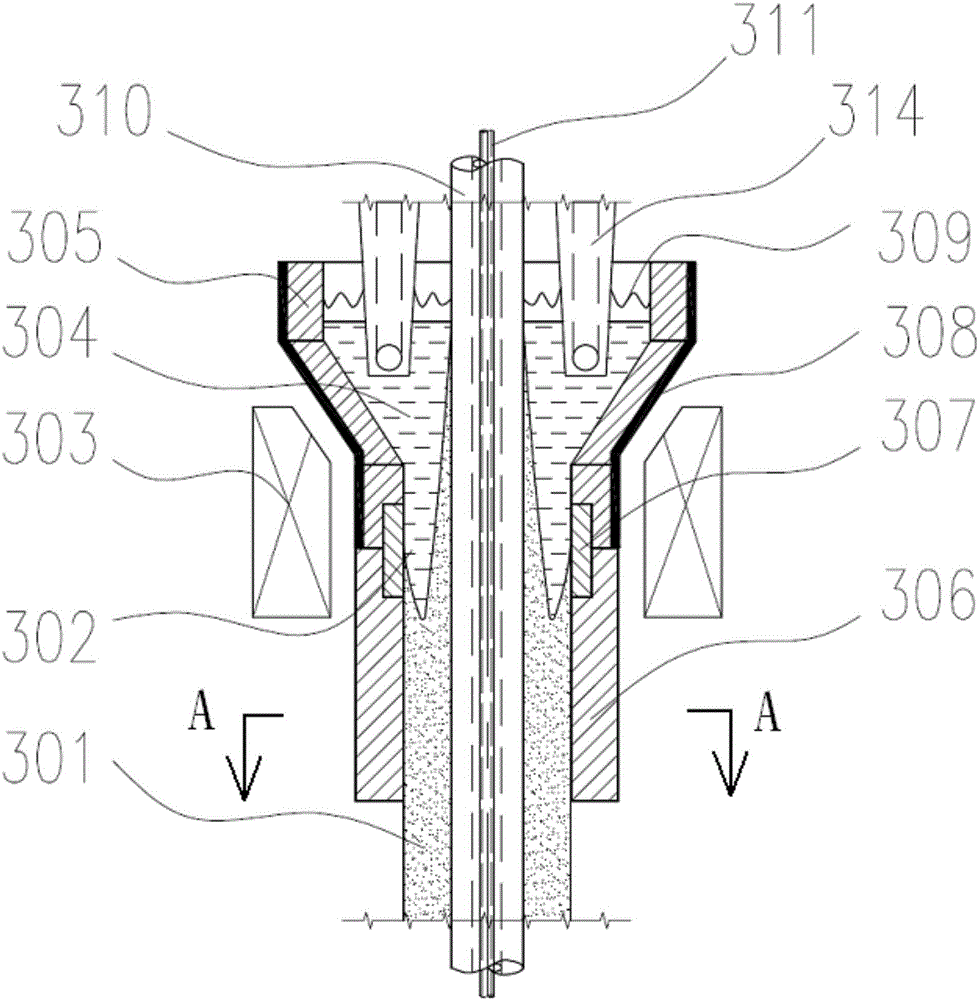

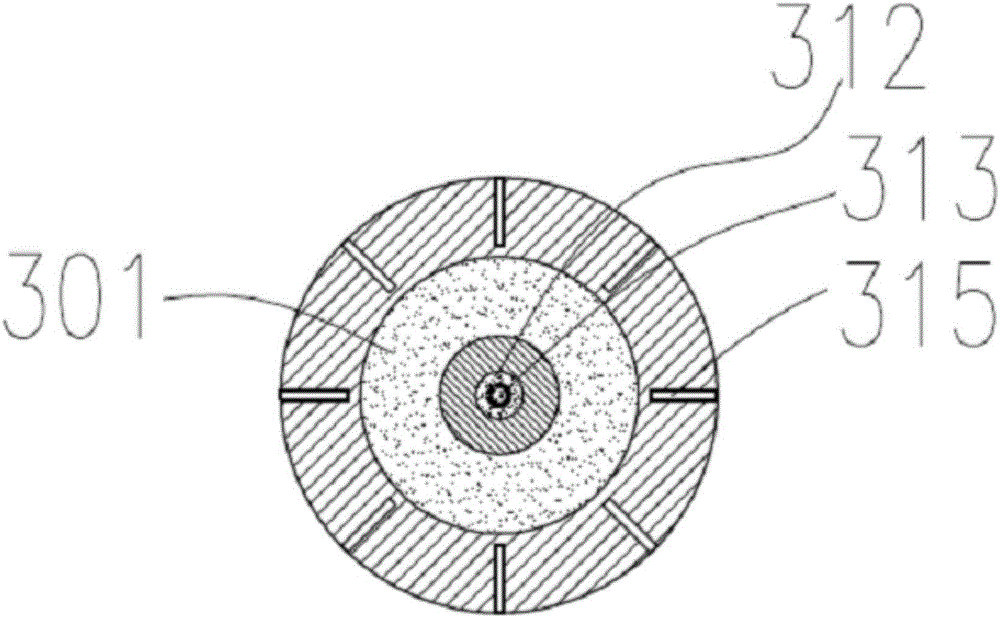

[0035] A pipe crystallizer, comprising an outer component 306 and an inner component 310 (which may be called an outer mold and an inner mold respectively), the outer component 306 is sleeved outside the inner component 310, and a lower end is formed between the outer component 306 and the inner component 310 An open annular cavity, the external assembly 306 contains an open hot top 305 and a lower cylinder correspondingly connected up and down, the open hot top 305 is funnel-shaped, and a graphite ring 307 is provided at the connection between the open hot top 305 and the lower cylinder , the graphite ring 307 is located on the inner surface of the external assembly 306, the open hot top 305 is provided with a metal shield 308, and the external assembly 306 is provided with an induction coil 303 (also called a magnetic field generator), which is used to conduct the molten metal 304 Electromagnetic stirring, such as figure 2 shown.

[0036] In this embodiment, the upper part...

Embodiment 2

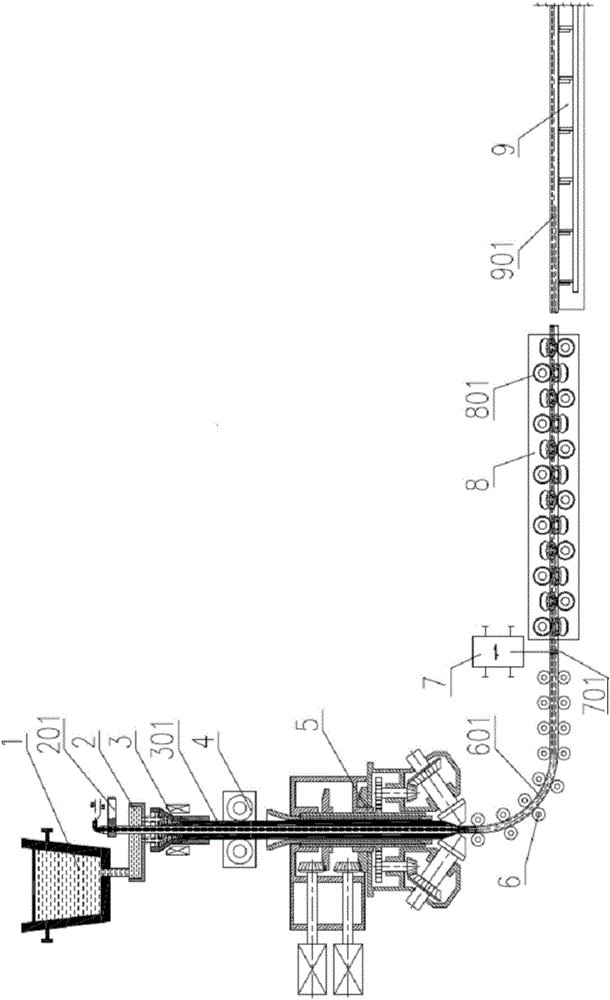

[0048] This embodiment is a preferred improvement to Embodiment 1. The continuous casting and rolling pipe production line includes a tundish 2, a crystallizer 3, and a pipe rolling mill 5 arranged sequentially from top to bottom. The mold 3 is the above-mentioned pipe crystallizer.

[0049] The continuous casting and rolling pipe production line also includes a steel ladle 1 arranged above the tundish 2, and a traction pinch roll 4 is arranged between the crystallizer 3 and the pipe rolling mill 5. The bending roller column 6, the sizing unit 8, the hot flying saw 7 and the cooling bed 9 below the pipe machine 5, such as Figure 6 shown.

[0050] After the hot flying saw 7 is moved to the sizing unit 8, the finished pipe after sizing is rapidly and synchronously sawed by the hot flying saw 7, and then enters the cooling bed 9, which eliminates the cutting of the steel pipe caused by the sizing process itself. Tail loss improves metal yield.

[0051] The rest of the technic...

Embodiment 3

[0053] This embodiment is a preferred improvement to Embodiment 1. The continuous casting and rolling pipe production line includes a tundish 2, a crystallizer 3, and a pipe rolling mill 5 arranged sequentially from top to bottom. The mold 3 is the above-mentioned pipe crystallizer.

[0054] The continuous casting and rolling pipe production line also includes a steel ladle 1 arranged above the tundish 2, and a traction pinch roll 4 is arranged between the crystallizer 3 and the pipe rolling mill 5. The guide roller 10 below the pipe machine 5, the hot flying saw 7, the turning disk 102, the sizing unit 8 and the cooling bed 9, the turning disk 102 can turn the waste pipe section 101 from the upright state to the horizontal state, as Figure 7 shown.

[0055] After the hot flying saw 7 is moved to the pipe rolling mill 5, and guide rollers 10 are added in between, the waste pipe section 101 sawn off by the hot flying saw 7 is clamped by the clamping roller 103 on the turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com