Method and plant for providing quantitative dough for bread continuously

A technology for making bread and dough, which is applied to dough forming machinery or equipment, dough extruder, dough sheeter/roller/rolling pin, etc., and can solve problems such as low efficiency and low dough efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

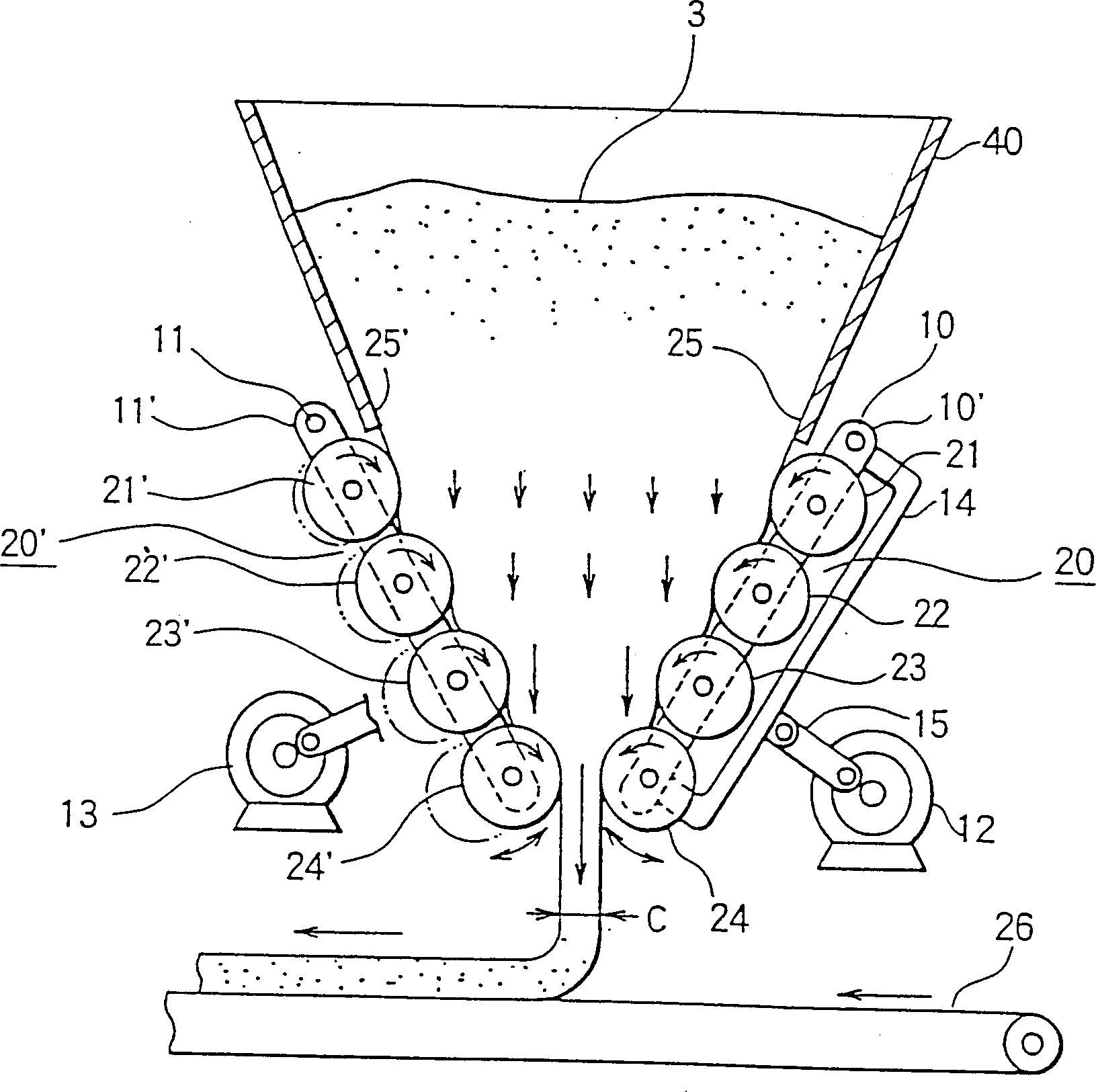

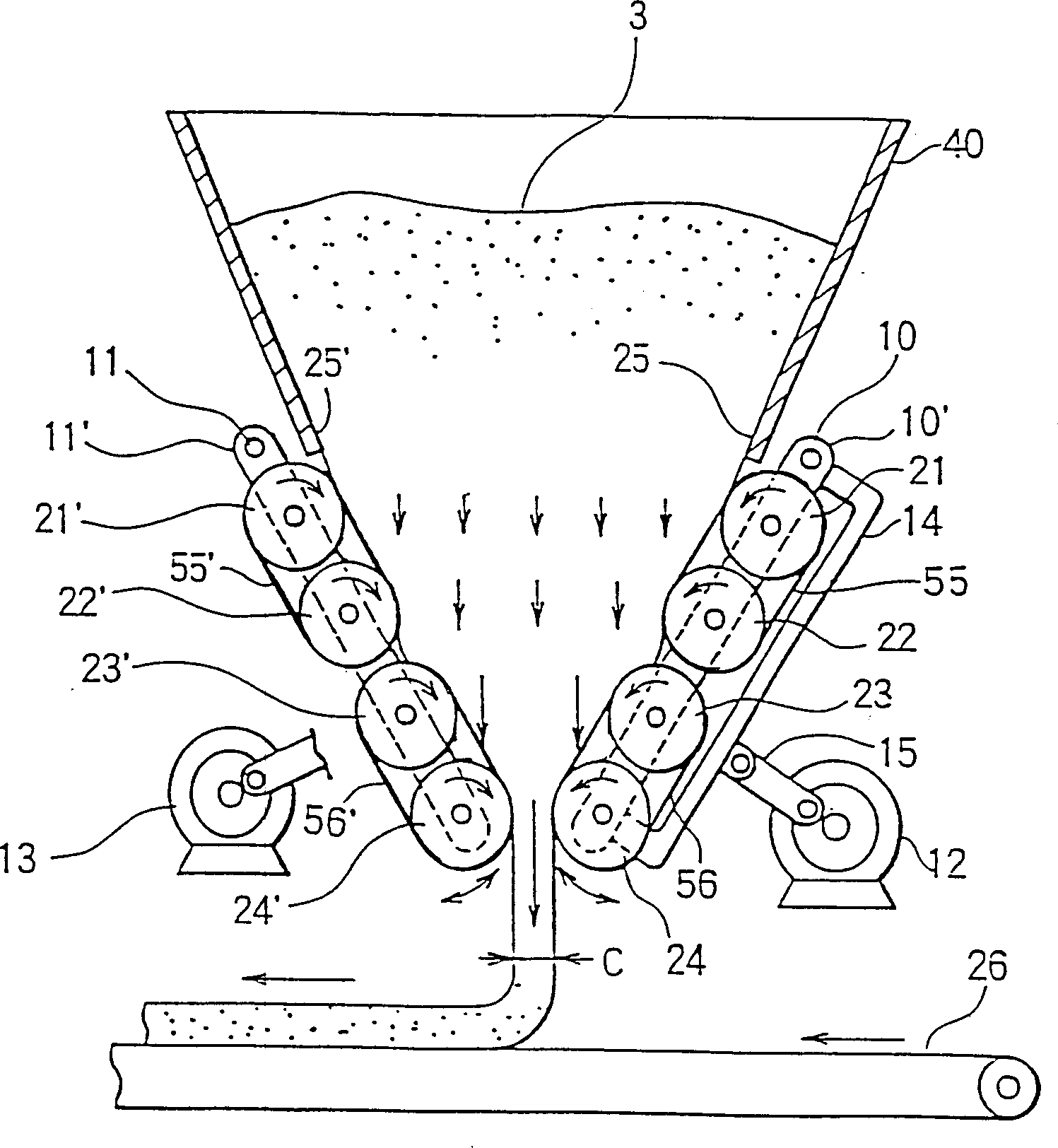

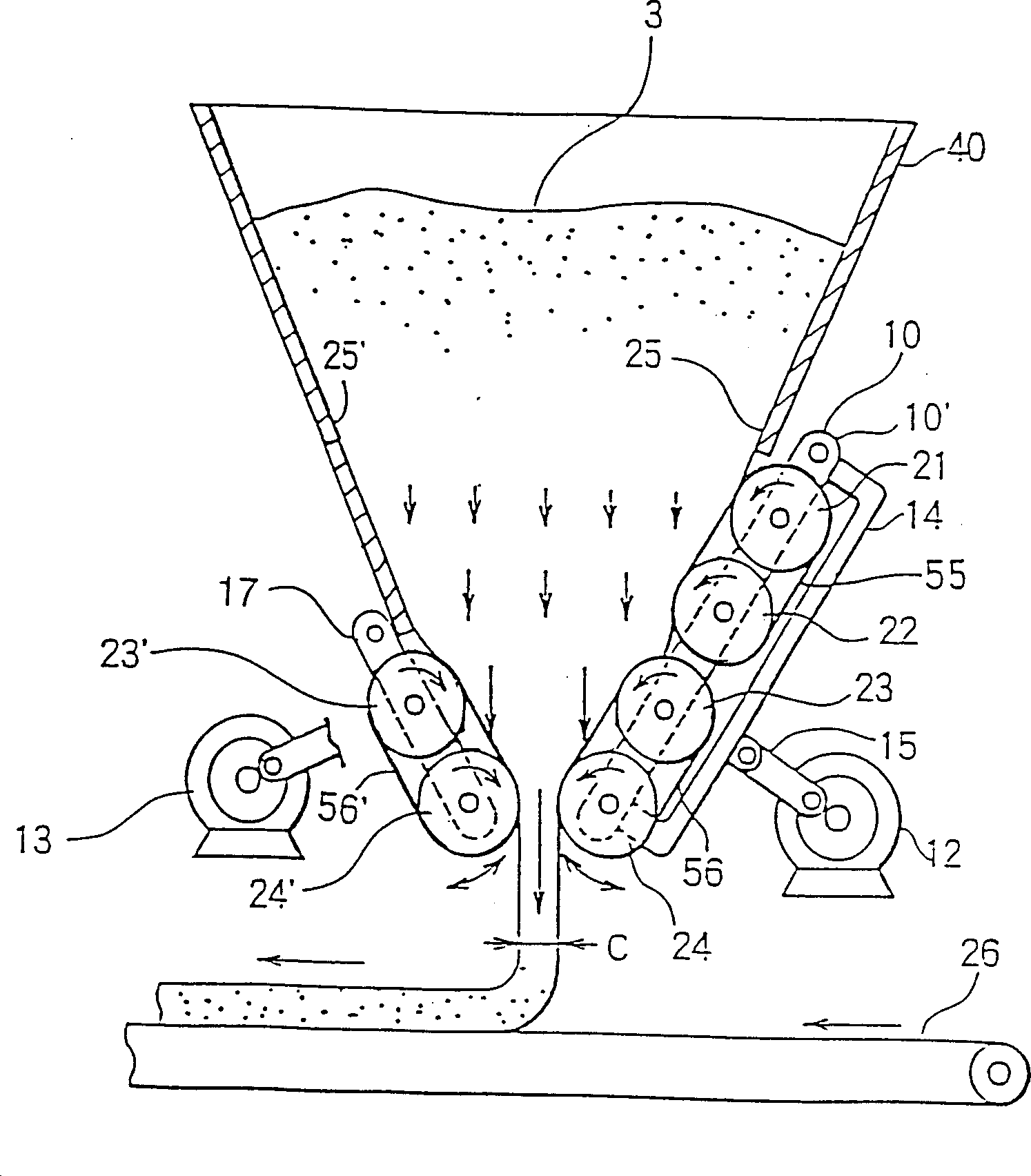

[0015] Combine below figure 2 A first embodiment of the present invention will be described.

[0016] Below the bottom opening of the bread dough feeder, ie the feed hopper 40, the pressing device of the present invention is arranged. It consists of two moving parts. One of the movable parts includes two belt conveyors 55 and 56 . The belt conveyor 55 includes rollers 21 and 22 and an endless belt conveyed on the rollers 21 and 22 . The pivots of the rollers 21 and 22 are located in bearings (not shown) on the swing lever 10'. Rollers 21 and 22 move along the figure 2 Rotate in the direction of the arrow, so that the conveying surface of the endless belt conveyed on the rollers 21 and 22 moves downward to draw the bread dough 3 downward.

[0017] Below the belt conveyor 55, a belt conveyor 56 is sequentially provided. The belt conveyor 56 includes rollers 23 and 24 and an endless belt conveyed on the rollers 23 and 24 . The pivots of the rollers 23 and 24 are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com