Motor rotor

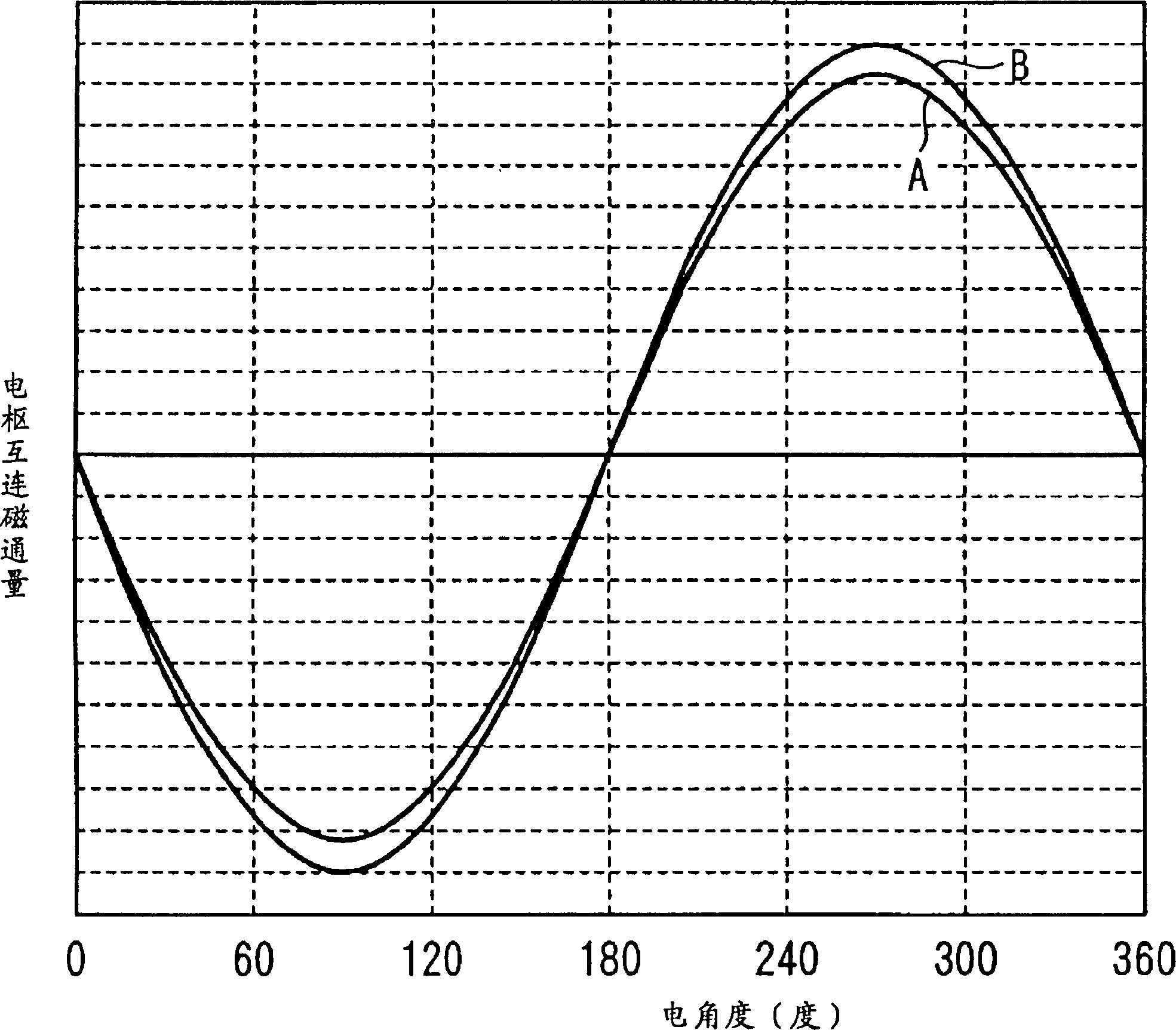

A technology of electric motors and synchronous motors, which is applied to electric components, synchronous motors with stationary armatures and rotating magnets, electrical components, etc., can solve problems such as noise, rotor vibration, and large torque changes, and achieve increased magnetic flux and improved Changes in torque and the effect of improving magnet torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

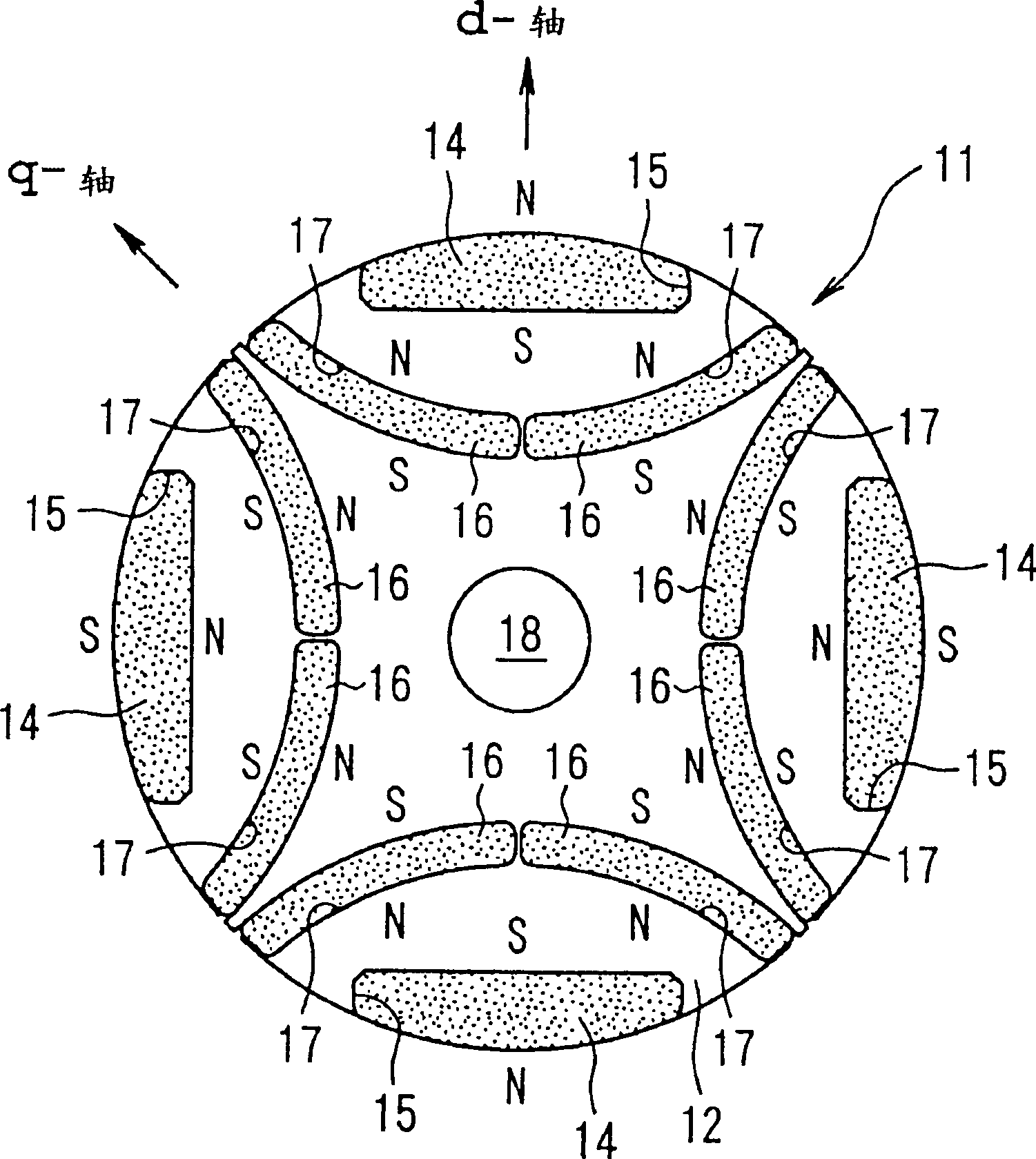

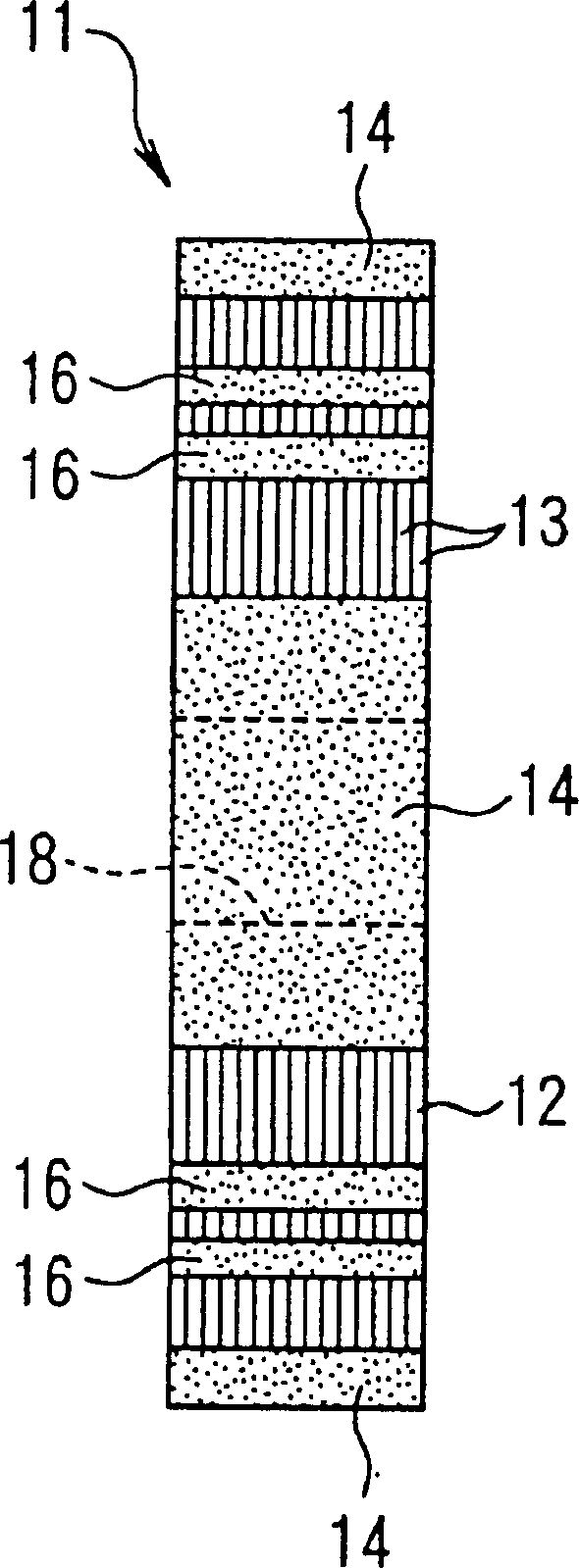

[0035] The structure of a first embodiment of the motor rotor of the present invention will be described below with reference to FIG. 1. FIG.

[0036] The rotor of the first embodiment is used in a permanent magnet type synchronous motor, and adopts a matching relationship with a known stator (not shown) of a permanent magnet type synchronous motor.

[0037] As shown in FIG. 1, the rotor 11 comprises a ferromagnetic core 12, which is a laminated steel plate block 13, made, for example, of silicon steel plates of a certain thickness. A certain number of permanent magnets 14 (for example, four pieces) are installed on the outer surface of the core 12 at certain intervals along the circumferential direction.

[0038] More specifically, four notches 15 are circumferentially provided on the outer surface of the core 12, and the permanent magnets 14 are firmly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com