Traverse controlling device

A control device and reciprocating motion technology, applied in transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of inability to rotate at high speed, poor winding shape of the winding package, and large change rate of current command, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

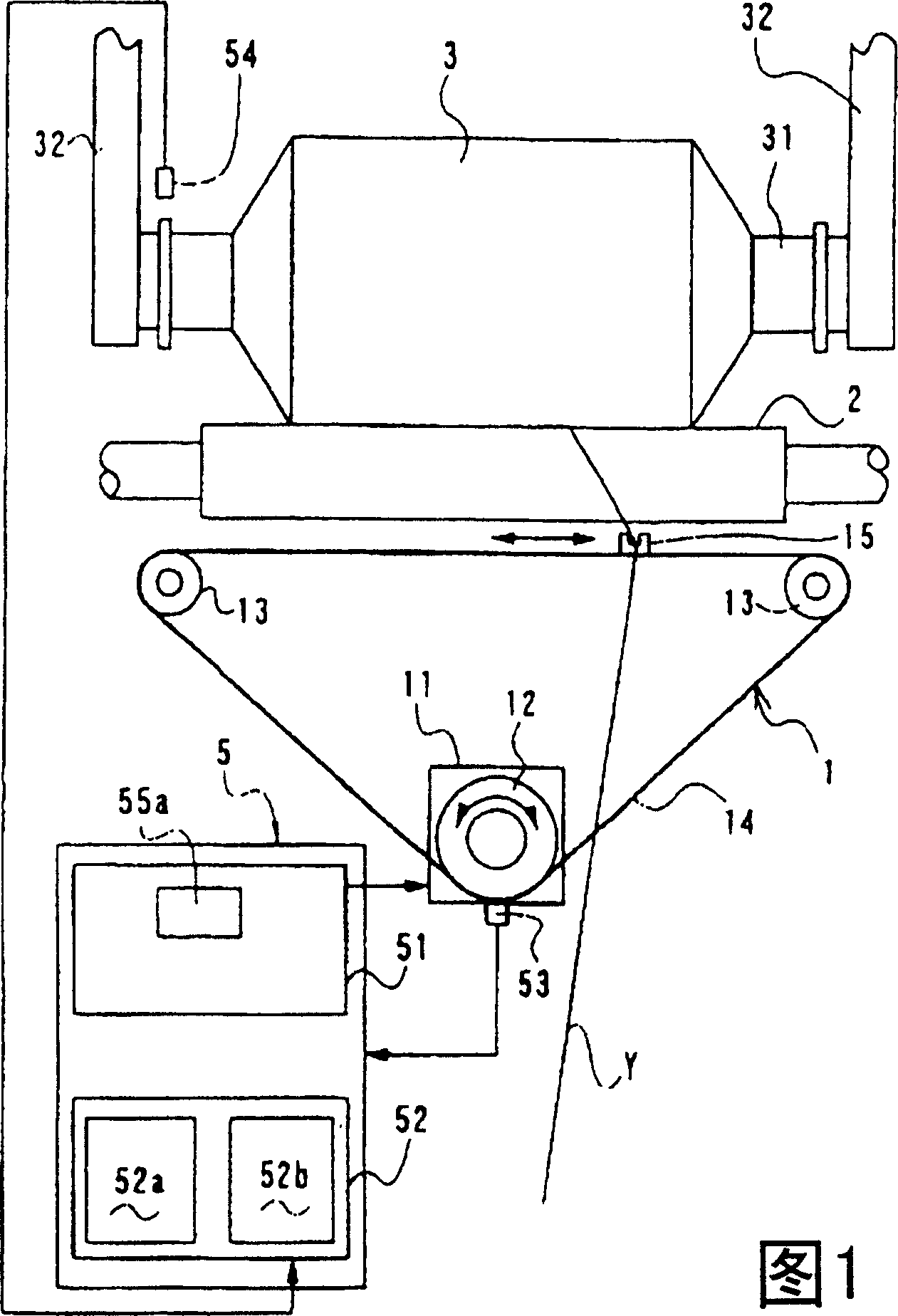

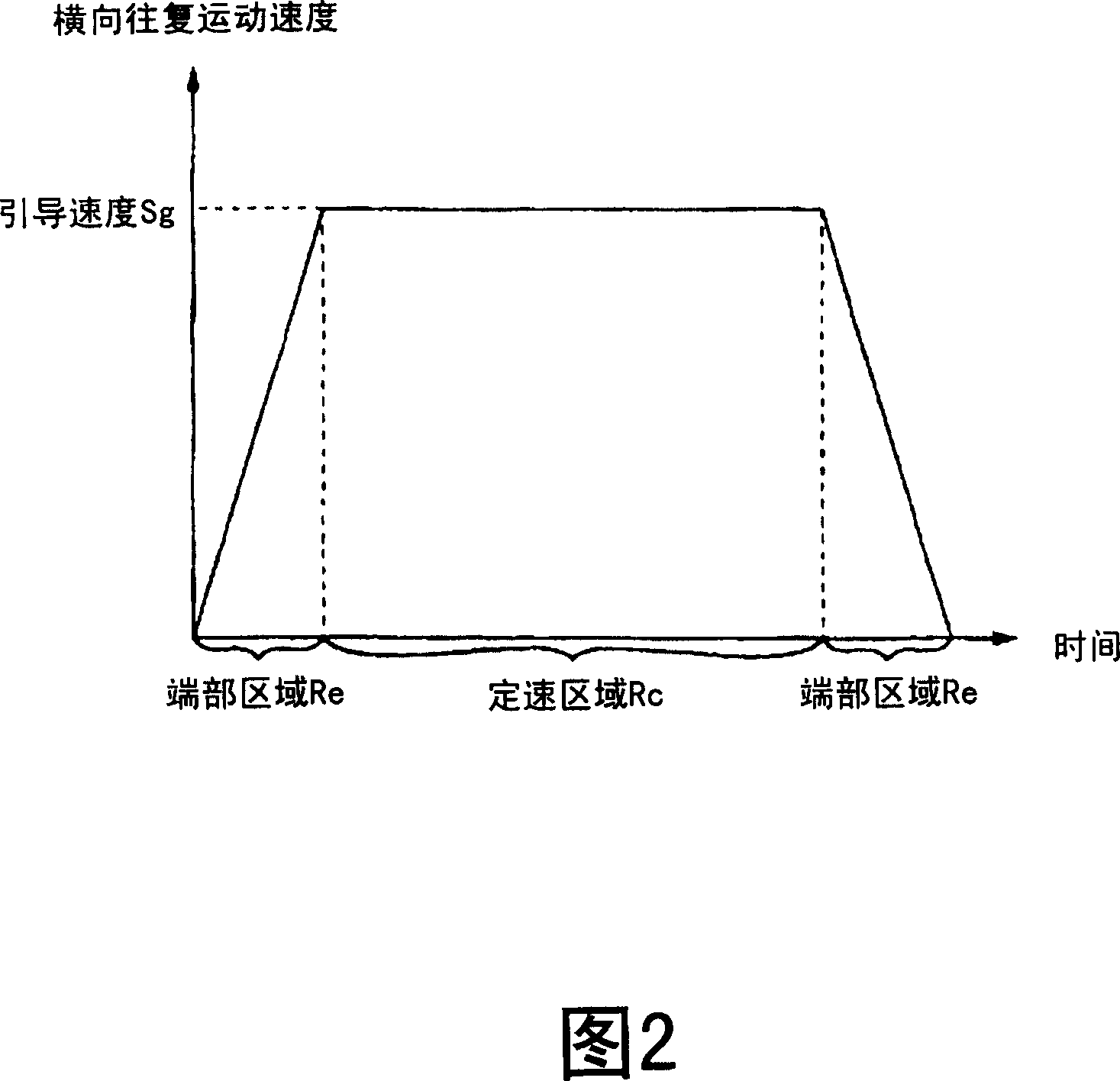

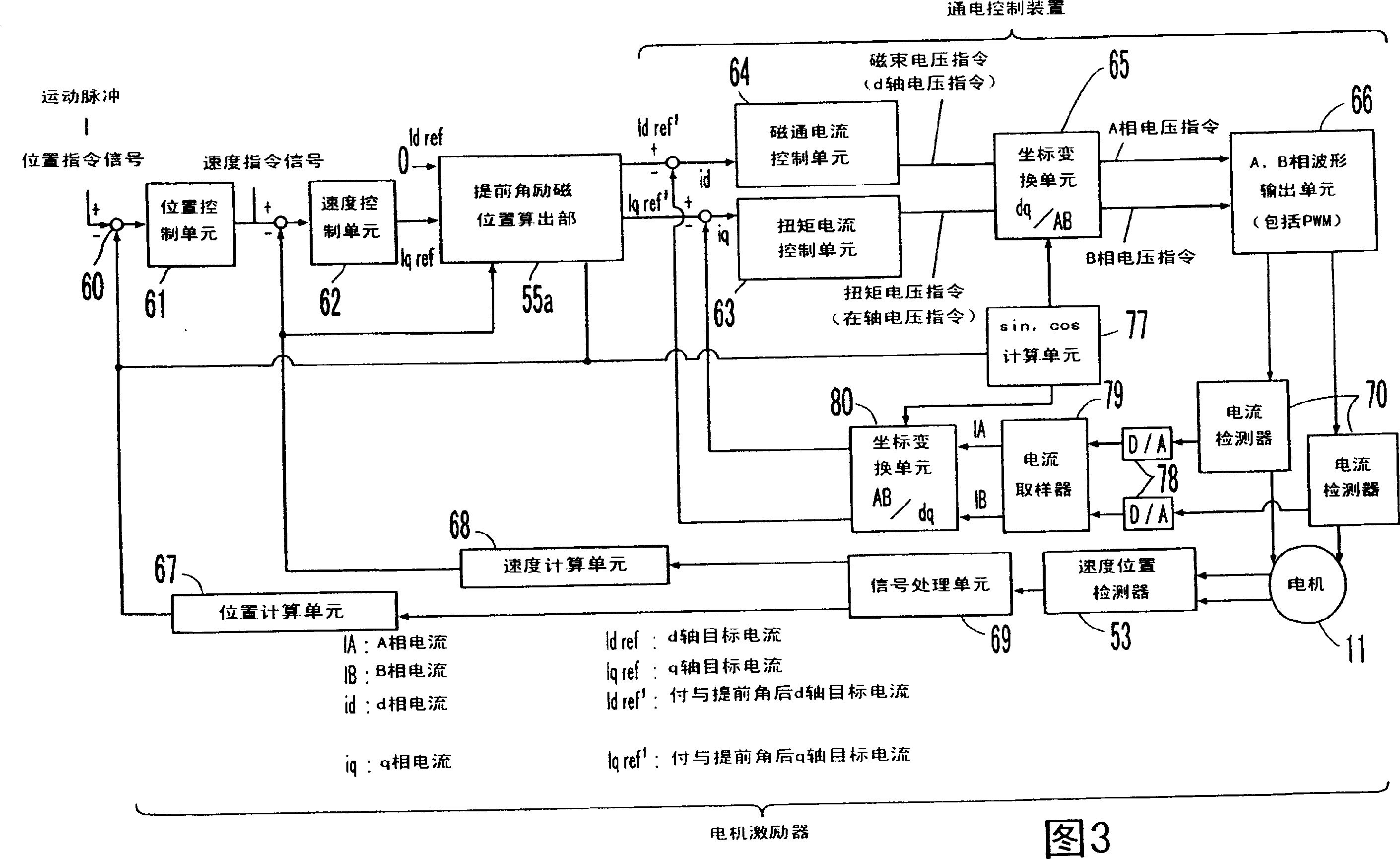

[0014] Embodiments of the present invention will be described with reference to the drawings. Fig. 1 is a schematic diagram of the overall composition of the traversing device of the present invention, Fig. 2 is a schematic diagram of the traversing speed at each traversing position in the traversing stroke, Fig. 3 is a schematic diagram showing the traverse motor used for vector control and advance angle control The block diagram of the composition of the motor actuator, Fig. 4 is a vector diagram illustrating the advance angle control with the motor rotation coordinates (d-q coordinates).

[0015] First, the configuration of a traverse device equipped with a traverse control device according to the present invention will be described. As shown in Fig. 1, the traversing device of the present application equipped with a traversing control device is applied to reciprocate the sliver Y unwound from the yarn feeding package not shown in the figure along the axial direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com