Engine casing assembly

A technology for engine hoods and engines, applied to engine frames, superstructure subassemblies, supporting machines, etc., can solve problems such as visibility impact, thermal expansion, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

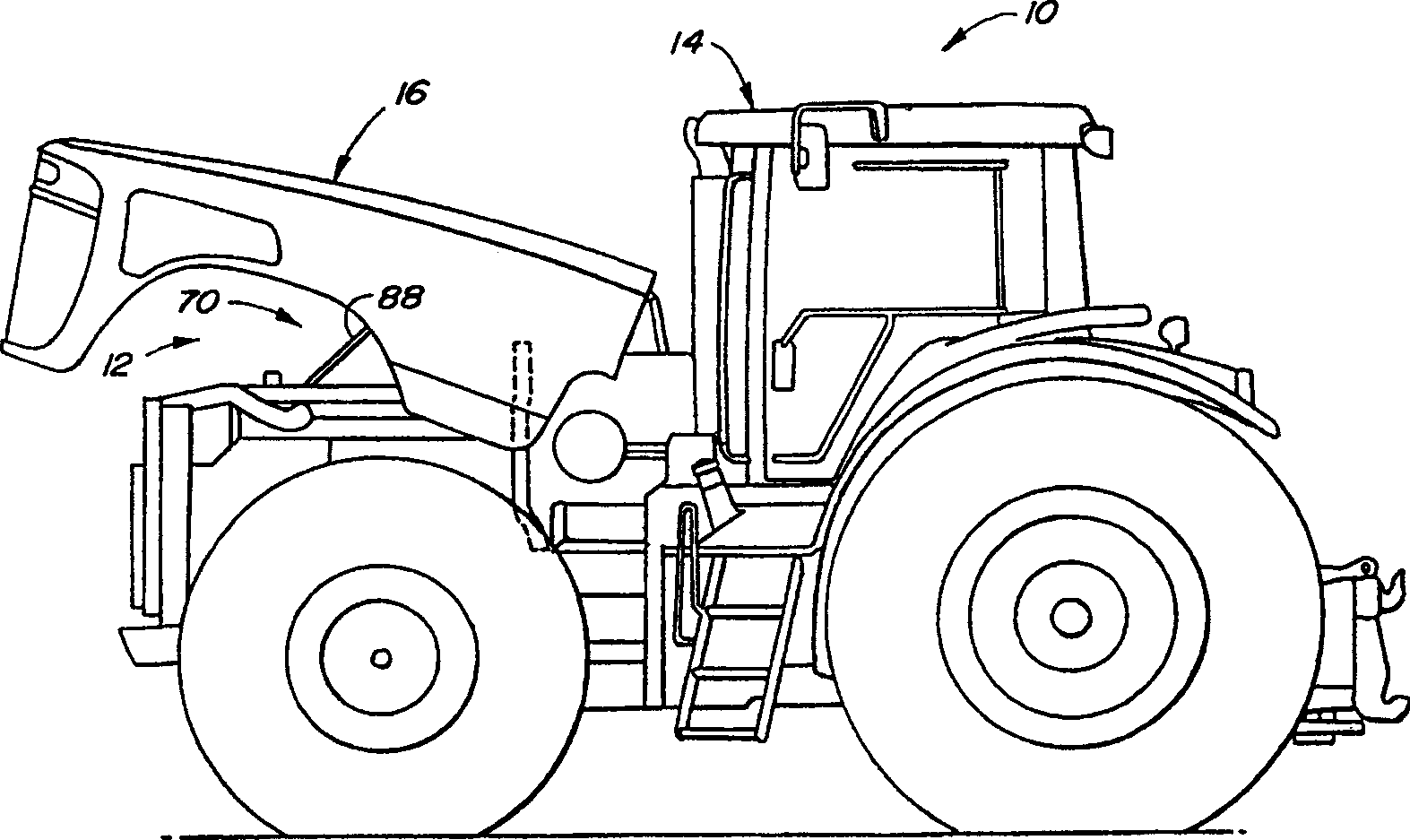

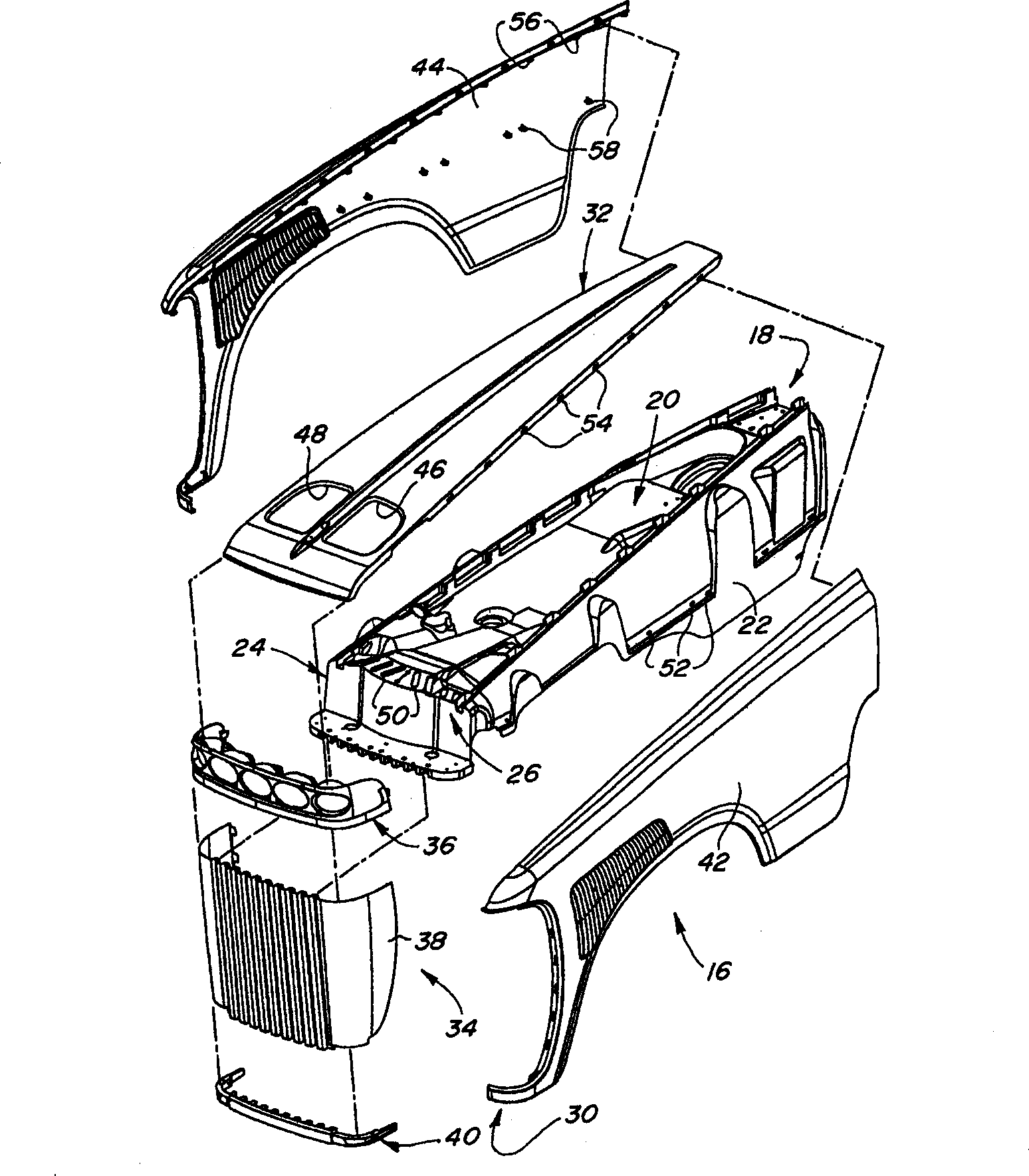

[0014] as attached figure 1 And attached figure 2 An agricultural vehicle 10 is shown having an engine 12 positioned forward of an operator's cab 14 and a hood assembly 16 joined to the tractor by a hinge 15 . It is best to refer to the attached figure 2 The hood assembly 16 includes an inner hood support 18 having a top surface 20 connected to the left and right sides 22 , 24 and also connected to the front side 26 . In order to achieve higher rigidity, the hood support 18 is preferably made of a plastic material with a higher glass fiber content. Top surface 20 includes a suction inlet 19 that is aligned with the location of an intake filter (not shown) of engine 12 .

[0015] The hood assembly 16 also includes a finished outer panel assembly 30 consisting of a finished top panel 32 mounted on the top surface 20, a mounting assembly including the headlight assembly 36, grille 38 and trim panel 40. Finished front outer panel assembly 34 on front side 26 , a finished lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com