Floating type photovoltaic power generation system with adaptive photovoltaic tracking performance

A photovoltaic power generation system, self-adaptive technology, applied in the direction of photovoltaic power generation, support structure of photovoltaic modules, photovoltaic modules, etc., can solve the problems of multiple reliability of devices, complex installation and debugging, complex control links, etc., to achieve easy handling and assembly, The effect of strong unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

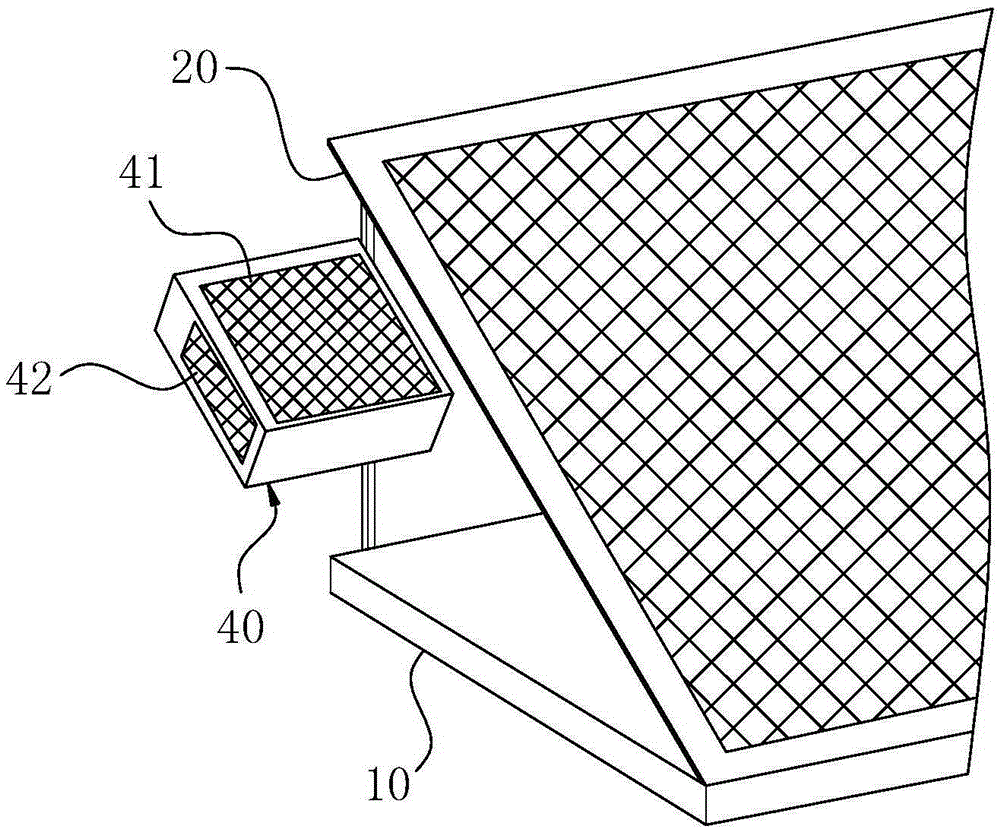

[0035] For ease of understanding, combined here Figure 1-10 One of the implementation structures of the present invention and its workflow are further described as follows:

[0036] The entire circuit control and driving structure of the present invention can be integrated in the control box 40 in the shape of a square box. The airtight inner cavity of the control box 40 is used for arranging lines, and the outer surface of the box body takes three adjacent surfaces to install the main photovoltaic panel 41 , the left photovoltaic panel 42 and the right photovoltaic panel. Specifically, as shown in 1, a relatively high-power main photovoltaic panel 41 is installed on the front side of the control box 40 parallel to and in the same direction as the light-receiving side panel surface of the solar panel 20, and two panels are installed on the left and right sides of the control box 40 respectively. Low power left photovoltaic panel 42 and right photovoltaic panel. The control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com