Water-proof rubber casing

A technology of rubber sleeves and components, which is applied in the direction of multi-purpose hand tools, electrical components, bases/housings, etc., can solve the problems of poor insertion workability, increased insertion resistance, and reduced waterproofness, so as to improve insertion workability , improve water resistance, uniform compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An embodiment of the present invention will be described below with reference to the accompanying drawings.

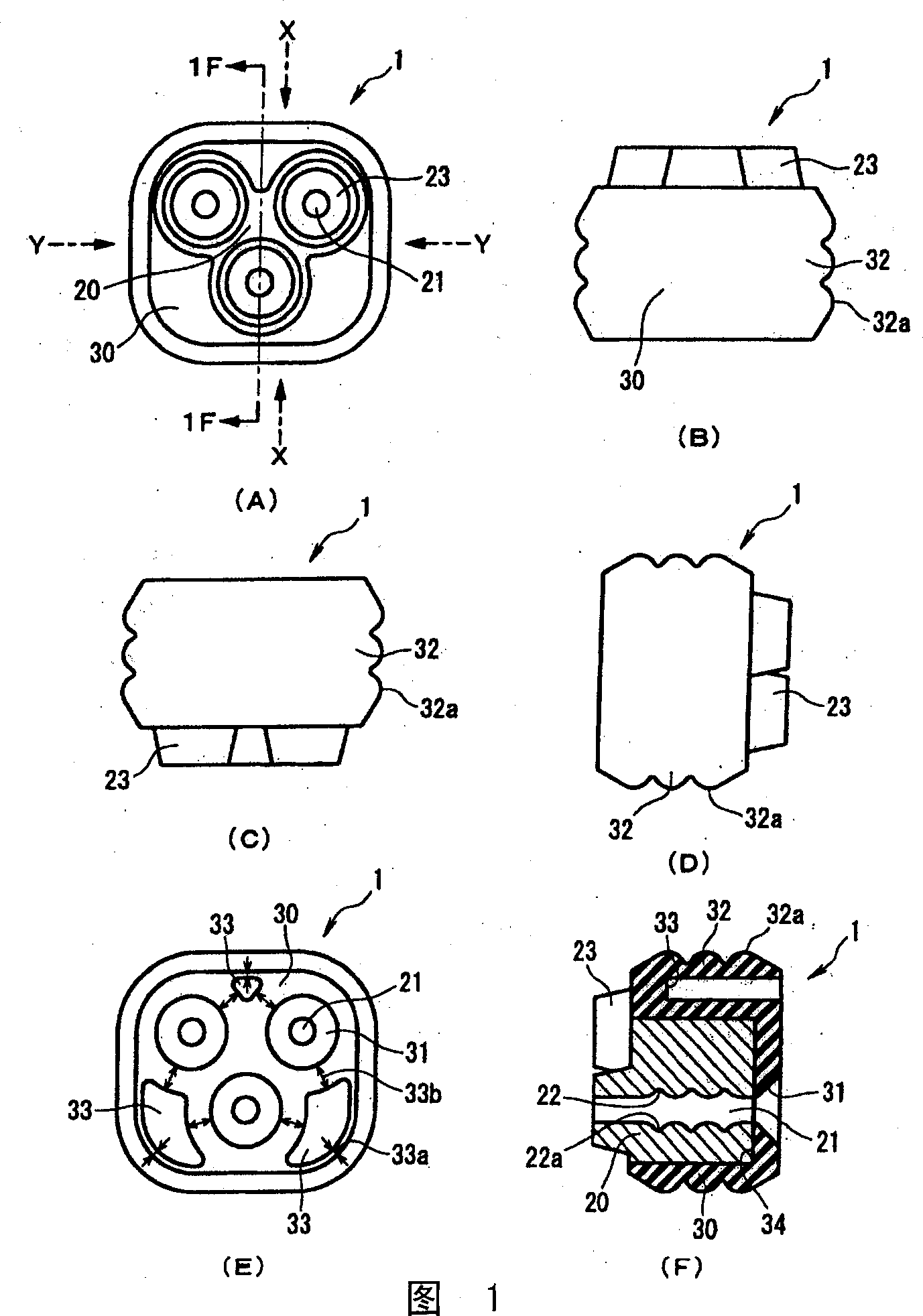

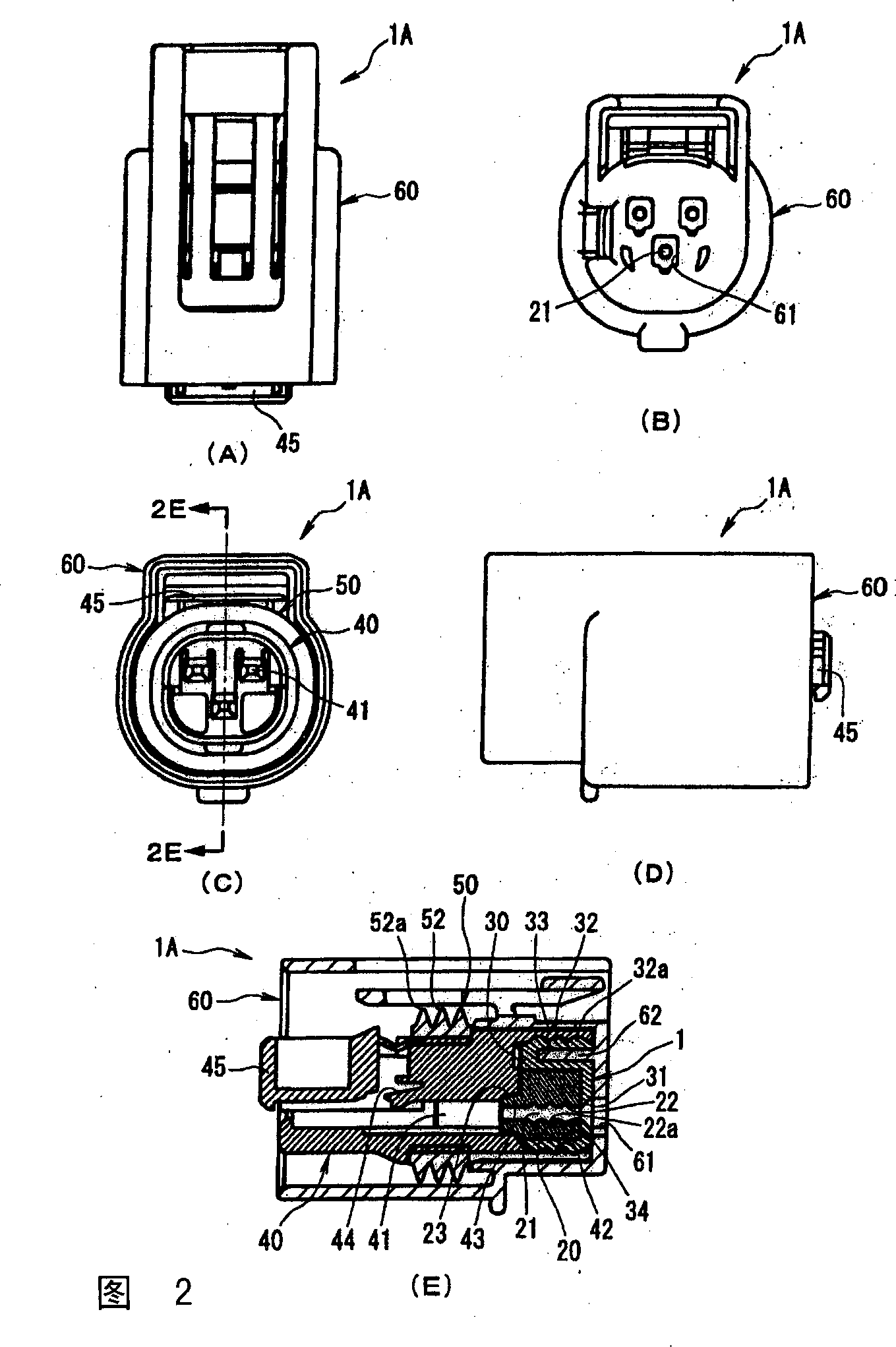

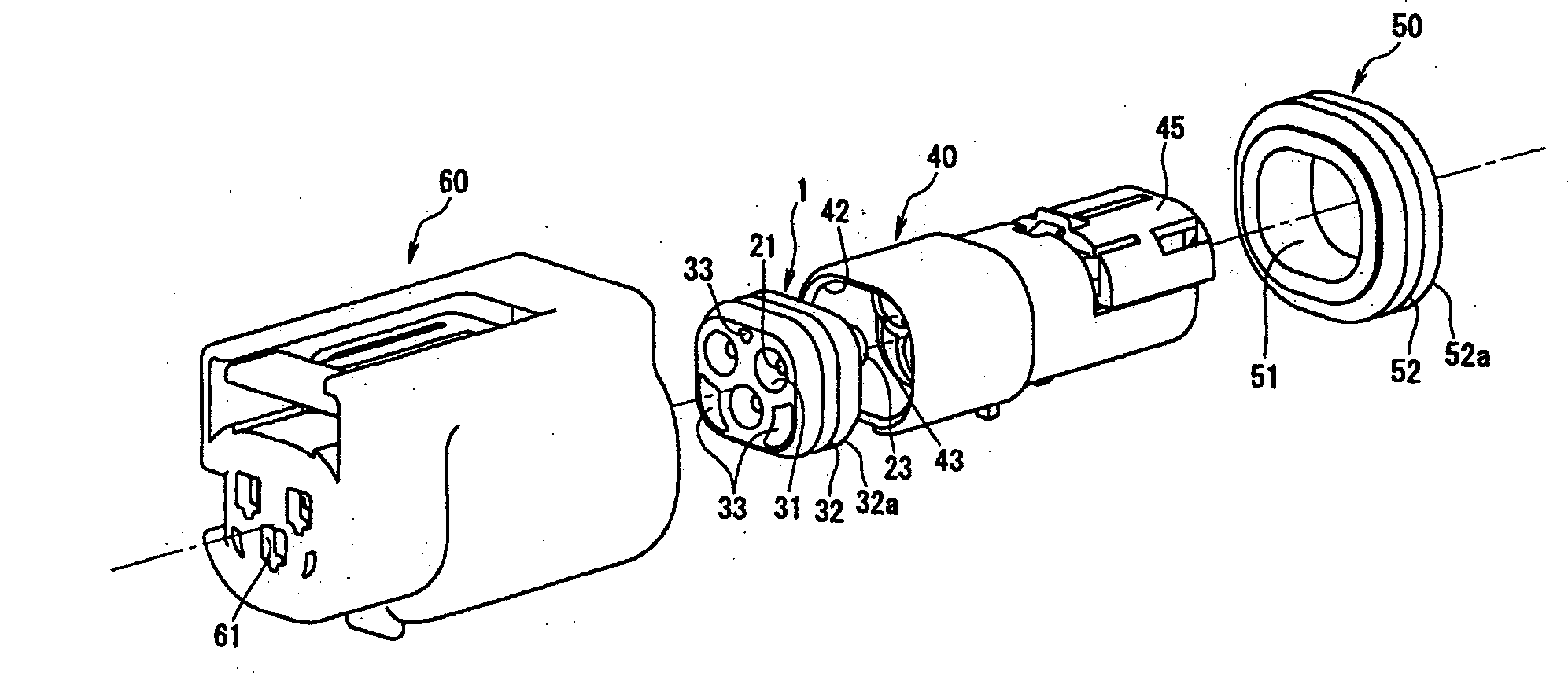

[0029] The waterproof rubber bushing 1 in the present invention, as shown in Fig. 1(A) to Fig. 1(F), is a substantially rectangular body, composed of a first member 20 and a second member 30 with different hardness, and is formed as The first part 20 is surrounded by the second part 30 . The first part 20 includes: three through holes 21 for passing the wires (not shown) connecting the contacts (not shown), and for aligning the waterproof rubber sleeve 1 with the connector housing 40 The three protrusions 23. The three through holes 21 are arranged in an inverted triangle shape, and are formed through the front and rear surfaces of the waterproof rubber sleeve 1 (the left and right surfaces in FIG. 1(F)). On the inner peripheral surface of each through hole 21, a first sealing portion 22 forming three annular ribs 22a for closely contacting the electric wire is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com