Friction piece

A technology of friction parts and friction modifiers, applied in the direction of friction linings, other chemical processes, aluminum compounds, etc., can solve the problems of reduced friction coefficient of wear, deterioration of operating environment, easy generation of dust, etc., to achieve improved fluidity and operating environment. The effect of improving and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

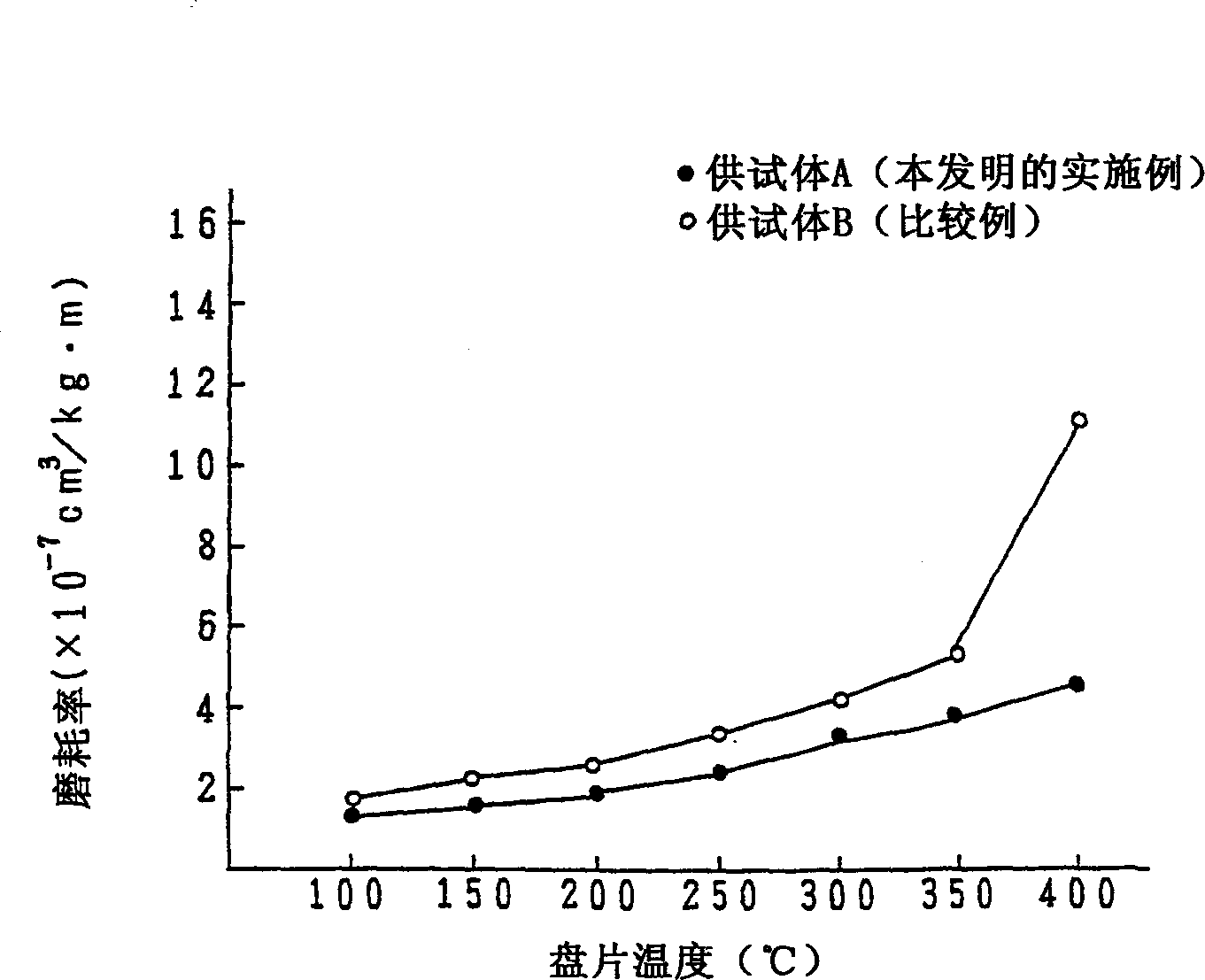

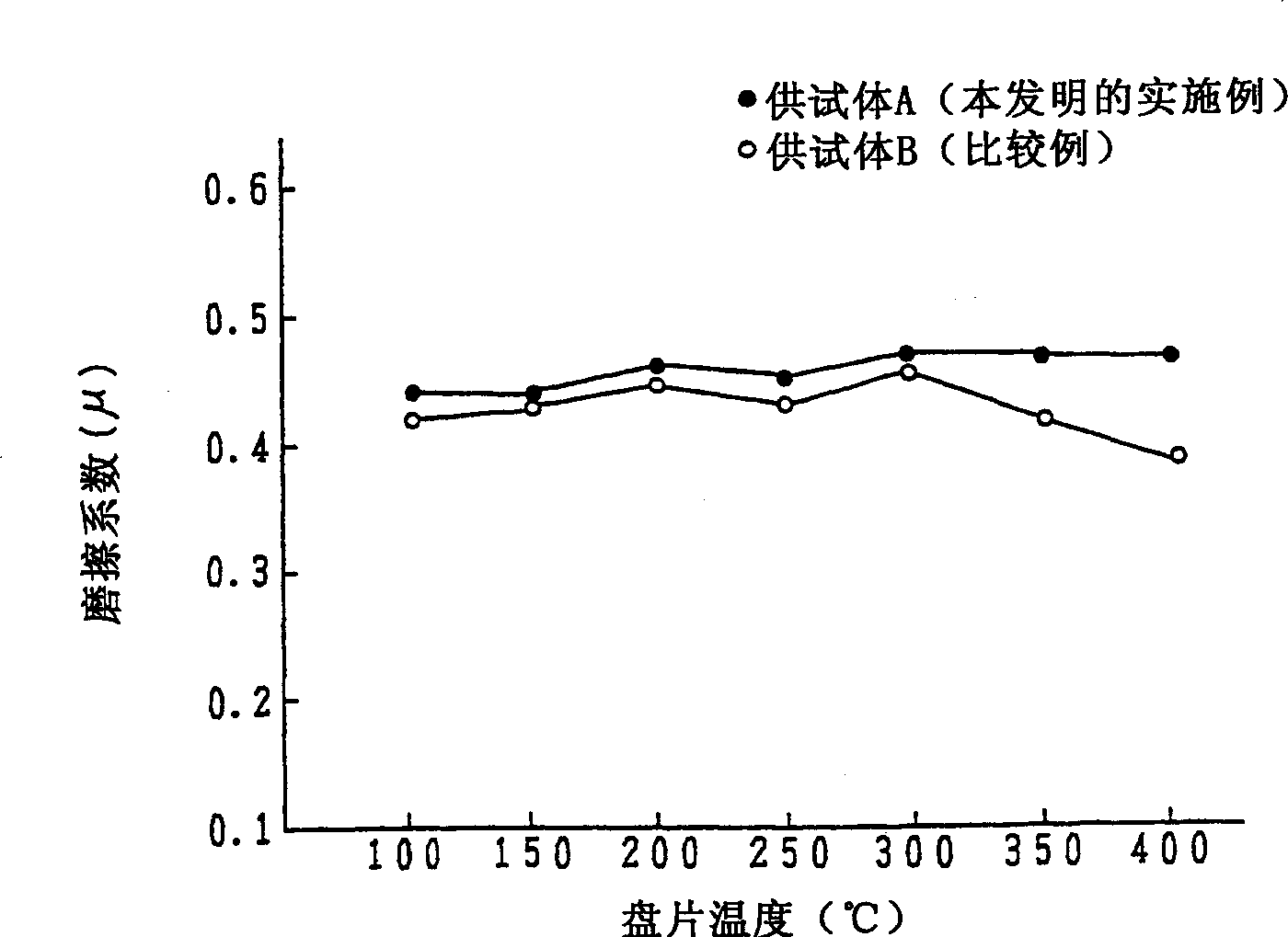

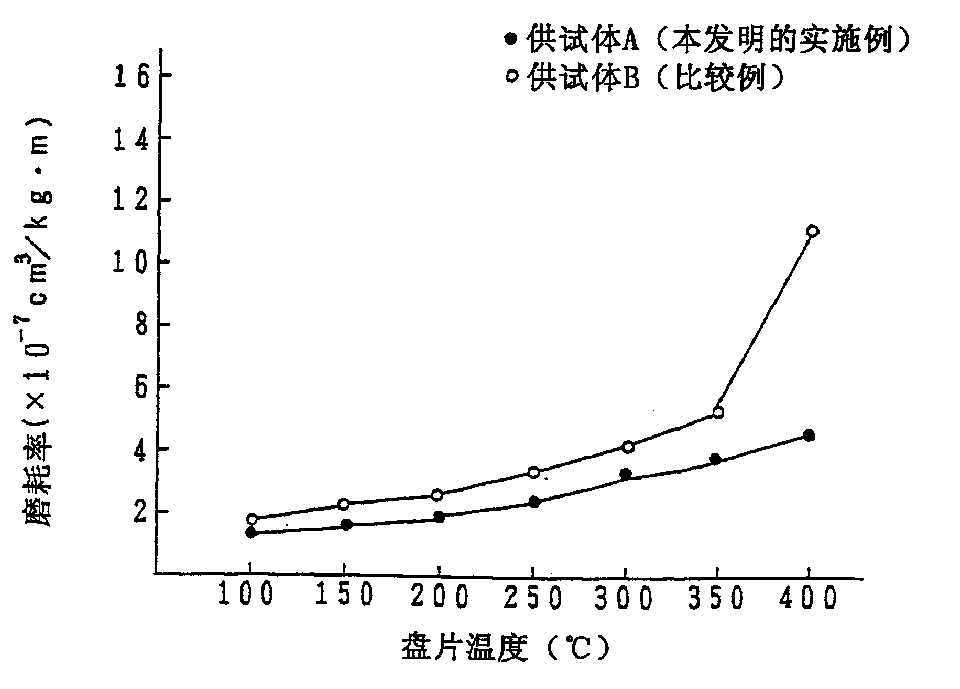

[0042] 15 parts by weight of potassium titanate fiber (trade name Tisumo D, manufactured by Otsuka Chemical Co., Ltd.), 4 parts by weight of aramid fiber (trade name Kebra-Palup, length 3mm, manufactured by Toray Co., Ltd.), 9 The binder (phenolic resin) of parts by weight, the organic additive (such as powder etc.) of 9 parts by weight, the scaly boehmite (made with the reference example) of 30 parts by weight, other of 33 parts by weight (Lubricants such as graphite, metal powder, oxide powder) are fully mixed and added into the mold, and bonded and formed (applied pressure: 150kgf / cm 2 , temperature 170°C, 5 minutes), after forming, release the mold for heat treatment (keep at 180°C for 5 minutes). Thereafter, grinding was performed to obtain a test body (A).

[0043] In addition, organic additives, lubricants, metal powders, and oxide powders are usually added to friction agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com