Feeding mechanism and spinning device

A technology of feeding mechanism and raw material box, applied in the field of spinning processing, can solve the problem of labor and other problems, and achieve the effect of reducing manual participation and avoiding excessive fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention are specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention, and are not intended to limit the scope of the present invention.

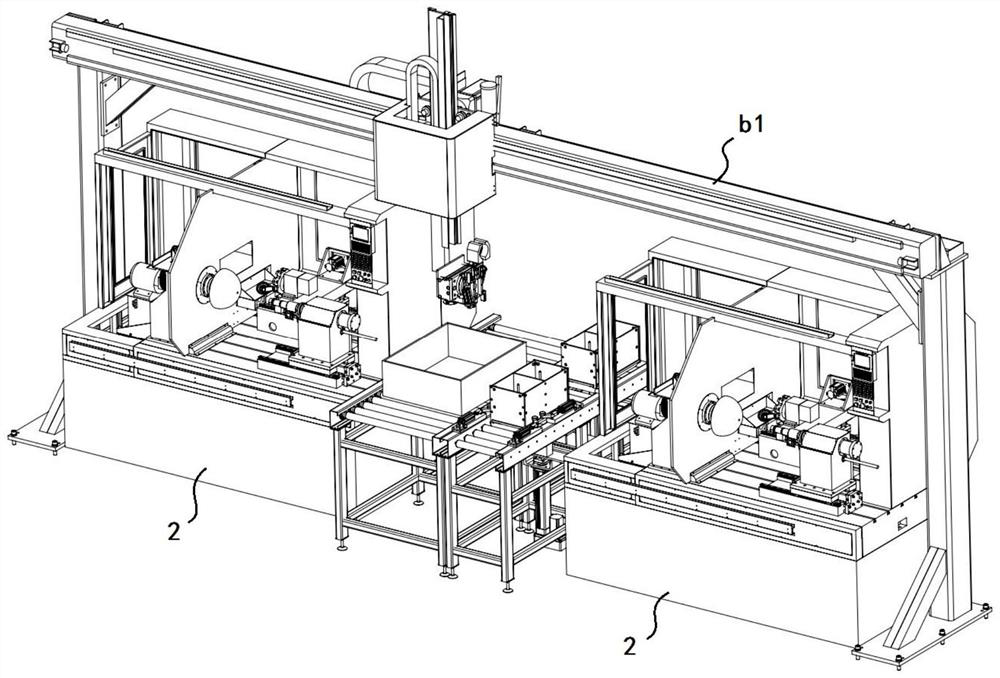

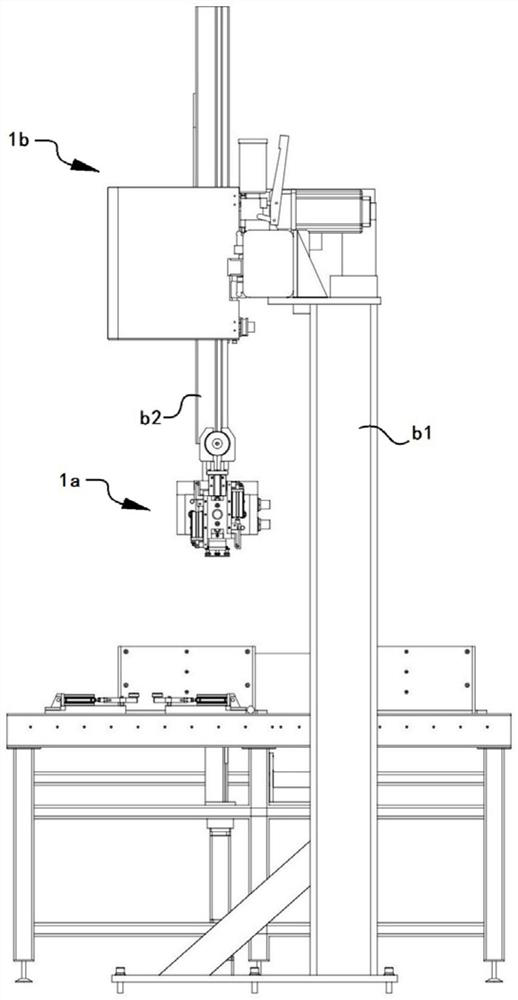

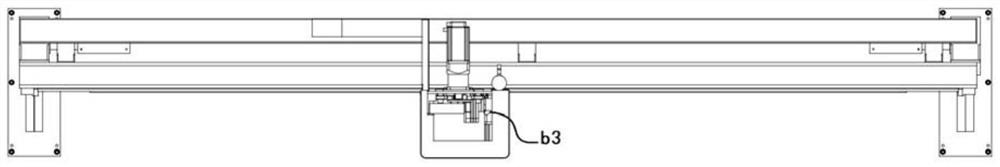

[0038] The invention provides a spinning device, such as Figures 1 to 19 As shown, it includes a feeding mechanism 1 and two spinning machines 2. The feeding mechanism 1 includes a clamping assembly 1a, a moving assembly 1b and a raw material conveying assembly 1c. The clamping assembly 1a includes a connecting seat a1, a suction cup a2, and a clamping piece a3 , the first rotating part a4, the first driving part a5 and the second driving part a6, the output end of the first rotating part a4 is connected to the connecting seat a1 for driving the connecting seat a1 to rotate, the suction cup p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com