Paper separation friction pad

A friction pad and paper technology, applied in the field of friction pads, can solve the problems of high operating power and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

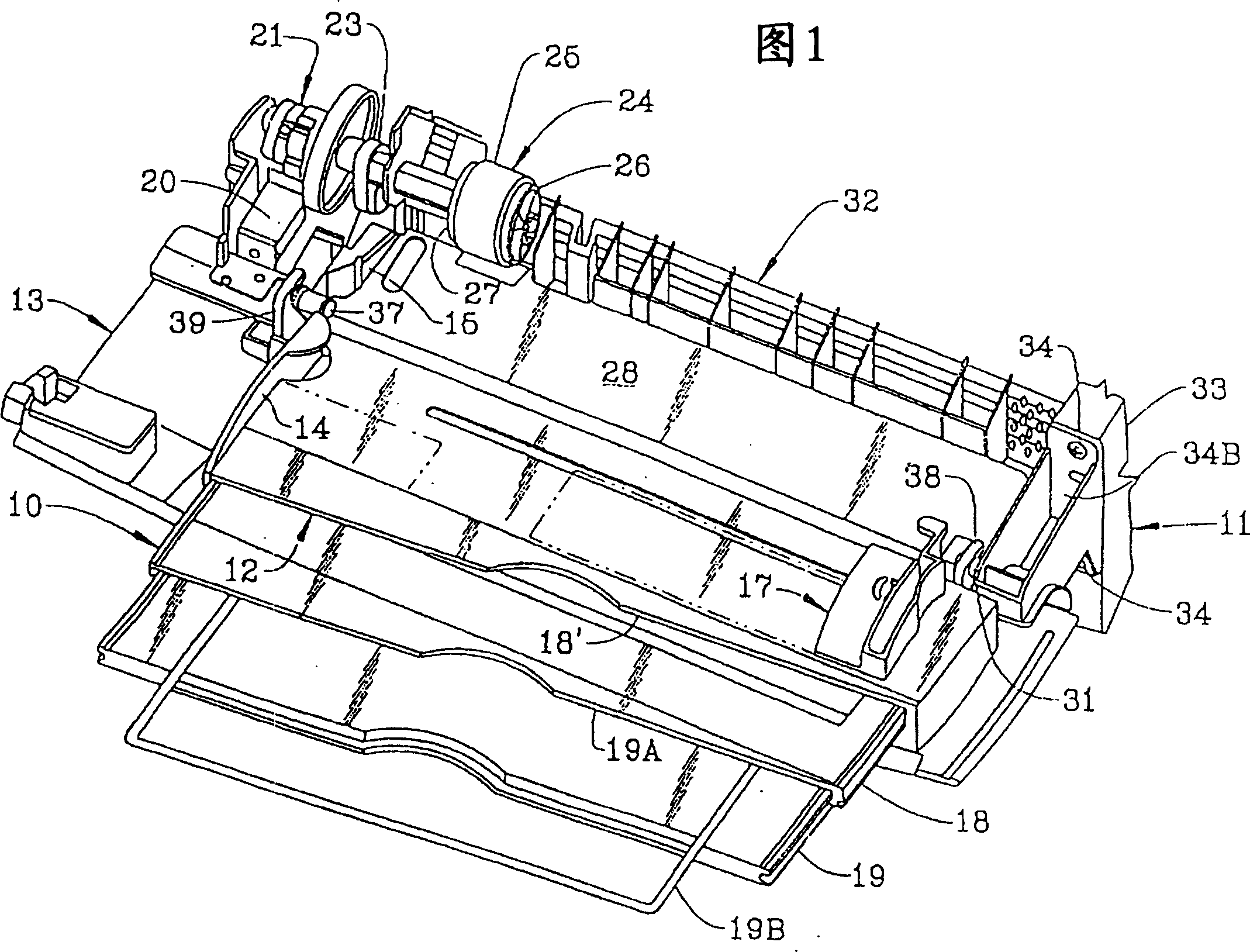

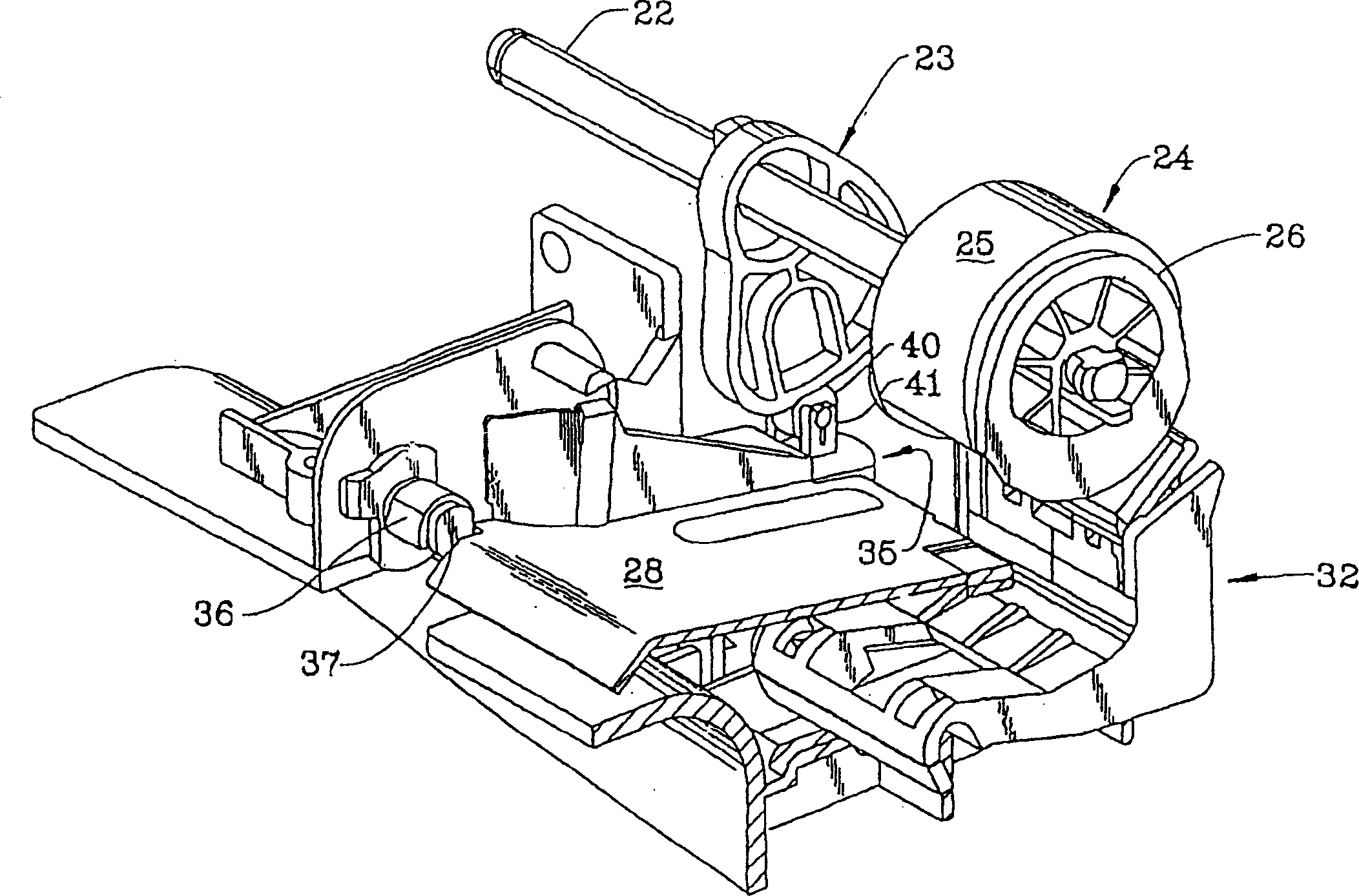

[0031] Referring to the Figures and in particular to Figure 1, there is shown a paper feeding device 10 of a printer 11. Paper feeder 10 includes a tray assembly 12 mounted on a swingably mounted door 13 of printer 11 .

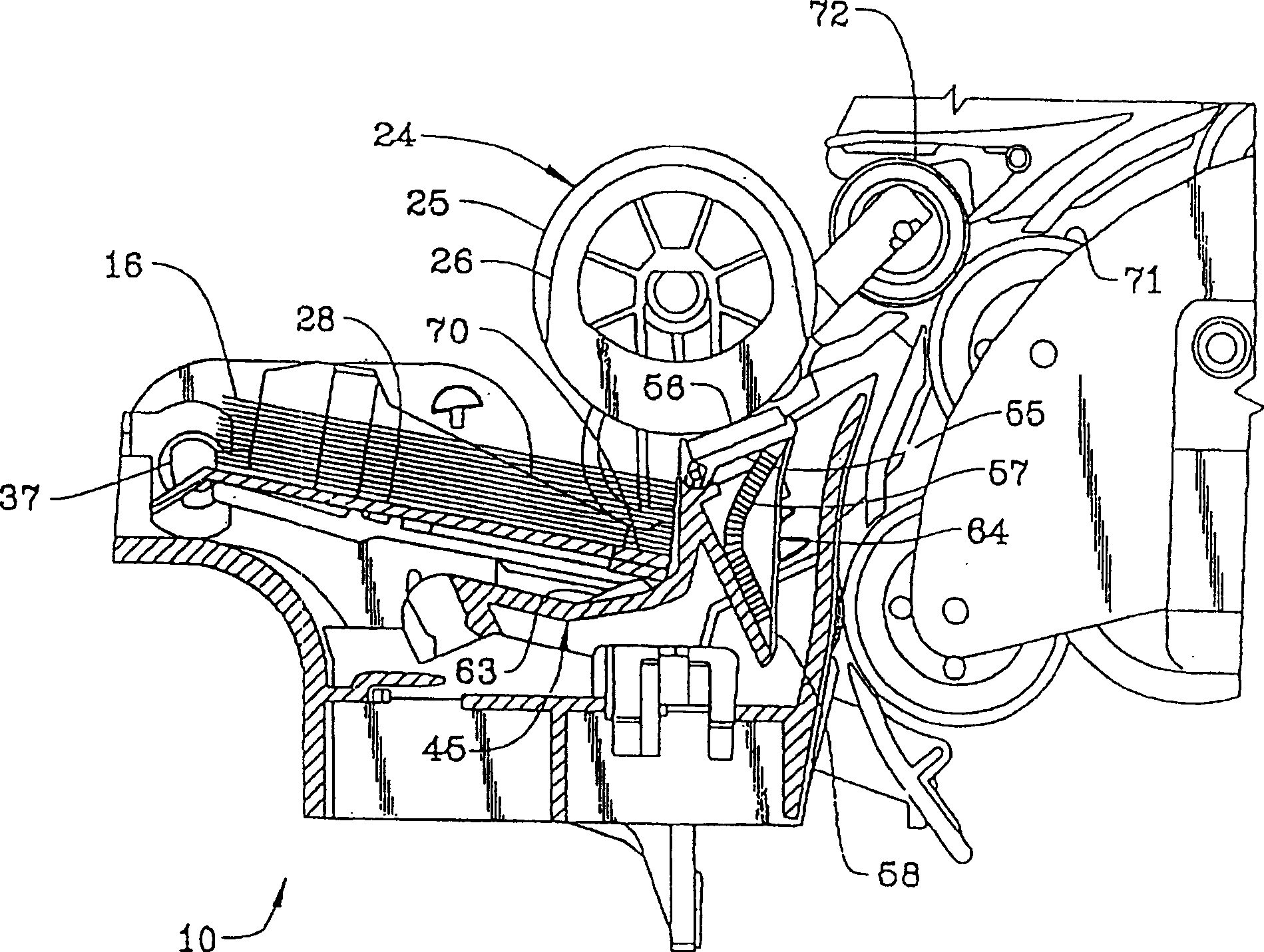

[0032] Tray assembly 12 has datum edge 14 and 15, and each media (16) is as paper (see image 3 )'s left edge rests on it as it advances. When sheets or stacks are placed in the tray assembly 12 (see Fig. 1), - a movable paper guide 17 (see Fig. 1) engages the right edge of each sheet 16 (see image 3 ). Thus, the paper feeder 10 employs an edge alignment system to align a stack of paper 16 (see image 3 ) into the printer (see Figure 1).

[0033] The tray assembly 12 includes a first slider 18 slidable in an opening 18 ′ and a second slider 19 slidable in an opening 19A in the first slider 18 . A wire 19B is fixed on the second slider 19 to pull it out from the first slider 18 until the stopper (not shown) in the second slider 19 and the stopper on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com