Sealing structure of organic electric field luminescence type display

An organic electric field and light-emitting technology, which is applied in the field of sealing structures of organic electric field light-emitting displays, can solve problems such as direct contact with external air, achieve the effects of reducing material costs, improving bonding strength, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention (hereinafter referred to as embodiments) will be described below with reference to the drawings.

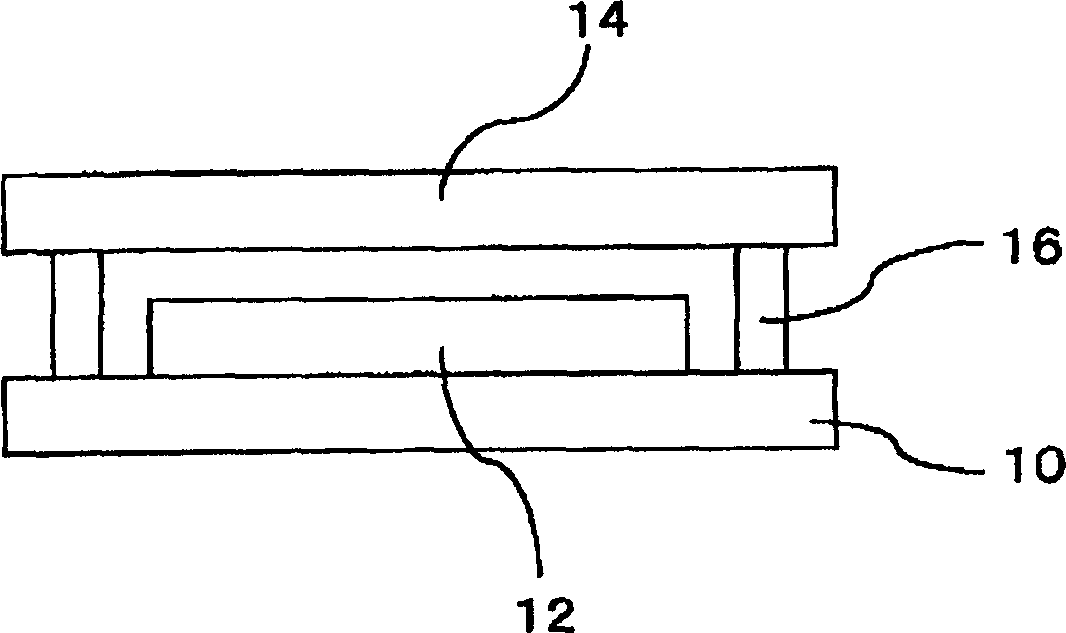

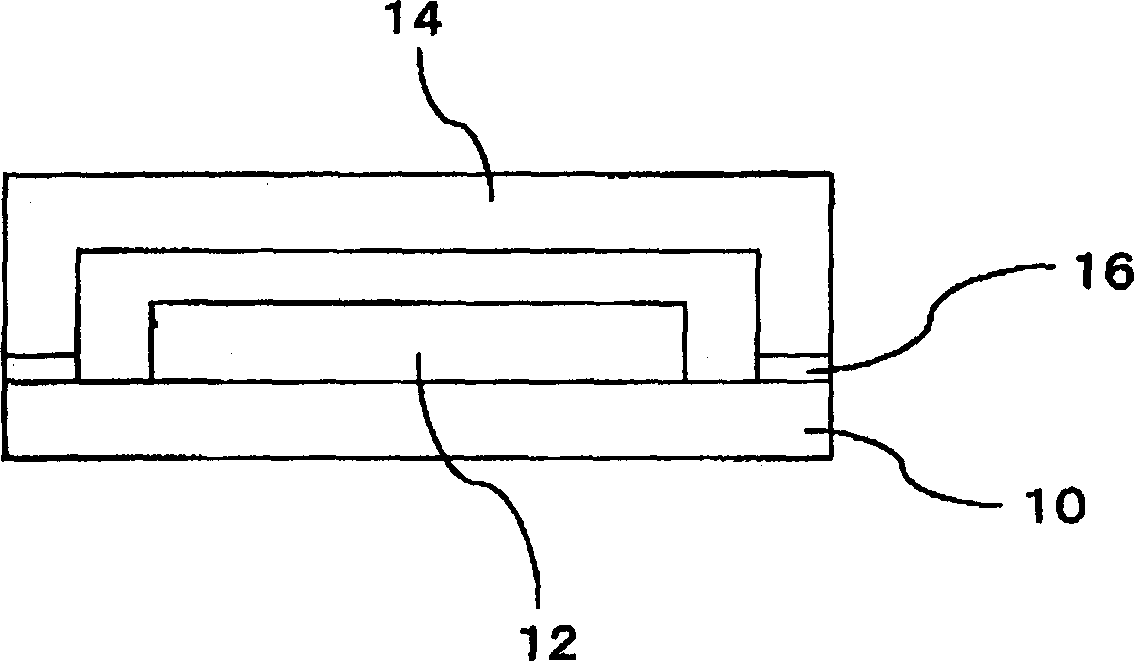

[0018] figure 1 It is a cross-sectional view of one embodiment of the sealing structure of the organic electroluminescent display of the present invention. exist figure 1 In the present invention, an organic electroluminescence element 12 is formed on a substrate 10 . In addition, the organic electroluminescence element 12 is sealed by bonding the sealing member 14 to the substrate 10 with an adhesive 16 made of an ultraviolet curable resin, and is thus insulated from the outside air. In this case, the sealing member 14 is a flat glass, and a material having a transmittance of ultraviolet rays, especially light of 300 to 320 nm, of 50% or more is used. Therefore, when the sealing member of this embodiment is produced, the curing reaction of the adhesive 16 which is an ultraviolet curable resin can be sufficiently advanced, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com