Leakage gas outlet valve

A technology of gas outlet valve and gas, which is applied in the direction of combustion ignition, combustion method, mechanical ignition, etc., and can solve problems such as fire accidents, slow fire collection, safety defects of gas outlet valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

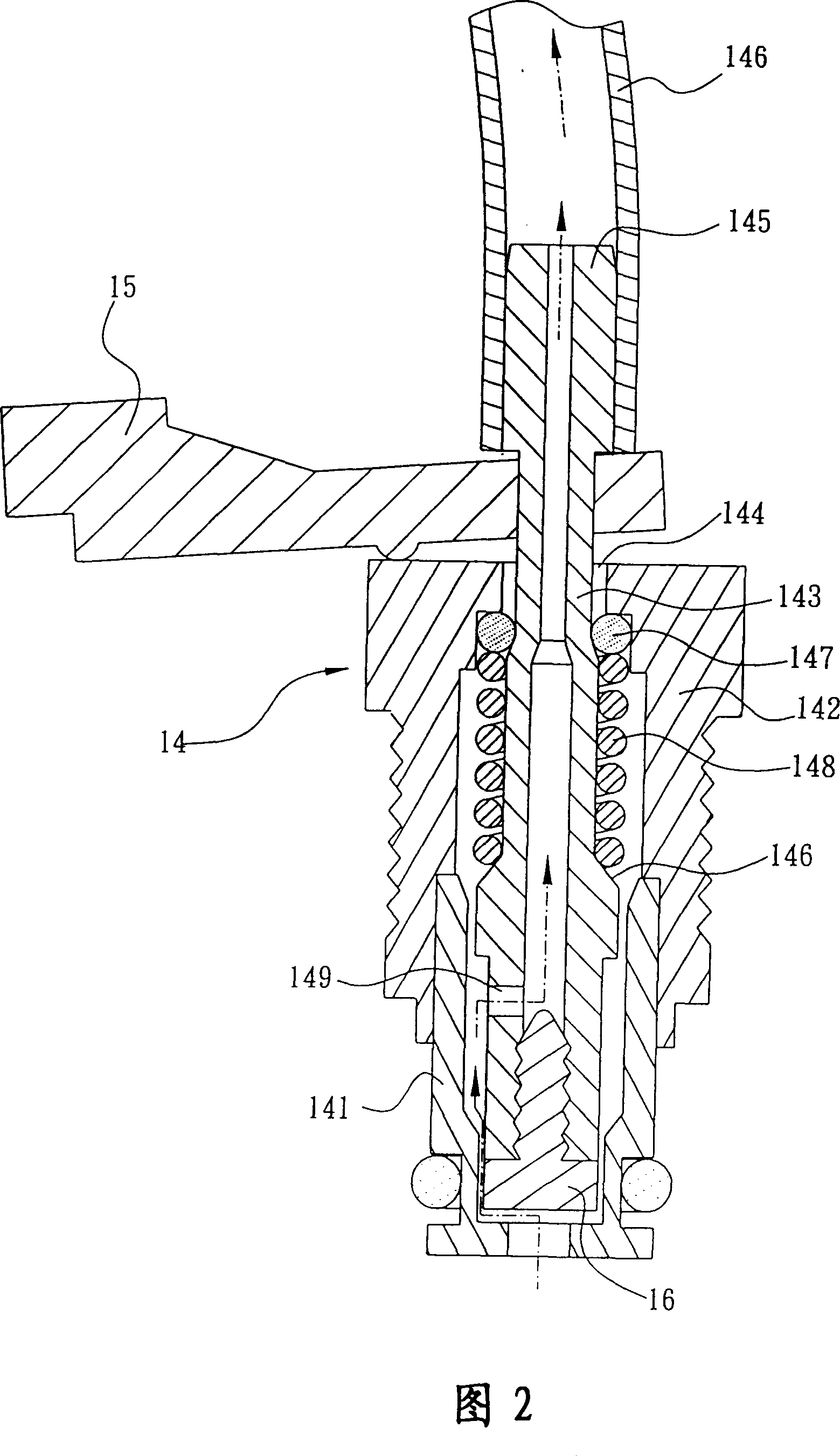

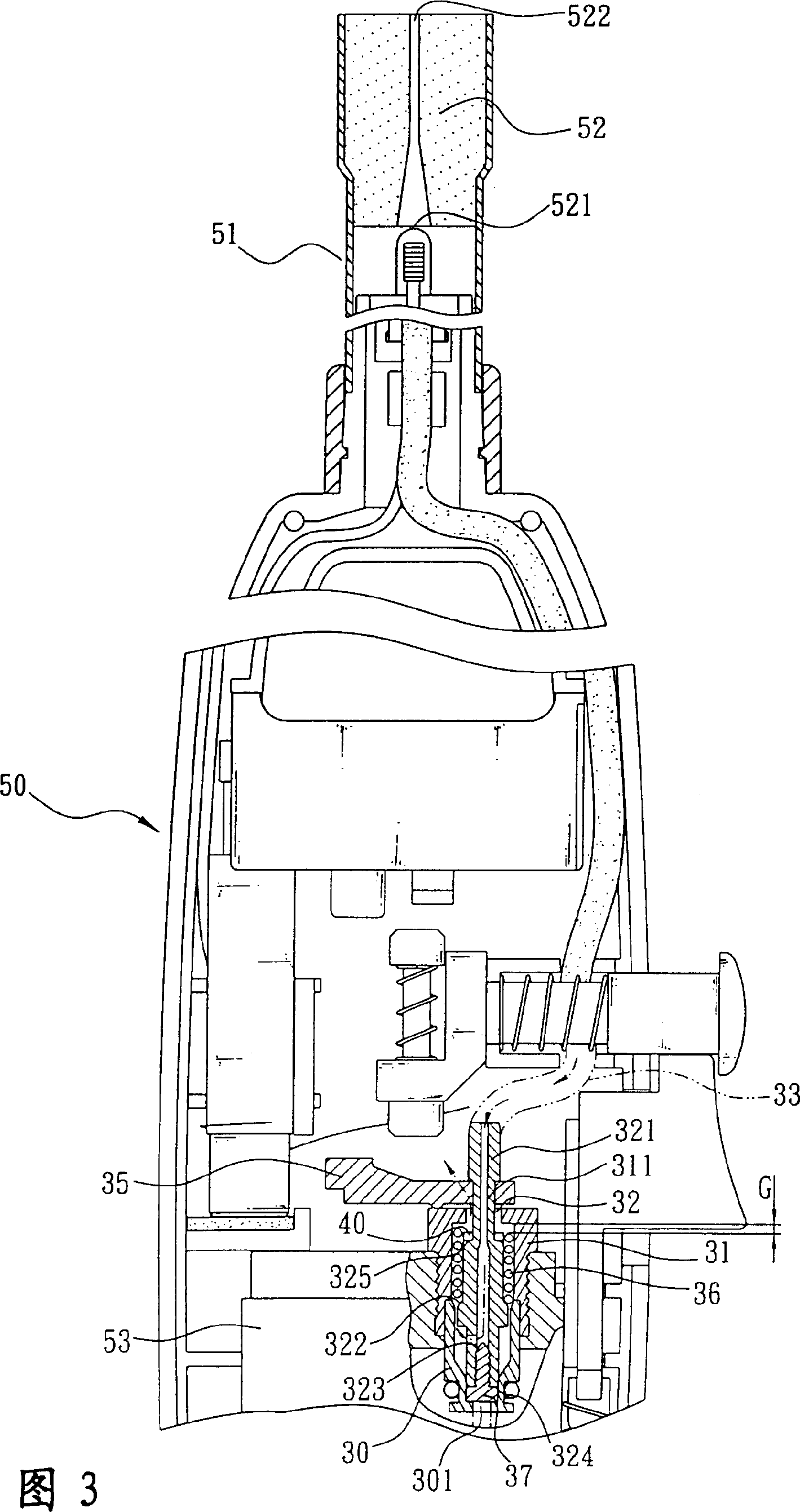

[0035] In order to facilitate your examiner to have a further understanding and understanding of the technical means and operation process of the present invention, the embodiments are hereby combined with the drawings, and the details are as follows:

[0036] The present invention is a leakable gas outlet valve, which is used in an igniter, which can be a pressure igniter or a general igniter. In this embodiment, please refer to Figure 3, which is an example Take a pressure igniter as an example, which has a slightly rectangular handle 50, one end of the handle 50 extends outward for a certain distance, and a hollow tube 51 is provided, and a pressure head 52 is arranged in the free end of the tube 51. One end 521 of the pressure head 52 has a larger inner diameter at the joint with the pipe body 51, while the inner diameter of the other end 522 is obviously smaller, and a gas cylinder 53 is arranged in the handle portion 50. The gas cylinder 53 one ends are connected with ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com