Backlight modular

A backlight module and light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as not conforming to environmental protection trends, CCFL damage, shortening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

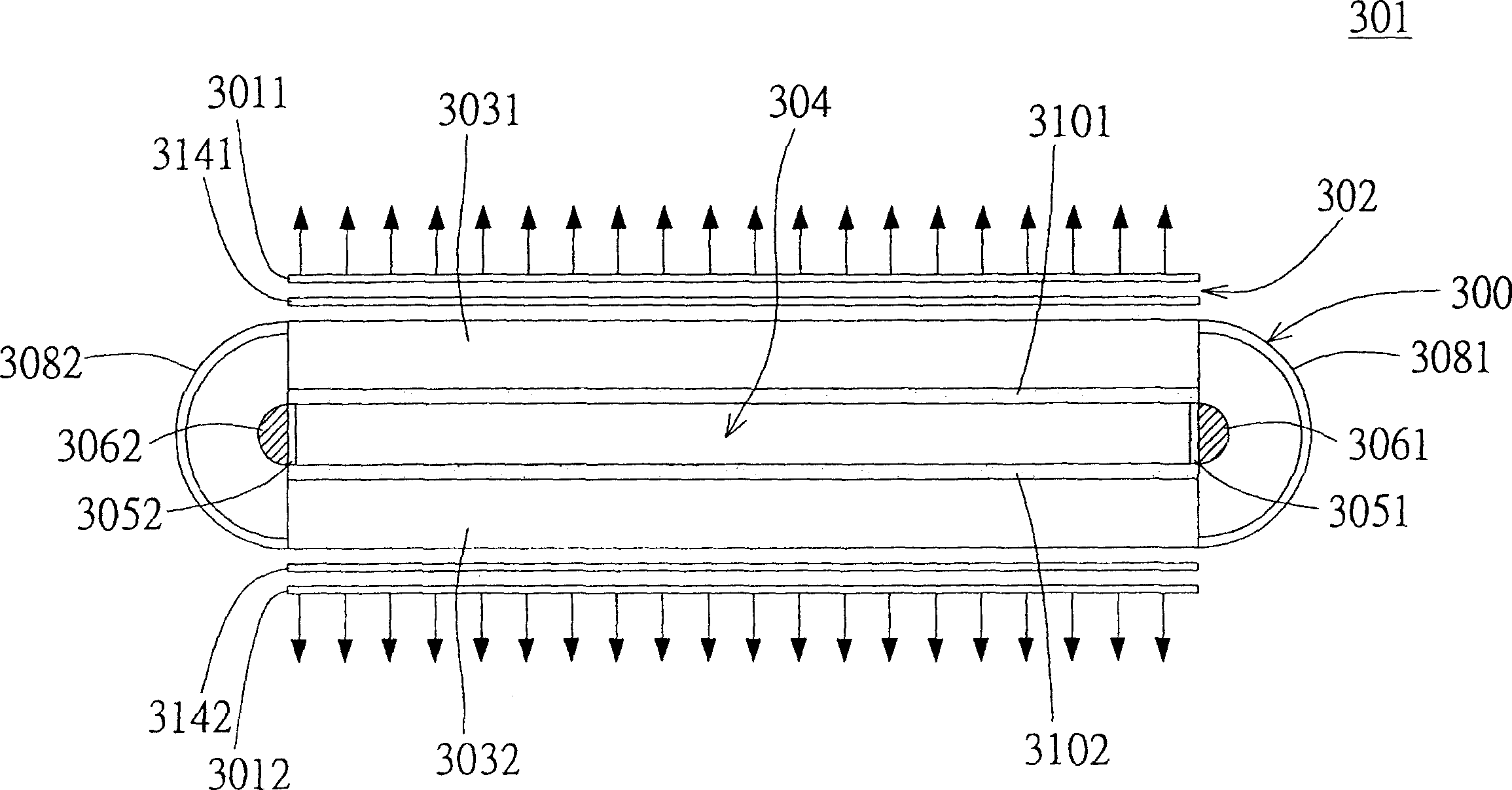

[0041] Please refer to Figure 3A , which shows a cross-sectional view of the backlight module according to the first embodiment of the present invention. exist Figure 3A Among them, the backlight module 300 is suitable for a double-sided display 301. The double-sided display 301 has two display panels 3011 and 3012 arranged flat to each other. A panel gap (gap) space 302 is formed between the display panels 3011 and 3012. The backlight module 300 is disposed in the panel gap space 302 to provide the light required by the double-sided display 301 .

[0042] The backlight module 300 includes at least a first light guide plate 3031 , a second light guide plate 3032 , a first circuit board 3051 and at least one first light emitting diode (LED) 3061 . The first light guide plate 3031 and the second light guide plate 3032 are both arranged in the panel gap space 302 and parallel to the display panel 3011 and the display panel 3012, and a light guide plate gap is formed between t...

no. 2 example

[0049] Please refer to Figure 4 , which shows a cross-sectional view of the backlight module according to the second embodiment of the present invention. exist Figure 4 Among them, the difference between the double-sided display 401 and the double-sided display of the first embodiment lies in the backlight module 400, and the difference between the backlight module 400 of this embodiment and the backlight module 300 of the first embodiment lies in the structure of the curved reflector , and the same symbols are used for the rest of the same constituent elements, and will not be repeated here.

[0050] The center of the concave surface of the first curved reflector 4021 has a first convex surface 4041 , and the first convex surface 4041 faces the first LED 3061 . Likewise, the center of the concave surface of the second curved reflector 4022 has a second convex surface 4042 , and the second convex surface 4042 faces the second LED 3062 . Through the design of the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com