Liquid crystal display panel with Gamma correction function and manufacturing method thereof

A technology of liquid crystal display panels and gamma, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven upper surface of transparent organic layer 312, influence on alignment of liquid crystal molecules, increase of production cost and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

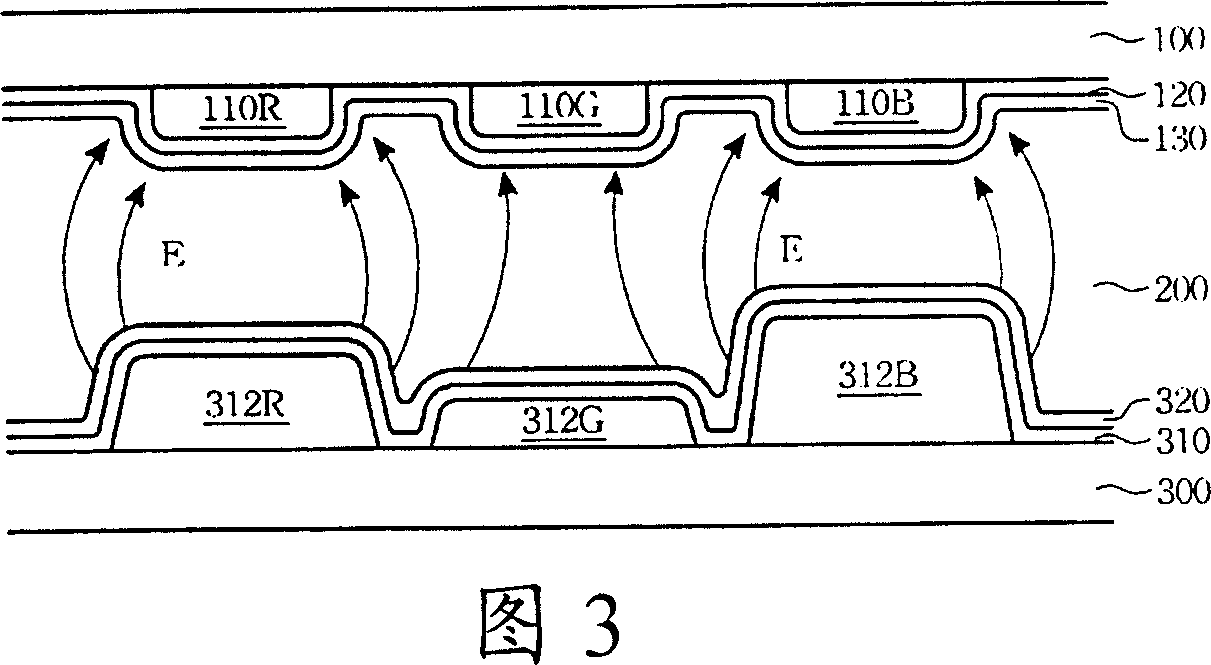

Embodiment Construction

[0032] The method of photo-alignment is to irradiate photosensitive polymer materials with ultraviolet light (Ultra-Violet, UV) having a specific polarization direction. The photosensitive polymer material utilizes specific functional groups to absorb the ultraviolet light energy to produce the effect of molecular rearrangement, thereby forming an alignment result similar to a traditional rubbing process. As mentioned above, because the photosensitive polymer material has the characteristic of photoalignment only through the ultraviolet light exposure reaction, the related exposure parameters such as the length of exposure time, the intensity of the exposure light source and the incident angle of the exposure light source are all It will affect the result of photoalignment.

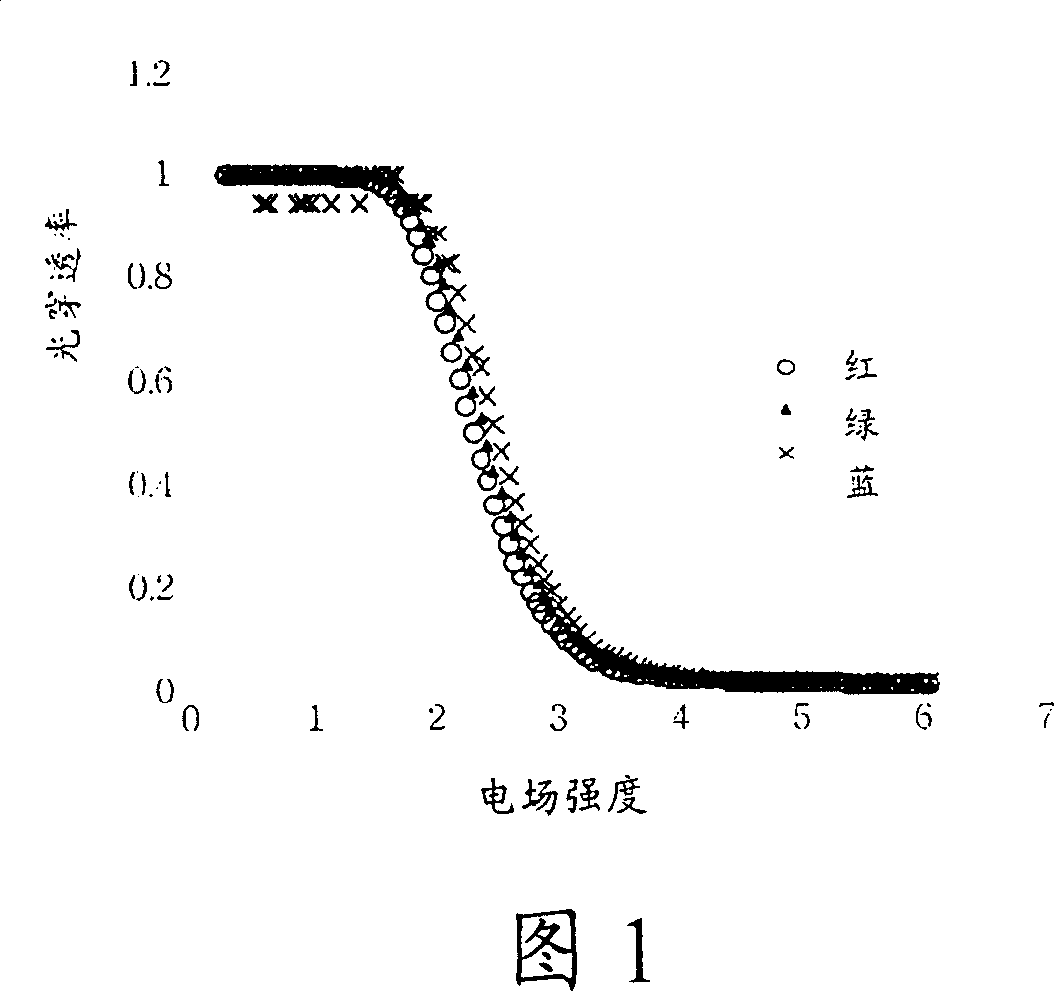

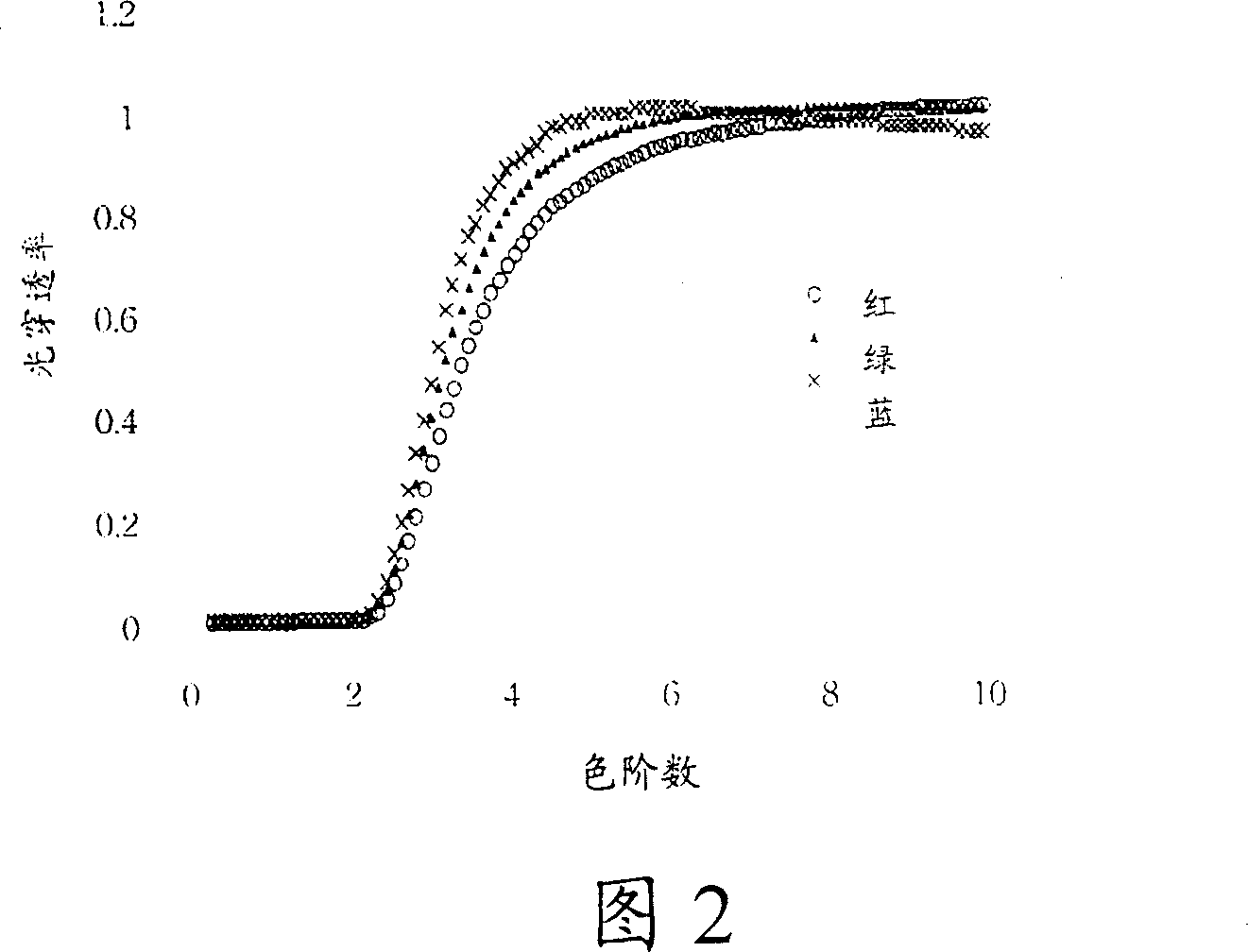

[0033] As shown in FIG. 4 , it shows the relationship between the exposure energy of a typical photo-alignment film and the light transmittance of the liquid crystal layer. The abscissa in the figure cor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap