Balancing valve

A technology of balancing valve and valve sleeve, applied in the field of hydraulic balancing valve, can solve the problems of decreased sensitivity, complicated system, easy oil leakage of pipes, etc., and achieve the effect of preventing the falling of load stall, the locking function being safe and effective, and avoiding unsafe factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

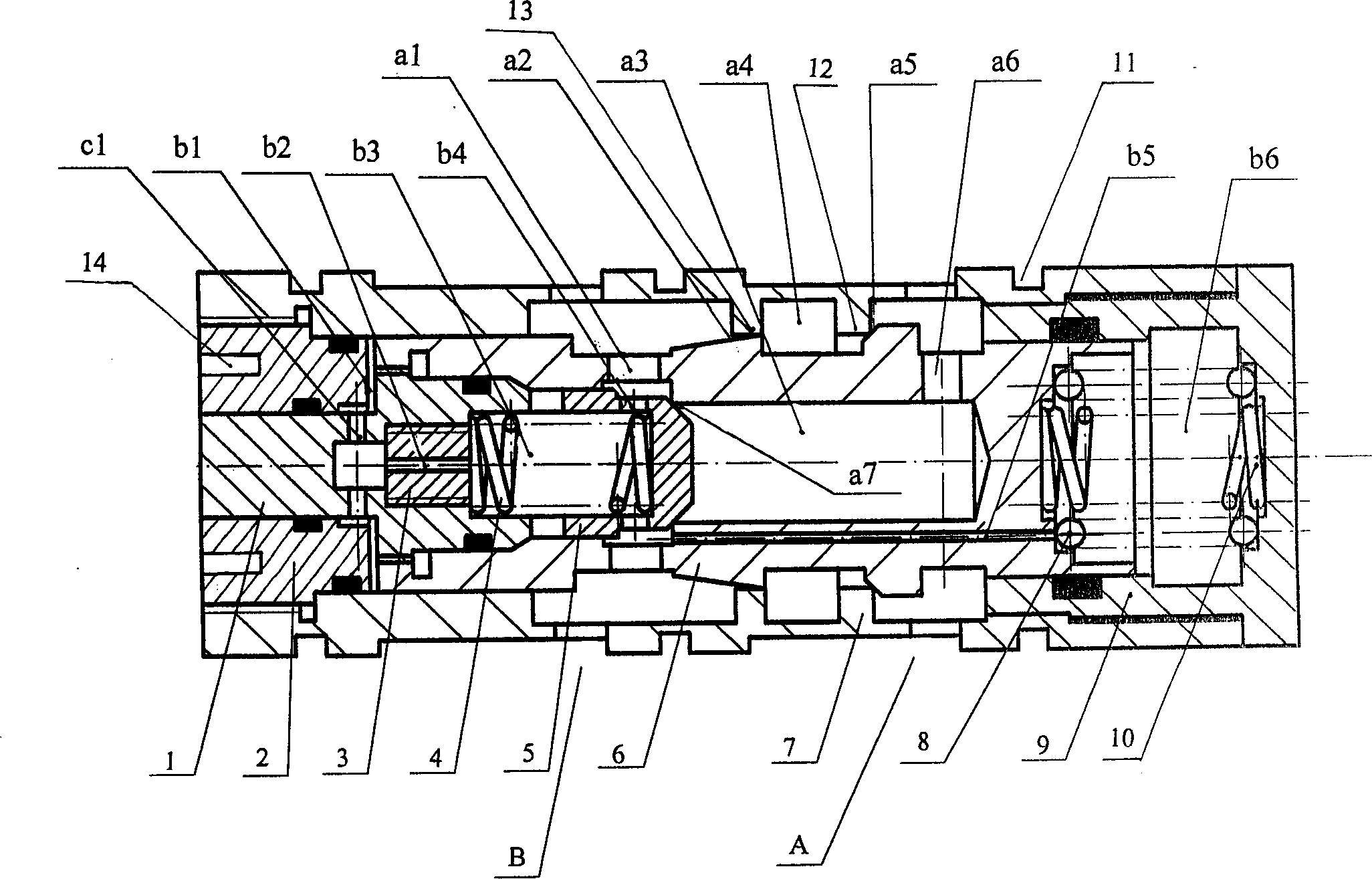

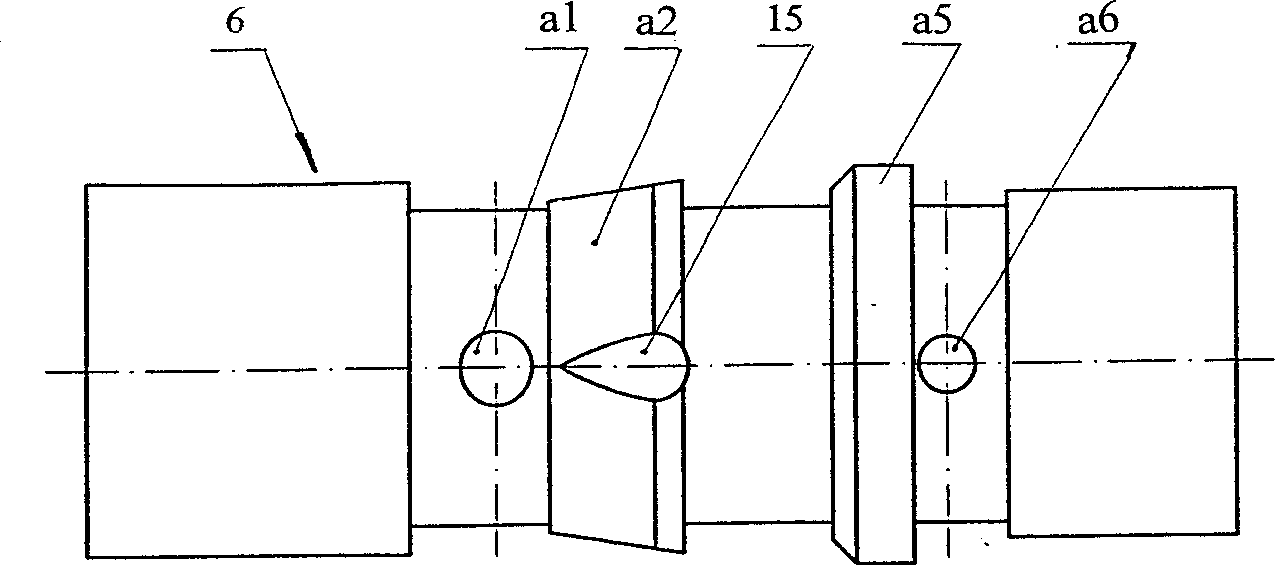

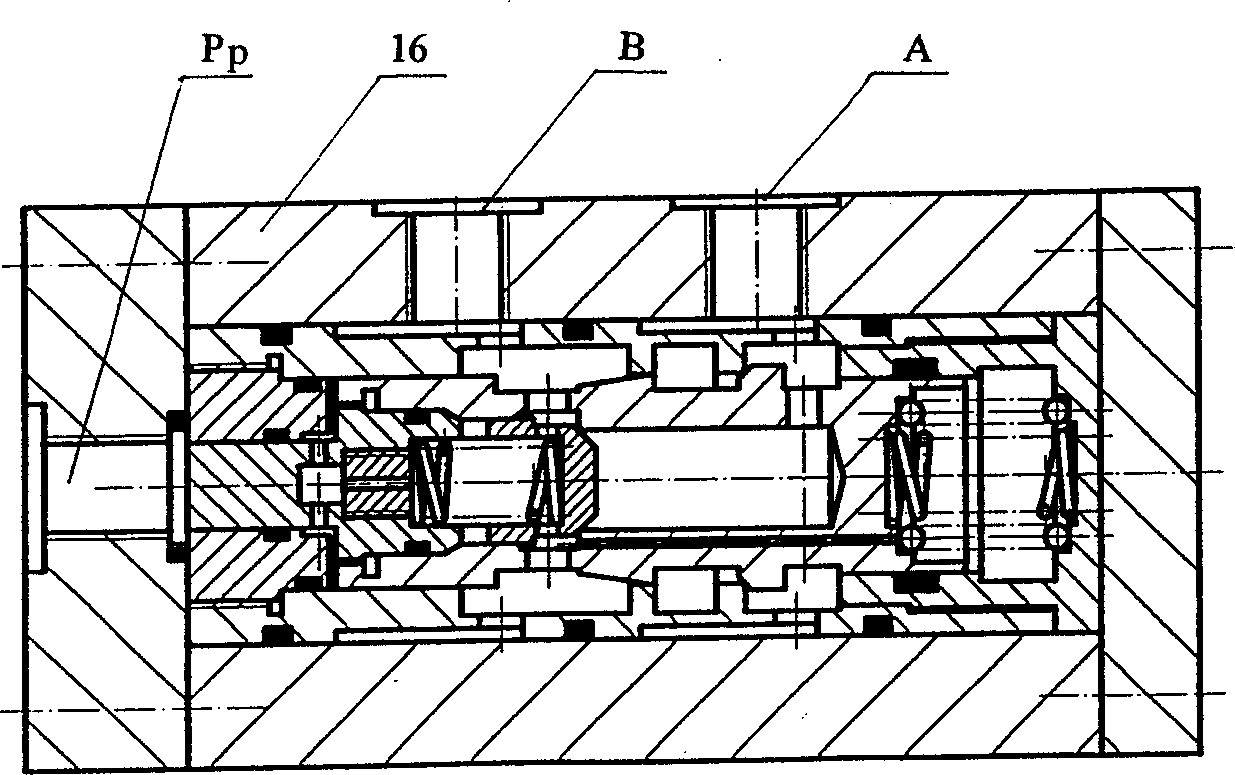

[0015] see figure 1 , the balance valve includes a main valve and a pilot valve, each of the above valves includes two cavities located in the front and rear of the valve core, wherein the main valve includes a valve sleeve 7 and a main valve core 6, the valve sleeve 7 is cylindrical, and the valve sleeve There are two main oil ports A and B on the outer side of the valve sleeve 7, and three grooves 11 are arranged on the outer side of the valve sleeve 7 around the circumference for inlaying the sealing ring, so that the balance valve can be inserted into the hydraulic cylinder to perform a sealing function. There are two bosses 12 and 13 on the inner wall of the valve sleeve 7, and an oil cavity a4 is formed between the two bosses 12 and 13; the outer middle of the main valve core 6 has two conical sides a2 and a5 separated by a certain dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com