Automobile indoor rear-viewing mirror

A technology for interior rearview mirrors and compartments, applied to vehicle components, transportation and packaging, optical observation devices, etc., can solve the problems of increasing the number of fixing parts, increasing the number of double-sided tapes, increasing the manufacturing process, etc., to reduce the number of parts , Prevent theft, and reduce the effect of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

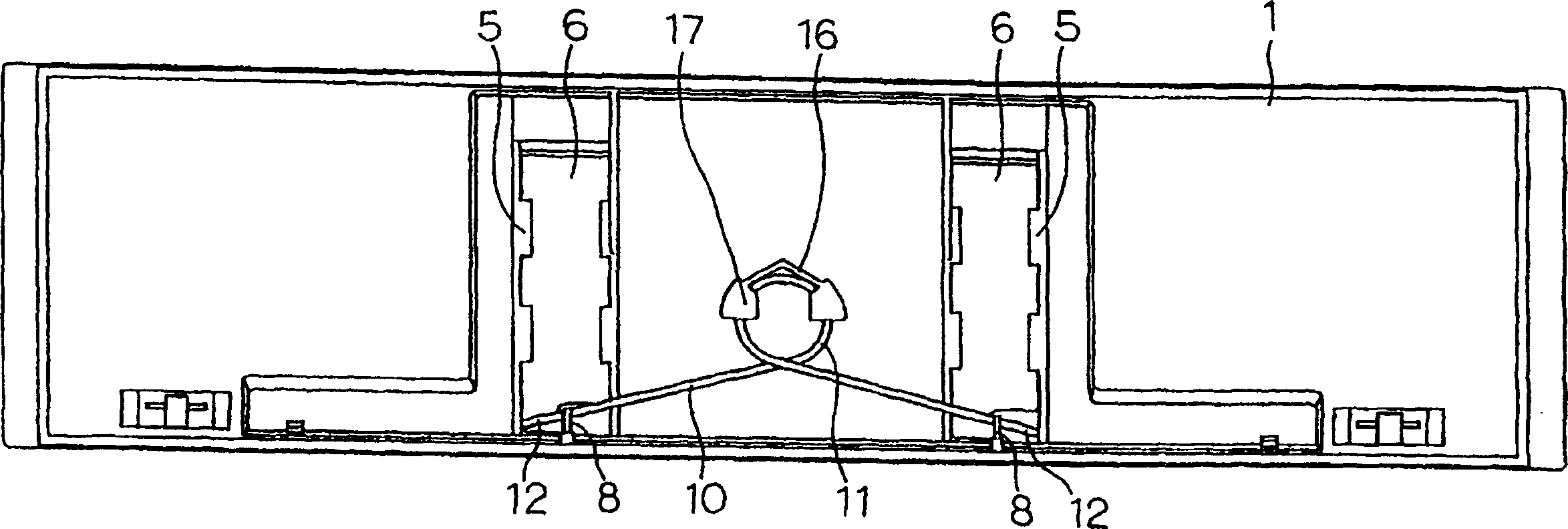

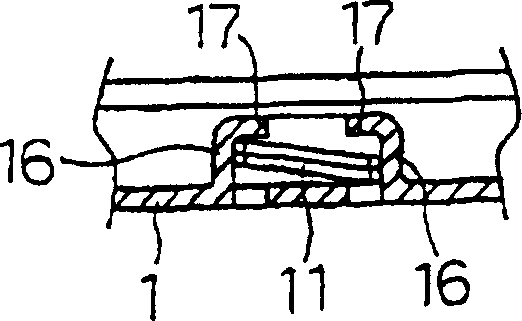

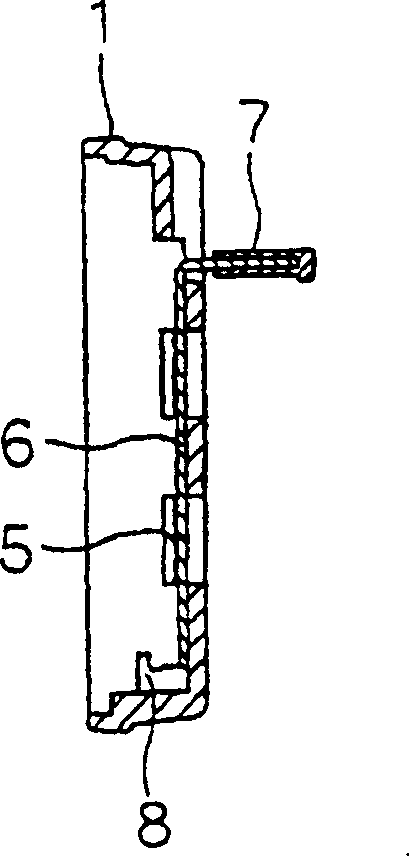

[0035] Embodiments of the present invention will be described below with reference to the drawings.

[0036] In the present invention, as Figure 1 ~ Figure 4 As shown, a pair of left and right abutment portions or abutment walls 16, 16 abutting against the outer peripheral surface of the annular portion 11 of the spring 10 are provided, and the front ends of the abutment walls 16 protrude radially inwardly, and The protruding portion 9 is provided at the front central portion of the rearview mirror body 1 of the vehicle interior instead of the flange portion 17 that covers a part of the end surface of the annular portion 11 to prevent the annular portion from falling out.

[0037] The automotive interior rearview mirror for rear installation of the present invention adopts the above-mentioned structure, so when it is assembled, if the end surface of the ring-shaped part 11 of the spring 10 passes through the flange part 17 that prevents the ring-shaped part from coming out T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com