Energy-saving and highly effective ice-making plant

A technology of refrigerant tubes and evaporators, applied in ice making, ice making, ice storage/distribution, etc., can solve the problems of increasing the earth’s heat load, wasting energy, and slow deicing, so as to prolong the service life and improve deicing Ice velocity, heat load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the specific embodiments given in the accompanying drawings, but the content of the present invention is not limited thereto.

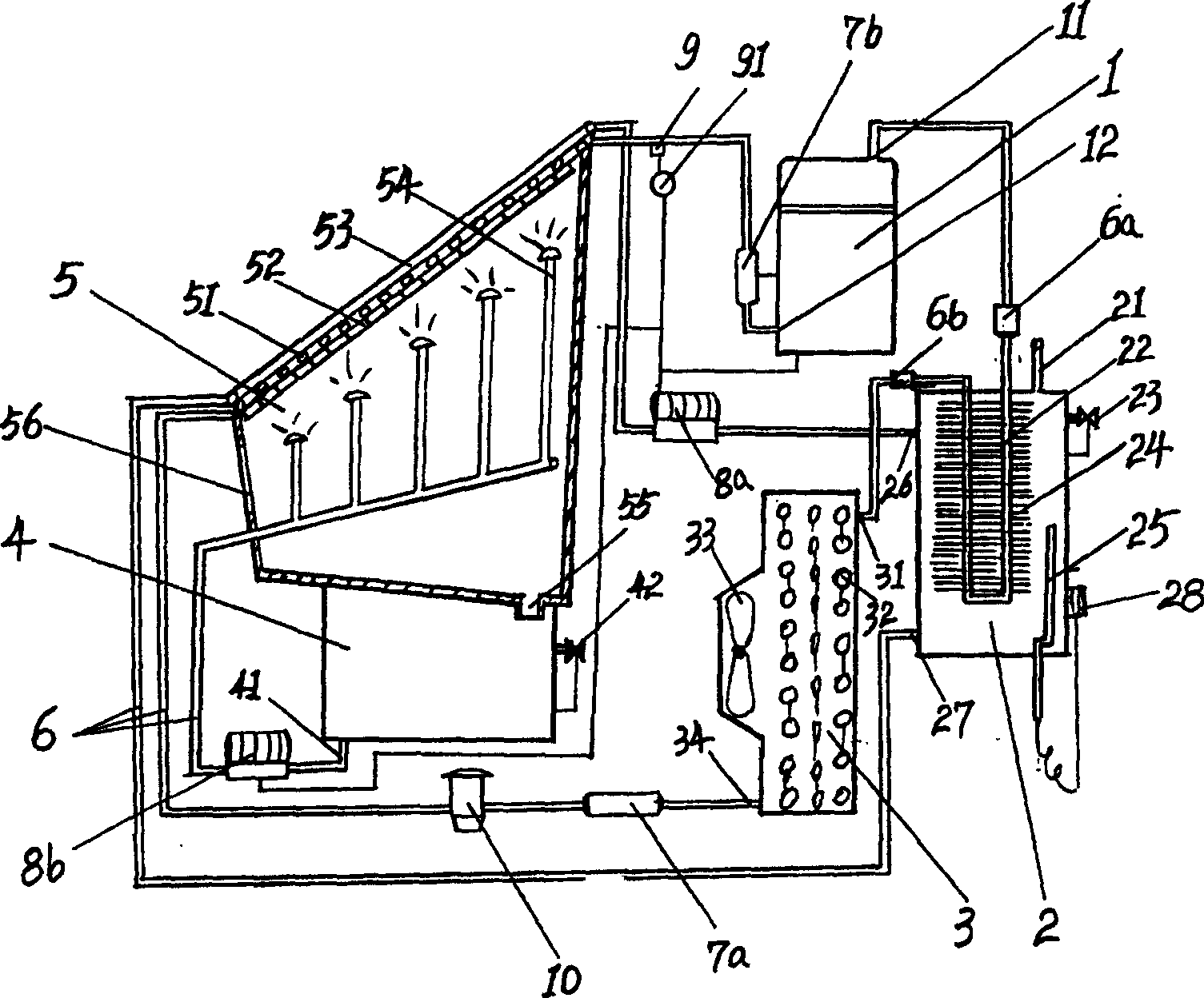

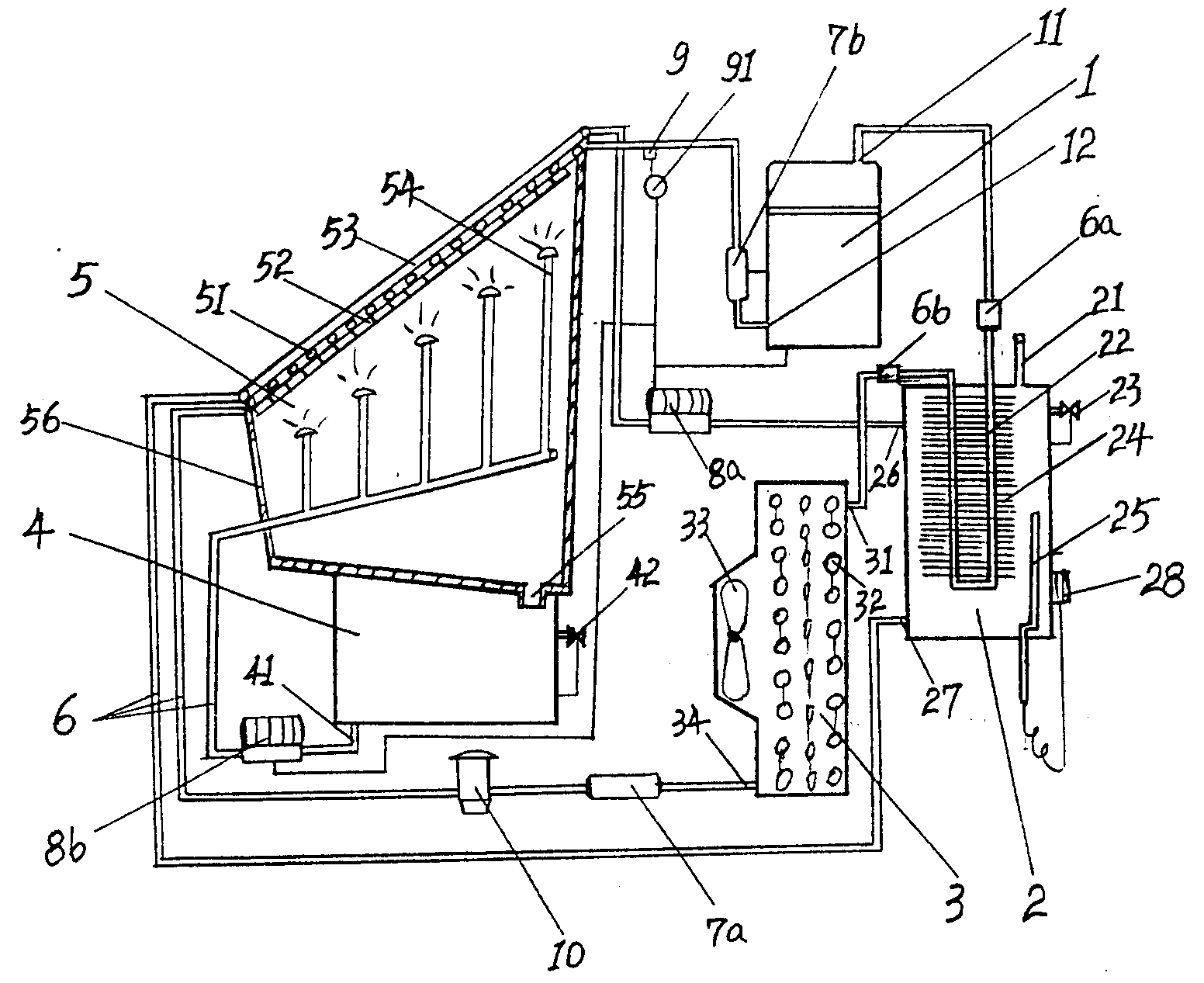

[0011] With reference to Fig. 1, the present invention mainly comprises compressor 1, heating water tank 2, air-cooled condenser 3, water storage tank 4, evaporator 5 and the conduit 6 that connects them. The high-pressure discharge port 11 of the compressor 1 is connected to one end of the refrigerant U-shaped pipe 22 through the conduit 6 through the pipe joint 6a. The refrigerant U-shaped pipe 22 is placed in the heating water tank 2, and the outer wall of the pipe is provided with cooling fins 24 arranged horizontally. To improve heat dissipation efficiency, the other end of the U-shaped pipe 22 is connected to the inlet 31 of the air-cooled condenser 3 through the pipe joint 6b and the conduit 6, and the outlet 34 of the air-cooled condenser 3 is connected to the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com