Flush valve attachment system

A technique for flushing valves and components, which is applied in the field of flushing valves, can solve problems such as difficulties, and achieve the effects of low production cost, easy installation, and firm assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

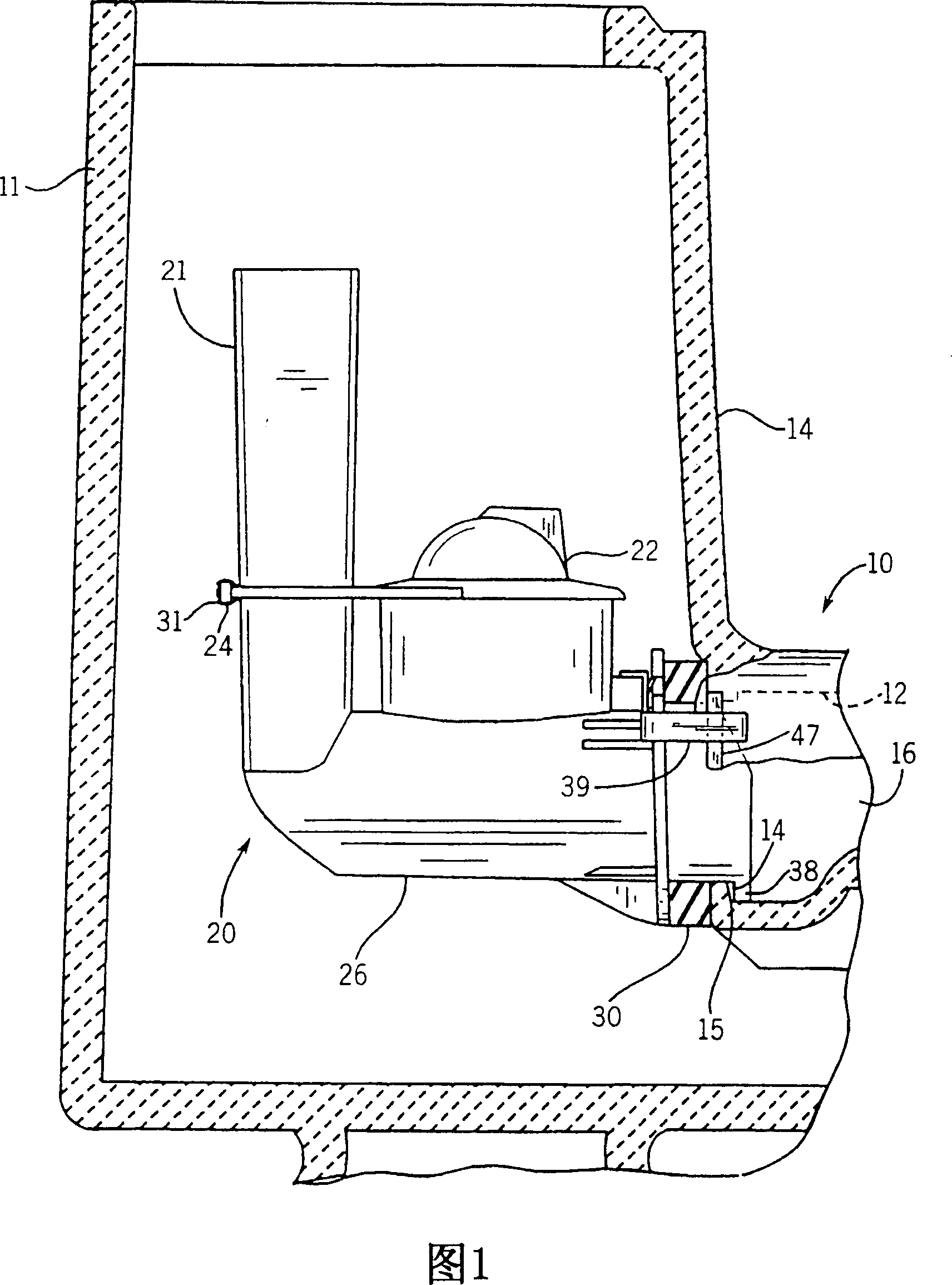

[0021] A one-piece toilet, generally indicated at 10 , includes a tank 11 having a forward substantially vertical wall 14 with an outlet aperture 15 leading to a channel 16 in a conventional toilet rim 12 .

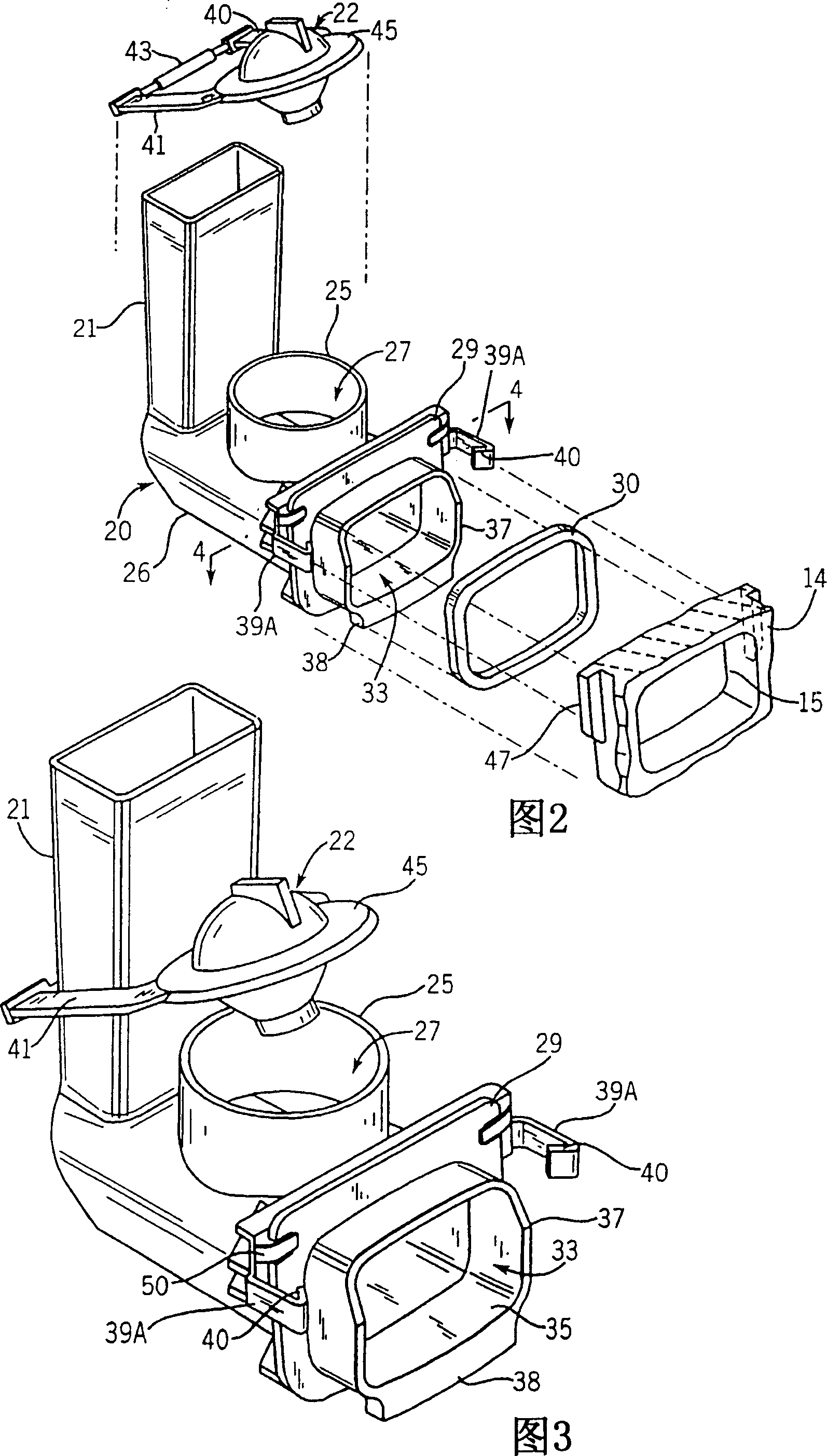

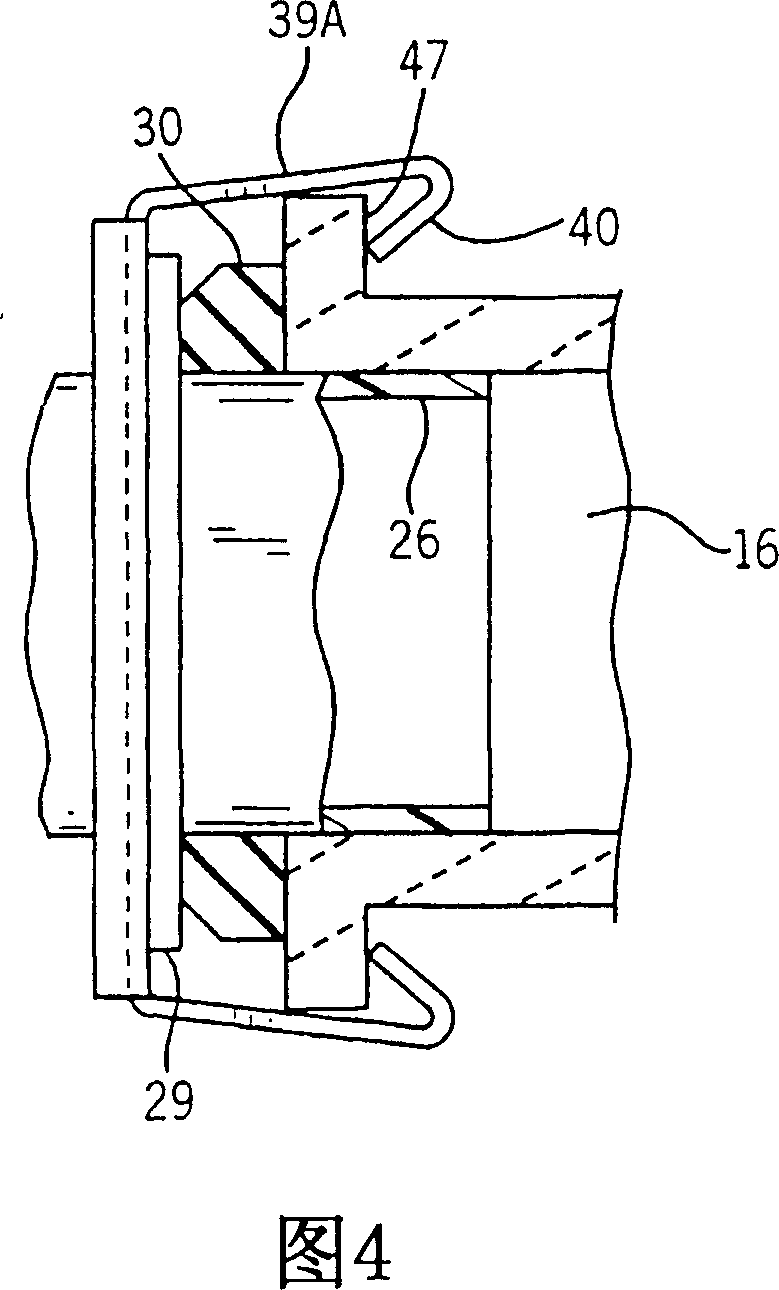

[0022] The flush valve assembly 20 according to the present invention is disposed in the lower portion of the water tank 11 . It has an overflow assembly 21 extending generally vertically. A horizontally extending valve housing 26 passes through the base body of the overflow assembly 21 and defines a channel by which water can be conveyed from the water tank to the channel 16 .

[0023] Regardless of the cross-section of the overflow assembly 21, the cross-section of the housing 26 is a more "flat" cross-section than a simple circular cross-section. For example, the figures show a generally rectangular cross-section with a distance defined by its horizontal walls 35 that is greater than that defined by its vertical walls 37, which still results in a volumetric flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com