Circular or annular coating film forming method

A coating film and circular technology, which is applied in the field of forming circular or annular coating films, can solve the problems of inability to form annular coating films and obtain uniform thickness coating films, and achieve the effect of eliminating waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

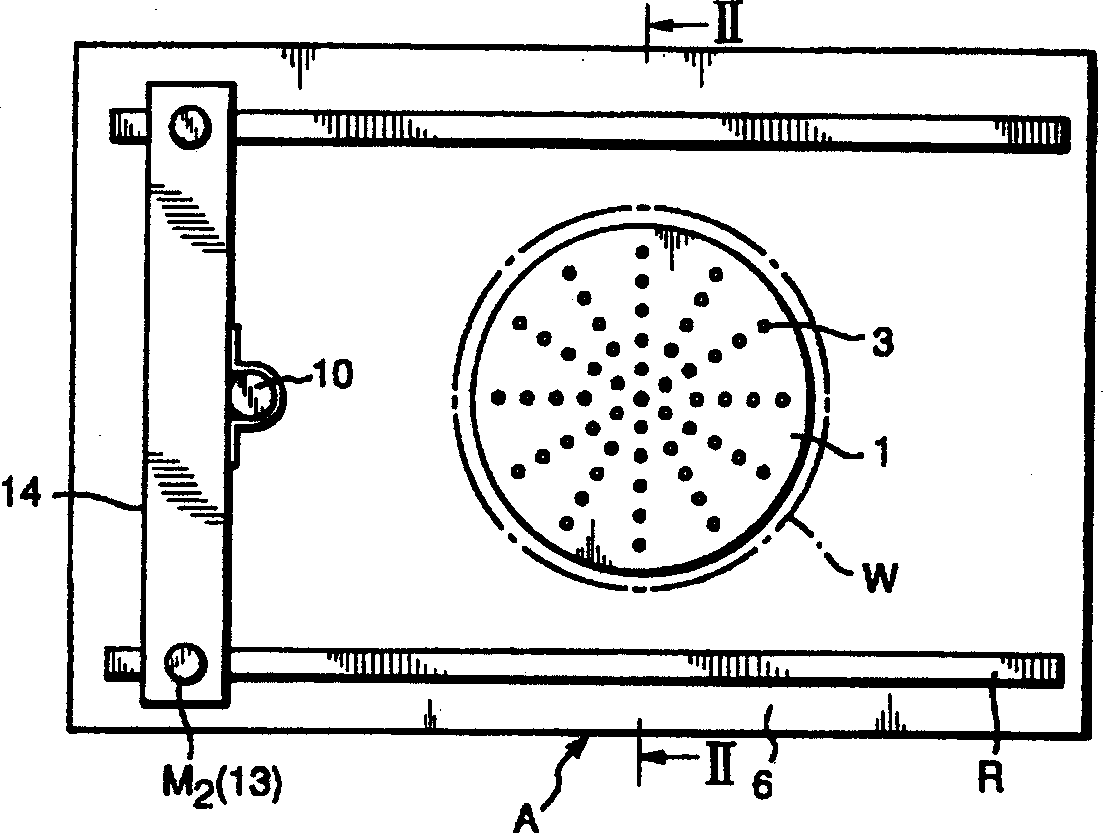

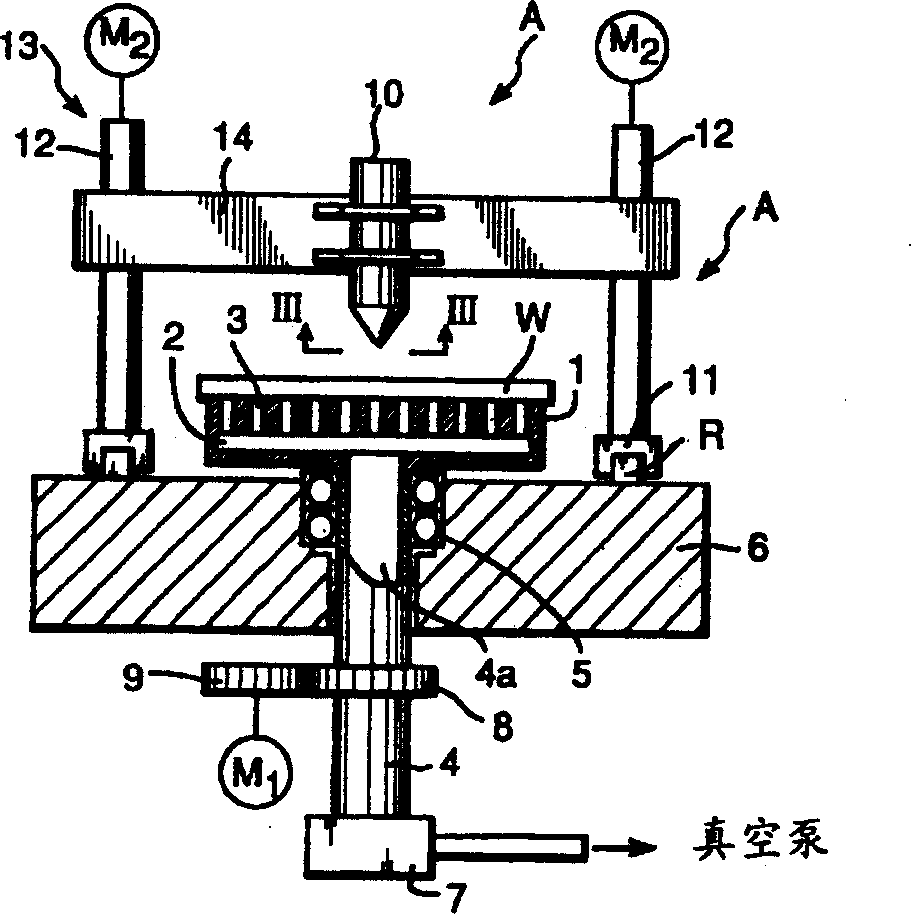

[0014] An embodiment of the present invention will be described below with reference to the drawings.

[0015] The figure shows a coating device A used to implement the present invention.

[0016] Such as figure 1 As shown, the coating device A is roughly composed of a worktable 1 and a nozzle 10. Such as figure 2 As shown, the workbench 1 is installed at one end of a hollow shaft 4 passing through the base 6, and the workbench is held by a bearing 5 provided at the penetrating part of the base 6 to rotate together with the hollow shaft 4. The other end of the hollow shaft 4 is connected to a vacuum pump not shown in the figure via a rotary joint 7. A gear 8 is provided on the protruding part of the hollow shaft 4 on the bottom surface of the base 6, using a motor M 1 To drive the gear 9 meshing with the gear 8 to rotate the table 1.

[0017] The surface of the table 1 has a predetermined flatness, for example, a flatness of 2 microns or less. A header 2 is radially provided ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com