Harness frame angle connecting device

A corner connection, heald frame technology, used in healds, transportation and packaging, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

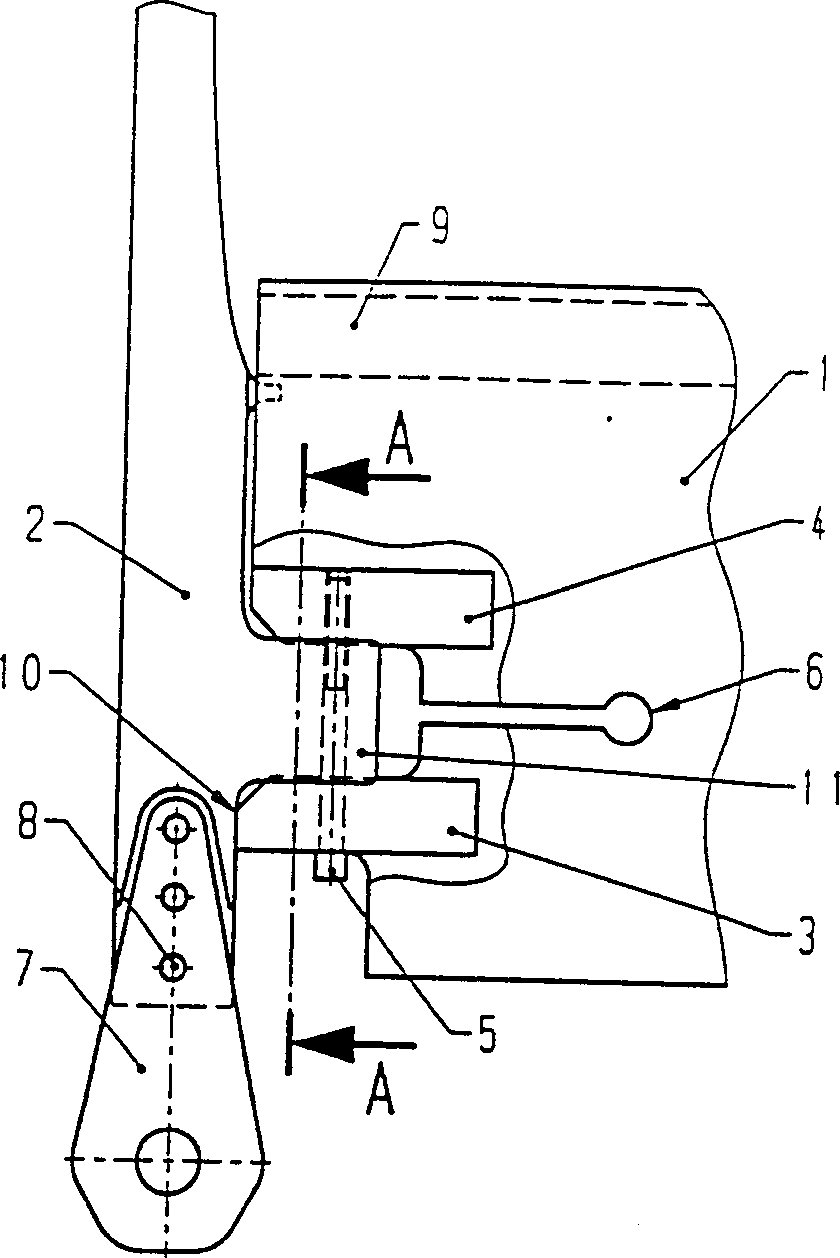

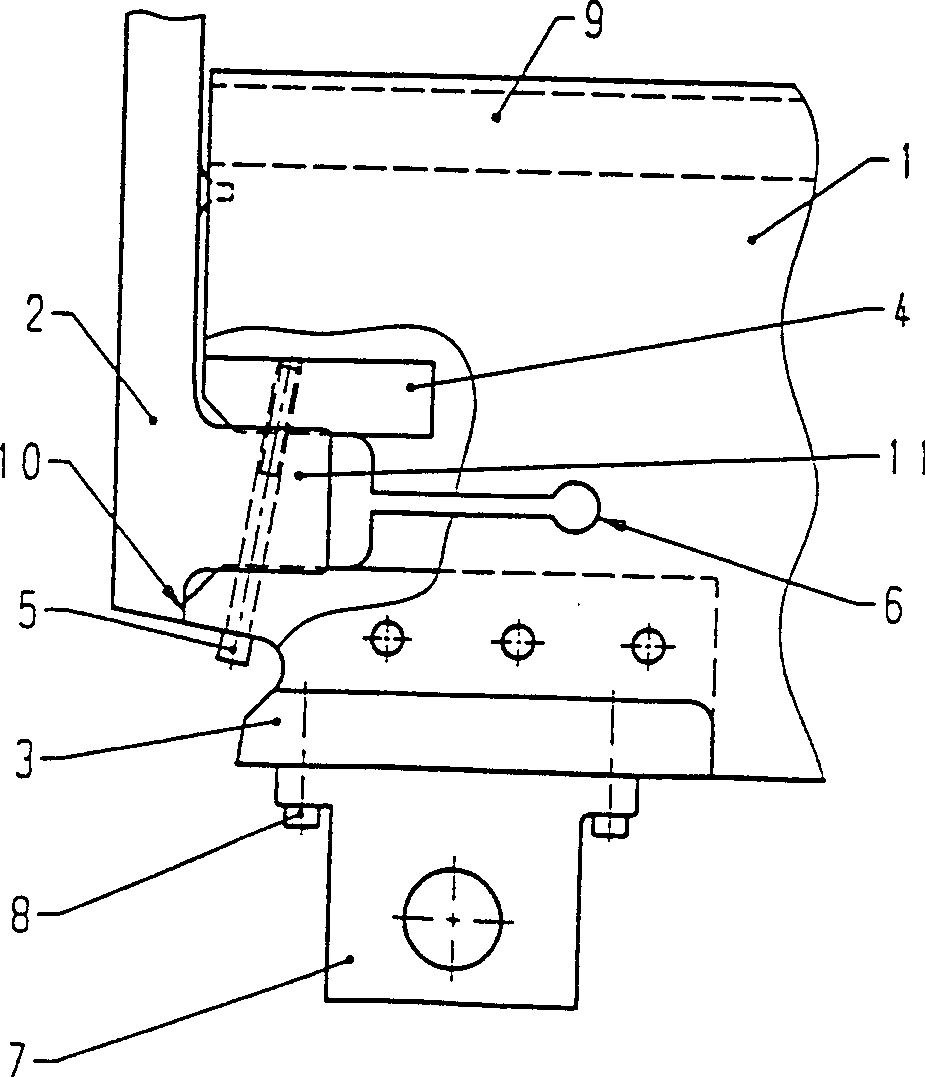

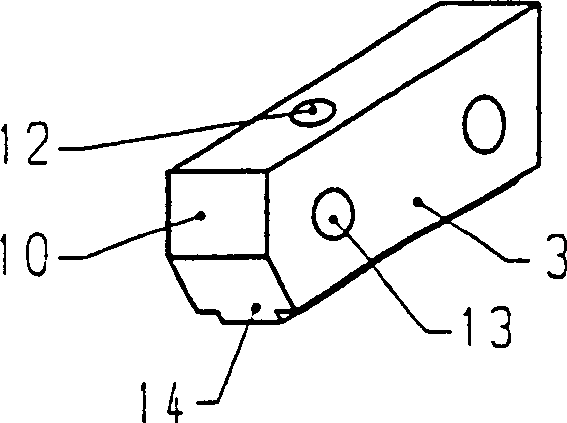

[0019] figure 1 It shows a longitudinal section of a structure of the new corner connection device proposed by the present invention. In an empty heddle plate 1 on which the heald guide bar 9 is fastened, a projection 11 of the side support arm 2 engages in two guide elements fixedly arranged on the heald plate 1 , namely the stop element 3 and the Between the threaded plates 4. The protrusion 11 of the side support arm is held by means of the locking screw 5 between the stop element 3 fixed on the heddle plate 1 and the threaded plate 4 also fixed on the heddle plate 1, at this time the stop element 3 is held Press against threaded plate 4. This is possible because the heald panels acquire a certain elasticity by means of the slots 6 in the end regions of the heald panels. Furthermore, the locking element 3 has a machined surface 10 for positioning the side support arm 2 in the longitudinal direction of the heddle profile 1 . Finally, press figure 1 In the structure show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com