Outer metering valve for fuel tank

A technology for fuel tanks and dosing valves, applied in fuel cells, fuel cell additives, gaseous engine fuels, etc., can solve problems such as product leakage, tool damage, and shortened service life of fuel tanks, so as to simplify the joining process and prolong the use lifespan, the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

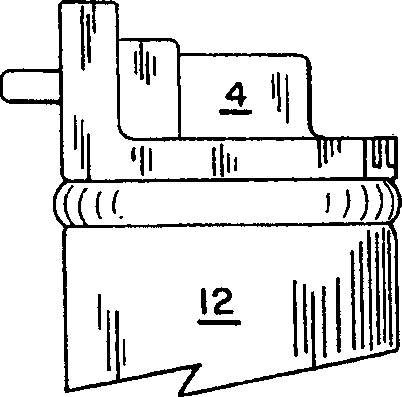

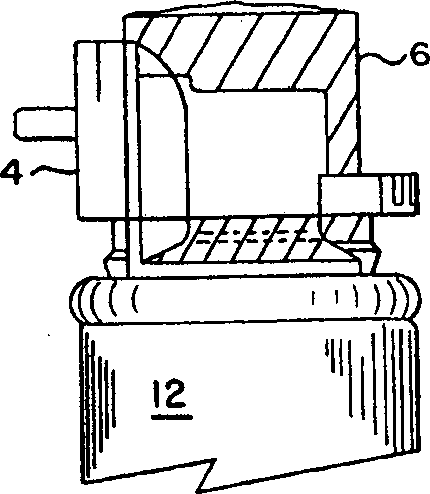

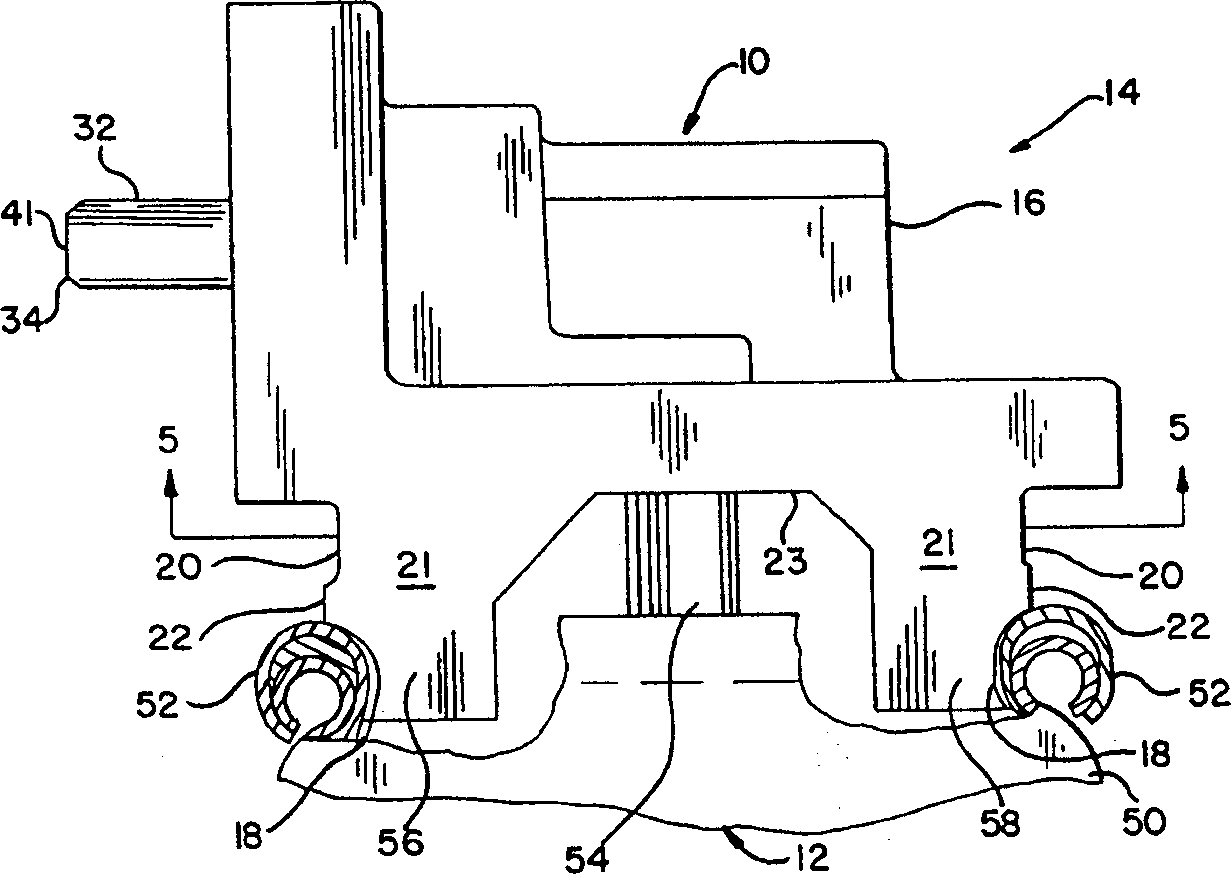

[0024] see now figure 1 and 2 , it can be seen that a prior art valve 4 is secured to the fuel tank 12 in a detached position by means of a securing cap or shipping cap 6 . As known in the art, such as figure 1 As shown, in order to move from the disengaged position to the engaged position, the user must first disassemble the retaining cap 6 together with the prior art valve 4 (these two parts are now connected together by a snap fit). The user then needs to disengage the retaining cap 6 from the prior art valve 4 and then place the prior art valve 4 on the fuel tank 12 to snap it into the engaged position. The engaged position is described in the prior art valve 4 engaged with the fuel tank 12. figure 1 can be seen in .

[0025] It is also known in the prior art that the fuel tank 12 is transported by fully engaging the prior art valve 4, as figure 1 shown. Because the prior art valve 4 is fully engaged with the fuel tank 12, the prior art valve is exposed to the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com