Embossed film and security document

A technology for security documents and films, applied in the field of embossed films, can solve the problems of unsatisfactory color changes of visually variable materials, unsatisfactory anti-counterfeiting items or document anti-counterfeiting requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

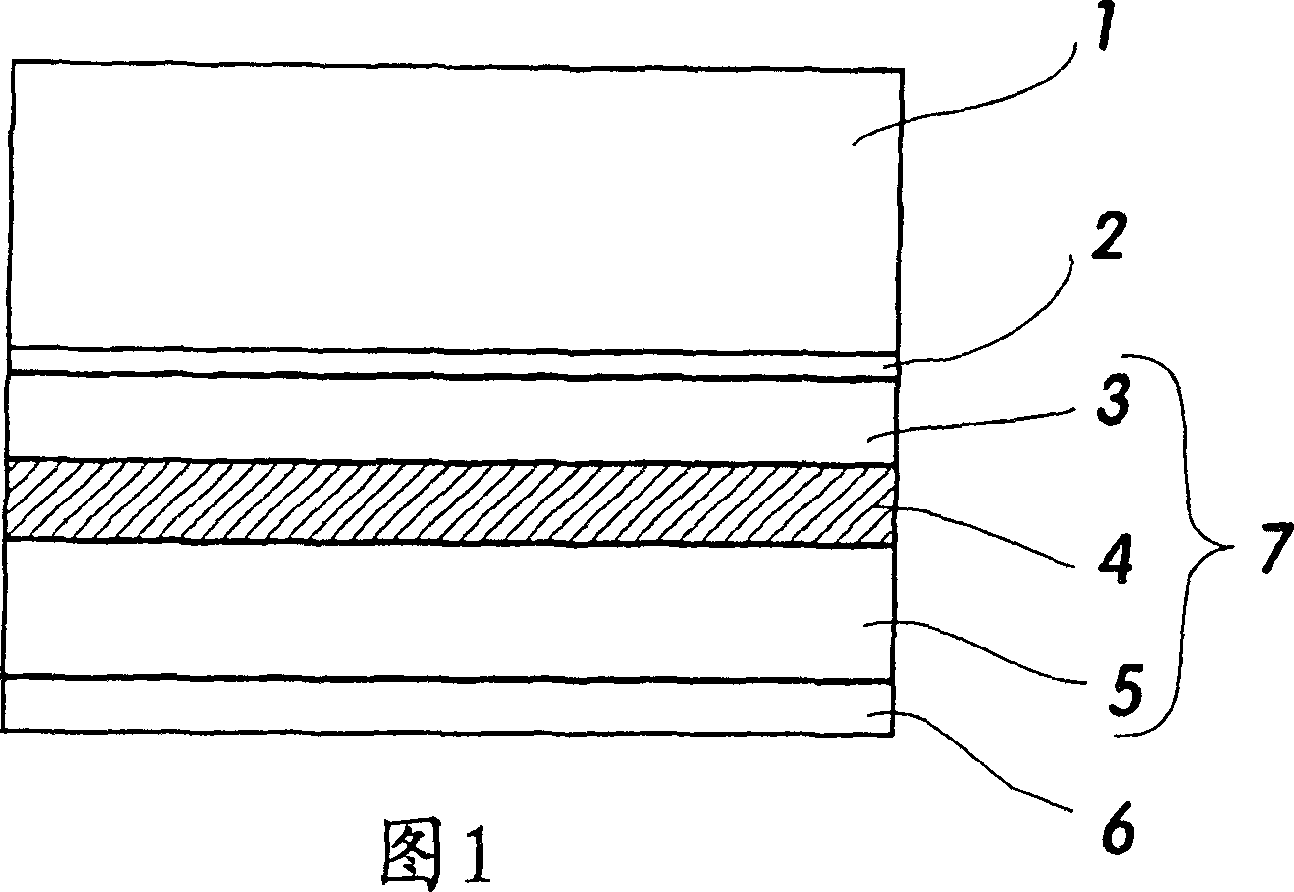

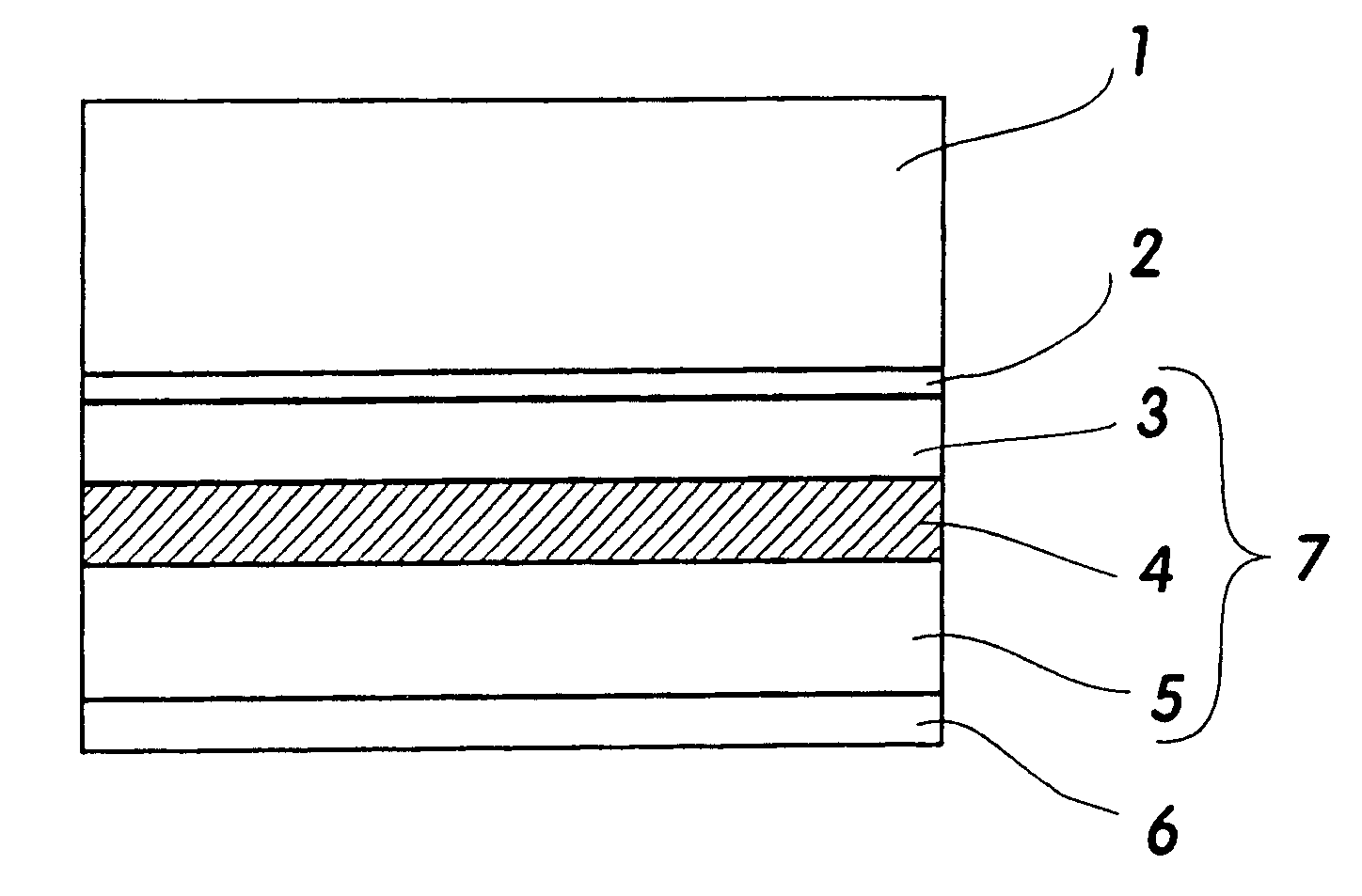

[0060] FIG. 1 shows a heat press film having a structure consisting of a base film 1 , a release layer 2 , a protective layer 3 , a color layer 4 , a magnetizable layer 5 and an adhesive layer 6 .

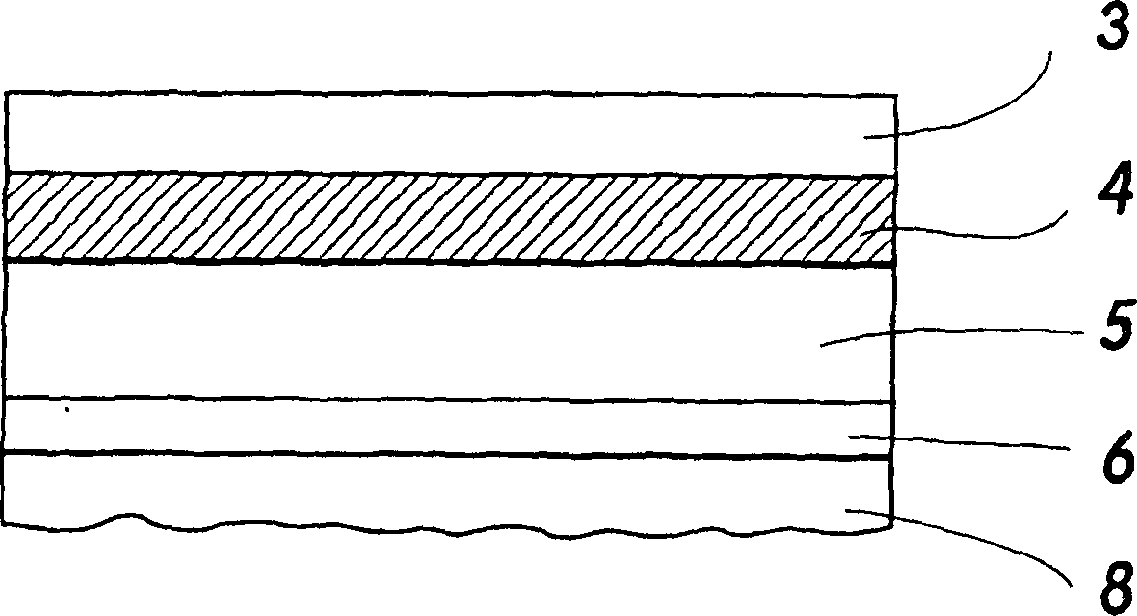

[0061] figure 2 A security document 8 is shown, which, starting from the security document 8 , is provided with a layered structure consisting of an adhesive layer 6 , a magnetizable layer 5 , a colored layer 4 and a protective layer 3 .

[0062] The film thicknesses or layer thicknesses given below are not limited to the examples given, but generally applicable.

[0063] thin film structure

[0064] - Base film 1: film thickness 12-26 μm, preferably 19-23 μm; material: polyester, preferably polyethylene terephthalate;

[0065] - Peeling layer or separation layer 2: common wax layer when embossing the film, layer thickness: at most about 1 μm;

[0066] - protective layer 3 (protective paint): layer thickness 1-5 μm, preferably 1-3 μm;

[0067] - Chromatic layer 4: Layer thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com