Electric control energy saving device for oil pump unit

An energy-saving device, electromechanical technology, applied in the direction of AC motor control, energy industry, electrical components, etc., can solve problems such as power grid impact, external equipment interference, etc., and achieve the effect of filtering harmonic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

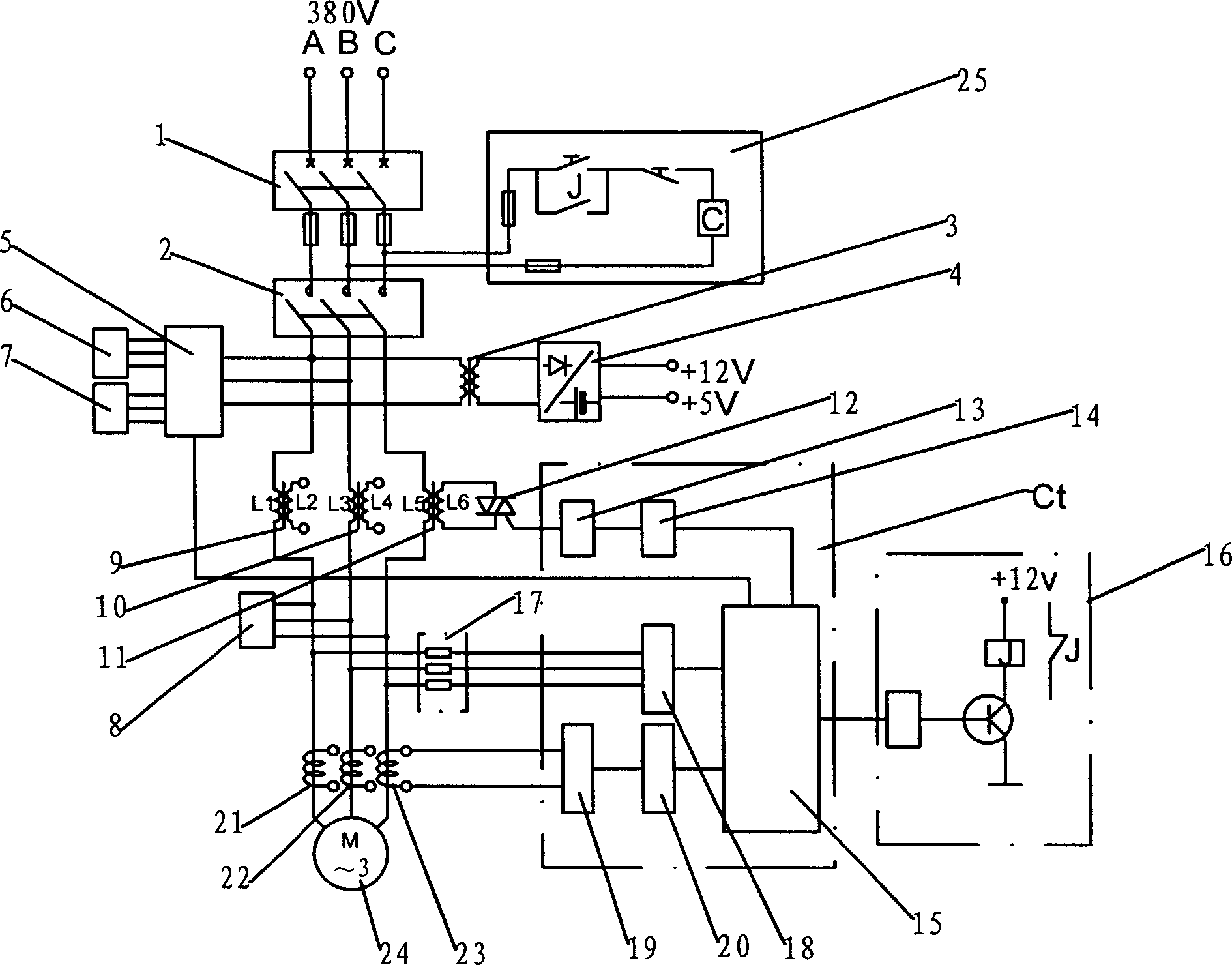

[0023] see figure 1 The electric control energy-saving device of the motor of the pumping unit shown in the present invention includes: a group of three-phase (380 volts alternating current) air switch 1, which is used to cut off the internal circuit of the external power supply and the electric control energy-saving device of the motor of the pumping unit The connection between them can also be used as a short circuit or extreme overcurrent protection element; a group of relays 2 are connected to the downstream end of the air switch 1, and when a phase loss or overcurrent condition occurs, the output of the controller Ct Under signal control, the relay 2 disconnects the main circuit to protect the pumping unit motor 24 connected to the main circuit; a group of variable step-down inductors 9, 10, 11 are respectively composed of the main circuit inductance coils L1, L3, L5 and auxiliary inductance coil L2, L4, L6 constitute, and its described main loop inductance coil L1, L3, L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com