Jacking screw

A screw and jacking technology, applied in the direction of screws, bolts, nuts, etc., can solve the problems of the separation of the buckle, the disengagement and separation of the jacking screw, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] DESCRIPTION OF THE PREFERRED EMBODIMENT

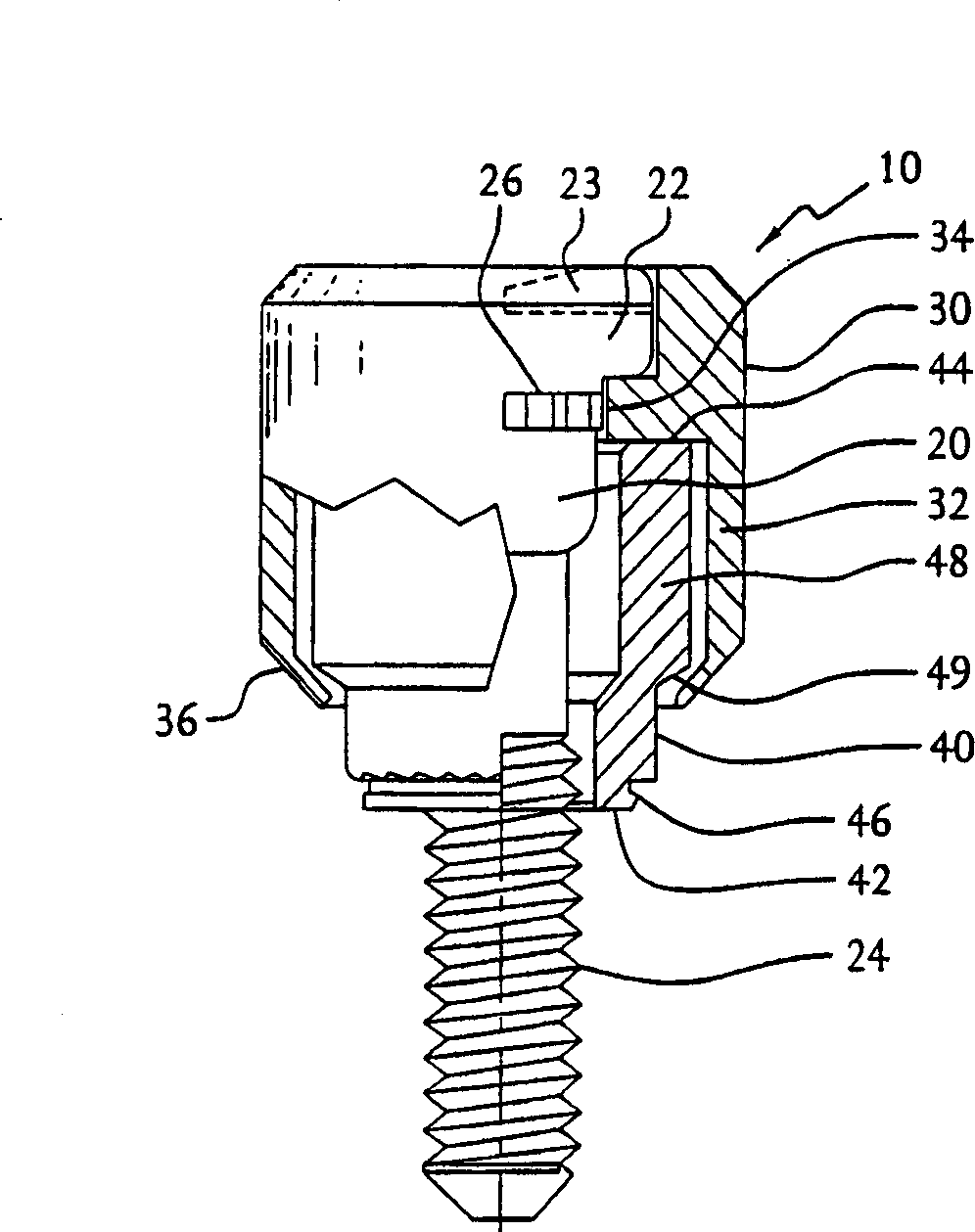

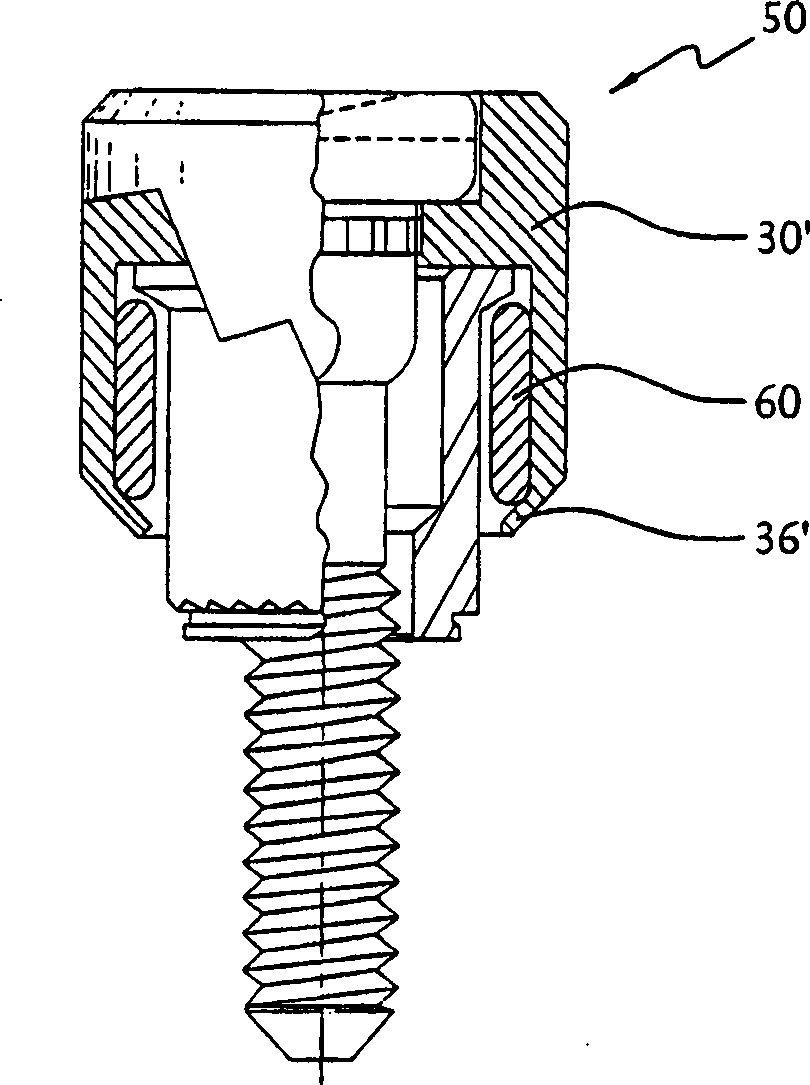

[0030] Reference is now made in detail to the drawings in which like numerals represent like elements throughout the several views. exist figure 1 A fixed jacking screw 10 according to a preferred embodiment of the present invention is shown in . The illustrated set jacking screw 10 generally comprises a screw 20 having a head 22 and a threaded shaft 24, a knob 30 preferably but optionally integral with the head of the screw 20, and a screw 20 mounted in standard fashion on the Collar 40 on first plate (not shown). The collar has a first end 42 and a second end 44 . The first end of the collar has a flat attachment means 46 which will be discussed in more detail below. The second end of the collar 40 is combined with the knob 30 and has means for securing the knob 30 (and therefore preferably the integral screw 20) to the collar 40, which enables the knob 30 and screw 20 to be positioned relative to the collar 40. The ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com