Drill bit supporting device of drilling machine

A technology of supporting device and drilling machine, which is applied to tool joints, metal processing machinery parts, large fixed members, etc. The effect of reducing vibration amplitude and improving drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

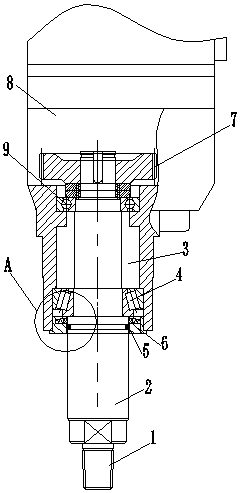

[0017] Drilling machine drill bit support device, the drill bit 1 is connected to the output shaft 2, and the output shaft 2 is arranged in the support hole 3 where the output shaft 2 is installed; The tapered roller bearing 4 is provided with a sealing device in close contact with the tapered roller bearing 4 outside the tapered roller bearing 4, and the sealing device is located in the support hole 3.

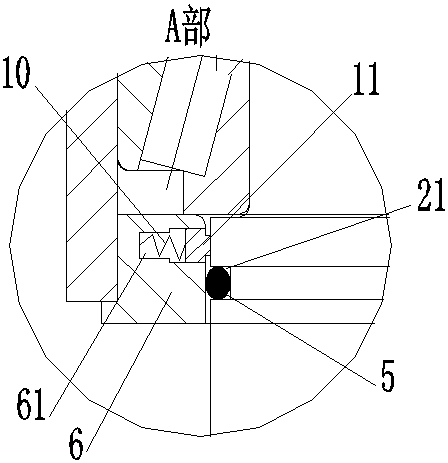

[0018] The sealing device includes: an annular groove 21 arranged on the output shaft 2 , a sealing ring 5 sleeved on the annular groove 21 and matched with the annular groove 21 , and a sealing ring 5 outside the sealing ring 5 A rigid ring 6 that cooperates with the sealing ring 5 is formed, and the rigid ring 6 is arranged in the support hole 3 .

[0019] The sealing ring 5 has a certain degree of elasticity, and the rigid ring 6 is pressed against the sealing ring 5 , so that the rigid ring 6 and the sealing ring 5 are in close contact.

[0020] The inner surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com