Hydraulic in-the-hole hammer with dual nozzles and combined valve

A technology of hydraulic down-the-hole hammer and compound valve, which is applied to the drilling driving device, drilling equipment, earth-moving drilling and mining in the wellbore, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

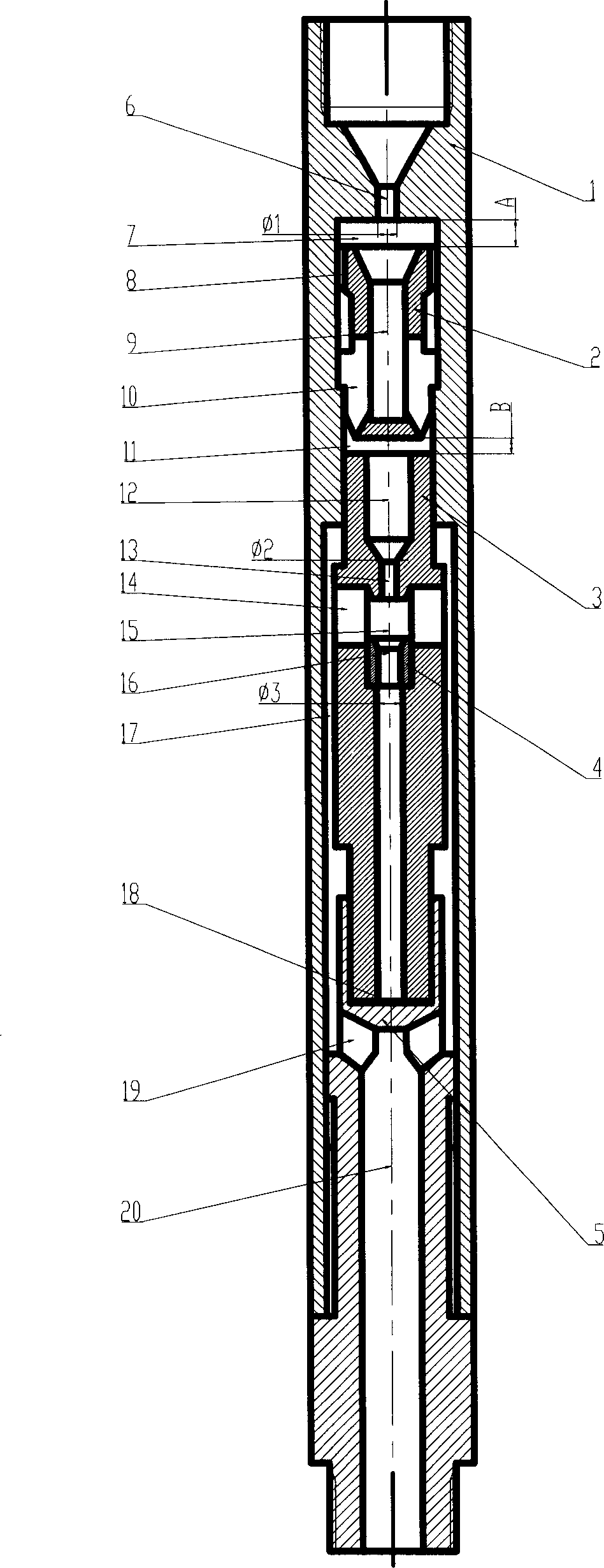

[0009] The double-nozzle composite valve type hydraulic down-the-hole hammer includes a casing 1, an upper valve 2, a hammer 3, a hammer bearing nozzle 4 and a lower joint 5. The upper center of the casing 1 is provided with an upper nozzle 6, which is facing the upper valve 2. The upper chamber 7 and the central hole 9 of the upper valve can use the jet formed by the high-speed movement of the liquid flow to generate a low-pressure effect at the upper chamber 7 of the upper valve; the outer diameter of the upper valve 2 forms a sliding fit with the inner diameter of this part of the shell 1, and the matching surface There is a longitudinal groove 8, the upper valve 2 can move freely up and down and has a limited position when moving downward, the movement stroke is A, and the value of A is 1-500 mm. The upper section of the hammer 3 forms a sliding fit with the shell 1, and the lower section forms a sliding fit with the inner hole of the upper section of the lower joint 5 to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com