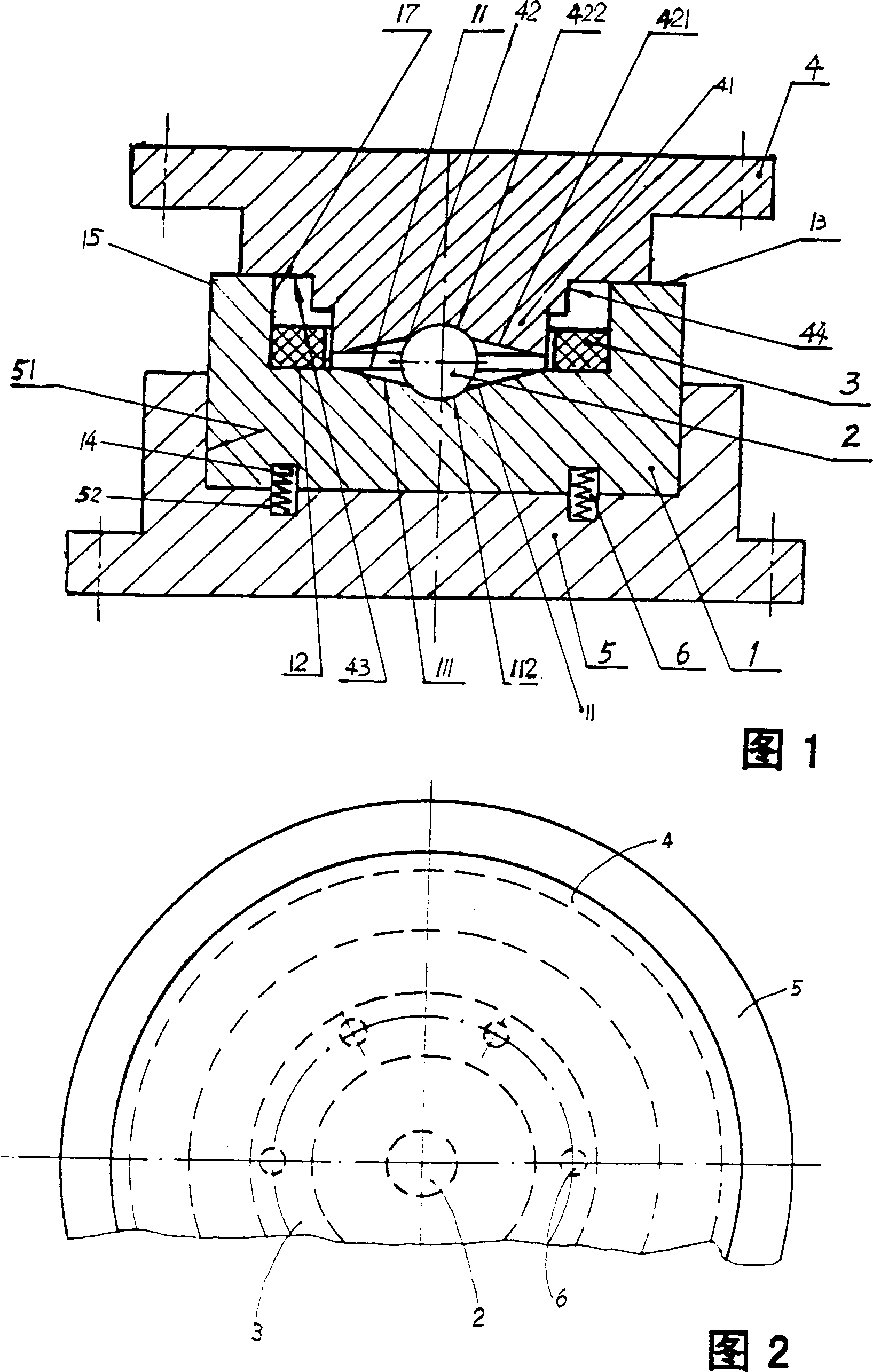

Earthquake damping and isolating mechanism

A seismic isolation, concave technology, applied in earthquake prevention, infrastructure engineering, building components, etc., can solve the problem of not considering the lifting and separation phenomenon, unable to form the function of building back, unable to play the role of shock absorption and isolation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

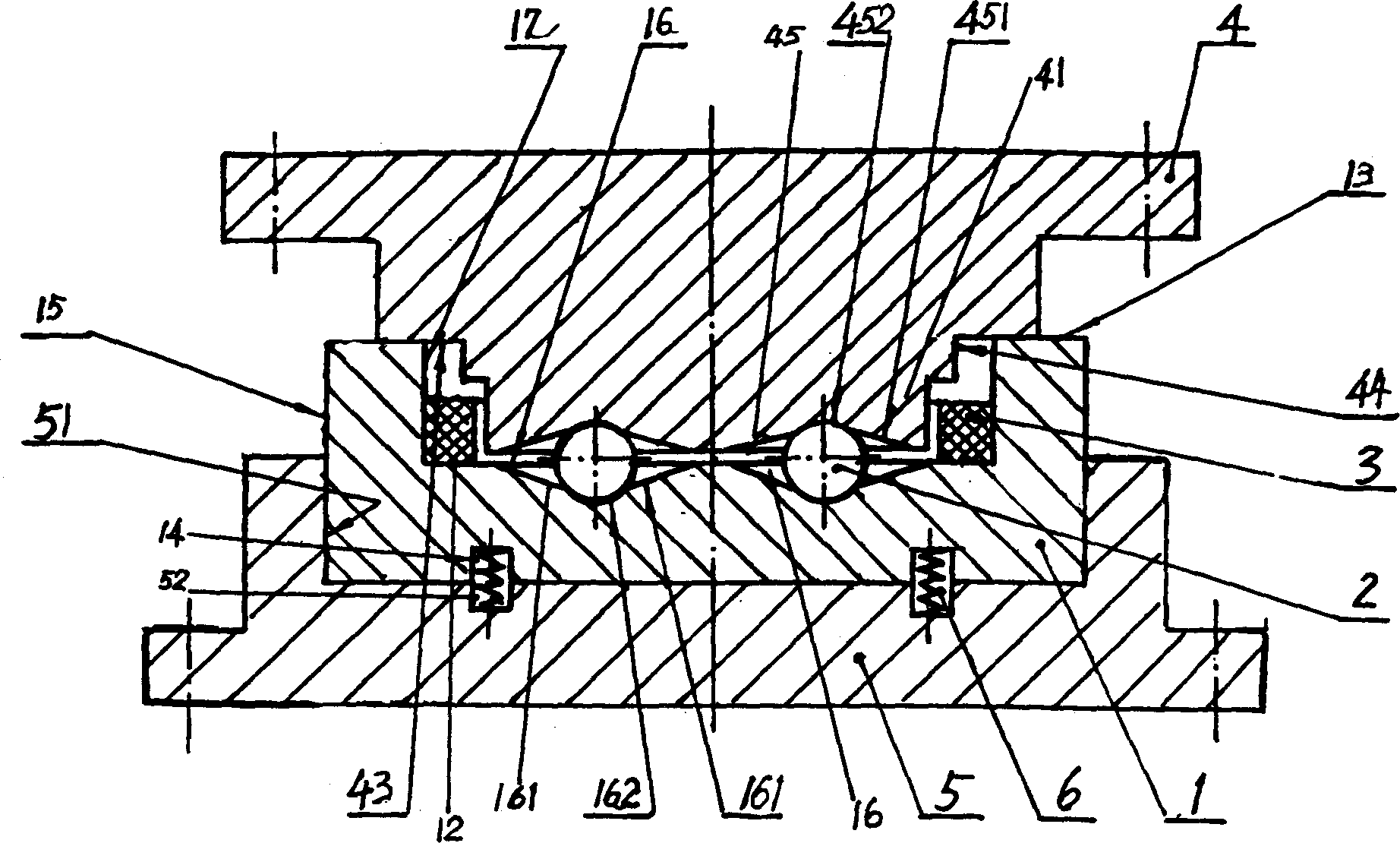

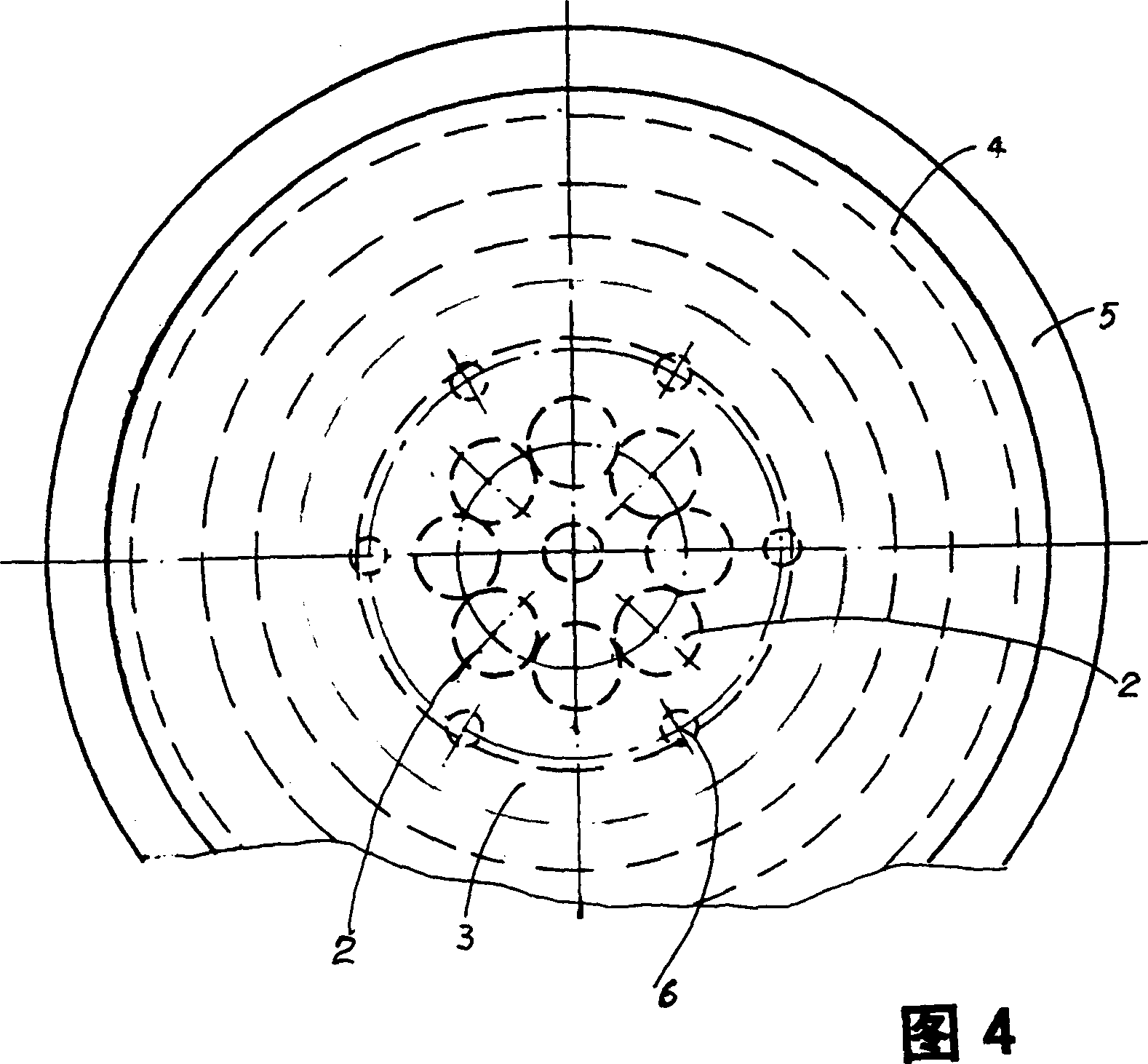

Embodiment 2

[0057] The main difference between the device in embodiment 2 and the device described in embodiment 1 is that: the pot body 1 and the cover plate 4 are each provided with an annular groove. The cross-sectional shape of the annular groove is similar to the cross-sectional shape of the concave bottom surface on the bowl body 1 and the cover plate 4 in the device described in Scheme 1, and both are composed of arc line segments and oblique line segments. A plurality of rolling balls 2 are placed in the annular groove, thereby increasing the bearing capacity of the device. When there is no earthquake, multiple rolling balls are subject to the same preload and elastic deformation between the annular grooves 16 and 45 . The vertical loads it bears are basically the same, but when a horizontal earthquake occurs, the loads borne by each rolling ball are different.

[0058] Four, the feature of device of the present invention:

[0059] 1. When no earthquake occurs, since the main lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com