Vibration isolation support structure of fuel tank for vehicle

A technology of supporting structure and fuel tank, which is applied to vehicle components, layout combined with internal combustion engine fuel supply, non-rotational vibration suppression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described below according to the embodiments of the present invention shown in the accompanying drawings.

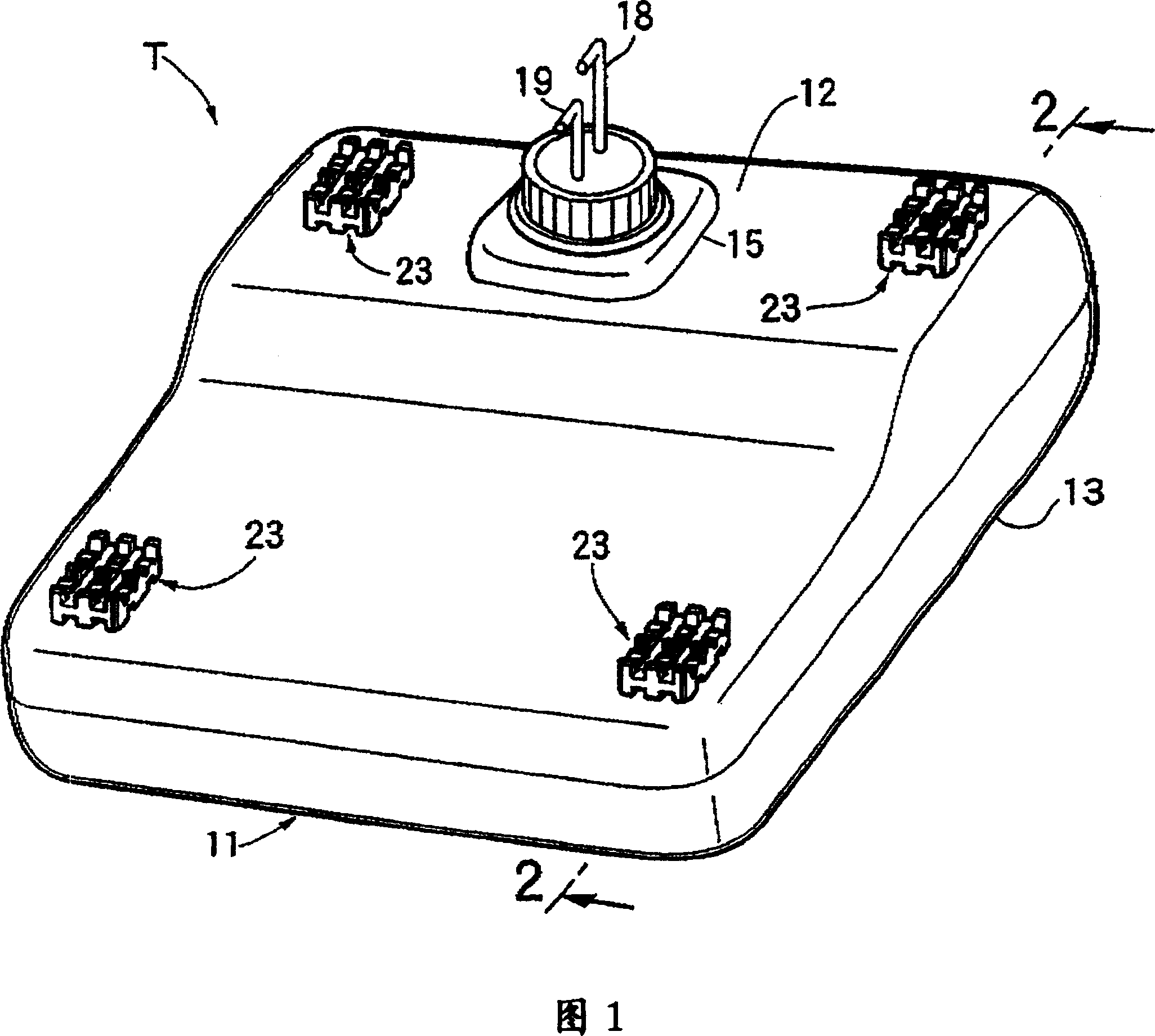

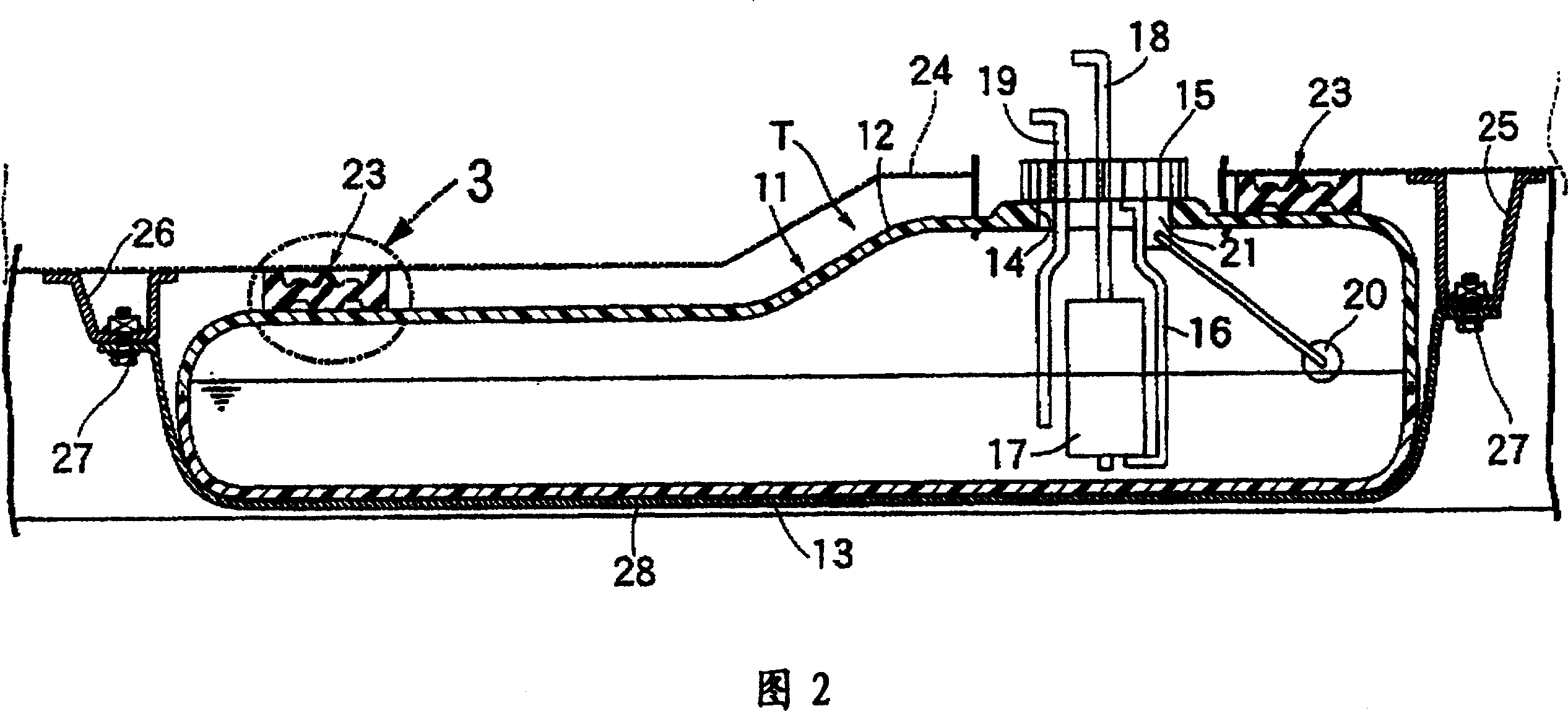

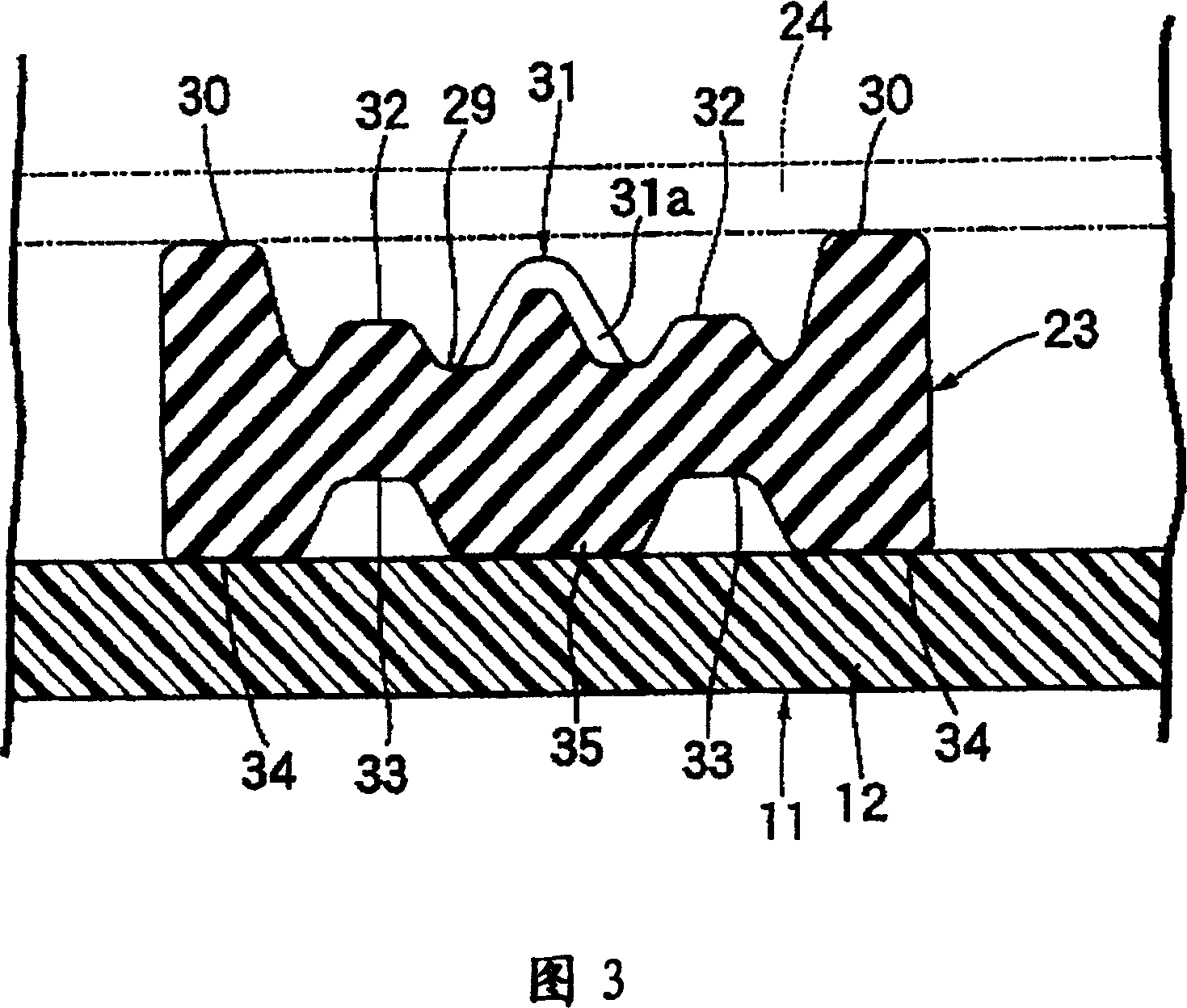

[0022] 1 to 6 are diagrams showing a first embodiment of the present invention, FIG. 1 is a perspective view of a fuel tank for a vehicle, FIG. 2 is a sectional view taken along line 2-2 in FIG. 1 , and FIG. 3 is a part indicated by 3 in FIG. 2 In the enlarged view, Fig. 4 is a perspective view of the cushion rubber pad viewed from the bottom plate side, Fig. 5 is a perspective view of the cushion rubber pad viewed from the box body side, and Fig. 6 shows the relationship between the compression amount of the cushion rubber pad and the compression load Graph.

[0023] As shown in Fig. 1 and Fig. 2, the tank body 11 of the vehicle fuel tank T is integrally molded from synthetic resin, and the opening 14 formed on the upper wall 12 thereof is covered by a mounting flange portion 15, and the mounting flange portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com