Submerged arc welding method of parallel double wire or single wire adding metal powder

A metal powder, submerged arc welding technology, applied in arc welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of uneven microstructure of the welding layer, large heat affected area, low welding productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

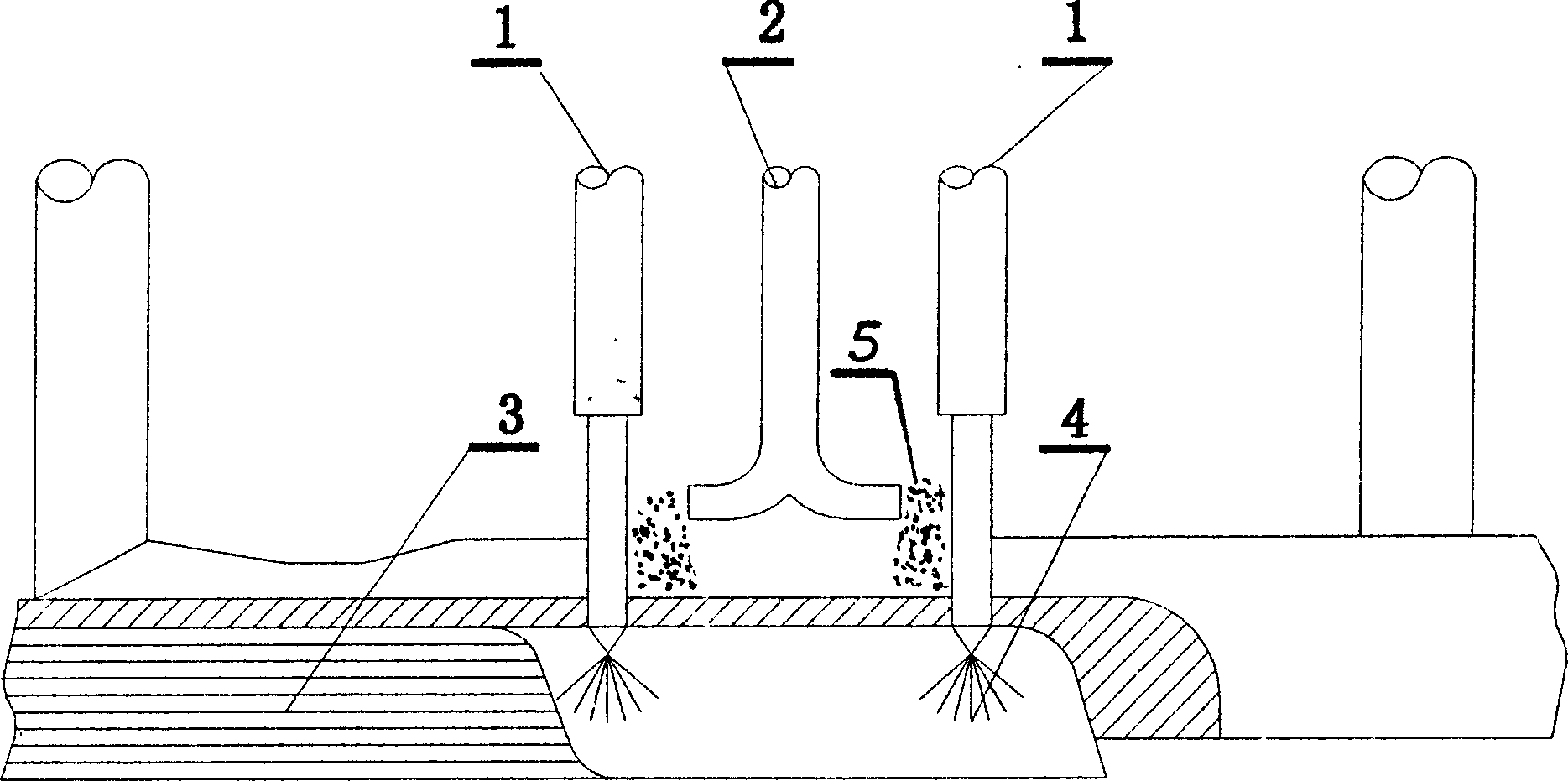

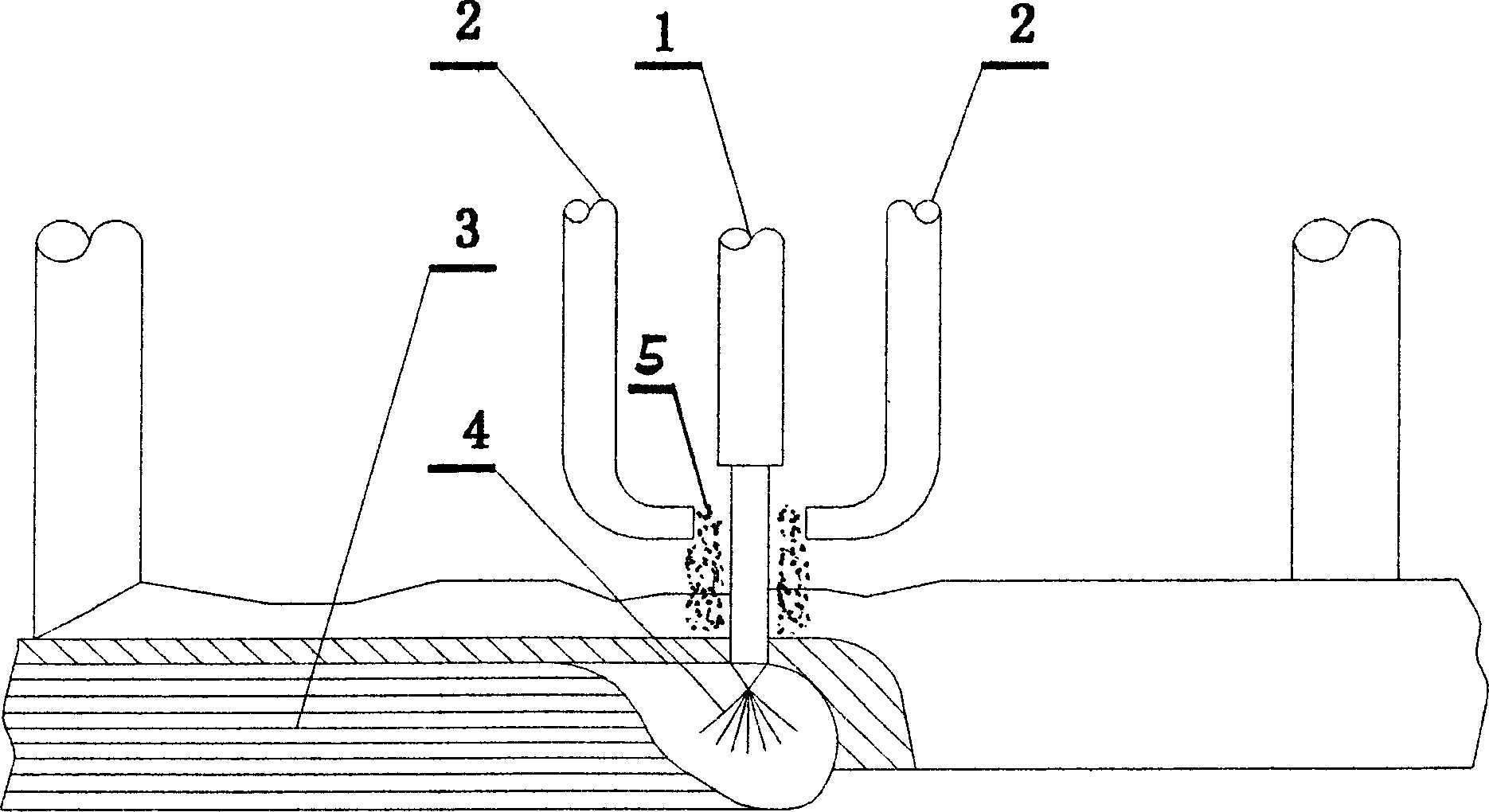

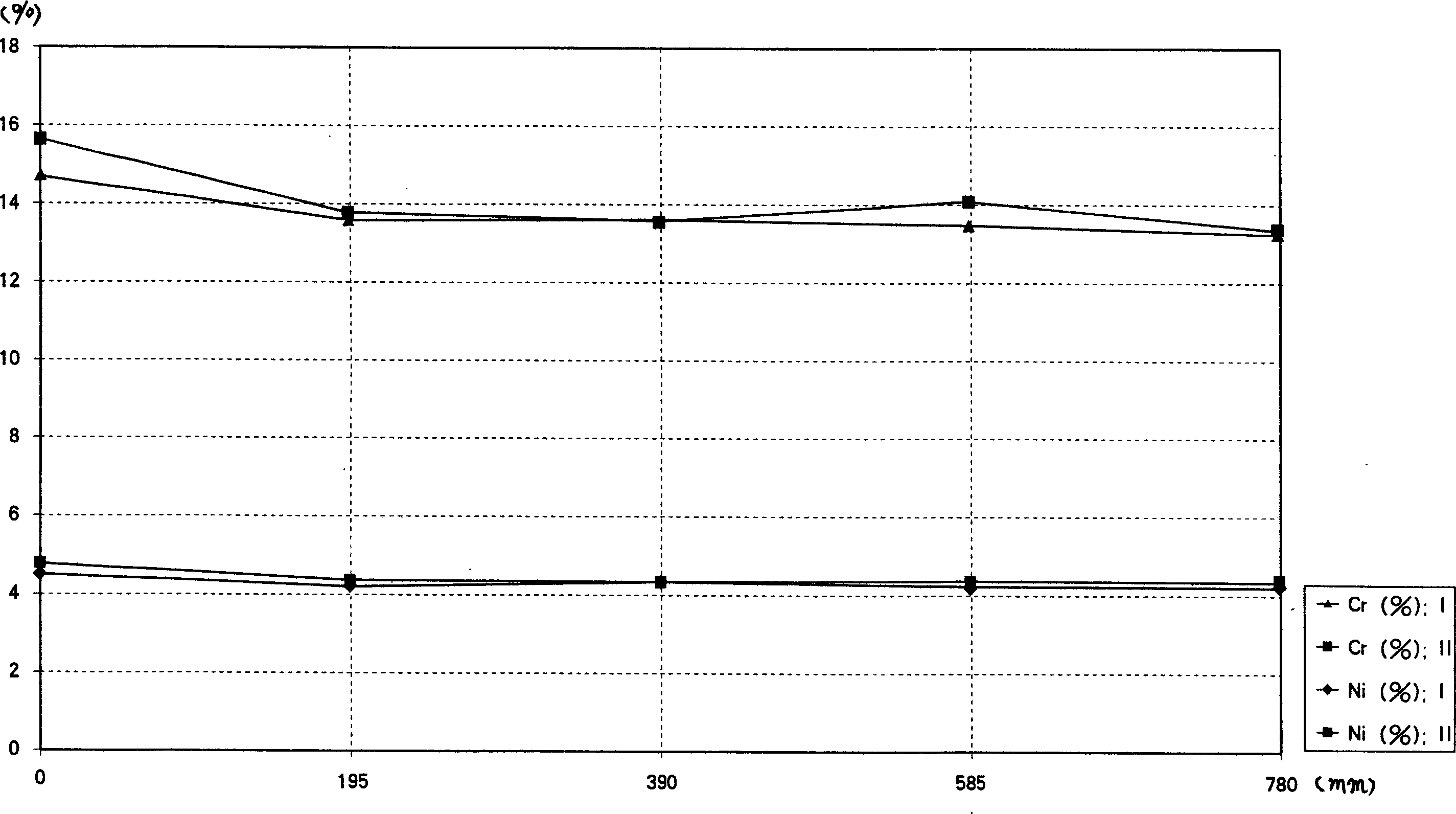

[0020] The invention relates to a submerged arc welding method for adding metal powder, which is divided into a submerged arc welding method for adding parallel twin wires and metal powder and a submerged arc welding method for adding metal powder to a single wire. It hardens the surface of one or two continuous casting rolls, and improves the process and equipment of ordinary submerged arc welding by filling metal powder surfacing, and uses and uses one or parallel two low Alloy steel welding wire, while welding, the metal powder is synchronously adhered to the welding wire. Since the metal powder is paired with the low-alloy steel welding wire, it is easy to obtain the weld layer of the desired alloy composition. Its main technical features are: using one or two parallel low-alloy steel welding wires and adding required alloying elements into the metal powder, wherein the metal powder accounts for the total alloy material including the low-alloy steel welding wire and metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com