Heated flexible tank for shipping viscous liquid

A technology for thermal insulation pads and heating fluids, applied in liquid distribution, transportation or transfer devices, packaging, distribution devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

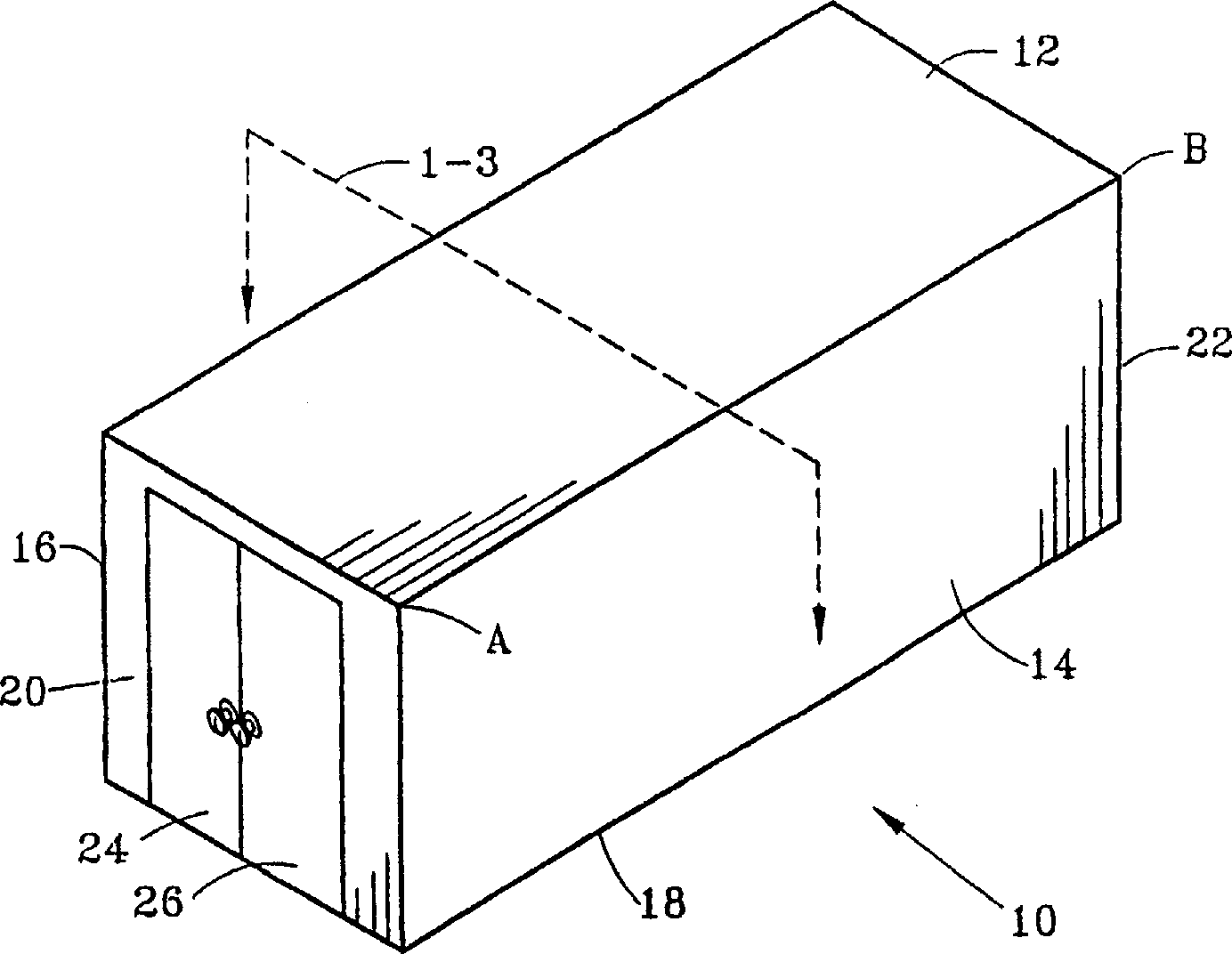

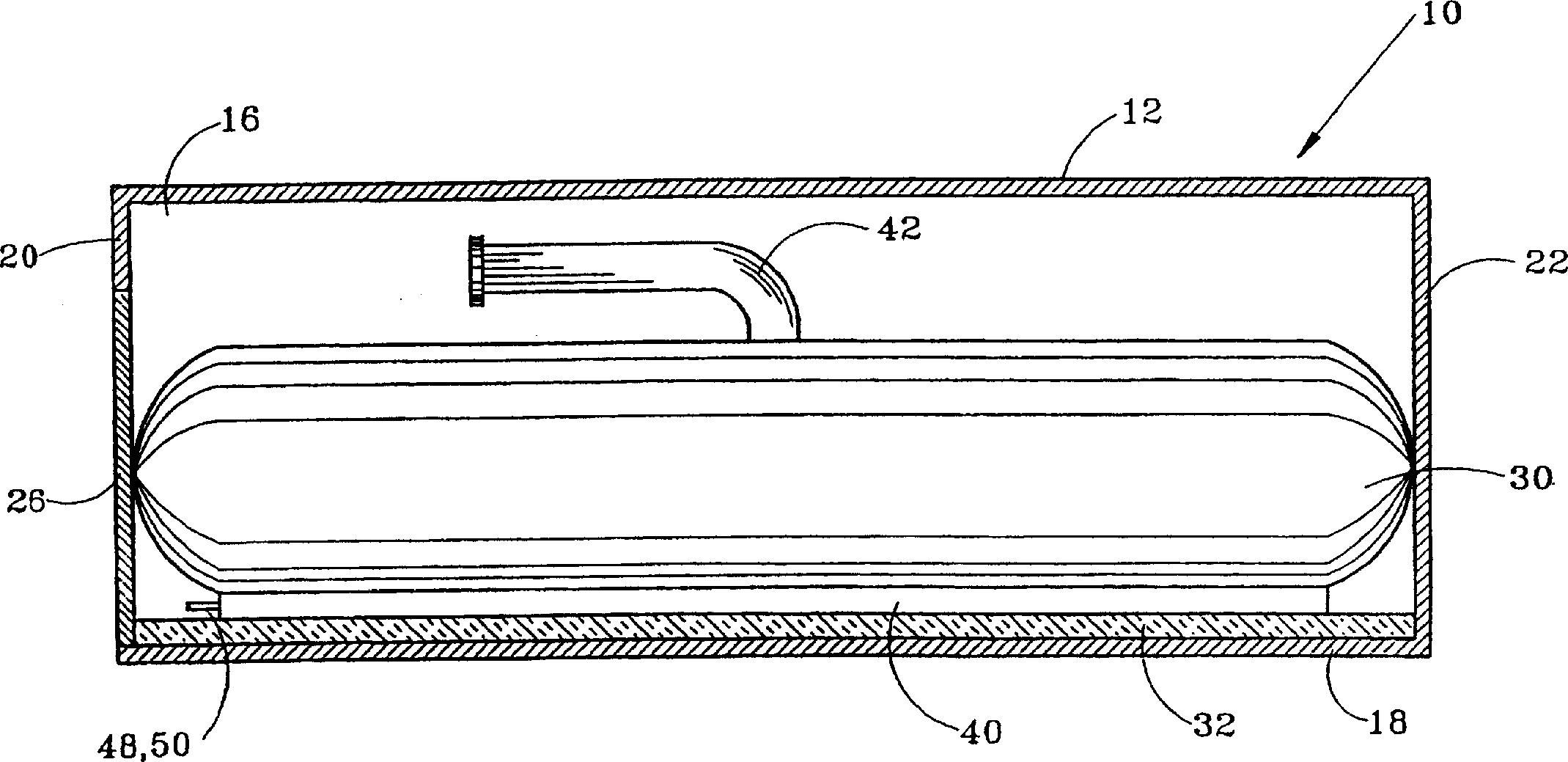

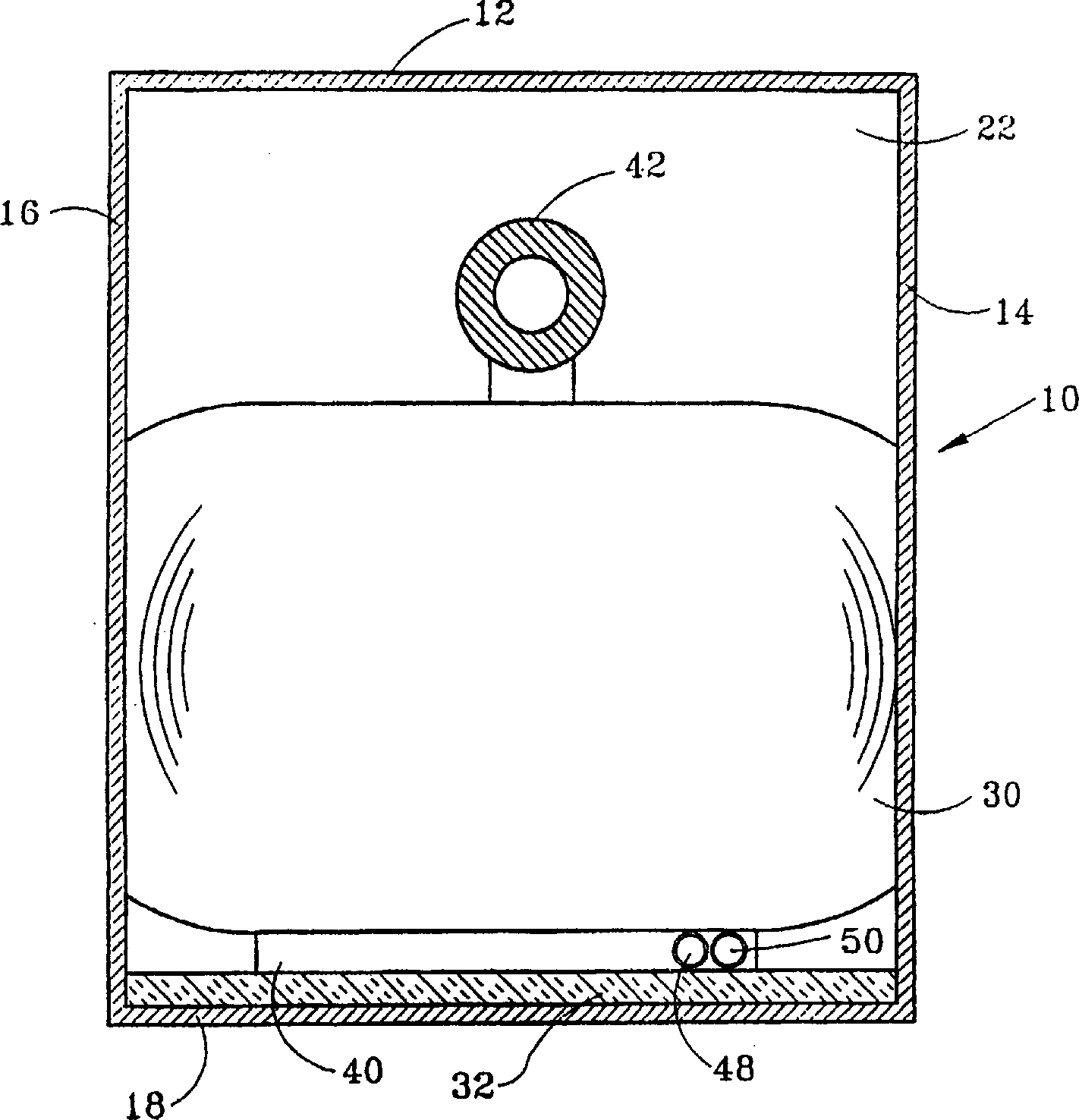

[0034] A standard 20-foot long shipping container is equipped with a stable K-factor of 0.14 Btu-in / ft on the floor, sides and ends 2 (BTU-inch / ft 2 ) of two-inch thick isocyanurate foam insulation (with aluminum foil on both sides). The 25 psi insulation compressive strength allows the installer to walk on the insulation without damaging it. The top of the loaded flexible tank was covered with a two inch thick layer of Fiberglass (fiberglass) felt. The average ambient temperature is 55°F.

[0035] Heating mats were installed on the floor insulation and a 23,000 liter R tank was installed on the heating mats. The heating pad does not interfere with the installation of the flex tank. It took two people 45 minutes to insulate and install.

[0036] The flexible tank was filled with 4000 gallons of water at 60°F and the tank was heated to 80°F using a standard domestic water heater. This proved ineffective, and then 50psi / 230°F low pressure steam was used to heat the hose. ...

Embodiment 2

[0042] The second set started with test water at 65°F and direct steam at 25 psi pressure. There was no insulation on the top of the flexible tank, but bottom and side insulation was installed in the container as before. The average ambient temperature is 60°F. During the first 24 hours the temperature rose to 101°F and over the next 24 hours the temperature rose to 122°F.

[0043] The flex tank is emptied. Observations indicated that little wear or tear occurred.

[0044] The test flexible tank and heating pad were refilled in the container and a third set of tests began.

Embodiment 3

[0046] The third set started with test water at 65°F and direct steam at 25 psi pressure. There is no insulation on the top of the flexible tank, but bottom and side insulation is installed in the container as before. The average ambient temperature is 65°F. During the first 24 hours, the temperature of the test water rose to 101°F. And over the next 24 hours, its temperature rose to 122°F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com