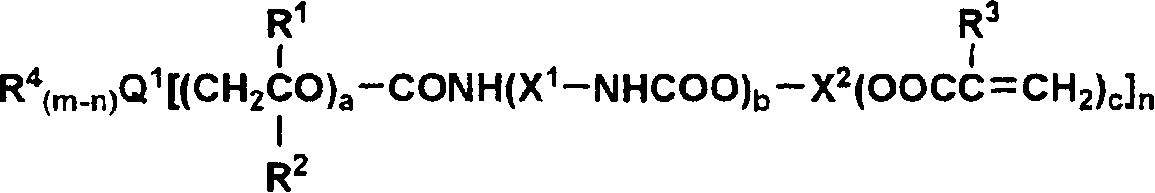

Photosensitive composition and photosenpsitive lithographic printing plate

A photosensitive composition and the technology of the composition are applied in the direction of polyhalogenated compound composition, optics, photographic plate-making process of pattern surface, etc., and can solve problems such as inability to achieve plate life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

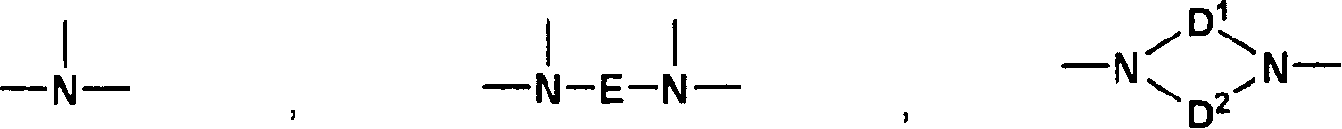

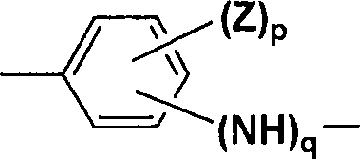

Method used

Image

Examples

Embodiment 1

[0267] Polymer Binder: Synthesis of Acryl Copolymer 1

[0268] Add 30 parts of methacrylic acid, 50 parts of methyl methacrylate, 20 parts of ethyl methacrylate, 500 parts of isopropanol and 3 parts of α, α'-azobisisobutyronitrile (α , α'-azobisisobutylonitrile) and reacted at 800 °C for 6 hours in a poi bath under nitrogen flow. The reaction mixture was then heated at reflux for 1 hour at the boiling point of isopropanol. And then 3 parts of trimethylammonium chloride and 25 parts of glycidyl methacrylate were added thereto and reacted for 3 hours to obtain an acryl copolymer 1 . The weight average molecular weight measured in GPC was about 35,000 and the glass transition temperature (Tg) measured in DSC (differential thermal analysis) was about 85°C.

[0269] Preparation of photosensitive lithographic printing plates

[0270] Preparation of vector

[0271] A 0.3 mm thick aluminum plate (Material No. 1050, H16) was dipped in an aqueous 5% sodium hydroxide solution kept at...

Embodiment 2

[0313] Photosensitive lithographic printing plate samples Nos. 61-90 were prepared similarly to sample No. 1 of Example 1, provided that ethylenically unsaturated monomers and photopolymerization initiators were used as shown in Table 2.

[0314] Comparative Samples No. 17-25 were also prepared similarly to Sample No. 1 of Example 1, provided that an ethylenically unsaturated monomer and a photopolymerization initiator were used as shown in Table 2.

[0315] Sample No.

Ethylenically unsaturated monomer (parts)

Photopolymerization initiator (parts)

record can

(μJ / cm 2 )

Board life (sheet)

61 (this hair

Bright)

M-3(25)

NK Ester 4G(15)

BR1(2.0)

I-2(4.0)

D-5(2.0)

D-7(2.0)

40

150000

62 (this hair

Bright)

M-3(25)

NK Ester 4G(15)

BR6(2.0)

I-2(4.0)

D-5(2.0)

D-7(2.0)

40

150000

63 (this hair

Bright)

M-3(25)

NK...

Embodiment 3

[0327] Photosensitive lithographic printing plate samples Nos. 3-1 to 3-11 were prepared analogously to sample No. 1 of Example 1, with the proviso that photosensitive lithographic printing plate samples Nos. 61-90 were prepared similar to sample No. 1 of Example 1 , provided that the photosensitive layer coating solution 1 was replaced with the following coating solution 3:

[0328] Photosensitive layer coating solution 3

[0329] Ethylenically unsaturated monomer (NK OLIGOMER U-4HA, Shin-Nakamura Kagaku Kogyo Co., Ltd.) 27.0 parts

[0330] Ethylenically unsaturated monomer a 14.0 parts

[0331] Multi-halogen compound (Table 3) 5.0 parts

[0332] Spectrum sensitizing dye d-0 3.0 parts

[0333] Organometallic compound a 4.0 parts

[0334] Acryl copolymer 1 40.0 parts

[0335] Phthalocyanine pigment (MHI 454, Mikuni Shikiso Co.) 6.0 parts

[0336] 2-tert-butyl-6-(3-tert-butyl-2-hydroxy-5-methyl-4-methylphenyl acrylate (SumilyzerGS, Sumitomo-3M Co.) 0.5 parts

[0337] Flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com