Display device and method for manufacturing same

A technology for display devices and display pixels, which is applied to identification devices, organic semiconductor devices, instruments, etc., can solve problems such as increased defective rate of short-circuited pixels, achieve the effect of improving display quality and ensuring the function of capacitance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

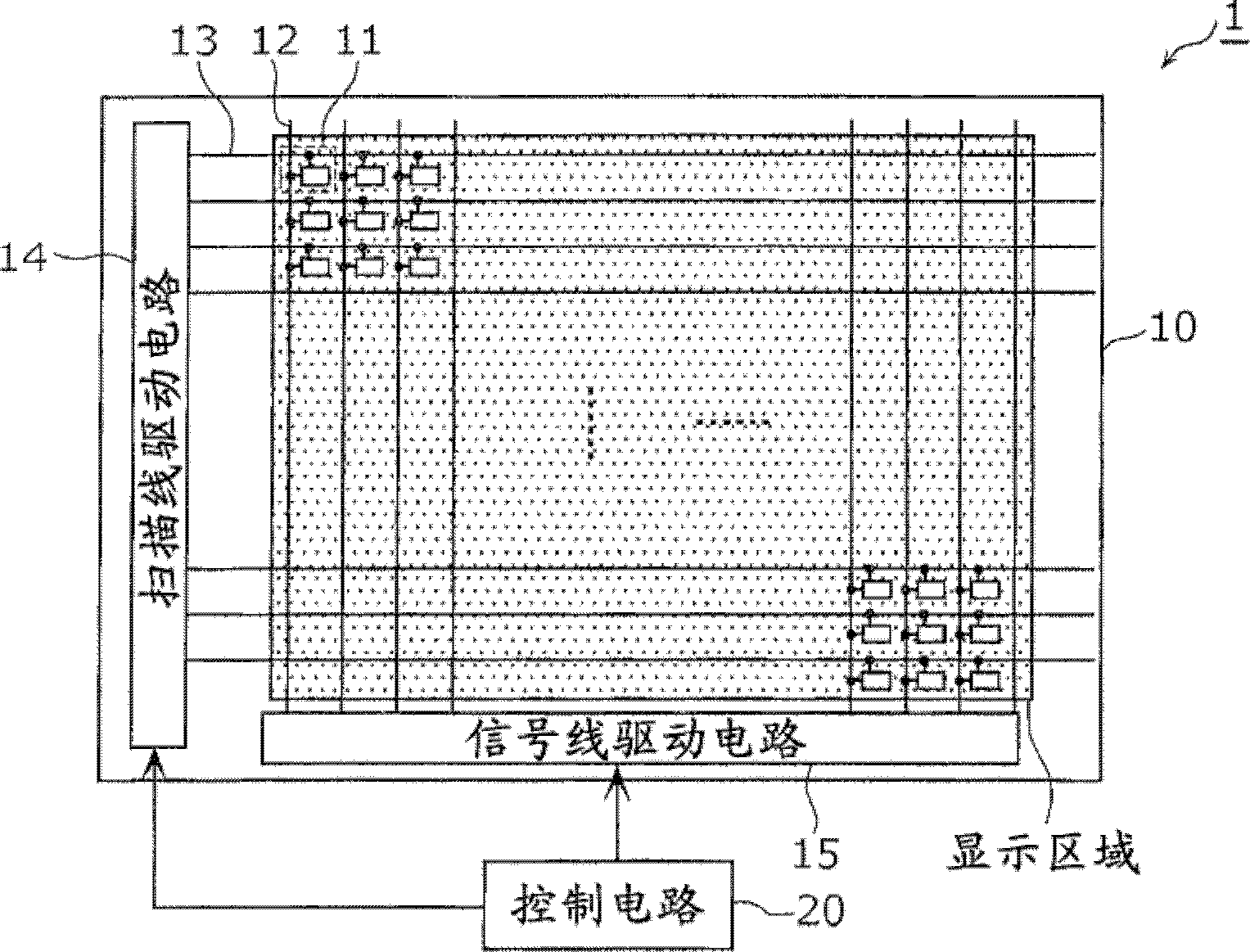

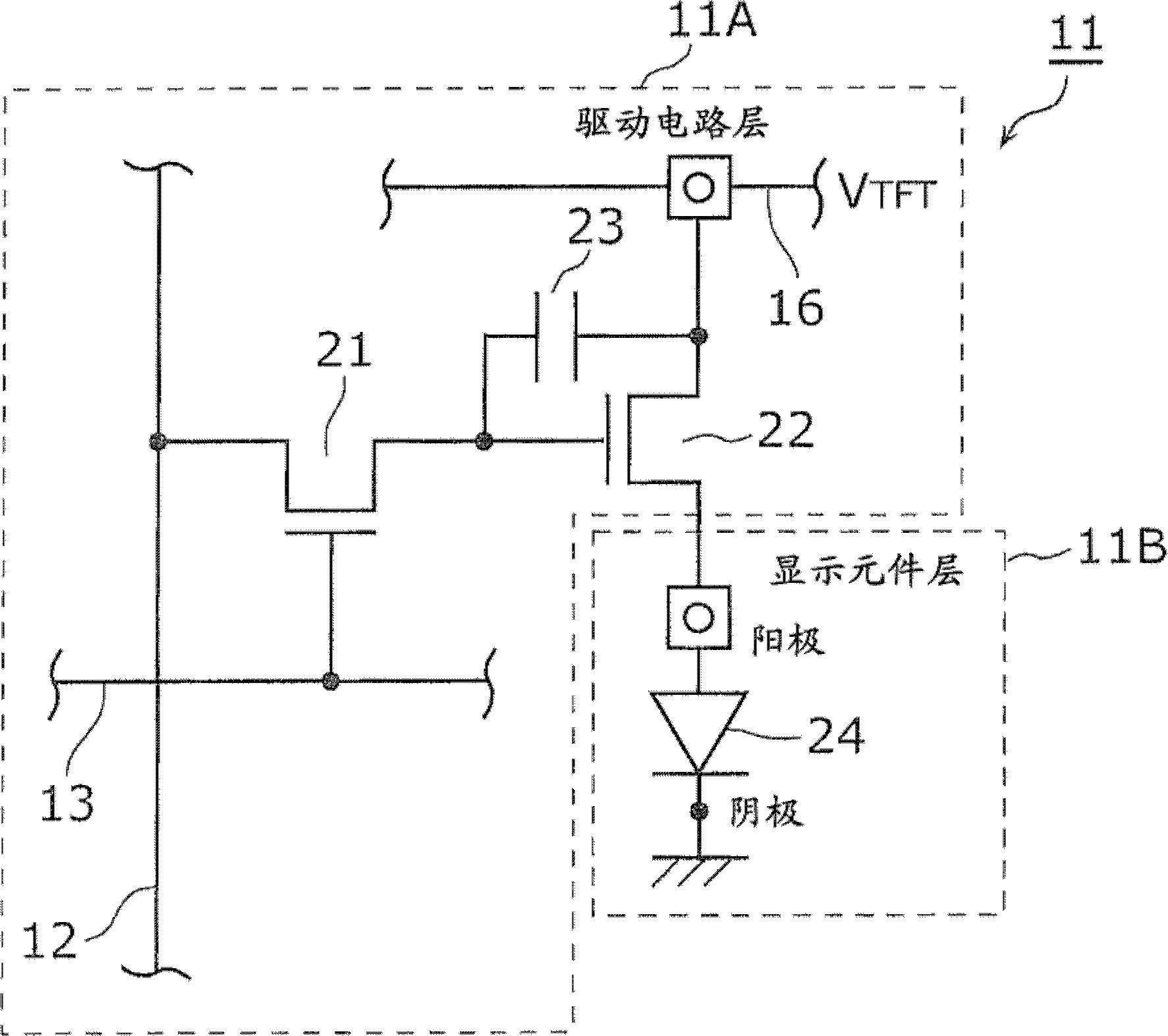

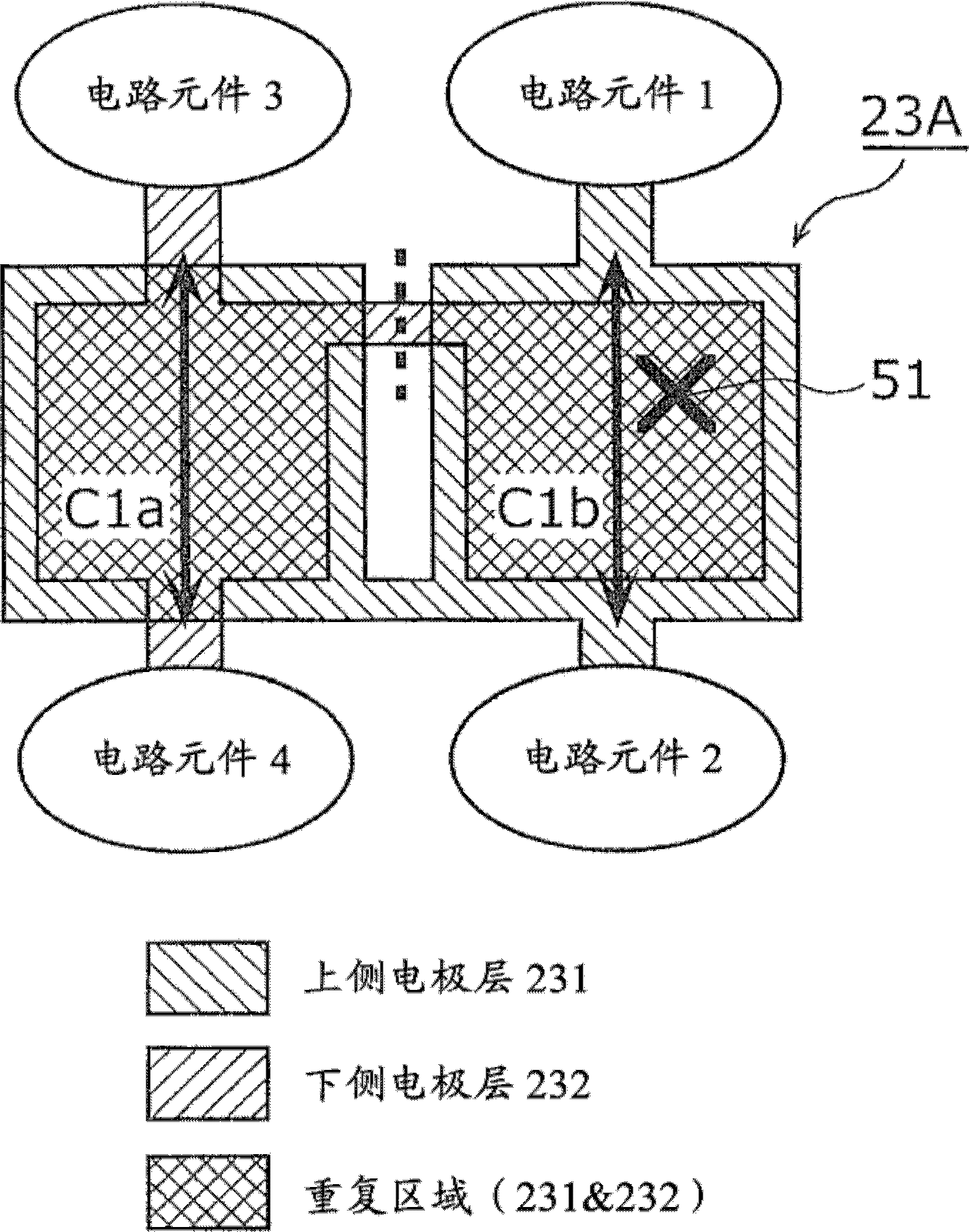

[0089] In the display device of this embodiment, a plurality of display pixels are arranged two-dimensionally, and a display element layer and a driving circuit layer for driving the display element layer are stacked in the plurality of display pixels. The drive circuit layer includes a parallel-plate capacitive element having an upper electrode layer and a lower electrode layer arranged to face each other in the stacking direction. The upper electrode layer includes: a first upper capacitor electrode portion having a circuit wiring function for connecting the first circuit element and the second circuit element; connected to the second upper capacitor electrode portion. The lower electrode layer includes: a first lower capacitive electrode portion having a circuit wiring function for connecting the third circuit element and the fourth circuit element; connected to the second lower capacitor electrode portion. The capacitive element is between the first upper capacitive elec...

Embodiment approach 2

[0159] In this embodiment mode, a method for manufacturing the display device of the present invention will be described. The method of manufacturing a display device of the present invention includes a step of forming a driving circuit layer, a step of forming a display element layer, a step of inspecting a pixel circuit, and a step of repairing a storage capacitor element. Here, the description will focus on steps different from those in the conventional display device manufacturing method, namely, the formation step of the storage capacitor element 23A included in the drive circuit layer, and the inspection step and repair step of the pixel circuit.

[0160] Figure 8 It is a flowchart showing the manufacturing method of the display device according to Embodiment 2 of the present invention.

[0161] First, the drive circuit layer 11A in which the storage capacitor element 23A and the switching transistor 21 as its peripheral elements, the drive transistor 22 , circuit wiri...

Embodiment approach 3

[0175] In this embodiment, the layout configuration and effects of light-emitting pixels in which the storage capacitor element of Embodiment 1 and other circuit elements constituting the driving circuit layer 11A are arranged will be described.

[0176] Figure 9A It is a first layout diagram of light-emitting pixels included in a conventional display device. The layout shown in this figure is the layout of one light-emitting pixel, and the signal line 12, the scanning line 13, the switching transistor 21, the driving transistor 22, the storage capacitance element having the electrostatic capacitance C1, and the circuit wiring are drawn. In addition, the switching transistor 21 and the driving transistor 22 are bottom gate type, the layer where the gate electrode is formed is the lower electrode layer, and the layer where the source electrode and the drain electrode are formed is the upper electrode layer. Although the area ratio of the light-emitting pixel is high, the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com