Anhydrous calcium chloride flue gas waste heat reusing and whiten-eliminating system

An anhydrous calcium chloride, flue gas waste heat technology, applied in the field of flue gas whitening, can solve the problems of visual pollution, a lot of white smoke, whitening technology and requirements lag, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

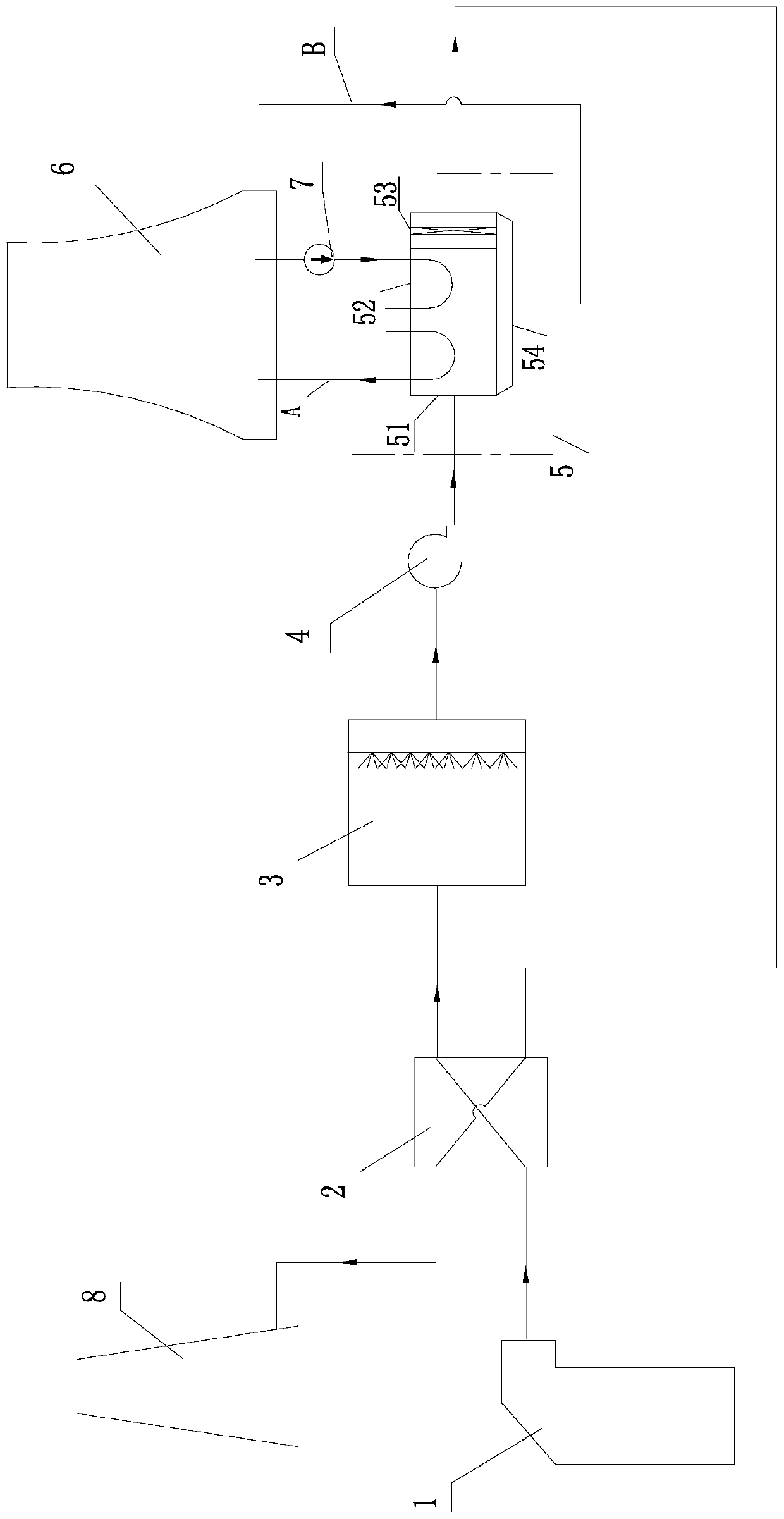

[0021] refer to figure 1 , an anhydrous calcium chloride flue gas waste heat recovery and whitening system of the present invention, comprising a boiling granulation tower 1, a GGH heat exchanger 2, a flue spray system 3, an induced draft fan 4, and a flue gas cooling and condensing system 5 , mechanical ventilation cooling tower 6, cooling water pump 7 and chimney 8, described flue gas cooling condensing system 5 is connected with mechanical ventilation cooling tower 6, cooling water pump 7 to form a cold cycle, described boiling granulation tower 1, GGH heat exchange Device 2, flue spraying system 3, induced draft fan 4, flue gas cooling and condensing system 5 are arranged in sequence along the flue gas treatment direction, the outlet of the boiling prilling tower 1 is connected with the GGH heat exchanger 2, and the flue spraying The inlet of the shower system 3 is connected to the GGH heat exchanger 2, the outlet of the flue gas cooling and condensing system 5 is connecte...

Embodiment 2

[0024] refer to figure 1 , this embodiment is on the basis of embodiment 1, with the heat pump system or floor heating system instead of mechanical ventilation cooling tower 6, to further recover the low-temperature waste heat of the circulating cooling water in the flue gas cooling and condensing system 5, which not only reduces the energy consumption of the system , but also to ensure the heating demand of the plant.

[0025] Working process of the present invention:

[0026] The working principle of an anhydrous calcium chloride flue gas waste heat recovery and whitening system of the present invention is as follows: Taking an anhydrous calcium chloride unit of an electrochemical plant as an example, the original flue gas discharged from the boiling granulation tower, the flue gas temperature At about 150°C, first introduce the GGH heat exchanger 2 to exchange heat with the condensed clean flue gas, once cool down to 100-120°C, then introduce the flue spray system 3 to exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com